A Virtual Glove System for the Hand Rehabilitation based on Two

Orthogonal LEAP Motion Controllers

Giuseppe Placidi

1

, Luigi Cinque

2

, Andrea Petracca

1

, Matteo Polsinelli

1

and Matteo Spezialetti

1

1

A

2

VILab, Department of Life, Health & Environmental Sciences, University of L’Aquila, Via Vetoio, L’Aquila, Italy

2

Department of Computer Science, Sapienza University, Via Salaria, Rome, Italy

giuseppe.placidi@univaq.it, cinque@di.uniroma1.it, andrea.petracca@graduate.univaq.it,

matteo.polsinelli@student.univaq.it, matteo.spezialetti@graduate.univaq.it

Keywords:

Hand Rehabilitation, Virtual Glove, LEAP Motion Controller.

Abstract:

Hand rehabilitation therapy is fundamental in the recovery process for patients suffering from post-stroke or

post-surgery impairments. Traditional approaches require the presence of therapist during the sessions, in-

volving high costs and subjective measurements of the patients’ abilities and progresses. Recently, several

alternative approaches have been proposed. Mechanical devices are often expensive, cumbersome and patient

specific, while virtual devices are not subject to this limitations, but, especially if based on a single sensor,

could suffer from occlusions. In this paper a novel multi-sensor approach, based on the simultaneous use

of two LEAP motion controllers, is proposed. The hardware and software design is illustrated and the mea-

surements error induced by the mutual infrared interference is discussed. Finally, a calibration procedure, a

tracking model prototype based on the sensors turnover and preliminary experimental results are presented.

1 INTRODUCTION

The hand is a fundamental organ of the human body

and fulfill several complex tasks corresponding to a

deep brain involvement. For patients suffering from

post-stroke or post-surgery residual impairments the

recovery of the hand functions is extremely impor-

tant for accelerating the rehabilitation process. The

possibility of the recovery is strictly related to the fre-

quency, the duration and the quality of the rehabilita-

tion sessions (Kopp et al., 1999; Liepert et al., 2000;

Hallett, 2001; Arya et al., 2011). In the traditional re-

habilitation approach, a therapist is required to follow

the patient during one-to-one expensive sessions and

subjective evaluations (the therapist, basing on his ex-

perience, evaluates the results). Over the last years,

several automated (tele)rehabilitation tools, based on

mechanic or virtual devices have been presented, in

order to allow patients to execute the therapy in a

domestic environment being followed by therapists

through Internet (Burgar et al., 2000; Kahn et al.,

2006; Placidi, 2007; Franchi et al., 2009; Franchi

et al., 2010; Zimmerli et al., 2013; Placidi et al., 2013;

Llor

´

ens et al., 2015).

Mechanical approaches usually involve the em-

ployment of gloves equipped with pressure sensors

and pneumatic actuators for assisting and monitoring

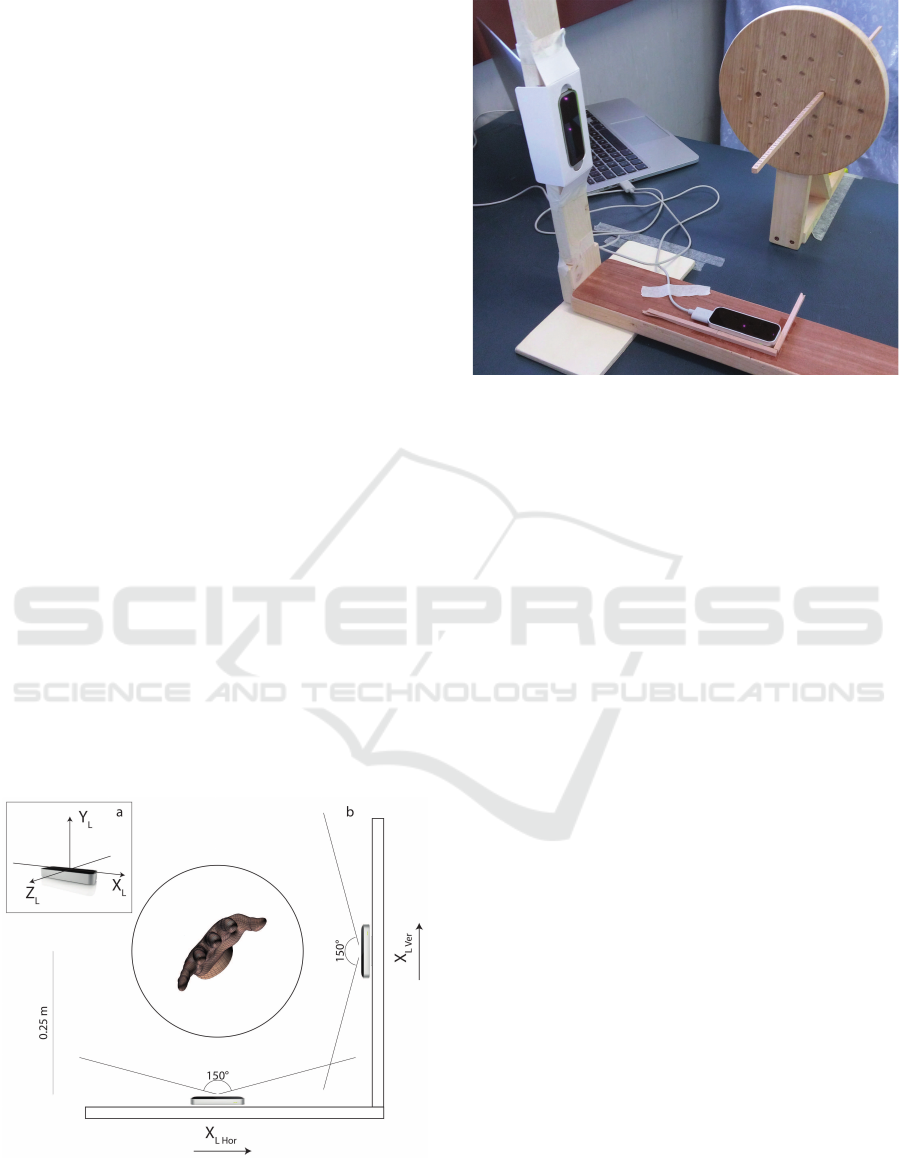

Figure 1: System based on a single LEAP sensor (left panel)

and based on two orthogonal LEAP sensors (right panel).

