DESIGN AND IMPLEMENTATION OF AN FPGA-BASED

SVPWM IC FOR PWM INVERTERS

Cheng-Hung Tsai

Department of Electrical Engineering, China Institute of Technology

245 Yen-Chiu Yuan Road, 3rd Sec., Taipei, 11581, Taiwan

Hung-Ching Lu

Department of Electrical Engineering, Tatung University

40 Chungshan North Road, 3rd Sec., Taipei, 10451, Taiwan

Keywords: FPGA, SVPWM IC, High-performance.

Abstract: This paper presents a new circuit design scheme of the space-vector pulse-width modulation (SVPWM)

strategy, including linear and overmodulation ranges. The proposed scheme has been developed using the

state-of-the-art field-programmable gate array (FPGA) technology. The SVPWM control integrated circuit

(IC) can be realized by using only a single FPGA (Cyclone) from Altera, Inc. Experimental results show

that this controller can present an excellent drive performance and its switching frequency, which can be set

to over 100kHz, is adjustable as well as its deadtime. The output fundamental frequency can be adjusted

over 2000Hz. This SVPWM IC can be included in the digital current control loop for stator current

regulation. The IC also provide a simple hardware and low cost for high-performance ac drives.

1 INTRODUCTION

In engineering practice, because of the complexity

of servo control algorithm, it is usually implemented

with software based on DSP (Lai and Chang, 1999)

(Marwali et al., 1999) (Ma et al., 2001) (Zadeh,

2001). This approach can provide a flexible control

scheme, but suffers from a long period of

development and exhausts many resources of the

CPU. In some cases, dual DSPs have to be adopted

to achieve superior performances (Tzou et al., 1996)

(Tzou et al., 1996b) (Tzou et al., 1996c). Such

additional hardware and software design for such a

dual-DSP controller will complicate the design

process enormously.

In recent years, a novel design methodology

has arisen, that is FPGA-based hardware

implementation technology (Carrica et al., 2003)

(Man et al., 1995) (Lin et al., 2005) (Zeidman et al.,

2002) (Tonelli et al., 2001). Because of the

programmable characteristics of FPGA and IP cores,

users can design their application-specific integrated

circuit (ASIC) in lab according to their schemes,

instead of participation of the semiconductor

manufacturer. In addition, since FPGA can carry out

parallel processing by means of hardware mode,

which occupies nothing of the CPU, a very high

speed level of the system can be obtained as well as

an exciting precision. This novel design

methodology has now been used in high

performance motion control field, such as (Tonelli et

al., 2001) (Tzou and Hsu, 1997) (Zhou et al., 2004).

Literature (Tonelli et al., 2001) proposed a universal

SVPWM controller with overmodulation and

deadtime compensation, but it is not a flexible

design and its switching frequency can not be set

arbitrarily; besides it also needs an extra EPROM for

sin and cosine values as a lookup table. In (Tzou and

Hsu, 1997), the constructed IC has a strong function

but it does not include overmodulation range and

also needs additional EPROM. In (Zhou et al.,

2004), the switching frequency can only be set to 40

kHz maximum.

Employing FPGA to realize PWM strategies

provides advantages such as rapid prototyping,

simple hardware, software design and very high

switching frequency. Thus, the realization of the

347

Tsai C. and Lu H. (2007).

DESIGN AND IMPLEMENTATION OF AN FPGA-BASED SVPWM IC FOR PWM INVERTERS.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 347-353

DOI: 10.5220/0001620203470353

Copyright

c

SciTePress

SVPWM schemes by state-of-the-art FPGA

technology is the best way to improve the bandwidth

of the current or speed controller. This paper

proposed a simple hardware FPGA-based control

structure for ac drives depicted in Fig. 1 and

develops a high performance realization scheme for

the SVPWM control IC employing a single FPGA

(Cyclone) from Altera, Inc.

The designed IC can serve either for ac motor

drives or three-phase ac-voltage regulation systems.

It can also be incorporated as part of the digital

current loop for ac drives. Fig. 2 shows the circuit

configuration of a DSP-controlled ac drive using the

SVPWM control IC. The rest of this paper is

organized as follows. Section II briefly introduces

the principle of the space-vector PWM method.

Section III discusses developing a strategy for the

hardware design scheme. Section IV implements the

circuits on a low cost FPGA and shows the

experimental results. In section V some conclusions

are drawn.

