Remote Control and Reconfiguration of Laboratories

for Education and Training

Wolfgang Burgstaller

1

, Olga Plaxina

1

, Kirill Seleznev

2

1

Vienna University of Technology, Institute of Computer Technology,

Gußhausstraße 27-29/E384, 1040 Vienna, Austria

2

Perm State Technical University, Department of Information Technology and Automation

Systems, Professor Pozdeev Str. 7, 614013 Perm Russia

Abstract. Organizing practical courses and training clearly indicates a demand

for remote training. This article describes the concepts of the BACnet (Build-

ing Automation Control Network) laboratory being set up by the authors. To

allow effective learning the control network (fieldbus) as well as the inputs

and outputs of the nodes attached to the laboratory environment must be ac-

cessible by the trainee. To achieve this goal a web based application which

uses a VNC (Virtual Network Computing) server and a special I/O interfacing

unit have been designed. Hence, trainees will be able not only to monitor and

control the activities on the control network (the primary goal of the offered

courses) but also will be able to see the effects of their activities on the labora-

tory environment.

1 Introduction

The authors’ experience with organizing practical courses, training courses and

laboratories at university clearly indicates the demand of training equipment that can

be used within a flexible and non-rigid time schedule. Aside the positive effect that

students can freely plan their timetables within the general schedule of the course

(commencement, deliverables and examination), the relief for instructors is almost

more important, since the laboratory can be operated, reconfigured and controlled

remotely. There is no need for fixed attendance times and special course rooms.

Based on the experience of previous projects described in section 0 this article will

describe on-going work to install a remote BACnet control network laboratory. Sec-

tion 0 will introduce the concepts for (long-distance) remote control of the BACnet

laboratory.

Burgstaller W., Plaxina O. and Seleznev K. (2004).

Remote Control and Reconfiguration of Laboratories for Education and Training.

In Proceedings of the First International Workshop on e-Learning and Virtual and Remote Laboratories, pages 52-59

DOI: 10.5220/0001149900520059

Copyright

c

SciTePress

2 Remote Control and Education for Control Networks

The Institute of Computer Technology and the Department of Information Technol-

ogy and Automation Systems have a common research focus on automation control

networks and ASIC (Application Specific Integrated Circuits) and FPGA (Field-

Programmable Gate Arrays) design and projects co-operating with the industry. In

the past these control networks also known as fieldbusses were installed in isolated

environments, but driven by the spread of the Internet remote control and mainte-

nance also become important for these systems. This section highlights two of the

various research projects, which not only focus on remote control but also have a

strong impact on teaching.

2.1 The asix4web Remote FPGA Prototype Board

In the ASIC design course at the beginners level students are implementing a micro-

controller, which runs a simple application program like a pocket calculator or a

stopwatch. The final test of the design is done by using a UP1 prototype board from

the major FPGA provider Altera. The board contains a FPGA, which can be "pro-

grammed" with a user's FPGA design, some switches, push buttons and 7-segment

displays as general-purpose input/output peripheral elements.

Webcam

Altera UP1 Education Board

Server at the

Vienna University of Technology

asix4web User Interface

(Web Browser)

Internet

Client

(e.g. a Students PC)

MAX+plus II FPGA Design Environment

Fig. 1. The asix4web project.

Students are able to develop their FPGA design at home by downloading electronic

versions of the lecture notes, a free student edition of Altera's FPGA design software

Max+plus II [1], as well as templates and design examples from the course website.

However, testing on the real hardware (Altera UP1 prototype board) was only possi-

ble at the university lab so far. To overcome this drawback, the project asix4web (an

51

acronym for "Application Specific Integrated Circuits for the web"), which aims to

connect a UP1 prototype board to the Internet, was started some time ago.

A web server and several dedicated application programs make it possible to up-

load a FPGA design (see Fig. 1). This is done by following a link to the asix4web

upload dialog on the asix4web website. Here, a JBC (Jam Byte Code) file is re-

quested which contains configuration data (a user's FPGA design) for the FPGA

which is contained on the UP1 prototype in the Altera STAPL (Jam Standard Test

and Programming Language) data format. The user has to generate the JBC file by

using Max+plus II prior to the upload. Once the user activates the upload, the re-

quested JBC file will be transferred from the client to the server. Next, the FPGA

contained on the prototype board which is connected to the asix4web server over the

PC's parallel port will be automatically configured with this file.