The view shown in the third row is occluded for a single

LEAP and not for a double configuration.

the hand movements and to apply forces to which the

fingers have to oppose (Lum et al., 2012; Maciejasz

et al., 2014). Despite the measurement accuracy they

are capable to achieve, these systems are expensive,

cumbersome (they limit the patients spontaneity and

freedom of movements) and patient specific (limiting

the possibility of reusing). For replacing mechanical

components, existing virtual approaches are based on

184

Placidi, G., Cinque, L., Petracca, A., Polsinelli, M. and Spezialetti, M.

A Virtual Glove System for the Hand Rehabilitation based on Two Orthogonal LEAP Motion Controllers.

DOI: 10.5220/0006197801840192

In Proceedings of the 6th International Conference on Pattern Recognition Applications and Methods (ICPRAM 2017), pages 184-192

ISBN: 978-989-758-222-6

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

evaluation of videos from RGB or depth sensing cam-

eras to calculate hand kinematic information in real

time, (Rus

`

ak et al., 2011; Avola et al., 2013; Chaud-

hary et al., 2013; Placidi et al., 2014; Charles et al.,

2014; Placidi et al., 2015).

The LEAP motion controller

(http://www.leapmotion.com, 2016) is a recently

presented low-cost and non-bulky hand tracking

device, characterized by high-resolution and high-

reactivity (Bachmann et al., 2015) and represents a

good system to be used for virtual reality applications

and rehabilitation (Petracca et al., 2015; Polsinelli,

2015). It is a stereo vision device composed by 3

LED sources and 2 infrared cameras, that suffers the

limitations of a monocular system being unable to

recognize every position of the hand (occlusions can

frequently occur). In order to address the occlusions

issue, in this work a multi-sensor approach based on

the use of two orthogonal LEAPs is proposed. The

rest of the paper is organized as follows: Section

2 describes the proposed strategy, by showing the

hardware structure (2.1), the software architecture

(2.2) and the evaluation of the infrared interferences

when using two sensors (2.3); Section 3 shows the

tracking model prototype and some hand tracking

preliminary results (3.3).

2 MATERIALS AND METHODS

The system has been designed to obtain simultaneous

information from two LEAPs, orthogonally placed

each other. The reason is that a single LEAP sensor is

Figure 2: (a) The LEAP sensor and its references system.

(b) Hardware configuration with two orthogonal LEAPs has

been designed in order to create a wide area in which the

hand can be tracked.

Figure 3: Experimental setup of the orthogonal LEAPs and

the tool used to calibrate the system.

not able to compute with accuracy the hand position

if the palm (and the fingers) is not visible, that is if the

vector orthogonal to the palm is approximately paral-

lel to the sensor plane (see Figure 1 third row). Using

two orthogonal sensors should ensure that at least one

of them is able to get the correct position. One of the

major issues to be addressed was the devices connec-

tion: the driver and the API are not able to manage

multiple instances of the LEAP on the same machine.

For this reason an architecture including a virtual ma-

chine has been designed. Moreover, in order to build

a consistent hand model using information from both

sensors, their reciprocal position had to be computed

with high accuracy through a calibration procedure.

2.1 Hardware Setup

A LEAP Motion Controller is a small device, de-

signed to be placed above the surface of a desk. It

can be connected to the PC through a USB port. The

hardware includes two monochromatic infrared cam-

eras and three LEDs emitting static IR beams (wave-

length 850 nm). Considered the 3-Dimensional ref-

erence system used by the LEAP to represent the ob-

jects, shown in Figure 2.a, the fields of view of the

sensor is 150

◦

along the X axis and 120

◦

along the

Z axis. The intensity of the emitted light, limited by

the power supplied by the USB port, allows to ob-

serve an object within a distance of about 0.6 m from

the sensor. Objects in the field of view of the LEAP

are enlightened by the LEDs and the reflected light is

captured by the cameras, producing a couple of grey-

scale images that are used, at software level, to iden-

tify the objects positions, thanks to a stereo vision al-

gorithm (Weichert et al., 2013). The sensor is able

A Virtual Glove System for the Hand Rehabilitation based on Two Orthogonal LEAP Motion Controllers

185

to track up to two hands simultaneously, by using a

3D model of the hand that includes the positions of

the fingers joints, but can also recognize objects like

sticks and pencils. In this work, two LEAPs have been

fixed to a support, in such a way as to be orthonormal

and distant 0.25 m from the center of the scene, in or-

der to create a wide area in which the hand can freely

move and can be tracked by both sensors (Figure 2.b

and Figure 3).