FPGA

A/D Converter

Vdc

Gate Drive

encoder

b

i

a

i

1

S

6

S

5

S

3

S

4

S

2

S

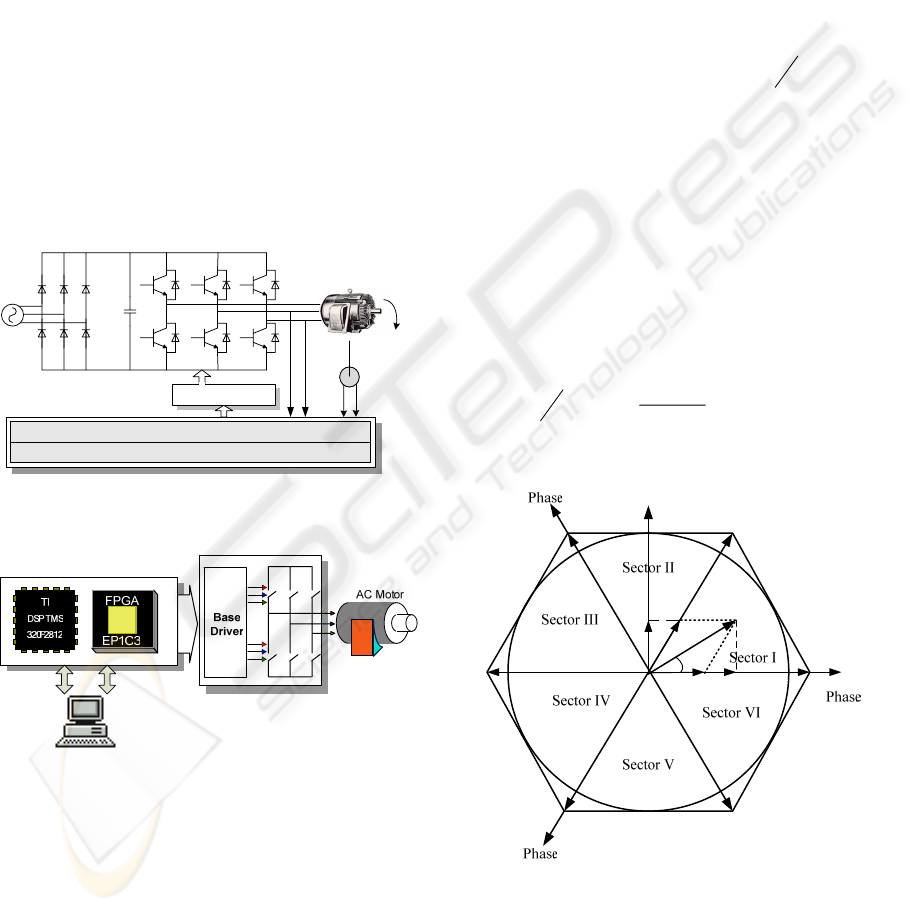

Figure 1: Circuit schematics of a voltage-source full

bridge three-phase PWM inverter.

Figure 2: Circuit configuration of the DSP-controlled

FPGA-based PWM current controller for the ac drive.

2 PRINCIPLE OF SVPWM

The main purpose of the PWM inverter is to

generate a variable-voltage variable-frequency

(VVVF) three-phase voltage to the ac motor.

Conventional sinusoidal PWM employs several

kinds of sampling methods with sinusoidal signals

according to a carrier signal, e.g., natural sampling

(Schonung and Stemmler, 1964) (Pollack, 1972), or

symmetric or asymmetric regular sampling (Bowers,

1975).

The principle of the SVPWM is more clearly

explained by representing a space vector (Park,

1929). The motor stator voltage vector can be

expressed as a combination of the inverter output-

phase voltage

a

V

,

b

V

,

c

V

which can be described in

vector form as:

cbas

VVVV

αα

++=

2

K

,

)

3

2

exp(

π

α

j=

(1)

where

)120sin(

)120sin(

sin

D

D

+=

−=

=

wtVV

wtVV

wtVV

dc

db

da

and

d

V

is the amplitude of the fundamental

component. As shown in Fig. 3, there are eight

voltage vector configurations of the three-phase

PWM inverter. Their corresponding voltage vectors

are expressed as:

6,...,2,1,

3

)1(

exp

3

2

=

⎥

⎦

⎤

⎢

⎣

⎡

−

= n

n

jVV

dn

π

K

(2)

0

07

=

=

VV

(3)

α

β

1

V

K

6

V

K

5

V

K

4

V

K

3

V

K

2

V

K

7

V

K

0

V

K

ref

V

K

1

V

′

K

2

V

′

K

a

b

c

θ

α

U

β

U

Figure 3: Voltage space vector diagram.

The stator voltage vector can be decomposed of a

combination of two basic vectors, as Fig. 3 indicates.

The advantage of the SVPWM strategy is the

minimization of harmonic distortion in the current

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

348

by selecting the appropriate switching vectors and

determination of the corresponding dwelling widths.