Finally, the state of the peripherals contained on the prototype board can be con-

trolled and observed via the internet. This is done over a digital I/O card which re-

sides in the server PC. The current on/off state of the 7-segment displays is read out

over the I/O card, transferred from the server to the client and displayed on the

asix4web user interface. Moreover, the current state of some checkboxes mimicking

the switches and push buttons contained on the education board is transferred from

the client to the server which stimulates the FPGA pins over the digital I/O card.

The asix4web project was implemented by using pure HTML, a few lines of

JavaScript and some CGI scripts. Only a standard web browser is required on the

client's side to test a FPGA design on the remote prototype board. Hence, students

have access to the board for 24 hours a day, 365 days per year and are able to test

their designs whenever they want.

The first version of asix4web is on-line since May 2002. It was successfully tested

on a number of common used web browsers (IE, Netscape, Opera) and works also on

slower Internet connections, e.g. 56K modems. Since the release of the first version

about 60 students per year are using the asix4web prototype board for the ASIC de-

sign course. The asix4web project can be visited on the web under [2] or directly at

the Institute of Computer Technology.

2.2 Web Interface to Control Networks in Smart Kitchen

One of the ICT's research projects called "Smart Kitchen" is devoted to situation-

dependent behavior in building automation but also serves as a laboratory for remote

control. The Smart Kitchen is a laboratory at the ICT equipped with various modi-

fied kitchen furniture like a control network enabled fridge and coffee machine as

well as with various sensors and actuators for cabinet doors, water pipes, etc. All

these devices are connected in order to exchange messages and to form a complex

entity. The sensors collect information within the kitchen, whereas the actuators try

to react appropriate depending on the actual situations (e.g. turn off the light after

the last person has left the kitchen).

Besides the interaction with the devices in the kitchen on site, it is also possible to

access the Smart Kitchen over the Internet. To interface the local hardware gateways

also called residential gateways are needed to translate between different network

52

protocols. Whereas control networks in general have rather simple communication

objects and are limited to a certain protocol, the Internet offers a variety of protocols

such as Simple Network Management Protocol (SNMP), the Common Object Re-

quest Broker Architecture (CORBA), the Java Remote Method Invocation (RMI)

interface, and the Distributed Component Object Model (DCOM). Gateways for the

above mentioned protocols were implemented in several projects.