2.2 Software Architecture

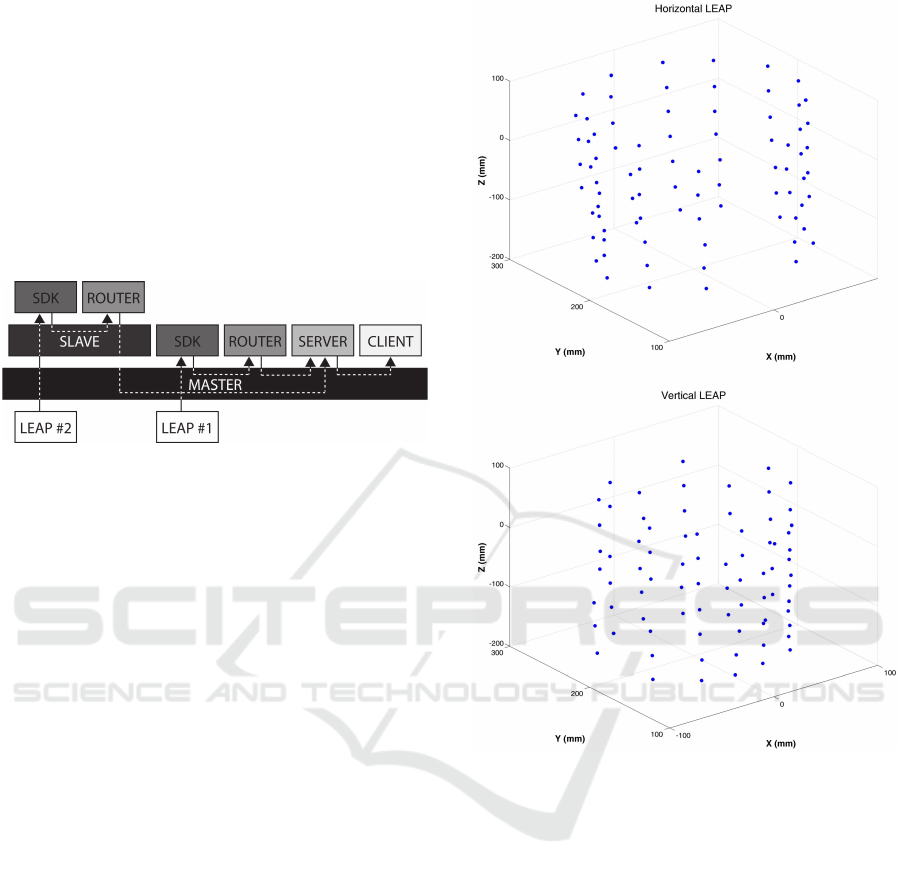

Figure 4: The software architecture: a virtual machine

(Slave) has been installed on the physical machine (Mas-

ter), for assigning each of the connected sensors to a dif-

ferent SDK; a javascript router was used to carry data from

both LEAPs to a single server.

LEAP is equipped with an SDK that allows to the

communication with the sensor both through a na-

tive and a web-socket based interface. By using the

latter it is possible to obtain a JSON data structure

containing tracking data (for more details, please re-

fer to (http://developer.leapmotion.com, 2016)). Un-

fortunately, the SDK does not allow the creation of

more than one instance of the device on a single ma-

chine. In order to address this issue, a virtual ma-

chine had to be included in the software setup (Figure

4 shows the diagram of the architecture). The vir-

tual machine (Slave) has been installed on the physi-

cal machine (Master): in this way, plugging both sen-

sors, one of them has been assigned to Master and the

other to Slave allowing to the machines to instanti-

ate their own driver. On each machine, data provided

by the SDK through the websocket (the port number

was fixed) were captured by a javascript router (ex-

ecuted on an instance of Node.js (http://nodejs.org,

2016)) and rerouted towards a Node.js server (hosted

on the Master machine). In this way, using again web-

sockets, the server was able to send data of both de-

vices to one or more clients running on Master.

2.3 Infrared Interferences Evaluation

The described setup has been used to evaluate the in-

frared interferences that the sensors could cause each

other. The main idea was to record the position of

Figure 5: The positions of the tested points seen from the

horizontal LEAP (up) and from the vertical LEAP (down)

each represented with its own reference system.

the same set of points (by tracking the tip of a stick,

see Figure 3), using both sensors, in different condi-

tions: just the LEAP used for the measure switched

on; both LEAPs switched on. The first case repre-

sented what we defined the “ideal condition” used for

estimating the “positioning error” (it contained just

the error intrinsic to the sensor). However, being the

considered ideal condition also a measure, what we

calculated was a “distance” between measurements

and not properly an “error”. In order to place the

stick in different positions, a circular wood disk con-

taining a series of holes on concentric circumferences

was used (Figure 3). The tool was designed in or-

der to be kept parallel to the X-Y plane of the LEAPs

and to place a wood stick at different positions along

the Z axis by making it move through the holes. The

stick (0.36 m long) was marked along its length in or-

der to know the distance between the tip and the sur-

ICPRAM 2017 - 6th International Conference on Pattern Recognition Applications and Methods

