A MANUFACTURING INFORMATION SYSTEMS

ARCHITECTURE FOR THE 21

ST

CENTURY

Kweku-Muata Osei-Bryson

The Information Systems Research Institute

Virginia Commonwealth University, Richmond, VA 23284

Delvin Grant

DePaul University

School of Accountancy and MIS, Chicago, IL 60604

Keywords: Information Systems Architecture; Manufacturing; Enterprise Integration; Value Chain; Enterprise

Engineering

Abstract: The 21

st

century marketplace poses many challenges for modern manufacturing organizations thus requiring

them to display increased levels of agility supported by an effective information systems infrastructure. The

objective of this paper is to propose an Information Systems Architecture that meets the challenges of

modern manufacturing organizations. For the manufacturing information systems architecture (MISA) to

successfully meet these challenges it must satisfy five objectives: 1. Support the Value Chain Activities; 2.

Support the interactions among the five Interacting Organizational Variables (i.e. Task, Communication,

Technology, People, Structure); 3. Effectively deal with Industry Factors and Forces; 4. Integrate the

organization internally and with its environment; and 5. Address other Enterprise Engineering issues. We

present a MISA that satisfies these five objectives.

1 INTRODUCTION

Modern manufacturing organizations must contend

with social, political, economic and technical

changes (Scott-Morton, 1991) that include

globalization (Rockart and Short, 1991), accelerated

product life cycles, demanding customers, and

rapidly changing technology. These changes require

modern manufacturing companies to display

increased levels of agility supported by an effective

information systems infrastructure (i.e. architecture)

that enables them to exchange information in an

inexpensive, efficient, and maintainable manner

(Nagel and Dove, 1993; Madnick, 1991).

Developing a MISA is difficult and challenging

because it must be balanced with the organization

structure, culture, processes, business strategy,

technology strategy, and the human resources

(Madnick, 1991). Currently there are few

methodologies for the systematic planning and

development of MISA (Grant, 1999). This has fostered

ad-hoc development practices that are associated with

a number of manufacturing problems (Grant, 1999)

In developing this paper, we researched the

literature to identify organizational characteristics

deemed necessary for the success of modern

manufacturing companies. The first characteristic is

that companies must effectively coordinate the

value-added activities of the business (Porter, 1985;

Snow et. al., 1992). Second, companies are viewed

as highly interactive social systems where

technology, tasks, people, communication, and

structure are intertwined (Leavitt, 1965; Grant and

Mergen, 1996; Scott-Morton, 1991). Changing one

part of the social system inevitably affects changes

to other parts and the lack of anticipation of such

changes has crippled companies in the past. Third,

companies operate in a business environment with

external forces (Porter, 1985). Fourth, companies

should be seamlessly integrated both internally and

externally (Grant 2002; Scheer, 2000; Truman

2000). Fifth, effective control-mechanisms for

product/process design and manufacturing are

extremely important for the long-term success of

companies (Grant, 2002; Hammer and Champy,

1993; Davenport, 1995). These and other control-

mechanisms are addressed in the enterprise-

engineering framework of Sarkis et al. (1997, 1995).

457

Osei-Bryson K. and Grant D. (2004).

A MANUFACTURING INFORMATION SYSTEMS ARCHITECTURE FOR THE 21ST CENTURY.

In Proceedings of the Sixth International Conference on Enterprise Information Systems, pages 457-463

DOI: 10.5220/0002618904570463

Copyright

c

SciTePress

If these control-mechanisms are poorly

implemented, quality control, process control, and

change management initiatives are compromised.

The objective of this paper is to propose a MISA that

meets the challenges of modern manufacturing

companies by addressing the five organizational

characteristics.

2 THE ORGANIZATIONAL

CONTEXT OF

MANUFACTURING

This section describes five theoretical models that

were chosen from the management information

systems (MIS) and engineering literature to support

the five characteristics and objectives listed earlier.

2.1 Value Chain

Every company has a set of value added activities

that are necessary for the production of goods and

services. The Value Chain Model (Cash et al., 1992)

defines this critical set of value-added activities as

Inbound Logistics, Operations, Outbound Logistics,

Sales and Marketing, and Customer Service.

2.2 Five Interacting Internal

Organizational variables

The second characteristic is that companies are a

collection of highly interactive mechanisms of Task,

Technology, People, Communication, and Structure

(Leavitt, 1965; Grant et al., 1996). This set of

organizational variables play an important role in

factory automation (Leavitt, 1965) and in

information systems (IS) (Grant, 1999).