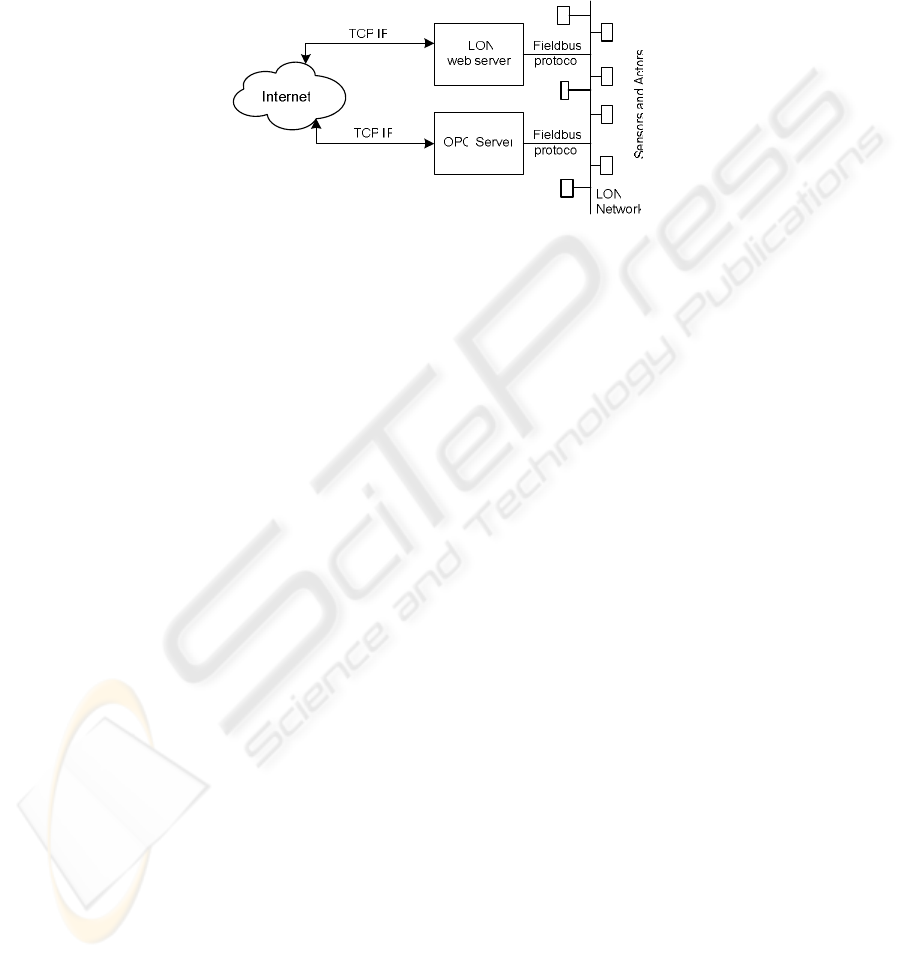

Fig. 2. Gateways between Internet and control network.

In the Smart Kitchen project (Fig. 2), OLE (Object Linking and Embedding) for

Process control (OPC) based on DCOM is used for visualization. The i.LON gateway

interconnects Internet and the LON network and can be used to access, manipulate

and monitor the fieldbus. Both technologies allow users using a standard web

browser, to get access to the physical network. The webpage of the Smart Kitchen

includes a graphical interface to the control network can be found at

http://smartkitchen.ict.tuwien.ac.at [3].

3 Remote Laboratory Models for Control Networks

Aside the research done for remote control the newly founded laboratory for BACnet

(Building Automation Control Network) should be organized in such a way that all

courses can be done remotely. This section will introduce the idea behind the

BACnet laboratory and introduce the technologies used.

3.1 The BACnet Laboratory of the ICT

Over the last decade the ICT has acquired substantial knowledge on all aspects of

control networks (fieldbus systems). Both scientific and industrial research projects

and activities as well as training courses for students and interested experts have

been organized and finished successfully.

Besides industrial automation, building automation has always been a main area

for ongoing research activities and therefore the construction of a BACnet (a well

known building automation network standard [6]) laboratory was initiated. Based on

experiences gained by other remote education projects like [5] a flexible and com-

53

prehensive environment for students as well as for industrial partners should be

created.

In the beginning of the course students should get familiar with BACnet as build-

ing automation protocol. Later stages present methods of commissioning and con-

figuration of the network. As a remote education lab, the course does not cover elec-

trical cabling but deals with principles of system engineering.

The planned distant education system provides a consistent representation of all

components within the lab which is presented via a web interface to distant trainees

in a unitary and useable way.