186

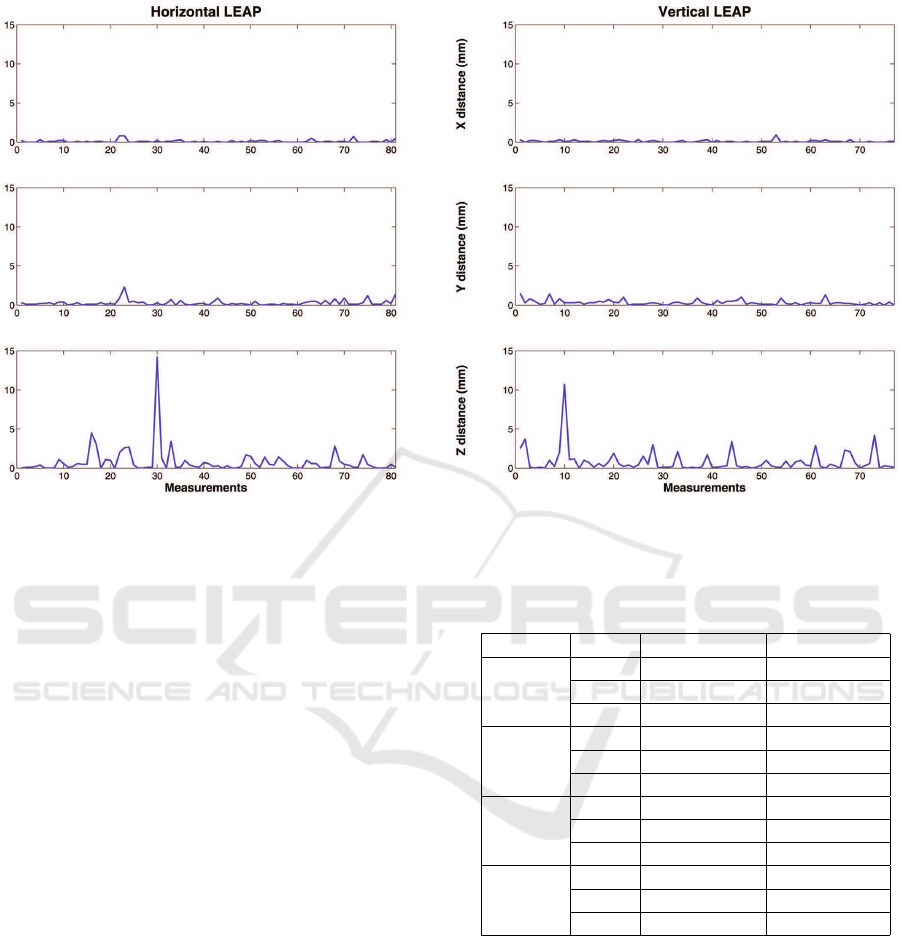

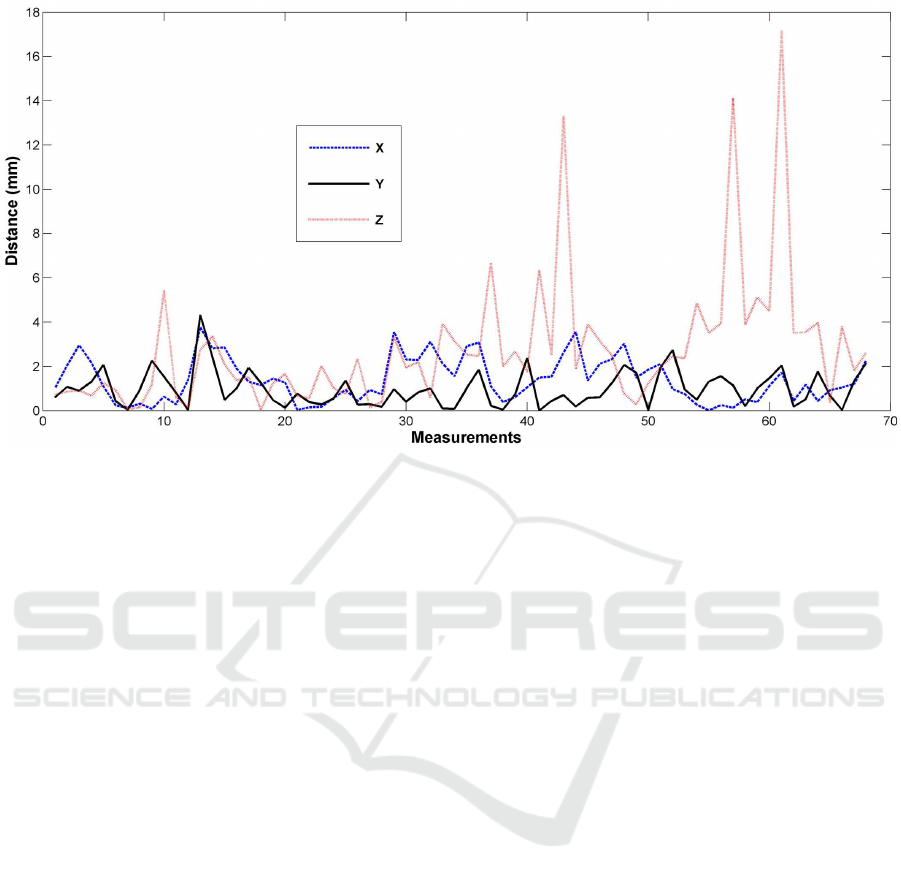

Figure 6: The distance (expressed in mm) between points measured in different conditions along the axes for the horizontal

(left panel) and vertical (right panel) sensors.

face of the disk. A set of 84 different positions of the

stick was measured from both sensors and repeated

for both conditions. A total of 3 and 7 points were

not considered during the test of the horizontal and

the vertical LEAP respectively, due to the impossibil-

ity of getting the positions (probably due to the closer

position of the points with respect to the sensor). It

has to be noted that the issue did not depend on the

infrared interferences, because the phenomenon hap-

pened in both conditions. Figure 5 shows the spatial

distribution of the points, measured with the LEAPs

without reciprocal interferences. The absolute values

of the variations in the measurements are represented

in Figure 6, for both LEAPs and separately for each

axes. Figure 7 also shows the distance between the

same points measured in different conditions.

Table 1 reports average values, standard devia-

tions and maximum values of the distance along all

the axes and in the space. Results have showed that

the displacement due to infrared interferences was

negligible (the average distance was 0.96 mm for

the horizontal LEAP and 1.03 mm for the vertical).

Moreover, by considering the axes separately, it is

possible to see that the tracking along the Z direction

was more affected by measurements “errors”. In par-

ticular, as can be seen also from Figure 6, the posi-

tions variation was most due to few points. In gen-

eral, considering the size of the fingertips and joints,

the displacement could be considered “tractable”.

Table 1: Average values, standard deviations and maximum

values of the distance along all the axes and in the space,

between points measured in different conditions.