2.3 Five Industry Forces

The third characteristic deals with external forces

from the business environment in which the

company operates. Porter’s Industry and

Competitive Analysis model, well known in

academia and practice, identifies these forces as:

power of buyers, new competitors, new product

substitutes, power of suppliers, and industry rivalry.

2.4 Integration Issues

The importance of integration and its impact on

company performance is well known (Somers and

Nelson, 2003; Madnick, 1991). Grant (Grant, 1995;

Grant et al.; 2002) identified six types of integration,

three of which are relevant to this discussion.

Islands of Technology integration ties together

various islands of manufacturing in order to support

the exchange of information. Socio-organizational

integration is concerned with how well the MISA

supports company goals, objectives, and mission

including internal vertical, internal horizontal,

strategic, and internal temporal integration. Global

integration is concerned with how well companies

effectively operate in the global economy, and

includes how well horizontal and temporal

information are exchanged at the international level.

2.5 Enterprise Engineering

Framework

Modern manufacturing organizations often have to

re-engineer both products and processes in order to

successfully meet the challenges of the marketplace.

It is fairly well known that the re-engineering of a

given process often affects other processes and so

business process reengineering (BPR) should have

an enterprise engineering focus. Therefore, to

address the fifth characteristic, which deals with

engineering mechanisms for process and product

control, we draw on Sarkis et al. (1995). His

enterprise-engineering model consists of four

activities (i.e. Develop Vision and Strategy, Change

Culture, Integrate & Improve Enterprise, Develop

Technology Solutions) that must be addressed in

BPR.

3 THE MANUFACTURING

INFORMATION SYSTEMS

ARCHITECTURE (MISA)

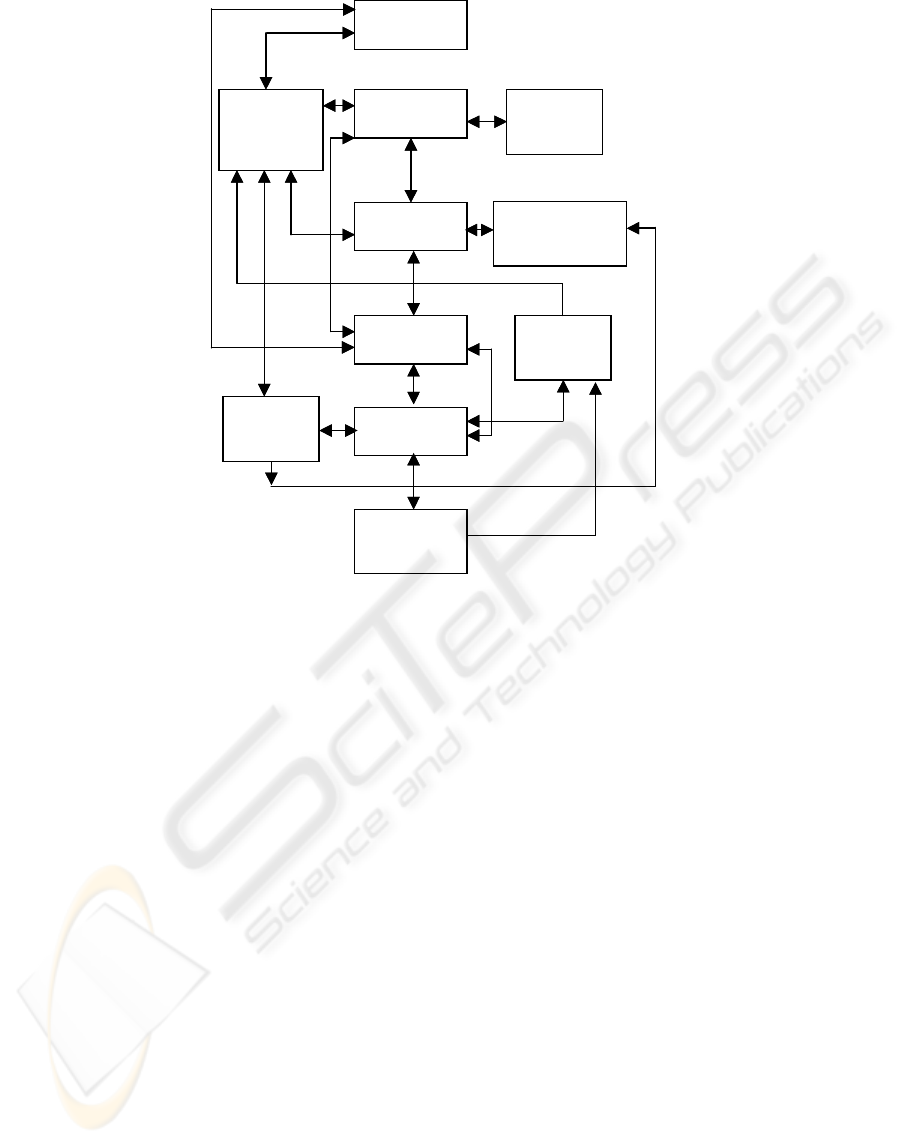

The proposed MISA (figure 1) is made up of eleven

conceptual models, many of which are well known

and have been used in the past with success.

