Evaluating Green and Resilient Supplier Performance:

AHP-Fuzzy Topsis Decision-Making Approach

Ahmed Mohammed, Irina Harris

,

Anthony Soroka, Naim Mohamed and Tim Ramjaun

Cardiff Business School, Cardiff University, Aberconway Building, Colum Dr, CF10 3EU, Cardiff, U.K.

Keywords: Supplier Selection, Green Development, Supply Chain Resilience.

Abstract: This paper presents an approach for evaluating and ranking suppliers with respect to their traditional, green

and resilience (TGR) characteristics. A set of criteria/sub-criteria were identified within a unified framework

and their relative importance weighted using the analytical hierarchy process (AHP) algorithm. In addition,

the suppliers were evaluated and ranked based on their performance towards the identified TGR criteria using

the fuzzy technique for order of preference by similarity to ideal solution (FTOPSIS) algorithm. The

applicability and effectiveness of the proposed approach was proved through a real case study by revealing a

comparatively meaningful ranking of suppliers. The study provides a noteworthy aid to management who

understand the necessity of building supply chain resilience while concurrently pursuing ‘go green’

responsibilities.

1 INTRODUCTION

The supplier selection decision-making process

represents a key activity in supply chain management

since purchasing expenses exceed fifty percent of all

firms’ costs (Mohammed et al., 2017a). Supplier

selection refers to a multi-criteria decision-making

problem in evaluating suppliers’ performance with

respect to several criteria in order to purchase

materials from the most appropriate source. Despite

the importance of price, other evaluation criteria

should be considered such as reliable delivery, which

will ultimately effect productivity and efficiency

within a production environment and therefore

overall costs. Dickson (1966) highlighted 23

parameters that can be used by decision-makers to

assess suppliers, Ha and Krishnan (2008) updated

these and suggested several additional criteria.

Nevertheless, the most prevalent traditional business

criteria are quality, cost, and delivery. Popular green

criteria include: environmental management systems,

resource consumption, eco-design and waste

management. Further supplier selection criteria can

be found in Weber et al. (1991); Govindan et al.

(2015); and Aissaoui et al. (2007).

Presently, there are ever increasing

responsibilities placed on companies to consider the

environmental impact of their supply chain activities

(Mohammed et al., 2017b and 2015; Konur et al.,

2016). Green supply chain management is the activity

of purchasing, producing, marketing and performing

various packaging and logistical activities that takes

into account environmental implications

(Mohamemd et al., 2017c). However, suppliers tend

to represent inevitable sources of external risk

(Rajesh and Ravi, 2015). Purchasing managers may

consider traditional and more recently green criteria

when assessing suppliers while neglecting resilience

(Kannan et al., 2015). Resilience is the capability of

the system to efficiently adapt an expected

disruptions and back to its normal process, is a vital

aspect of any supply chain management (Torabi et al.,

2015). Following an earthquake in Japan (2011),

Apple was unable to produce the iPad 2 due to lack of

flash memory and super-thin battery (BBC News, 18

Mar 2011) caused by an unanticipated disruption to

the supply chain. This particular event also

interrupted the automotive sector and retail supply

chains in the UK (Hall, 16 Apr 2010). Recently,

hurricane Sandy led to massive disruptions in US

supply chains (Torabi et al., 2015; Burnson, 30 Oct

2012). To protect their business, purchasing

managers should include resilience in to their

decision-making criteria (Torabi et al., 2015).

Resilience criteria is represented by a supplier’s

capability to cope with risk and unexpected events

more efficiently and quickly than other suppliers. The

current work considers resilience criteria identified

Mohammed, A., Harris, I., Soroka, A., Mohamed, N. and Ramjaun, T.

Evaluating Green and Resilient Supplier Performance: AHP-Fuzzy Topsis Decision-Making Approach.

DOI: 10.5220/0006619902090216

In Proceedings of the 7th International Conference on Operations Research and Enterprise Systems (ICORES 2018), pages 209-216

ISBN: 978-989-758-285-1

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All r ights reserved

209

and analysed by Purvis et al. (2016). The latter

proposed a framework for the development and

implementation of a resilient supply chain strategy,

which illustrates the relevance of various

management paradigms. The authors considered four

pillars (enablers) as key factors to improve supply

chain resilience: redundancy, agility, leanness and

flexibility (RALF). However, visibility was

suggested as an essential resilience criterion by the

purchasing manager for our case study.