If the reference vector

ref

V

K

is located in sector I,

then it is composed of voltage vector

1

V

,

2

V

, and

zero voltage vectors

7

V

and

0

V

as illustrated in Fig.

3. The flux produced by the reference voltage vector

in a PWM switching period is a combination of each

individual flux produced by its corresponding

voltage vector. The relationships of the voltage

vector can be expressed as:

∫∫∫∫∫

+++=

7210

0

7

0

2

0

1

0

0

0

.

TTTTT

ref

dtVdtVdtVdtVdtV

s

(4)

Because the voltage vectors

1

V

and

2

V

are basic

vectors and

0

V

and

7

V

are zero vectors, that gives

ss

ref

T

T

V

T

T

VV

2

2

1

1

+=

(5)

Where

s

T

is the switching period and

1

T

,

2

T

are the dwelling time of

1

V

and

2

V

,

respectively. This voltage space vector can

be expressed in rectangular coordinates as

follows:

⎥

⎦

⎤

⎢

⎣

⎡

⋅⋅=

⎥

⎥

⎦

⎤

⎢

⎢

⎣

⎡

⋅⋅⋅+

⎥

⎦

⎤

⎢

⎣

⎡

⋅⋅⋅

θ

θ

sin

cos

3

2

2

60sin

60cos

3

2

0

1

3

2

21

MV

T

VTVT

d

s

dd

D

D

(6)

Where

d

ref

V

V

M

3

2

=

,

D

600 ≤≤

θ

, and the

dwelling time of each vector can be got.

D

D

60sin

)60sin(

2

1

θ

−

⋅⋅= M

T

T

s

(7)

D

60sin

)sin(

2

2

θ

⋅⋅= M

T

T

s

(8)

2170

2

TT

T

TT

s

a

−−==

. (9)

If the calculated value

s

TTT >+

21

, i.e., the zero

vector time is minus, overmodulation occurs and the

duration time should be processed again. To

improve the resolution of the binary divider, the new

time can be reconsidered as follows:

If

21

TT >

, then

′

−=

′

+

=

′

12

21

1

1

2

,

2

T

T

T

T

TT

T

T

ss

(10)

otherwise

′

−=

′

+

=

′

21

21

2

2

2

,

2

T

T

T

T

TT

T

T

ss

(11)

3 DESIGN OF THE FPGA-BASED

SVPWM IC

Many factors need to be considered in designing the

PWM control IC, such as simplicity, flexibility, and

complexity of the circuit design. In practical

applications, the PWM IC is not possible to

corporate with a conventional microprocessor,

therefore, the control IC is stand alone. The major

design goal is to relieve the microprocessor from

time-consuming computational tasks such as PWM

signal generating, deadtime compensation , and

current control.