HOR. LEAP VER. LEAP

X

distance

AVG 0.11 0.11

STD 0.17 0.13

MAX 0.80 0.90

Y

distance

AVG 0.28 0.32

STD 0.36 0.32

MAX 2.30 1.50

Z

distance

AVG 0.79 0.83

STD 1.75 1.48

MAX 14.20 10.70

3D

distance

AVG 0.96 1.03

STD 1.73 1.44

MAX 14.20 10.70

3 TRACKING MODEL

PROTOTYPE

3.1 Calibration Procedure

The proposed strategy was based on the proper rigid

transformation (roto-translation) of the vertical LEAP

information. In order to minimize the errors in the

tracking procedure, the position and the orientation

of one LEAP with respect to the other had to be eval-

A Virtual Glove System for the Hand Rehabilitation based on Two Orthogonal LEAP Motion Controllers

187

Figure 7: The distances (expressed in mm) between points measured in different conditions for the horizontal (up panel) and

the vertical (down panel) sensors.

uated as precisely as possible. The calibration pro-

cedure aimed to compute the roto-translation trans-

formation that links the vertical reference system to

the horizontal, starting from the coordinates of the

same set of points in the space observed from the

viewpoints (only one sensor was turned on during

each measure). The problem of estimating 3D body

transformations that aligns two sets of points with

known correspondences is well known in the com-

puter vision field (Sabata and Aggarwal, 1991; Eg-

gert et al., 1997). The corresponding set registra-

tion strategy used to compute the transformation (Besl

and McKay, 1992) started from two sets of points

A = {~a

i

: 1 ≤ i ≤ m} and B = {

~

b

i

: 1 ≤ i ≤ m} and

found a rotation matrix R and a translation vector

~

t

such that it was possible to move from a reference

system to the other:

~

b = R~a +

~

t, (1)

minimizing the error:

err =

1

m

m

∑

i=1

kR~a

i

+t −

~

b

i

k

2

(2)

For each set, the Center Of Mass (COM) was com-

puted:

~

C

A

=

1

m

m

∑

i=1

~a

i

and

~

C

B

=

1

m

m

∑

i=1

~

b

i

(3)

and used to center the clouds on the origin:

A

+

= {

~

a

+

i

:

~

a

+

i

= ~a

i

−

~

C

A

}

B

+

= {

~

b

+

i

:

~

b

+

i

=

~

b

i

−

~

C

B

}.

(4)

Then, the 3 x 3 cross-covariance matrix between the

sets A

+

and B

+

was computed:

H =

1

m

m

∑

i=1

~

a

+

i

~

b

+

i

T

(5)

and the Singular Value Decomposition (SVD) was ap-

plied, in order to decompose H in the vector of trans-

formations [U,S,V ] = SV D(H), such that

H = USV

T

(6)

where U and V were orthogonal matrices and S was a

non-negative diagonal matrix. Since the desired trans-

formation R was a rigid rotation, it could be computed

as:

R = UV

T

. (7)

The sign of the determinant ∆(V ) had not to be nega-

tive: in this case the third column of V was multiplied

for -1 and R was computed again. The translation was

derived as follows:

~

t = −R

~

C

A

+

~

C

A

. (8)

Lastly, the roto-translation was summarized with a

unique matrix (represented in homogeneous coordi-

nates):

W =

R

1,1

R

1,2

R

1,3

t

1

R

2,1

R

2,2

R

2,3

t

2

R

3,1

R

3,2

R

3,3

t

3

0 0 0 1

. (9)

The calibration phase was implemented in MATLAB

to run off-line. Given the set of points P, and fol-

lowing a cross validation strategy, the described point

ICPRAM 2017 - 6th International Conference on Pattern Recognition Applications and Methods

188

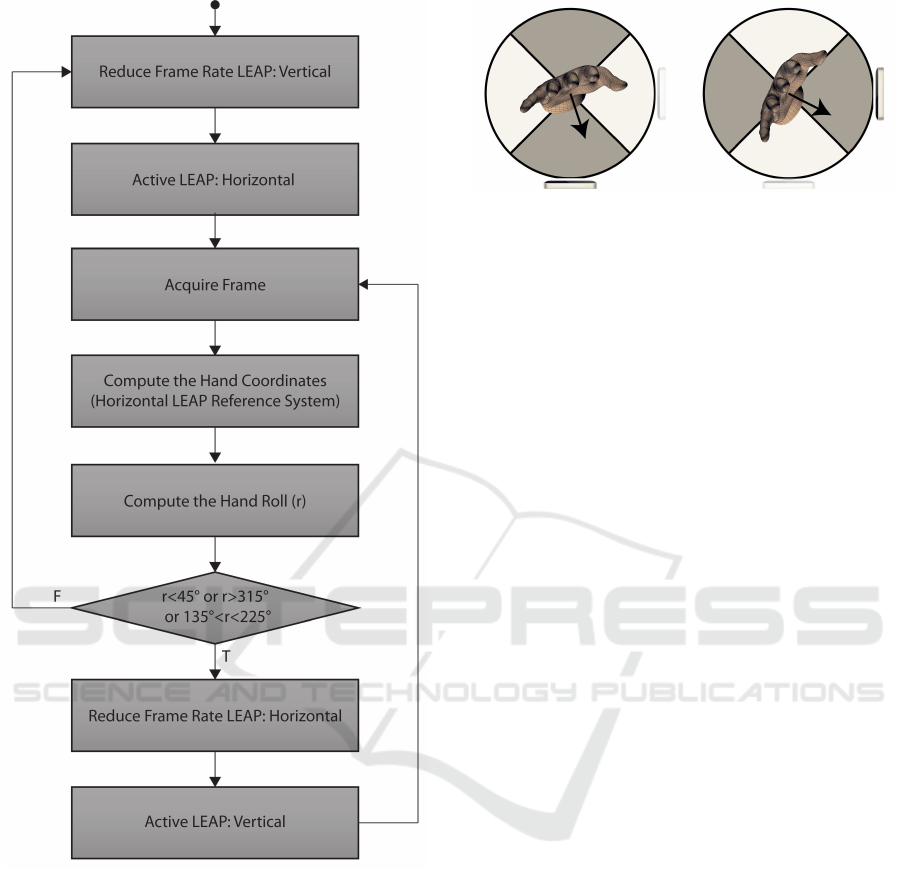

Figure 8: The flow diagram of the tracking prototype: the

hand was tracked by both sensors, the roll r with respect to

the horizontal reference system was computed using the in-

formation from the active LEAP and used to determine the

active sensor. The calibration was done in order to consider

the horizontal LEAP reference system as the world refer-

ence system.