Since additional criteria, such as environmental

sustainability and resilience are paramount to

building a successful and competitive supply chain,

supplier selection complexity has increased. A novel

approach is required, which incorporates three main

criteria: traditional business, green and resilience.

Despite the significant quantity of research already

conducted around these topics, the vast majority of

current literature considers the green and resilience

aspects of supplier selection independently.

This paper addresses the knowledge gap by

proposing a unified supplier selection approach that

considers traditional, green and resilience criteria

simultaneously. The evaluation criteria were

identified from the literature and based on discussions

with the purchasing manager from our case study.

The development of this approach can be detailed into

three phases. In phase one, the main traditional, green

and resilience criteria and their sub-criteria were

identified in a unified framework. Phase two, AHP

was used to integrate judgments from a decision

maker with the purpose of determining the weights of

the criteria and sub-criteria. In the third phase,

FTOPSIS was applied to evaluate and rank suppliers

based on their TGR performance. The robustness of

the proposed approach is validated within a case

study for a manufacturing company and the work

contributed to providing a framework for the supplier

selection strategy, which incorporates traditional,

green and resilience criteria.

2 LITERATURE REVIEW

Previous studies on supplier selection consider

traditional criteria to be more extensive than the less

established, green supplier selection (Govindan et al.,

2015; Amindoust et al., 2012). Most Recently,

Govindan et al. (2015) reviewed published research

from 1997 to 2011 on MCDM and mathematical

modelling used for green supplier selection problems.

Shen et al. (2013) proposed a fuzzy approach for

evaluating the green suppliers. Büyüközkan and Çifçi

(2010) developed a fuzzy analytic network process

(ANP)-based approach within a multi-person

decision making scheme under incomplete preference

relationships. Kuo and Lin (2011) proposed an

integrated approach using ANP and DEA for green

supplier evaluation. Akman (2015) suggested a two-

step supplier-assessment framework to evaluate

green suppliers. Kannan et al. (2015) investigated a

green supplier selection problem in a plastic company

using a fuzzy axiomatic design approach. Govindan

and Sivakumar (2016) developed an integrated multi-

criteria decision-making and multi-objective linear

programming approach as an aid to select the best

green supplier. Songa et al. (2017) proposed an

integrated approach for evaluating suppliers with

respect to economic, green and social criteria using

the merit of pairwise comparison method in

determining relative importance, the strength of

decision making trial and evaluation laboratory

(DEMATEL) in manipulating the complex and

intertwined problems with fewer data, and the rough

number's advantage in flexibly dealing with vague

information.

Supply chain management includes a variety of

complex activities subject to disruptions caused by

unexpected incidents. Improving supply chain

resilience is crucial for managing potential

disruptions (Torabi et al., 2015). The reviewed

literature showed that research studies using

quantitative approaches to solve resilient supplier

problem are limited. Mitra et al. (2009) and Sawik

(2013) identified several pillars and criteria that

should be considered for selecting resilient suppliers.

Haldar et al. (2014) developed a fuzzy MCDM

approach for supplier selection considering the

importance degrees of specific attributes as linguistic

variables formulated by triangular and trapezoidal

fuzzy numbers. Torabi et al. (2015) proposed a fuzzy

stochastic bi-objective optimization model to solve a

supplier selection and order allocation problem to

improve the supply chain resilience under operational

and disruption risks. Sahu et al. (2016) proposed a

supplier evaluation decision support system using the

VIKOR method considering general and resiliency

criteria. Pramanik et al. (2016) presented a fuzzy

MCDM approach as an aid to developing a resilient

supplier selection activity. Klibi and Martel (2012)

formulated a mixed integer programming model for

handling supplier selection and order allocation

problem. Sawik (2013) designed a mixed-integer

programming model to solve a supplier selection

problem in a supply chain under disruption risks.

ICORES 2018 - 7th International Conference on Operations Research and Enterprise Systems

210

3 DEVELOPED GREEN AND

RESILIENT SUPPLIER

SELECTION APPROACH

A laboratory instrumentation Original Equipment

Manufacturer wants to develop a resilient supplier

selection approach for evaluating their current

suppliers in order to plan for unexpected events.