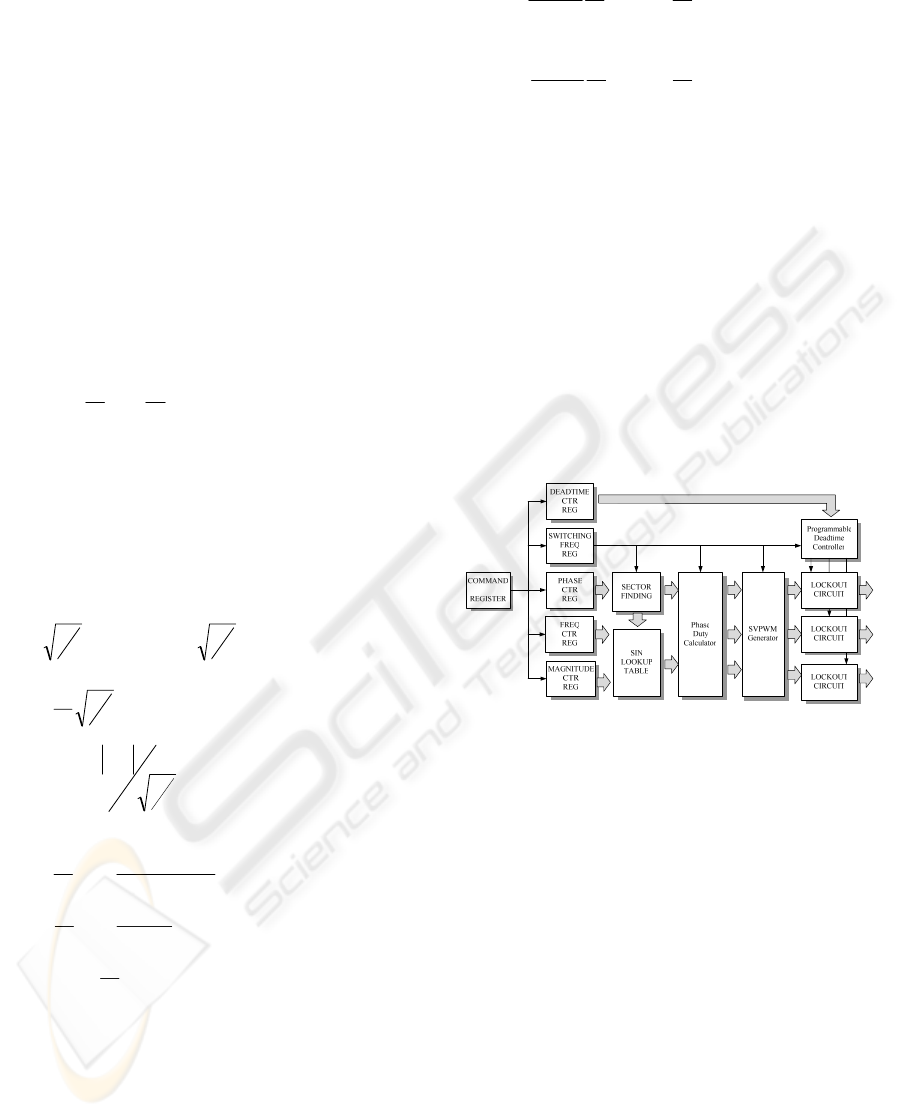

Figure 4: Functional block diagram of the programmable

FPGA-based SVPWM IC.

Fig. 4 depicts the block diagram of a proposed

programmable FPGA-based SVPWM control IC.

This design consists of five registers for the

command frequency, modulation factor, phase of the

stator voltage vector, the switching frequency of the

PWM and the deadtime for the power module.

To simplify the interface circuit, the commands of

these five registers are downloaded from the

computer directly. The control parameters can be set

in the original project file. The internals of the

designed IC consist of a sin-table address decoder, a

duty-ratio calculator, a PWM waveform generator

and a programmable deadtime register. The firing

time width of an SVPWM waveform involves

computing of sin function. Therefore, arithmetic

computational methods and the bit length for

manipulating data are important factors in designing

the digital hardware for the SVPWM. Floating-point

arithmetic complicates the approach to hardware

DESIGN AND IMPLEMENTATION OF AN FPGA-BASED SVPWM IC FOR PWM INVERTERS

349

design greatly; only positive integer arithmetic can

provide a feasible solution. In this paper, all positive

integer arithmetic without external EPROM sin-table

reference has been adopted for the digital realization

of the SVPWM IC.

The simple requirements for realizing the SVPWM

scheme is to first compute the time width of each

voltage vector. Second, these three-phase PWM

waveforms are converted to centralized PWM

waveforms. Finally, the PWM gating signals are

inserted with adjustable time delay to protect the

power module from short circuit.

The specified voltage amplitude, frequency,

switching frequency, initial phase and deadtime are

set in the VHDL file or received from DSP to

produce the three-phase PWM gating signals. The

sin reference is recorded in the built in memory of

the FPGA for the PWM duty-ratio generator.

In ideal conditions, the gating signals to the power

switches of same phase leg of the PWM inverter

should be complementary. However, in order to

avoid short circuit in the power semiconductors, an

appropriate delay time must be inserted between

these two gating signals. The length of this deadtime

is depending on the characteristic of adopted IGBT

module. Typically the deadtime is set to 2~4

us

. A

programmable deadtime controller is included in the

designed SVPWM IC, which greatly facilitates its

practical applications.