1) Internet Model (IO): This model provides a

blueprint of how the company should be connected

and integrated with its external environment via B2B

and B2C. Relevant issues include supply chain

management, customer relationship management,

employee mobile computing, and business alliances.

2) Intranet Model (IN): This model facilitates the

dissemination of information between individuals,

groups, functions, and departments. It focuses

discussion on the primary information arteries that

exist between islands of technology, business

functions, and groups.

ICEIS 2004 - INFORMATION SYSTEMS ANALYSIS AND SPECIFICATION

458

3) Activity Model (AT): This model represents the

business activities performed by employees of the

company and the information that flow between

them. It is a model of how the business operates and

it serves to document the operations and the

activities of the company. Information from the

activity model aids the development of the data

model, responsibility model, and the knowledge

management model.

4) Responsibility Model (RS): This model

describes the roles that employees perform and the

information requirements to support them. A

connection exists between the activities of

employees and their roles, hence the connection

between the activity model and the responsibility

model.

5) Enterprise Data Model (ED): This model

describes the data objects used or generated by the

business activities, and the relationships between

them. The model is the foundation and the source for

satisfying the daily information and business

intelligence requirements of the business.

6) Database Model (DB): This model describes the

collection of databases that are required to hold the

data that were defined in the enterprise data model.

It should also identify the locations of the databases,

and the rules for maintaining currency and security

of data.

7) Client Server Network Model (CSM): This

model describes the types of computer networks

required to link the various parts of the company or

islands of technology. It makes explicit the systems,

middleware, computing platforms, and operating

systems that need to communicate and how the

communication is handled.

Internet Model

Intranet Model

Responsibility

Model

Activity Model

Data Model

Database

Model

Business

Intelligence

Model

Client

Server

Model

Knowledge

Management

Model

Work Flow

Model

Ontology

Model

Internet Model

Intranet Model

Responsibility

Model

Activity Model

Data Model

Database

Model

Business

Intelligence

Model

Client

Server

Model

Knowledge

Management

Model

Work Flow

Model

Ontology

Model

Figure 1: Manufacturing Information System Architecture

8) Business Intelligence (BI) Model: The Business

Intelligence model addresses non-trivial business

questions that cannot be answered from an

operational database. It includes understanding the

value chains of major customers, primary suppliers,

and major competitors, while improving the firm’s

ability to perform at an optimal level. Part of the

Data Model is represented here.

9) Knowledge Management Model (KM): The

knowledge management model identifies, captures,

stores, manages, and disseminates relevant

organizational knowledge. Knowledge from this

model will find its way in the Activity, Workflow,

and the Ontology models.

10) Ontology Model (ONT): An ontology is a

formal, machine-readable, explicit specification of

the conceptualization that consists of a

representational vocabulary with precise definitions

plus a set of formal axioms that constrain

interpretation and well formed use of these terms

(Bernaras et. al., 1996; Campbell and Shapiro,

1995). It can be used to communicate between

A MANUFACTURING SYSTEMS ARCHITECTURE FOR THE 21ST CENTURY

459

systems, people, and organizations, support the

design and development of knowledge-based and

general software systems, as well as support

knowledge management, knowledge sharing,

knowledge acquisition, and knowledge reuse, and

the specification of vision & strategy.

11) Work Flow Model (WF): The purpose of the

Work Flow Model is to capture, store, and

disseminate information concerning the routing (i.e.,

movement) of widgets and information about them.

It should also capture and disseminate information

about manufacturing machines and robots that are

responsible for manufacturing the parts. The

capability of a robot will affect the path (routing) a

product takes through the manufacturing plant. This

information becomes critical especially in a non-

flexible production environment with demanding

schedules.