Additionally, the company is keen to take ownership

of their environmental responsibilities. This research

supports the company’s requirements through

development of a supplier selection approach to

facilitate evaluation and ranking of suppliers based on

their performance with respect to traditional, green

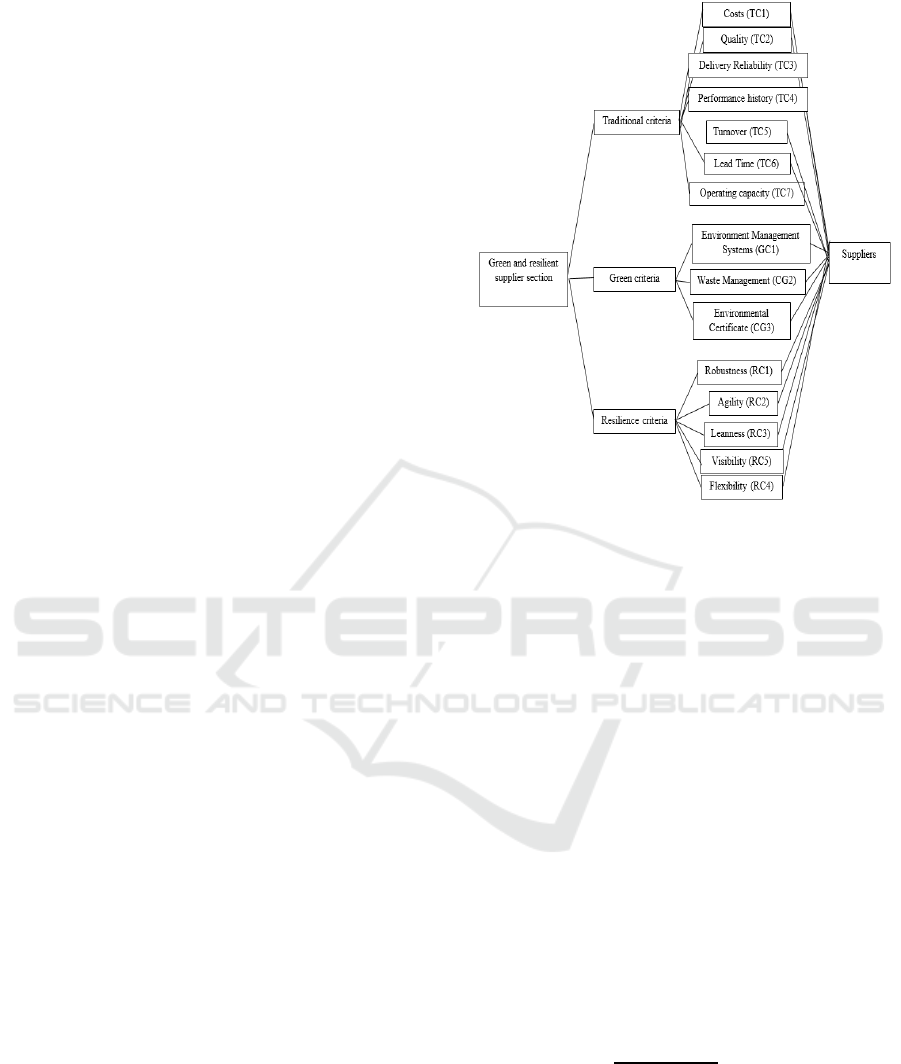

and resilience criteria. Figure 1 shows the hierarchical

supplier selection framework developed for this task.

The traditional sub-criteria include: cost, quality,

delivery reliability, performance history, turnover,

lead time, and operating capacity. The green sub-

criteria include: environmental management system,

waste management and environment related

certificate. The resilience sub-criteria include:

flexibility, leanness, agility robustness and visibility

(FLARV). AHP used linguistic expert assessment to

determine the importance weight for each criteria and

sub-criteria. FTOPSIS was then adapted towards

evaluating suppliers based on their performance

towards the criteria shown in Figure 1. Subsequently,

the ranking order of suppliers was determined based

on evaluation derived from FTOPSIS.

3.1 AHP

AHP is a multi-criteria decision making algorithm,

developed for considering both qualitative and

quantitative aspects of evaluation (Saaty, 1977). It

attempts to reduce complex decisions to a series of

pairwise comparisons and then reveals the final

weights. In this work, AHP was applied for

determining the importance weight for each TGR

criteria and sub-criteria. Table 1 shows the evaluation

scale in terms of linguistic variables that were used to

perform pairwise comparisons among TGR criteria

and sub-criteria. Decision makers need to give their

opinion about the importance of every criteria and

sub-criteria. AHP was implemented as follows:

Figure 1: Criteria and sub-criteria for the traditional, green

and resilient supplier selection.