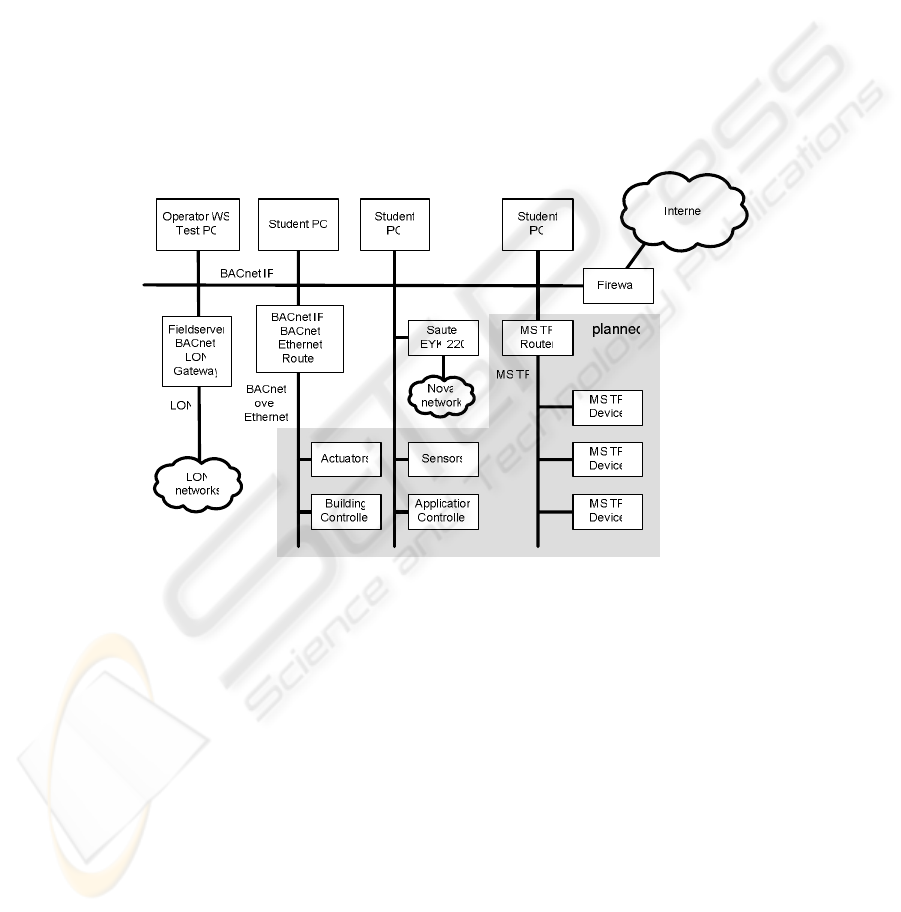

The BACnet laboratory will be composed by diverse hardware from multiple ven-

dors such as Siemens or Sauter. It includes BACnet equipment from simple sensors

and actuators to complex building controllers. For the networking topology, all con-

ceivable media types, which are used in the standard, will be provided, to gain

maximum flexibility for the interconnected nodes. Up to now BACnet/IP,

BACnet/Ethernet and BACnet/Lon are already used. Fig. 3

Fig. 3. The BACnet laboratory.

On the software side several applications, like OPC (Open Process Control) software

or the Hethereal protocol analyzer are available for the students. These tools permit a

modern way of training which is closely related to real life systems. Especially

Hethereal [7] a web-enabled version of the popular packet sniffer Ethereal [8] is an

important component since it permits the user to capture protocol messages within

the lab and to survey the results over the web interface. Hence, Hethereal will be used

to visualize the behavior of the protocol stack, the content of the protocol messages

and the sequence of packets.

The creation of the BACnet laboratory is currently ongoing. All components, in-

dependent of their vendor and their preferable application, are integrated into the

lab, in order to provide the same functionality to remote trainees as well as to stu-

dents on site.