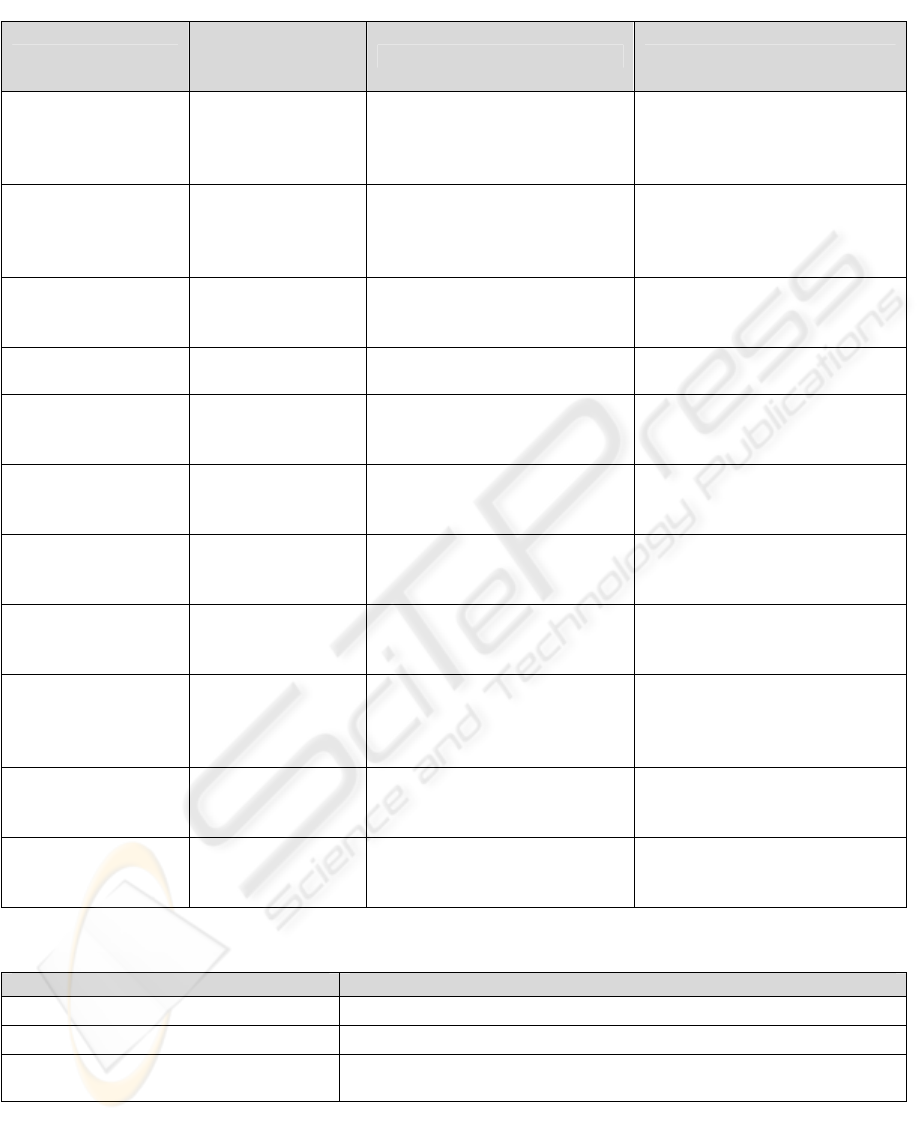

4 RELATIONSHIP OF

OBJECTIVES AND

CONSTITUENT MISA MODELS

Given our position that a good MISA must possess

the five characteristics identified in section 1, each

characteristic must be addressed by one or more of

the constituent models of the MISA. Tables 1, 2 and

3 describe the relationships between the MISA

models and the characteristics.

5 THE MODELING PROCESS

The MISA is comprised of eleven interconnected

enterprise-wide conceptual models. Developing such

comprehensive models requires the use of a

methodology that is appropriate for large scale

enterprise-wide IS architecture development. While

there may be several appropriate methodologies, we

choose the 7-phase information engineering (IE)

approach by McDonald (1986). Table 4 shows the

connection between the models, the IE phases and

some of the issues that ought to be considered in the

development of the architecture. In this paper we

only show a subset of the possible combinations,

focusing on those IE phases that differ from

traditional systems development methods.

6 CONCLUSION/DISCUSSION

In this paper, we presented an MISA that satisfies

five critical objectives of modern manufacturing

organizations. We recommended the use of IE as an

appropriate modeling process, and established the

connection between the IE modeling process and the

models of the MISA.