1. Use a decision maker’s preference to build a pair-

wise comparison matrix (A) using the evaluation

scale shown in Table 1:

1,2 1,

2,1 2,

,1 ,2

1

1

; 1, 2, 3,..., ; 1, 2, 3, ...,

... ... ...

1

j

j

ii

aa

aa

A i I j J

aa

(1)

where I refers to the number of suppliers and J refers

to the number of criteria.

2. Sum each column of A as follows:

,

i ij

jJ

Column S a

(2)

3. Build the normalised decision matrix (R) by

dividing each value in matrix A by the sum of its

column:

S

i

A

R

Column

(3)

4. Determine the weight w

j

of each criterion by

calculating the average of its weight with respect

to other criteria:

Evaluating Green and Resilient Supplier Performance: AHP-Fuzzy Topsis Decision-Making Approach

211

Table 1: Evaluation scale in linguistic variables.

Scale

Linguistic Variable

1

Equally important (EI)

3

Weakly important (WI)

5

Strongly more important (SMI)

7

Very strongly important (VSI)

9

Extremely important (EI)

1

I

i

i

i

rowS

w

J

(4)

3.2 Fuzzy TOPSIS

Hwang and Yoon (1981) developed TOPSIS to select

an alternative based on its distance to the ideal

solution and the negative ideal solution. FTOPSIS is

an extension of TOPSIS developed by Chen (2006) to

handle the uncertainty in the linguistic assessment. In

this work, after determining the importance weight

for each green and resilient criteria and sub-criteria,

Fuzzy TOPSIS was applied to evaluate and rank

suppliers with respect to their TGR performance. It is

noteworthy to mention that fuzzy TOPSIS was used

rather TOPSIS to cope with uncertain evaluation of

some suppliers. Table 2 presents the linguistic

variables and the correspondent triangular fuzzy

numbers that were used to rank the alternatives

considering each criterion. Decision makers need to

give their opinions about the performance of every

supplier based on TGR criteria. FTOPSIS was

implemented as follows:

Eq. (6) is used to normalise the fuzzy decision

matrix to get the normalised decision matrix ( ):

~~

ij

nxm

Rr

(5)

where

~

222

,,

ij ij ij

ij

ij ij ij

iii

a n m

r

mmm

(6)

The weights of the criteria (w

j

) obtained from the

AHP approach need to be multiplied by the elements

of the normalised decision matrix (

~

R

) to form the

weighted normalised decision matrix (

~

V

).

~~

ij

nxm

Vv

(7)

where

~

ij

v

is obtained using the following equation:

~~

ij

ij

j

v r x w

(8)

The fuzzy positive and negative ideal solutions are

determined using Eqs. 9 and 10, respectively (Roy et

al., 2004).

~ ~ ~ ~

12

, ,...,

n

A v v v

(9)

~ ~ ~ ~

12

, ,...,

n

A v v v

(10)

The distance of supplier ‘I’ from the fuzzy positive

ideal solution (

i

d

) and the fuzzy negative ideal

solution (

i

d

) are calculated as follows:

~

~

, ;

,;

i v ij j

jn

i v ij j

jn

d d v v

d d v v

(11)

where

j

v

and

j

v

are fuzzy positive and negative

ideal points for criterion ‘j’, respectively.

Based on

and

ii

dd

, the fuzzy closeness

coefficient (CC) for each supplier is then determined

using Eq. 12. The supplier with the highest CC (varies

between 0 and 1) is selected as the best green and

resilient supplier.

i

ii

d

CC

dd

(12)

Table 2: Linguistic variables and their TFN used for

evaluating and ranking suppliers.