registration process could be iterated k time, random

selecting, at each step, the training subset T

k

⊂ P (with

|T

k

| = s) used for the registration and computing the

average distance (between a point seen from the hor-

izontal sensor and the roto-translation of the same

point seen from the vertical sensor), over the remain-

ing set P \ T

k

. At the end, the training set character-

ized by the lowest distance was selected and the corre-

sponding roto-translation matrix stored in order to be

Figure 9: The switching approach: depending on the orien-

tation of the hand, one of the sensor was active and used to

track the hand, while the other was paused, in order to save

computational resources.

used by the server in run-time. This choice was made

to avoid that points affected by not negligible mea-

surement errors could affect negatively the calibration

process. P, k and s were the input of the calibration

function.

3.2 Tracking Module

The proposed approach could be easily employed in

a hand tracking system. The process to obtain the po-

sitions, illustrated in Figure 8, was based on a con-

trol switching approach: both LEAPs acquired their

frames stream, but only one, depending on the rota-

tion of the hand with respect to the horizontal LEAP

references system, is used to represent the hand (Fig-

ure 9). Both LEAPs were simultaneously turned on

and remained in this state for the whole session be-

cause the time necessary to switch on and off a sen-

sor would be too high for real-time purposes. At

each time, only one LEAP was selected as “active”

and the corresponding frame was acquired and used

to track the hand. The vector v, orthogonal to the

palm and usually used by the sensor to estimate the

hand orientation, was used to compute the roll r of

the hand, that is the angle between the X axis and the

projection of the vector on the X-Y plane, with re-

spect to the horizontal LEAP reference system. As

shown in Figure 9, if r was in the range from 225

◦

to 315

◦

(the palm was facing downwards) or in the

range from 45

◦

to 135

◦

(the palm was directed up-

wards) the horizontal LEAP was selected as active,

while the vertical was “paused” (it was still turned

on, but its frame rate was reduced to the minimum

in order to save computational resources). Out of

these ranges, the vertical and the horizontal LEAPs

had to act in the opposite way: the vertical was

active and the horizontal was paused. The proto-

type has been developed following the architecture

scheme shown in Figure 4: the server component

received data from routers and manipulated the in-

formation from the vertical LEAP (that is the data

A Virtual Glove System for the Hand Rehabilitation based on Two Orthogonal LEAP Motion Controllers

189

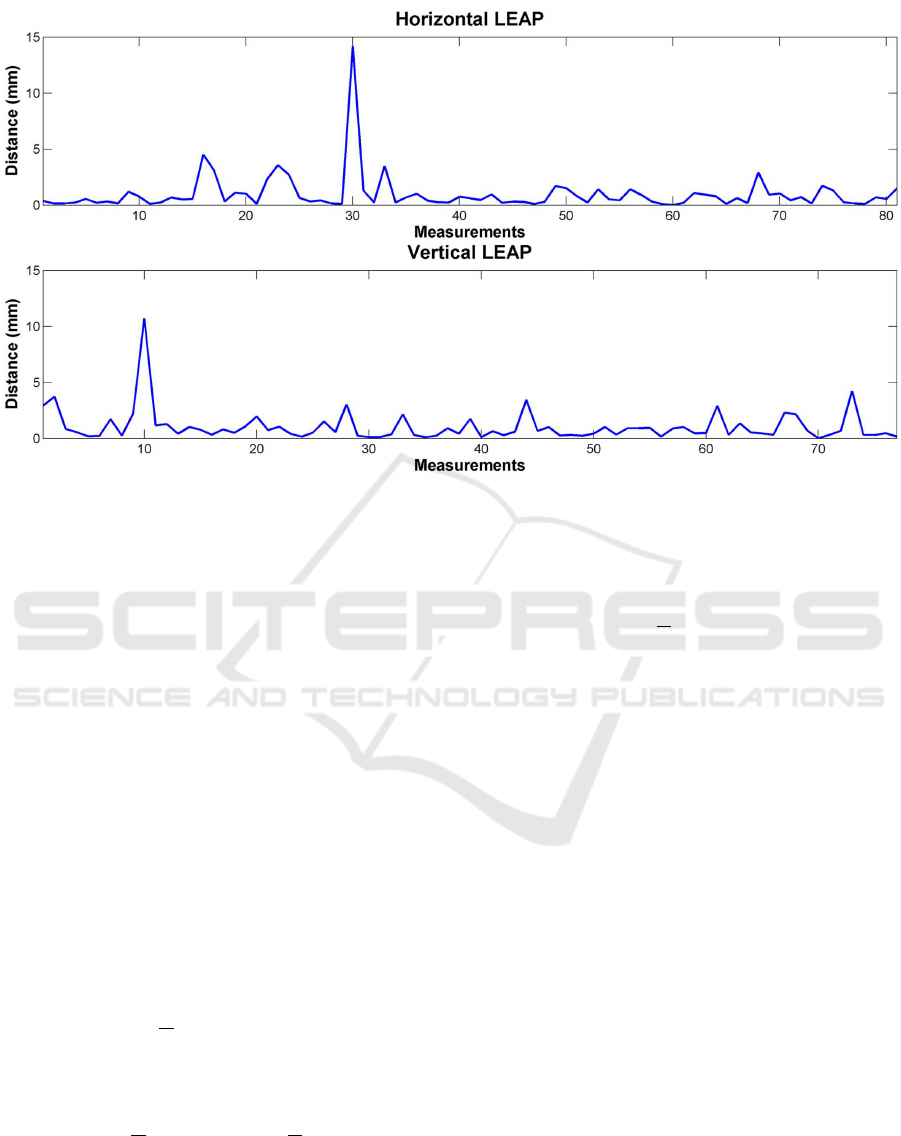

Figure 10: The distance computed along the axes during the calibration procedure.