While there is considerable overlap between the

MISA and a generic ISA, there is some significance

difference between them. The overlap stems from

the fact that modern organizations, regardless of the

type of business, require a minimum set of models

as described in the MISA. However, two models of

the MISA (i.e. Workflow, Ontology) stand out in a

manner unique to manufacturing. Although these

two models may be useful in some non-

manufacturing organizations, they are likely to be

critical to the success of modern manufacturing

organizations. The nature of work in manufacturing

places a premium on the movement of parts through

the shop floor. Workflow should be a highly

coordinated and efficient process that pays specific

attention to the route a part takes through the shop

floor, how fast it moves, it design specifications, the

design processes, machine capabilities, and so on.

The ontology model is critical to manufacturing

because many minute and specific details need to be

specified. This level of specification is required by

machines and people and are often in the form of

mechanical drawings and manufacturing processes

that must be translated in a from intelligible to

human and machines. Consequently, there is a need

for formal representational schemas and axioms that

constrain multiple interpretations of data and

process. These two models in conjunction with the

Knowledge Management Model, account for the

bulk of the production issues that are prevalent in

manufacturing. It is these production issues and the

emphasis placed on them that separate

manufacturing from the non-manufacturing

companies

ICEIS 2004 - INFORMATION SYSTEMS ANALYSIS AND SPECIFICATION

460

Table 1: Relationship between MISA models and first three MISA Objectives

Models

Interacting

Organizational

Variables

Value Chain Five Forces

Knowledge

Management Model

Task Inbound Logistics, Outbound

Logistics, Sales & Marketing,

Customer service

Power of Buyers; Power of

Suppliers; New Substitutes;