Linguistic variable

Triangular fuzzy number

Very low (VL)

(1, 1, 3)

Low (L)

(1, 3, 5)

Medium (M)

(3, 5, 7)

High (H)

(5, 7, 9)

Very high (VH)

(7, 9, 9)

~

R

ICORES 2018 - 7th International Conference on Operations Research and Enterprise Systems

212

4 APPLICATION: A REAL CASE

STUDY

In To validate the applicability and effectiveness of

the developed methodology, it was applied with a

manufacturing company (Company A, henceforth)

that design and produce thermal desorption and time-

of-flight mass spectrometry instrumentation in the

UK. Their products are used for a variety of

applications such as: environmental monitoring,

detection of chemical warfare agents, quality control

& safety of food products, aroma profiling and

environmental forensics. Company A aims to develop

a purchasing strategy that helps in evaluating their

current supplier with respect to green and resilience

performance in addition to the traditional business

criteria such as cost and quality. Company A aim to

meet their growth target by 2020, however, current

and projected turnover have not been revealed upon

the company’s request. Our novel approach to

supplier selection has been applied in this case study

to help the purchasing manager: (1) develop a unified

TGR purchasing strategy and (2) evaluate their

current supply chain resilience in term of suppliers’

performance towards the previously defined TGR

criteria (Figure 1).

The purchasing manager (PM) was invited to

select a number of suppliers to validate the proposed

approach in evaluating their performance towards the

identified criteria illustrated in Figure 1. The PM has

more than 18 years procurement experience. Two

deep discussions (each about 2 hours) were held to

explain, discuss and evaluate the TGR criteria, sub

criteria and five suppliers’ (S) performance.

In the first step, AHP was implemented to

determine the importance weight for each TGR

criteria and sub-criteria. Thus, the PM was invited to

perform a pairwise comparison among TGR criteria

and sub-criteria using the linguistic variables

presented in Table 1. A pair-wise comparison matrix

was built via the correspondence scale evaluation

(refer to Table 1) as shown in Table 3. Eqs.1-4 were

then applied to determine the importance weights of

each criteria and sub-criteria which are presented in

Table 4. According to the calculations shown in Table

4, the weight of traditional criteria is 0.263293; the

weight of green criteria is 0.051821; and the weight

of resilience criteria is 0.684886. The resilience

criteria obtained the highest weight followed by the

traditional and then green pillar. Thus, the resilience

criteria are deemed to be the most important

compared with the other traditional and green criteria.

The PM confirmed that the company’s current

strategy was to build a resilient supply chain rather

Table 3: Decision matrix among TGR criteria.

TGR criteria

Traditional

Green

Resilience

Traditional

1

9

1/5

Green

1/9

1

1/9

Resilience

5

9

1

than selecting suppliers according to performance

towards traditional criteria such as costs and quality.