from the Slave router) performing a roto-translation

to obtain the coordinates with respect to the horizon-

tal LEAP reference system. The server was respon-

sible to check which LEAP was active, to send only

the information received from it to the client and, if

needed, to change the active status of the sensors. The

client was obtained by using a modified version of an

example application included in the LeapJS frame-

work (http://github.com/leapmotion/leapjs, 2016),

“Threejs-bones.html”.

3.3 Preliminary Results

In order to observe the online behavior of the system,

the calibration procedure was performed by using a

cloud of 68 points (P = 68). The size s of T

k

was

set to 5. The registration was iterated k = 3 ∗ 10

4

times. The points was acquired by means of the same

tool used for the infrared interference evaluation (Fig-

ure 3). The average distance of the selected train-

ing set was err = 3.62mm, with standard deviation

σ = 2.89mm and a maximum value M = 17.36mm.

As it is possible to observe from Figure 10, like in

the infrared interference analysis, there was a small

group of points with large distance values and the “er-

ror” was concentrated on the Z axis. This suggested

that distance was mostly due to the intrinsic impre-

cision of the sensors along the Z axis than to a cali-

bration lack in accuracy. Anyway, also in this case,

the average distance was not too large with respect to

the size of the fingertips and joints and the accuracy

was acceptable. Figure 11 shows a set of hand po-

sitions and the corresponding model reconstructions,

obtained with the proposed approach. The accuracy

and the fluidity of the tracking process were adequate

(about 25 frames per second) and the change of per-

spective did not produce any jumps or other visually

observable effects. Moreover the hand was correctly

tracked also in those positions that would be critical

in the single sensor scenario.

4 CONCLUSIONS

A multi-sensor approach for hand tracking, based on

the use of two orthogonal LEAP sensors, was pre-

sented. The hardware and software design choices

and the resulting development was illustrated and dis-

cussed. A calibration procedure, aiming to align the

reference system of the LEAP has been proposed and

evaluated in term of accuracy. The detected discrep-

ancy was not enough to compromise the operation of

the system. Experimental data, to observe the be-

havior of the system in presence of infrared interfer-

ences, showed an adequate tolerance to the disturb.

An interesting result regarded the displacement dis-

tribution along the axes: the Z direction seemed to

be more affected by disturb with respect to the others

(this occurred also during calibration). This suggested

that, both in the infrared interferences and in the refer-

ence system roto-translation experiments, most of the

discrepancy was not introduced by the proposed ap-

proaches, but was due to an intrinsic lack of accuracy

of the LEAP along the Z direction. In order to ex-

plore the phenomenon, future developments will con-

ICPRAM 2017 - 6th International Conference on Pattern Recognition Applications and Methods

190

Figure 11: Examples of hand positions with the correspond-

ing model obtained by means of the proposed prototype.

Also critical positions for the single sensor scenario have

been correctly tracked.

cern the use of a refined and graduated setup tool or an

external position sensor ((Placidi et al., 2007)) to be

used for the definition of a “real” reference system, in

order to measure the accuracy of the LEAP and take

it into consideration during the assessment of the pro-

posed system effectiveness. Regarding the proposed

hand tracking prototype, it could be improved by sub-

stituting the turnover strategy with the fusion of the

models from the two LEAPs, instead of using just one

of them at once. In this case also residual occlusions

could be better overcome. Moreover, synchronizza-

tion issues should be studied and managed. Finally,

the proposed system will be tested for rehabilitation

purposes.

REFERENCES

Arya, K. N., Pandian, S., Verma, R., and Garg, R. K. (2011).

Movement therapy induced neural reorganization and

motor recovery in stroke: a review. Journal of body-

work and movement therapies, 15(4):528–537.

Avola, D., Spezialetti, M., and Placidi, G. (2013). Design

of an efficient framework for fast prototyping of cus-

tomized human–computer interfaces and virtual envi-

ronments for rehabilitation. Computer Methods and

Programs in Biomedicine, 110(3):490–502.

Bachmann, D., Weichert, F., and Rinkenauer, G. (2015).

Evaluation of the leap motion controller as a new

contact-free pointing device. Sensors, 15(1):214.

Besl, P. J. and McKay, N. D. (1992). A method for registra-

tion of 3-d shapes. IEEE Trans. Pattern Anal. Mach.

Intell., 14(2):239–256.

Burgar, C. G., Lum, P. S., Shor, P. C., and Van Der Loos,

H. F. M. (2000). Development of robots for rehabil-

itation therapy: The palo alto va/stanford experience.

Journal of Rehabilitation Research and Development,

37(6):663–673.

Charles, D., Pedlow, K., McDonough, S., Shek, K., and

Charles, T. (2014). Close range depth sensing cameras

for virtual reality based hand rehabilitation. Journal of

Assistive Technologies, 8(3):138–149.

Chaudhary, A., Raheja, J. L., Das, K., and Raheja, S.