ON

T

OFF

T

s

T

s

T

OFF

T

ON

T

ON

T

tΔ tΔ

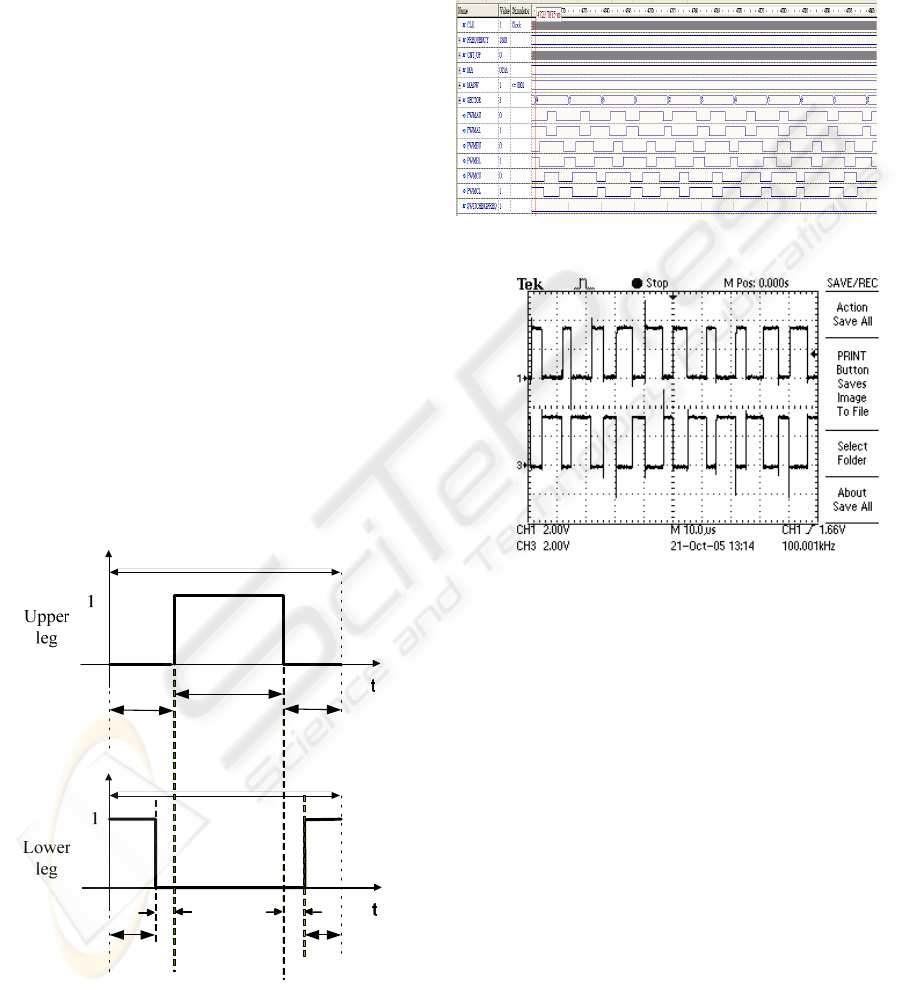

Figure 5: Timing diagram of the PWM signal with

deadtime.

The PWM signal waveforms and their

corresponding delay signals are described in Fig. 5.

The

t

Δ

is the specified deadtime. The deadtime

controller generates the gating signals to the

registers, which includes a digital comparator and

results in PWM signals with a specified time delay.

Fig. 6 shows simulation results of the programmable

FPGA design for the PWM waveform.

(a)

PWMAU

PWMAL

(b)

Figure 6: Simulation and experimental results of the

voltage vector to three-phase PWM duty ration converter

at switching frequency is 100kHz and the output

frequency is 1800Hz.

4 HARDWARE

IMPLEMENTATIOAND

EXPERIMENTAL RESULTS

For the realization of the proposed SVPWM scheme,

cost and speed considerations led to selecting an

SRAM-based FPGA Cyclone EP1C3 from Altera,

Inc. for realizing of the SVPWM IC. The EP1C3 has

around 2910 logic gates, 60k RAM bits, and 1

phase-locked loop (PLL). The internal clock can

operate at 200 MHz. Some important specifications

of the EP1C3 are listed in Table I. Altera also

provides EDA tools (Quartus II) for the development

of ASIC’s employing FPGA’s. The Quartus II

consists of a schematic entry editor, an interface

with the schematic entry editor, logic and timing

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

350

simulation software, and design implementation

software. The logic and timing simulation software

is especially relevant to the design of complicated

digital circuits because it is best suited to resolve

circuit problems during the early design stage.