Industry Rivalry; New

Competitors

Internet Model Communication,

Technology

Inbound Logistics, Outbound

Logistics, Sales & Marketing,

Customer service

Power of Buyers; Power of

Suppliers; New Substitutes,

Industry Rivalry; New

Competitors

Intranet Model Task,

Communication,

Technology

Enterprise Data

Model

Task Sales & Marketing, Customer

service

Power of Buyers, Power of

Suppliers

Database Model Task, Technology Inbound Logistics, Outbound

Logistics, Sales & Marketing,

Customer service

Power of Buyers; Power of

Suppliers

Activity Model Task Inbound Logistics, Outbound

Logistics, Sales & Marketing,

Customer service

Power of Buyers; Power of

Suppliers

Responsibility

Model

People, Task Inbound Logistics, Outbound

Logistics, Sales & Marketing,

Customer service

Client/Server Model Structure,

Technology,

Communication

Inbound Logistics, Outbound

Logistics, Sales & Marketing,

Customer service

Business

Intelligence Model

People, Task Sales & Marketing, Customer

service

Power of Buyers; Power of

Suppliers; New Substitutes,

Industry Rivalry; New

Competitors

Work Flow Model Task, Technology Inbound Logistics, Outbound

Logistics, Sales & Marketing,

Customer service

Ontology Model People, Task,

Communication

Inbound Logistics, Outbound

Logistics, Sales & Marketing,

Customer service

Table 2 Integration Levels and MIS Models

Integration Level MISA Models

Islands of technology Process, Ontology, Intranet, Client Server

Socio-organizational Ontology, Knowledge Management, Responsibility, Intranet

Global Ontology, Knowledge Management, Intranet, Internet, Client

Server

A MANUFACTURING SYSTEMS ARCHITECTURE FOR THE 21ST CENTURY

461

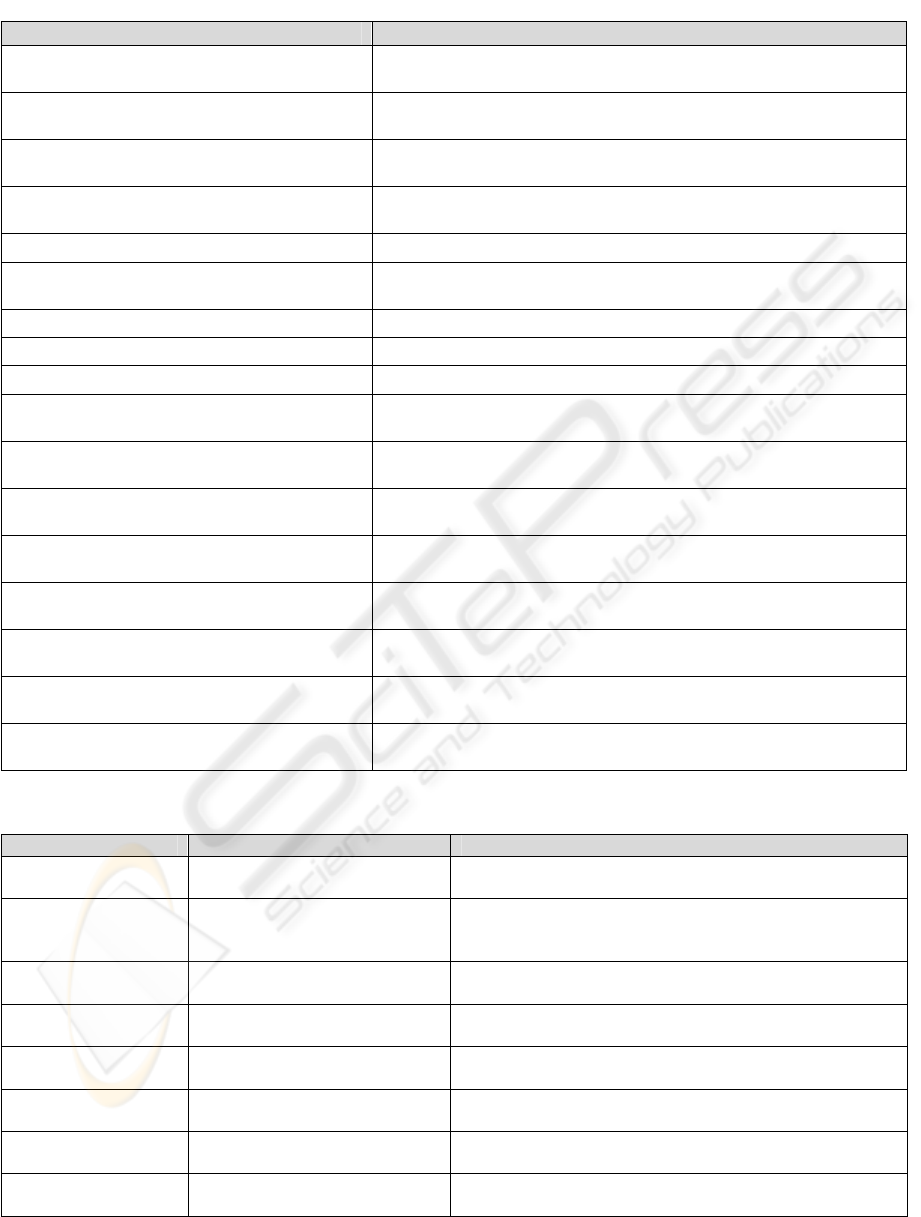

Table 3: Enterprise Engineering Framework Sub-Activities & MISA Models

Sub-Activity MISA Models

1.1. Develop Vision Intranet, Ontology, Knowledge Management, Business

Intelligence

1.2 Develop Enterprise Engineering

Strategy

Intranet, Ontology, Knowledge Management, Business

Intelligence

1.3 Develop Business Strategy Intranet, Ontology, Knowledge Management, Business

Intelligence y

1.4. Organize for Improvement Intranet, Ontology, Knowledge Management, Business

Intelligence, Responsibility

2.1 Evaluate & assess existing culture Intranet, Responsibility

2.2 Facilitate & commit to improved

communication

Ontology, Intranet, Responsibility

2.3 Share & sell vision Ontology, Intranet, Responsibility

2.4 Build Trust Intranet, Responsibility

2.5 Empower people Responsibility, Internet, Intranet

3.1 Understand the Customer Business Intelligence, Knowledge Management, Data,

Database, Internet

3.2 Understand the Product Knowledge Management, Business Intelligence, Ontology,