After determining the importance for each TGR

criterion, fuzzy TOPSIS was implemented to obtain

the ranking order of suppliers based on their TGR

performance. The PM was invited for another

interview to evaluate the performance of selected

suppliers with respect to each sub-criterion using the

evaluation scale presented in Table 2. Table 5 shows

the linguistic evolution of suppliers towards their

TGR performance. Fuzzy TOPSIS was applied using

Eqs 5-12 to determine the matrix of normalized and

weighted normalized triangular fuzzy numbers in

addition to the positive ideal solution (

i

D

) and the

negative ideal solution (

i

D

). The closeness

coefficient (CC) for each supplier is determined by

the obtained distances using Eq. 12. Table 6 shows

the performance evaluation and rank of suppliers with

respect to each TGR criterion, which is represented

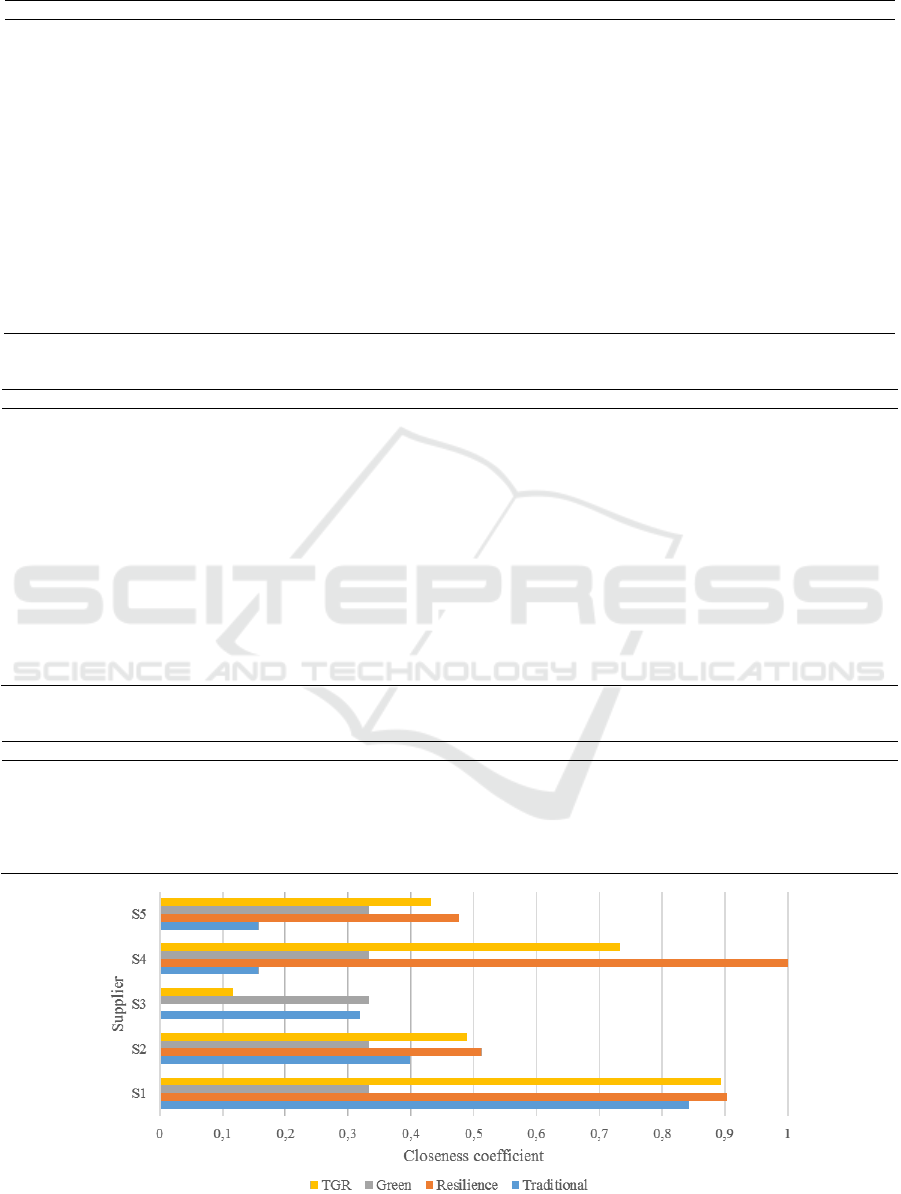

graphically, Figure 2. According to the obtained

results, S

2

revealed the highest TGR performance

with a closeness coefficient of 0.89373. Comparing

with the other suppliers the closeness coefficient of S

4

(0.733641), S

2

(0.489352), S

5

(0.432518) and S

3

(0.117511) were respectively in rank after S

1

.

5 CONCLUSIONS

This work presents a unified traditional business,

green and resilient supplier selection approach. The

framework was developed by identifying traditional,

green and resilience criteria and sub-criteria. Two

steps were followed to evaluate and rank suppliers.

Firstly, AHP was applied to determine the importance

weight of each criterion and sub-criterion based on

the linguistic evaluation of a purchasing manager.

The AHP results indicate that the resilience criteria

are deemed the most important for company A,

followed by traditional and green, respectively.

Secondly, fuzzy TOPSIS was applied to reveal the

order ranking of suppliers based on their TGR

performance with respect to the importance weight of

each criterion and sub-criterion. Based on the

obtained suppliers’ performance, we recommended

that company A works with some of their suppliers

(e.g. S

3

and S

5

) to improve their resilience. The results

Evaluating Green and Resilient Supplier Performance: AHP-Fuzzy Topsis Decision-Making Approach

213

Table 4: Weights of TGR criteria and sub-criteria obtained by AHP.

Criteria

IW

Ranking

Sub-criteria

IW

Ranking

Traditional

0.263293

2

TC1

0.188584

2

TC2

0.148292

4

TC3

0.146552

5

TC4

0.02105

7

TC5

0.082984

6

TC6

0.250322

1

TC7

0.162216

3

Green

0.051821

3

GC1

0.481354

1

GC2

0.282937

2

GC3

0.235709

3

Resilience

0.684886

1

RC1

0.033343

5

RC2

0.192122

3

RC3

0.093336

4

RC4

0.429723

1

RC5

0.251476

2

Table 5: Evaluation of suppliers towards their traditional, green and resilience performance.