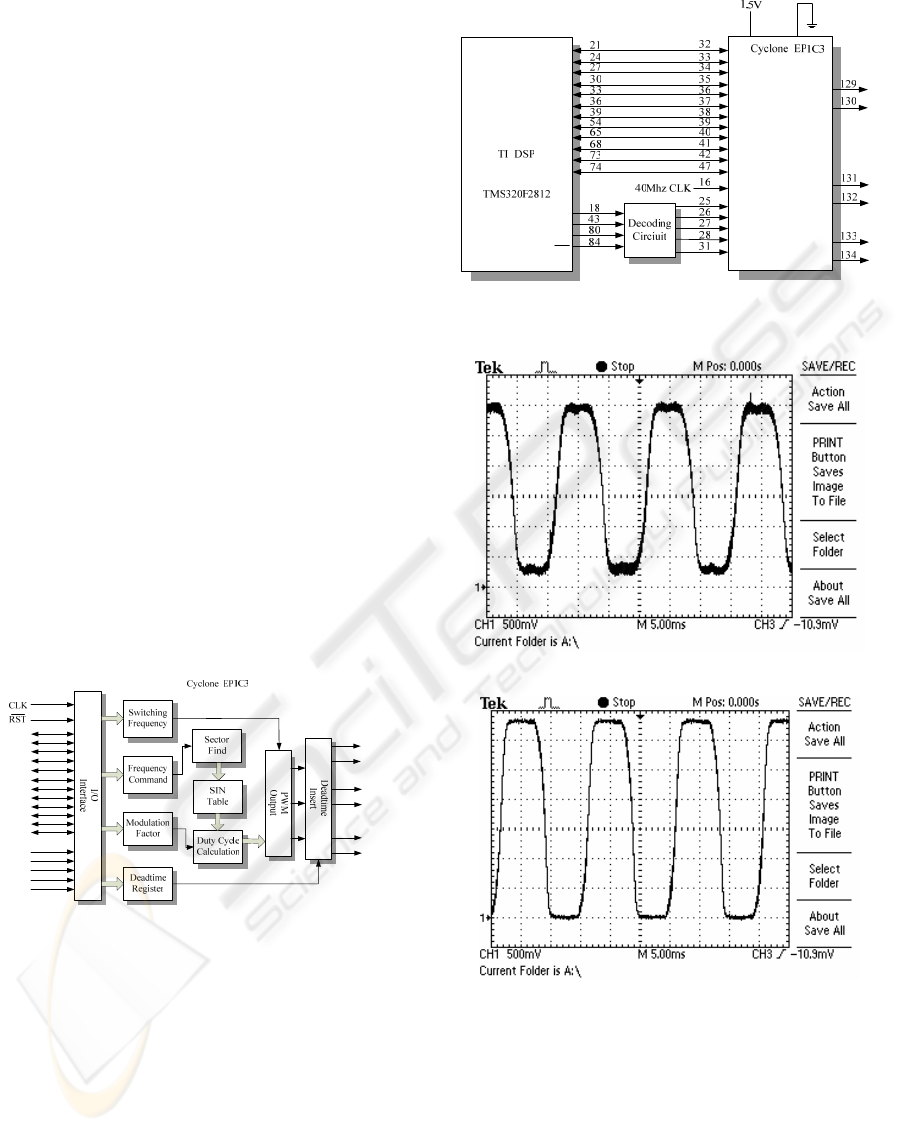

Fig. 7 illustrates the pin assignment of the

designed SVPWM IC. The SVPWM modules are all

described with VHDL and synthesized with Synplify

software. The designed IC can operate at 200Mhz

system clock by using the internal PLL, and the

switching frequency as well as deadtime is

adjustable. Fig. 8 is the circuit configuration of the

SVPWM IC employing a single-chip DSP

(TMS320F2812) from Texas Instruments. The

simplicity in the interface circuit design illustrates its

feasibility for practical applications. The IC can

construct a current loop, and it can also be

considered as an IP core which can be integrated

into a system on one chip (SOC) with other IP cores.