Workflow, Data, Database

3.3 Understand & Improve the Process Ontology, Knowledge Management, Activity, Responsibility,

Workflow

3.4 Design & Implement Effective

Controls

Activity, Responsibility, Intranet, Ontology, Knowledge

Management

4.1 Understand the Needs Activity, Responsibility, Workflow, Intranet, Ontology,

Knowledge Management

4.2 Design the System/Solution Activity, Responsibility, Workflow, Intranet, Ontology,

Knowledge Management

4.3 Construct System/Solution Model Activity, Responsibility, Workflow, Intranet, Ontology,

Knowledge Management

4.4 Implement the System/Solution Activity, Responsibility, Workflow, Intranet, Ontology,

Knowledge Management

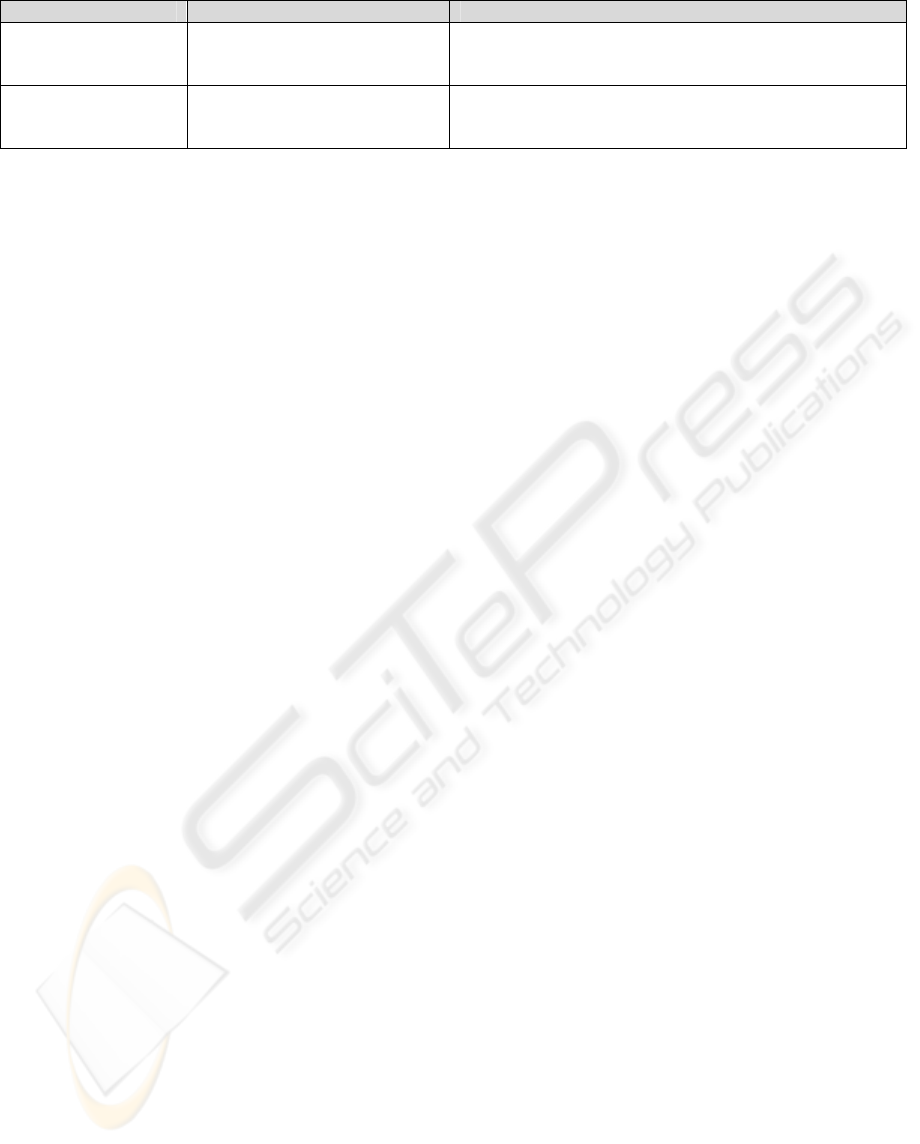

Table 4: relationship between models, IE phases, and consideration issues

MISA MODEL IE PHASES ISSUES TO CONSIDER

Knowledge

management

Information strategy planning,

Business area analysis

Organization wide best practices; Problems to avoid;

Business unit best practices

Intranet/Internet Business area analysis, Technical

design, Business design

Information content; Which intranets should be connected;

How should they be connected; What information should be

shared

Business intelligence Information strategy planning,

Technical design

Information content; Sources of information; Schema

representation

Enterprise Data Information strategy planning,

Technical design

What has to be represented; What entities are required;

Centralized vs. decentralized DB

Database Information strategy planning,

Technical design

What has to be stored; What questions require answers;

Type of DBMS

Ontology Information strategy planning,

Business area analysis

Organizational terms to be defined; Terms specific to

business units

Client server Business design, Technical

design

Type of data to be supported; Data Traffic patterns; What

type of network; Network Performance requirements

Responsibility Information strategy planning,

Business design

Access to information; Data security; Roles and

responsibilities

ICEIS 2004 - INFORMATION SYSTEMS ANALYSIS AND SPECIFICATION

462

MISA MODEL IE PHASES ISSUES TO CONSIDER

Work Flow Information strategy planning,

Business design, Technical

design

Information to support work processes; Process flow;

Efficiency

Activity Information strategy planning,

Business area analysis, Technical

design

What information supports a particular activity; What are

the activities of the business unit; How best to implement

the activity

REFERENCES

Bernaras, A., Laresgoiti, I., and Corera, J. “Building and

Reusing Ontologies for Electrical Network

Applications”, Proceedings of the 12th ECAI, 1996,

pp. 298–302.