54

3.2 Remote Control Model for Control Networks

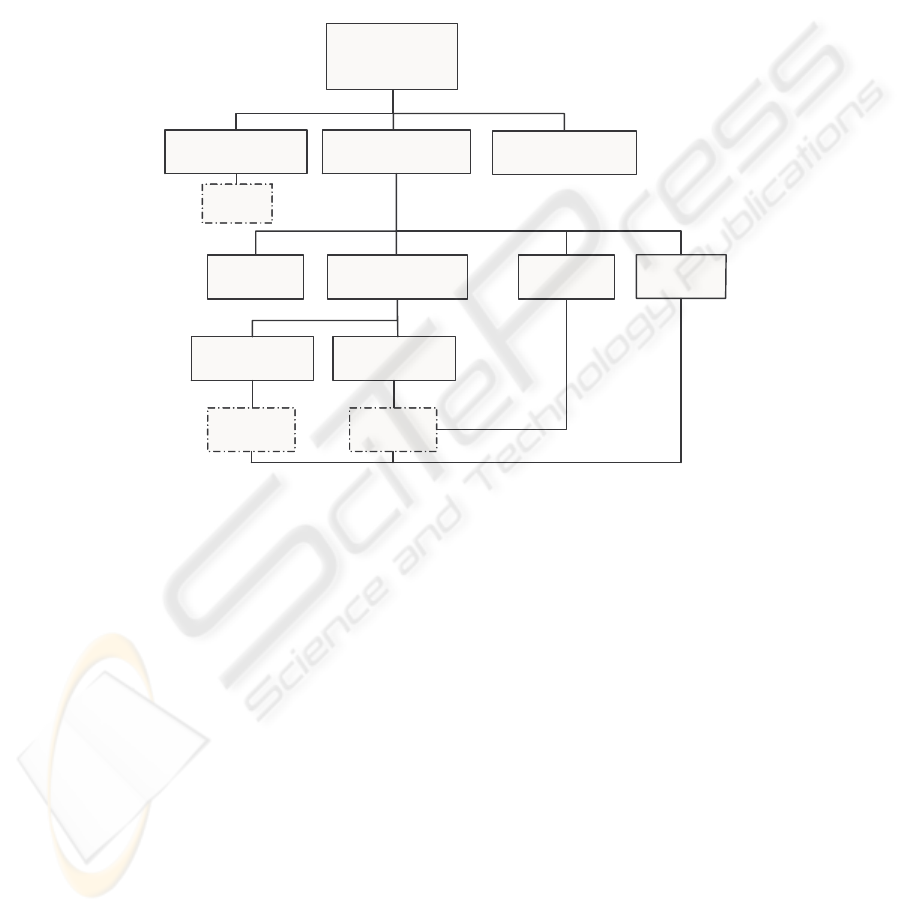

Fig. 4 shows the general structure of the remote education system for training on

distributed control networks. Users enter the system via web portal. At the second

level aside the server for the virtual laboratory there are an authentication server and

a server to offer resources for teaching such as e-books, articles, and tutorials. The

virtual lab is organized around the stands, where the actual hardware (I/O nodes,

controllers, switchers and so on) is located.

Virtual

Laboratory

Authorization Control

Theoretical Resources

Database

Database

Remote Control System

(VNC-Client)

Web-CameraJAVA-applet

I

/

O

-

i

n

t

e

r

f

a

c

e

StandStand

Server of

technologie matter

(VNC-Server)

Server of

technologie matter

(VNC-Server)

WEB-Server

Fig. 4. General structure of the “Remote education system for training on

distributed automation networks”.

To access the control network on the stand the VNC (Virtual Network Computing)

server (left side of Fig. 4), which permits the configuration of the network, code

uploads to the stand and enables the debugging of the system, is used. VNC-server

offers the functionality of local software tools and drivers such as LonMaker configu-

ration tool and LNS interface for LonWorks or VIGO for P-NET.

The student or trainee uses a standard web browser to access the VNC-server. To

offer a similar look-and-feel to the local control software JAVA applets are used for