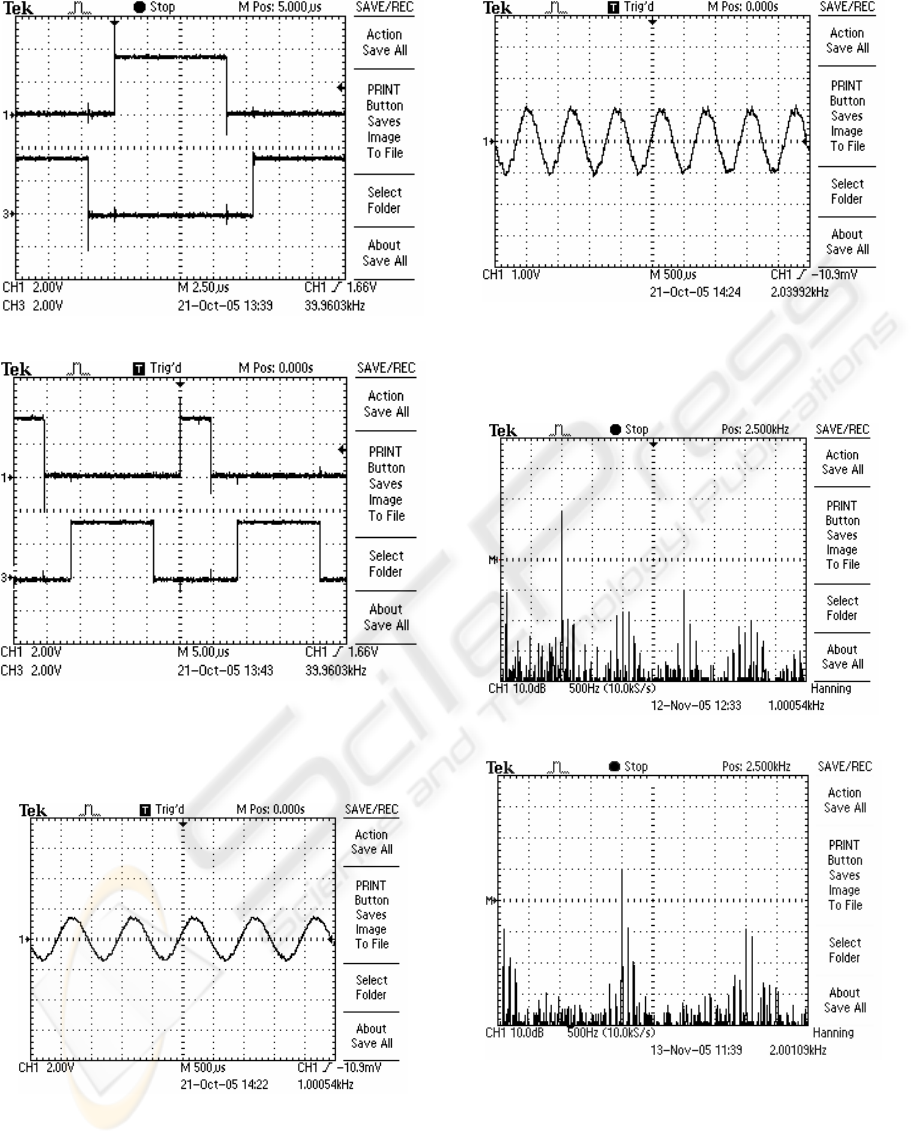

Fig. 9 illustrates the experimental results of the

phase voltage of the SVPWM gating signals from

linear to overmodulation region. The output

fundamental frequency can be adjusted for over

2000Hz. Such a wide frequency control range, with

high-frequency switching, is only feasible by

utilizing the state-of-the-art VLSI digital circuit

design technique. In this designed IC, the SVPWM

scheme is finished in 70 clocks. It means the whole

software takes only 350

ns

. Therefore, the PWM

switching frequency can be set for over 100kHz. The

deadtime for the PWM gating signals is also

adjustable. The PWM waveforms with deadtime are

shown in Fig. 10 by using Tektronix oscilloscope.

Fig. 11 shows the experimental results of the

designed SVPWM IC used in a PWM inverter ac

motor drive with 1000 and 2000Hz output,

respectively. Experimental results show the

constructed SVPWM IC can generate a wide range

of output frequencies with controlled fundamental

voltage.

5 CONCLUSIONS

This paper presents the design and realization of a

programmable SVPWM control IC for high

performance ac servo drives. The SVPWM scheme

is implemented and tested by using an FPGA

technology. Simulation and experimental results are

provided to verify the implemented SVPMW control

IC. The designed IC is also easy to interface with

DSP or other IP cores to form a closed loop control

system. Besides, it doesn’t need external EPROM,

and the source codes can be easily replanted to

different FPGA’s without any changes. Given that an

economic manufacturing cost can be achieved, it is

believed that the PWM control IC’s will become the

important components in power converters and

motor drives of the future

.

ACKNOWLEDGEMENTS

This work was supported by the National Science

Council of the republic of China under the contract

of NSC 93-2213-E036-018.

REFERENCES

Y. S. Lai, and S. C. Chang, 1999, “DSP-based

implementation of new random switching technique of

inverter control for sensorless vector-controlled

induction motor drives,” IEE Proceedings- Electric

Power Applications, Vol. 146, No. 2, pp. 163-172.

M. N. Marwali, A. Keyhani, and W. Tjanaka, 1999,

“Implementation of indirect vector control on an

integrated digital signal processor-based system,”

IEEE Transactions on Energy Conversion, Vol. 14,

No. 2, pp. 139-146.

J. D. Ma, W. Bin, N. R. Zargari and S. C. Rizzo, 2001, “A

space vector modulated CSI-based AC drive for

multimotor applications,” IEEE Transactions on

Power Electronics, Vol. 16, No. 4, pp. 535-544.

S. V. Zadeh, 2001, “Variable flux control of permanent

magnet synchronous motor drives for constant torque

operation,” IEEE Transactions on Power Electronics,

Vol. 16, No. 4, pp.527-536.

Y. Y. Tzou, M. F. Tsai, Y. F. Lin and H. Wu, 1996, “Dual

DSP based fully digital control of an AC induction

motor,” Proceedings of the IEEE International

Symposium on Industrial Electronics, Vol. 2, pp. 673-

678.