Criteria

Sub-criteria

S

l

S

2

S

3

S

4

S

5

Traditional

TC1

H

H

M

M

M

TC2

M

M

M

M

M

TC3

M

M

M

M

M

TC4

VL

L

M

M

M

TC5

H

L

M

L

L

TC6

M

M

M

M

M

TC7

H

M

M

M

M

Green

GC1

M

M

M

M

M

GC2

M

M

M

M

M

GC3

M

M

M

M

M

Resilience

RC1

M

M

M

H

L

RC2

H

H

M

M

L

RC3

M

M

M

L

L

RC4

H

M

L

H

L

RC5

L

L

L

M

L

Table 6: Closeness coefficient and distances from the positive ideal/negative ideal solutions related to suppliers.

S

1

S

2

S

3

S

4

S

5

i

D

0.008212

0.008212

0.068047

0.023736

0.042167

i

D

0.069065

0.069065

0.009061

0.065376

0.032138

CC

0.89373

0.489352

0.117511

0.733641

0.432518

rank

1

3

5

2

4

Figure 2: A graphical comparison of suppliers’ closeness coefficient performance with respect to TGR criteria individually.

ICORES 2018 - 7th International Conference on Operations Research and Enterprise Systems

214

demonstrate the applicability of the novel approach in

assisting the purchasing manager at company A to

produce a green and resilient purchasing strategy

through supplier evaluation.

The developed methodology can be applied to

other companies as a tool to measure the healthiness

of their supply chain in terms of resilience and green

performance. Furthermore, it mediates the

uncertainty in experts’ opinions through the use of

fuzzy evaluation.

Ongoing work includes the incorporation of social

criteria to those already studied here. Finally, the

authors are developing a multi-objective optimization

model to help decision makers in solving order

allocation problem with respect to TGR performance

of suppliers.

REFERENCES

Akman, G., 2015. Evaluating suppliers to include green

supplier development programs via fuzzy c-means and

VIKOR methods. Comput. Ind. Eng. 86, 69–82.

BBC News, 18 Mar 2011. Japan disaster: Supply shortages

in three months. BBC News. (accessed 11.02.17).

Bing, X., Bloemhof-Ruwaard, J., Chaabane, A., van der

Vorst, J., 2015. Global reverse supply chain redesign

for household plastic waste under the emission trading

scheme. J. Clean. Prod. 103, 28-39. Aissaoui, N.,

Haouari, M., Hassini, E., 2007. Supplier selection and

order lot sizing modeling: a review. Com. Oper. Res.

34, 3516–3540.

Burnson, P., 30 October 2012. Nation’s Supply Chains

Disrupted by Hurricane Sandy. Logistics Management.

(accessed 14.06.17).

Büyüközkan and Çifçi, 2010 G. Büyüközkan, G. Çifçi.

Evaluation of the green supply chain management

practices: a fuzzy ANP approach. Production Planning

& Control, iFirst (2010), pp. 1-14

Chen, C.T., Lin, C.T., Huang, S.F., 2006. A fuzzy approach

for supplier evaluation and selection in supply chain

management. Int. J. Prod. Econ. 102, 289–301.

Dickson, G., 1966. An analysis of vendor selection systems

and decisions, J. Purch. 2(1), 5–17.

Govindan, K., Rajendran, S., Sarkis, J., Murugesan, P.,

2015. Multi criteria decision making approaches for

green supplier evaluation and selection: a literature

review. J. Clean. Prod. 98, 66–83.

Govindan, K., Sivakumar, R., 2016. Green supplier

selection and order allocation in a low-carbon paper

industry: integrated multi-criteria heterogeneous

decision making and multi-objective linear

programming approaches. Ann. Oper. Res. 238, 243–

276.

Ha, S.H., Krishnan, R., 2008. A hybrid approach to supplier

selection for the maintenance of a competitive supply

chain. Expe. Sys. with Appl. 34, 1303–1311.

Haldar, A., Ray, A., Banerjee, D., Ghosh, S., 2014. Resi-

lient supplier selection under a fuzzy environment. Int.

J. Manage. Sci. Eng. Manage. 9 (2), 147–156.

Hall, J., 16 Apr 2010. Volcanic Ash Cloud Leaves Shops

Facing Shortages of Fruit, Vegetables and Medicine.