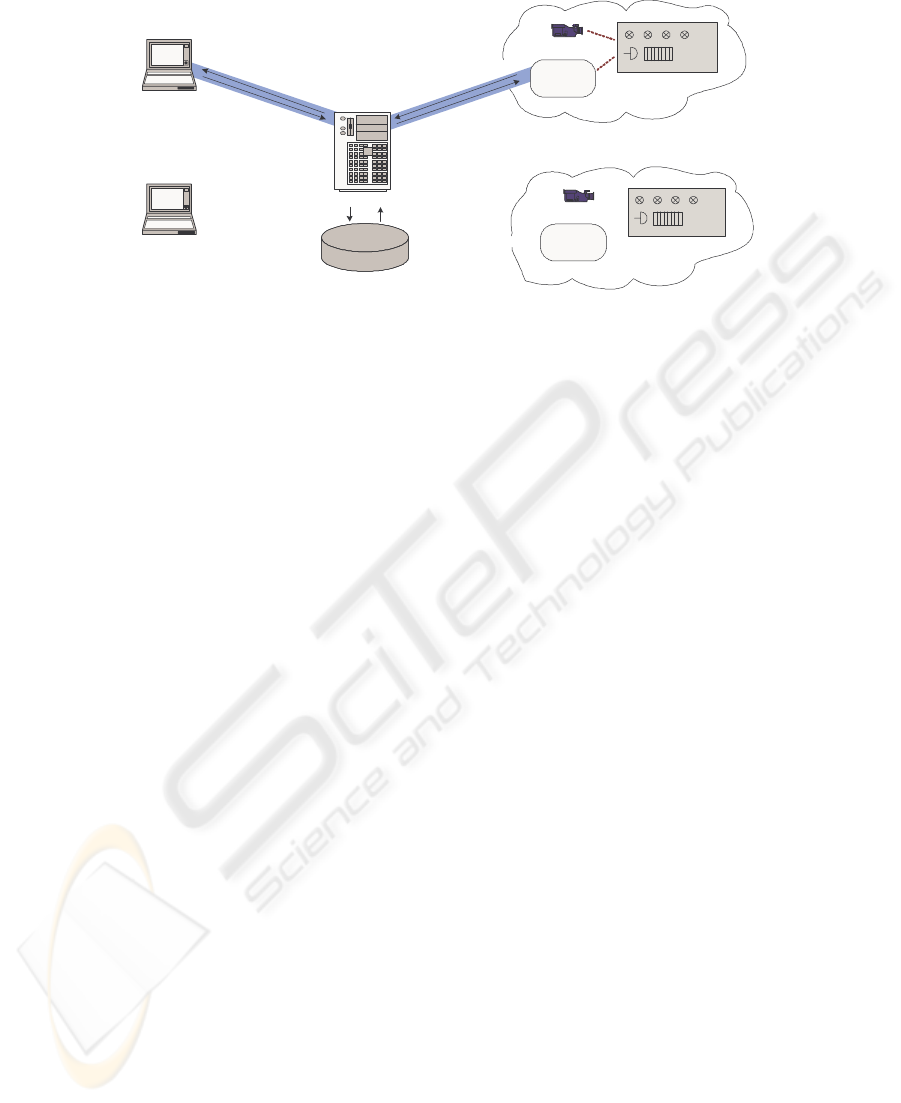

setting up the VNC client. Fig. 5 illustrates the message flow during a remote ses-

sion. Special attention is drawn to the capability of multi-user access. Therefore the

VNC-Client always encloses additional information identifying the user and the used

control network and stand.

55

End User

Web-Server

End User

Database

Technology

Server 1

WEB-cam

Stand

ID - Access_Rights -...

Redirect

VNC-Client

VNC-Server

Technology

Server 2

WEB-cam

Stand

VNC-Server

Fig. 5. Communication channel between a user and a stand.

3.3 Interfacing with I/O

Aside from being able to control the network it is also important to see the responses

of the system (stand) to its environment. In many cases it is sufficient for a trainee to

get feedback from the stand via a web cam (right side of Fig. 4), but for more ad-

vanced tasks it is necessary to stimulate the hardware inputs of a device and/or

measure its outputs (e.g. reading analog outputs of stand modules or simulating a

keystroke on an evaluation board). For such cases the trainees should have the possi-

bility to interact with the inputs and outputs of the device on the stand.

To support such operation a special I/O device is designed at ICT. In order to have

a versatile and reusable device for a wide area of applications the following boundary

conditions should be met:

• The device should be controlled by plain HTTP for communication

• The implementation should be versatile for other laboratory setups

• The configuration should be simple to allow easy integration in a variety of

common software

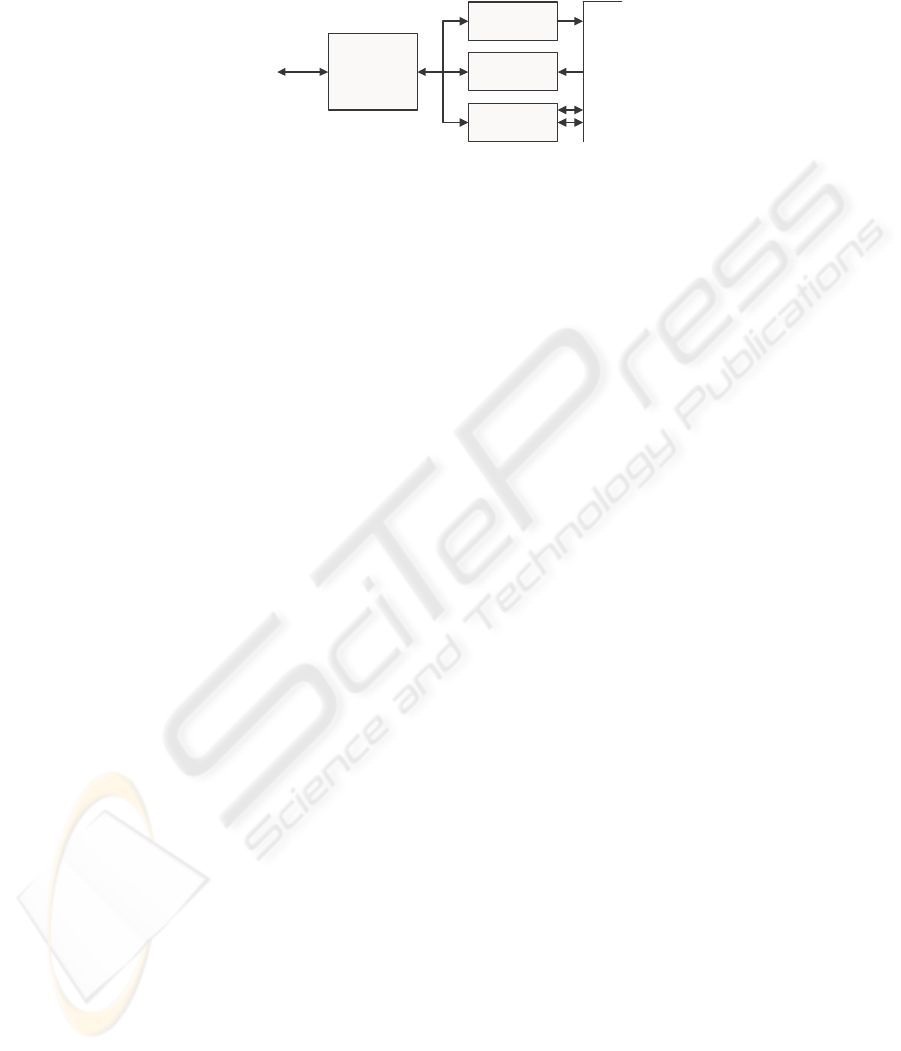

To meet these constraints a modular concept as shown in Fig. 6 was introduced by

the authors. A web server running on an embedded system interfaces different I/O

modules connected via an I

2

C (Inter-Integrated Circuit) bus [8]. The I/O modules are

designed as stackable modules and therefore can be individually put together accord-

ing to the needs of the actual laboratory setups.

In several projects the authors already gained experience on the embedded system

IPC@CHIP SC12 [9] from Beck. This chip already includes an Ethernet controller,

512 KB RAM and ROM (Flash) and an I

2

C bus interface. The software design must

also meet the modular hardware approach. To make the configuration as simple as

possible a configuration file is supplied with each module that defines the HTTP post

commands as well as I

2

C address and messages to the stackable module.

A CGI (Common Gateway Interface)-Procedure uses the APIs of the IPC@CHIP

to convert the commands from the web browser into commands on the I

2

C bus ac-

56

cording to the description in the configuration file. This allows for adoption without

reprogramming the IPC@CHIP.

Web server

Analog/Digital-

Converter

Digital/Analog-

Converter

Digital I/O

. .

. .

HTTP I

2

C

Device to be controlled

Fig. 6. Embedded device for remote control of laboratory stands.

4 Conclusion

Based on the experience of past projects the authors set up a BACnet control network

laboratory for distance courses for students and professional training of companies at

the ICT. The access to this laboratory should be totally web based and is based on

two components: A remote control model developed by the Perm State Technical

University (already running for LonWorks control network) and a gateway to control

the I/Os of the used control network devices. The work described here is still work in

progress, but finished tasks and past experience clearly indicates that web based

approach offers the best flexibility for students and laboratory staff.

5 References

1. Altera MAX+PLUS II Getting Started, Version 8.1, Altera Inc., USA, September 1997.

(http://www.altera.com/)

2. Website of the asix4web project, Version January 2003, Institute of Computer Technology,

Vienna University of Technology, 2003. (

http://www.ict.tuwien.ac.at/asicdesign/asix4web)

3. Website of the Smart Kitchen project, Version August 2003, Institute of Computer Tech-

nology, 2003. (http://smartkitchen.ict.tuwien.ac.at)

4. ISO/TC 205, ISO/FDIS 16484-5 – Building automation and control systems – Part 5: Data

communication protocol, 2003.

5. S. Soucek, G. Russ, C. Tamarit, The Smart Kitchen Project - An Application on Fieldbus

Technology to Domotics, Proceedings of the 2nd International Workshop on Networked

Appliances (IWNA2000), 2000.

6. H. Müller, C. Buchenau, T. Abenath, Entwurf und Beginn der Implementierung eines

BACnet/IP-Protokollanalysators in einem embedded system unter dem Betriebssystem

Linux, FH Dortmund, 2001.

7. A. Orebaugh, G. Morris, E. Warnicke, G. Ramirez, Ethereal Packet Sniffing, Syngress

Publishing, 2004.

8. The I2C-Bus Specification Version 2.1, Philips Semiconductors, 2000.

(http://www.semiconductors.philips.com/)

9 Hardware Manual IPC@CHIP Embedded Controller Family SC11/SC12/SC13 V1.5, BECK

IPC GmbH ,2004. (http://www.beck-ipc.com/)

57