Y. Y. Tzou, M. F. Tsai, Y. F. Lin and H. Wu, 1996, “Dual

DSP based fully digital control of an AC induction

motor,” Proceedings of the IEEE International

Symposium on Industrial Electronics, Vol. 2, pp. 673-

678.

Y. Y. Tzou, W. A. Lee and S. Y. Lin, 1996 , “Dual-DSP

sensorless speed control of an induction motor with

adaptive voltage compensation,” 27th Annual IEEE

Power Electronics Specialists Conference, Vol. 1, pp.

351-3.57.

D. Carrica, M. A. Funes and S. A. Gonzalez, 2003, “Novel

stepper motor controller based on FPGA hardware

implementation,” IEEE/ASME Transactions on

Mechatronics, Vol. 8, No. 1, pp. 120-124.

K. F. Man, Y. C. Ho, K. P. Cheuk and S. Kwong, 1995,

“Hardware implementation of variable pulse

frequency algorithm,” Electronics Letters, Vol. 31,

No. 10, pp. 839-840.

DESIGN AND IMPLEMENTATION OF AN FPGA-BASED SVPWM IC FOR PWM INVERTERS

351

F. J. Lin, D. H. Wang and P. K. Huang, 2005, “FPGA-

based fuzzy sliding-mode control for a linear induction

motor drive,” IEE Proceedings- Electric Power

Applications, Vol. 152, No. 5, pp. 1137-1148.

B. Zeidman and R. Zeidman, 2002, Designing with

FPGAs and CPLDs, Berkeley.

M. Tonelli, P. Battaiotto and M. I. Valla, 2001, “FPGA

implementation of an universal space vector

modulator,” The 27

th

Annual conference of the IEEE

Industrial Electronics Society, pp. 1172-1177.

Y. Y. Tzou and H. J. Hsu, 1997, “FPGA realization of

space-vector PWM control IC for three-phase PWM

inverters,” IEEE Trans. On Power Electronics, Vol.

12, No. 6, pp. 953-963.

Z. Zhou, T. Li, T. Takahashi and E. Ho, 2004, “Design of

a universal space vector PWM controller based on

FPGA,” IEEE Applied Power Electronics Conference

and Exposition, Vol. 3, pp. 1698-1702.

A. Schonung and H. Stemmler, 1964, “Static frequency

changers with subharmonic control in conjunction

with reversible variable speed ac drives,” Brown

Boveri Rev., Vol. 122, No. 5, pp. 555-577.

J. J. Pollack, 1972, “Advanced pulsewidth-modulated

inverter techniques,” IEEE Transaction on Industrial

Applications., Vol. IA-8, No. 2, pp. 145-154.

S. R. Bowers, 1975, “New sinusoidal pulse width

modulated inverter,” Proceedings of Industrial

Electrical Engineerings., Vol. 122, No. 5, pp. 514-

520.

R. M. Park, 1929, “Two-reaction theory of synchronous

machines part I: Generalized method of analysis,”

AIEE Trans., Vol. 48, pp. 716-730.

0

D

1

D

10

D

9

D

8

D

7

D

6

D

5

D

4

D

3

D

2

D

11

D

0

MS

1

MS

4

MS

2

MS

3

MS

PWMAU

PWMCL

PWMCU

PWMBL

PWMBU

PWMAL

Figure 7: Pin assignment of the FPGA-based SVPWM

control IC.

SVPWM

Control

IC

0

D

1

D

10

D

9

D

8

D

7

D

6

D

5

D

4

D

3

D

2

D

11

D

0

MS

1

MS

4

MS

2

MS

3

MS

PWMUH

PWMWL

PWMWH

PWMVL

PWMVH

PWMUL

WE

2

A

0

A

1

A

0

D

1

D

10

D

9

D

8

D

7

D

6

D

5

D

4

D

3

D

2

D

11

D

Figure 8: Circuit block diagram of the designedSVPWM

IC interface with a sing-chip DSP TMS320F2812.

(a)

(b)

Figure 9: Experimental phase voltage wave form in the (a)

linear region; (b) overmodulation region.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

352

(a)

(b)

Figure 10: Experimental results of the programmable

delay time with (a) 2 and (b) 4 us, respectively.

(a)

(c)

Figure 11: Experimental results of the SVPWM IC used in

a PWM inverter drive with 1000- and 2000-Hz output: (a)

and (c) are the phase currents.

(b)

(d)

Figure 11: Experimental results of the SVPWM IC used in

a PWM inverter drive with 1000- and 2000-Hz output: (b)

and (d) are the corresponding frequency spectrum.

DESIGN AND IMPLEMENTATION OF AN FPGA-BASED SVPWM IC FOR PWM INVERTERS

353