Campbell, A. and Shapiro, S., “Ontological Mediation: An

Overview,” Proceedings of the IJCAI Workshop on

Basic Ontological Issues in Knowledge Sharing,

Menlo Park, CA: AAAI Press, 1995.

Cash, J., McFarlan, F., McKenny, J., and Applegate, L.,

“Corporate Information Systems Management,” Irwin,

Boston, MA 1992.

Davenport, T., Beers, M. “Managing Information about

Processes”, Journal of Management Information

Systems, Vol. 12:1, 1995, pp. 57-80.

Gomez-Perez, A., and Benjamins, R., “Overview of

Knowledge Sharing and Reuse Components:

Ontologies and Problem-Solving Methods”,

Proceedings of the IJCAI-99 Workshop on Ontologies

and Problem-Solving Methods (KRR5), Stockholm,

Sweden, 1999.

Grant, D., “Using Existing Conceptual Modeling As The

Basis For Manufacturing Processes Reengineering,”

Journal of Computers in Industry, Vol. 40, 1999, pp.

37-49.

Grant, D., Mergen, E., “Applying Quality to Leavitt’s

Framework to Solve Information Technology

Problems: A Case Study,” International Journal of

Information Technology and People, Vol. 9, No. 2,

1996.

Grant, D., “Six Levels of Integration,” International

Association for Computer Information Systems,

Toronto, Canada, 1995.

Grant, D., Tu, Q., “Levels of Enterprise Integration: Can

ERP Meet the Challenge,” Working paper, 2002.

Grant, D., “A wider view of business process

reengineering,” CACM, Vol. 45, No. 2, pp. 85-90,

2002

Gunn, T. “Manufacturing For Competitive Advantage,”

Ballinger Publ., MA, 1987.

Hammer, M. and Champy, J. “Reengineering the

Corporation” Harper Colins, New York 1993.

Leavitt, H. “Applied Organizational Change in Industry:

Structural, Technological & Humanistic Approaches,”

ref. in Handbook of Organizations, edited by March,

James, Rand McNally & Co., Chicago, 1965, pp.

1144-1170.

Madnick, S., “The Information Technology Platform,” ref

in The Corporation of the 1990s edited by Scott-

Morton, S., Oxford University Press, New York

(1991).

McDonald, Ian G., “Information Engineering” in

Information Systems Methodologies edited by Olle, T.

W., Sol, H. G., and VerrijnStuart, A., North Holland,

1986.

Nagel, R. and Dove, R., “21st Century Manufacturing

Enterprise Strategy,” Iacocca Institute, Lehigh

University, Bethlehem, PA, 1993.

Porter, M. Competitive Advantage, New York, Free Press,

1985.

Rockart, J., and Short, J., “The Networked Organization

and The Management of Interdependence,” ref in The

Corporation of the 1990s edited by Scott-Morton, S.,

Oxford University Press, New York, 1991.

Sarkis, J., Presley, A., and Liles, D. “Management of

Technology within an Enterprise Engineering

Framework,” Computers & Industrial Engineering, 28

No. 3, 1995, pp. 497-511.

Sarkis, J., Presley, A., and Liles, D., “The Strategic

Evaluation of Candidate Business Process Re-

Engineering Projects,” International Journal of

Production Economics 50, 1997, pp. 261-274.

Scheer, A., Habermann, F. “Making ERP a Success”.

Communications of the ACM, Vol.

43:4, 2000, pp. 57-61.

Scott Morton, M., “The Corporation of the 1990s,” Oxford

University Press, New York, 1991.

Snow, C., Miles, R., and Coleman, H. “Managing the 21st

Century Network Organizations”. Organizational

Dynamics, 20:3, 1992, pp. 3–12.

Somers T., Nelson, K., “The impact of strategy and

integration mechanisms on enterprise system value:

Empirical evidence from manufacturing firms,”

European Journal of Operational Research, Vol. 146,

2003, pp.315-338.

Truman, G.E. “Integration in Electronic Exchange

Environments”, Journal of Management Information

Systems, Vol. 17, No. 1, ,2000 pp. 209-244.

A MANUFACTURING SYSTEMS ARCHITECTURE FOR THE 21ST CENTURY

463