(2013). Intelligent approaches to interact with ma-

chines using hand gesture recognition in natural way:

a survey. arXiv preprint arXiv:1303.2292.

Eggert, D. W., Lorusso, A., and Fisher, R. B. (1997). Esti-

mating 3-d rigid body transformations: a comparison

of four major algorithms. Machine Vision and Appli-

cations, 9(5):272–290.

Franchi, D., Maurizi, A., and Placidi, G. (2009). A nu-

merical hand model for a virtual glove rehabilitation

system. In Proc. of the IEEE Med. Meas. & Appl.,

MeMeA 2009, pages 41–44.

Franchi, D., Maurizi, A., and Placidi, G. (2010). Charac-

terization of a simmechanics model for a virtual glove

rehabilitation system. In Computational Modeling of

Objects Represented in Images, volume 6026, pages

141–150.

Hallett, M. (2001). Plasticity of the human motor cortex

and recovery from stroke. Brain Research Reviews,

36(2):169–174.

http://developer.leapmotion.com (Accessed: 2016). Leap

motion developers.

http://github.com/leapmotion/leapjs (Accessed: 2016).

Javascript client for the leap motion controller.

http://nodejs.org (Accessed: 2016). Node.js.

http://www.leapmotion.com (Accessed: 2016). Leap mo-

tion inc.

Kahn, L. E., Lum, P. S., Rymer, W. Z., and Reinkensmeyer,

D. J. (2006). Robot-assisted movement training for

the stroke-impaired arm: Does it matter what the robot

does? Journal of rehabilitation research and develop-

ment, 43(5):619.

Kopp, B., Kunkel, A., M

¨

unickel, W., Villringer, K., Taub,

E., and Flor, H. (1999). Plasticity in the motor system

A Virtual Glove System for the Hand Rehabilitation based on Two Orthogonal LEAP Motion Controllers

191

related to therapy-induced improvement of movement

after stroke. Neuroreport, 10(4):807–810.

Liepert, J., Bauder, H., Miltner, W. H. R., Taub, E., and

Weiller, C. (2000). Treatment-induced cortical reorga-

nization after stroke in humans. Stroke, 31(6):1210–

1216.

Llor

´

ens, R., No

´

e, E., Colomer, C., and Alca

˜

niz, M. (2015).

Effectiveness, usability, and cost-benefit of a vir-

tual reality–based telerehabilitation program for bal-

ance recovery after stroke: A randomized controlled

trial. Archives of physical medicine and rehabilita-

tion, 96(3):418–425.

Lum, P. S., Godfrey, S. B., Brokaw, E. B., Holley, R. J., and

Nichols, D. (2012). Robotic approaches for rehabili-

tation of hand function after stroke. American Journal

of Physical Medicine & Rehabilitation, 91(11):S242–

S254.

Maciejasz, P., Eschweiler, J., Gerlach-Hahn, K., Jansen-

Troy, A., and Leonhardt, S. (2014). A survey on

robotic devices for upper limb rehabilitation. J. Neu-

roeng. Rehabil, 11(1):10–1186.

Petracca, A., Carrieri, M., Avola, D., Basso Moro, S.,

Brigadoi, S., Lancia, S., Spezialetti, M., Ferrari, M.,

Quaresima, V., and Placidi, G. (2015). A virtual

ball task driven by forearm movements for neuro-

rehabilitation. In Virtual Rehabilitation Proceed-

ings (ICVR), 2015 International Conference on, pages

162–163.

Placidi, G. (2007). A smart virtual glove for the hand tel-

erehabilitation. Computers in Biology and Medicine,

37(8):1100–1107.

Placidi, G., Avola, D., Ferrari, M., Iacoviello, D., Petracca,

A., Quaresima, V., and Spezialetti, M. (2014). A low-

cost real time virtual system for postural stability as-

sessment at home. Computer methods and programs

in biomedicine, 117(2):322–333.

Placidi, G., Avola, D., Iacoviello, D., and Cinque, L.

(2013). Overall design and implementation of the

virtual glove. Computers in biology and medicine,

43(11):1927–1940.

Placidi, G., Franchi, D., Marsili, L., and Gallo, P. (2007).

Development of an auxiliary system for the execu-

tion of vascular catheter interventions with a reduced

radiological risk; system description and first experi-

mental results. Computer Methods and Programs in

Biomedicine, 88(2):144–151.

Placidi, G., Petracca, A., Pagnani, N., Spezialetti, M., and

Iacoviello, D. (2015). A virtual system for postural

stability assessment based on a tof camera and a mir-

ror. In Proceedings of the 3rd 2015 Workshop on ICTs

for Improving Patients Rehabilitation Research Tech-

niques, pages 77–80.

Polsinelli, M. (2015). Implementation of a virtual glove

for rehabilitation through the use of leap motion con-

trollers. Master’s thesis, University of L’Aquila.

Rus

`

ak, Z., Antonya, C., and Horv

`

ath, I. (2011). Methodol-

ogy for controlling contact forces in interactive grasp-

ing simulation. International Journal of Virtual Real-

ity, 10(2):1.

Sabata, B. and Aggarwal, J. K. (1991). Estimation of mo-

tion from a pair of range images: A review. CVGIP:

Image Understanding, 54(3):309 – 324.

Weichert, F., Bachmann, D., Rudak, B., and Fisseler, D.

(2013). Analysis of the accuracy and robustness of the

leap motion controller. Sensors, 13(5):6380–6393.

Zimmerli, L., Jacky, M., L

¨

unenburger, L., Riener, R.,

and Bolliger, M. (2013). Increasing patient engage-

ment during virtual reality-based motor rehabilita-

tion. Archives of physical medicine and rehabilitation,

94(9):1737–1746.

ICPRAM 2017 - 6th International Conference on Pattern Recognition Applications and Methods

192