The Daily Telegraph.

Hwang, C.L, Yoon, K., 1981. Multiple attribute decision

making: methods and applications. New York:

Springer-Verlag.

Kannan, D., Govindan, K., Rajendran, S., 2015. Fuzzy

axiomatic design approach based green supplier

selection: a case study from singapore. J. Clean. Prod.

96, 194–208.

Klibi, W.; Martel, A. Scenario-based Supply Chain

Network risk modeling. Eur. J. Oper. Res. 2012, 223,

644–658.

Konur, D., Campbell, J.F., Monfared, J.A., 2016. Economic

and environmental considerations in a stochastic

inventory control model with order splitting under

different delivery schedules among suppliers. Omega,

71, 46–65.

Kuo, R.J., Y.J. Lin. Supplier selection using analytic

network process and data envelopment analysis.

International. Journal of Production Research (2011),

pp. 1-12iFirst.

Mitra, K.; Gudi, R.D.; Patwardhan, S.C.; Sardar, G.

Towards resilient supply chains: Uncertainty analysis

using fuzzy mathematical programming. Chem. Eng.

Res. Des. 2009, 87, 967–981.

Mohammed A. and Wang Q. 2015. Integrity of an RFID-

enabled HMSC Network. Proceedings of the Third

International Conference on Digital Enterprise and

Information Systems, Shenzhen, China, 2015a, 79-86.

Mohammed A. and Wang Q. and Li X. 2017a. Developing

a meat supply chain network design using a multi-

objective possibilistic programming approach. British

Food Journal, 119, 3, 690-706.

Mohammed, A. and Wang, Q., 2017b. The fuzzy multi-

objective distribution planner for a green meat supply

chain. International J. Pro Eco., 184, 47–58

Mohammed, A., Wang, Q., Alyahya, S. and Binnette, N.

2017c. Design and optimization of an RFID-enabled

automated warehousing system under uncertainties: A

multi-criterion fuzzy programming approach. The

International Journal of Advanced Manufacturing

Technology. 91 (5), 1661-1670.

Pramanik, D., Subhash, N., Haldar, A., Mondal, S.C.,

Naskar, S.N., Ray. A., 2017. Resilient supplier

selection using AHP-TOPSIS-QFD under a fuzzy

environment. International Journal of Management

Science and Engineering Management, 12 (1), 45-54.

Purvis, L., Spall, S., Naim, M. and Spiegler, V. 2016.

Developing a resilient supply chain strategy during

‘boom’ and ‘bust’, Production Planning & Control,

27:7-8, 579-590.

Rajesh, R.; Ravi, V. Supplier selection in resilient supply

chains: A grey relational analysis approach. J. Clean.

Prod. 2015, 86, 343–359.

Saaty, T. L. (1977). A scaling method for priorities in

hierarchical structures. Journal of Mathematical

Psychology, 15(3), 234–281.

Evaluating Green and Resilient Supplier Performance: AHP-Fuzzy Topsis Decision-Making Approach

215

Sahu, A.K., Datta, S., Mahapatra, S.S., 2016. Evaluation

and selection of resilient suppliers in fuzzy

environment: Exploration of fuzzy-VIKOR.

Benchmarking: An International Journal, 23 (3), 651-

673.

Sawik, T. Selection of resilient supply portfolio under

disruption risks. Omega 2013, 41, 259–269.

Shen, L., Olfat, L., Govindan, K., Khodaverdi, R. and

Diabat, A. (2013), “A fuzzy multi criteria approach for

evaluating green supplier’s performance in green

supply chain with linguistic preferences”, Resources,

Conservation and Recycling, Vol. 74 No. 1, pp. 170-

179.

Songa, W., Xub, Z. and Liu, H-C. 2017. Developing

sustainable supplier selection criteria for solar air-

conditioner manufacturer: An integrated approach.

Renewable and Sustainable Energy Reviews 79 (2017)

1461–1471.

Torabi, S.A., Baghersad, M., Mansouri, S.A., 2015.

Resilient supplier selection and order allocation under

operational and disruption risks. Transportation

Research Part E 79, 22–48.

Weber, C.A., Current, J.R., Benton, W.C., 1991. Vender

selection criteria and methods, Eur. J. Oper. Res. 50 (1),

2–18.

ICORES 2018 - 7th International Conference on Operations Research and Enterprise Systems

216