Recovery of Chitin from Shrimp Waste by Co-fermentation

Qixin Wang

1

, Zhongliang Su

1,*

, Kunmei Huang

1

, Xueying Han

2

and Mingyan He

1

1

College of Chemical Engineering, Qingdao University of Science & Technology, Qingdao, Shangdong, China

2

College of Marine Science and Biological Engineering, Qingdao University of Science & Technology, Qingdao,

Shangdong, China

Keywords:

Chitin, Monomicrobial Fermentation, Two-Step Fermentation, Co-Fermentation.

Abstract:

The large amount of shrimp waste produced every year contains a large amount of natural cellulose material

(chitin), which causes a waste of resources. This paper uses co-fermentation to recover chitin from shrimp

waste and compares it with other common methods (monomicrobial fermentation, two-step fermentation). By

adjusting the inoculation ratio of the Bacillus zanthoxyli strain and Streptococcus thermophilus strain, the

ratio of glucose to sucrose, temperature, and pH, we obtained chitin with DP% and DM% of 68.89% and

83.80%, respectively. Through a comparative analysis, we found that DP% and DM% of chitin extracted by

co-fermentation were more balanced. The chitin improved by the small-size shrimp shells was DP%, DM%

and DA% of 83.76%, 91.48% and 93.47%, respectively, which proved the potential of obtaining the high

quality of chitin using the co-fermentation method. Co-fermentation is a viable alternative biological

fermentation method for extracting chitin from shrimp waste.

1 INTRODUCTION

The annual global amount of biosynthesized chitin

(β(1→4) linked GlcNAc) is approximately 100

billion tons (Ablouh 2020, Zhang 2020). It is the most

abundant natural polysaccharide after cellulose and is

used as a structural component to support cells and

body surfaces (Kumirska 2010, Gbenebor 2017,

Balitaan 2020). The world produces approximately 6

to 8 million tons of waste crab, shrimp, and lobster

shells annually (Yan, Chen 2015). The global market

for chitin and its derivatives include applications in

sewage treatment, food and beverages, cosmetics,

bioplastics, biomedicine, and agriculture (Casadidio

2019, Abdel-Mohsen 2020, Abdel-Mohsen 2020, Liu

2020). The amount of chitin prepared is

approximately 28,000 tons, but its demand exceeds

60,000 tons (Eddya 2020). Therefore, it is urgent to

discover a convenient, fast, environmentally friendly,

and cost-saving alternative for production.

Shrimp shells are composed of three layers (outer

layer, middle layer and inner layer). Chitin is located

in the inner layer of the shell and is wrapped with

protein. The middle layer is composed of chitin and

minerals, and the outer layer contains calcium

carbonate and protein (Balitaan 2020, Xin 2020).

There are two main methods for extracting chitin:

biological extraction and chemical methods. Acids

from microorganisms or HCl solutions in chemical

methods remove minerals from shrimp shells,

whereas proteases or NaOH solutions remove

proteins (Marzieh 2019). Deproteinization rate

(DP%) and demineralization rate (DM%) are often

used as standards of extracted chitin product

(Nidheesh, Suresh 2015). The degree of acetylation

(DA%) is defined as the average number of GlcNAc

units per 100 monomers, expressed as a percentage

(Tolaimate 2003). Chitin can deacetylate partially by

alkali (50% NaOH) in chemical methods or chitinase

in biological extraction (Hamed 2016). When the

DA% of chitin is less than 50%, it will dissolve in an

aqueous acid solution (pH <6.0), which is chitosan

(Kumirska 2010). DA% is the most important factor

affecting the application of chitin and chitosan (e.g.,

biodegradability, chemical modification steps, and

solubility). DA% of chitin depends on the raw

material and the deproteinization process (Tolaimate

2003). The chitin with high DA% and low protein

content is considered as good final products (Marzieh

2019).

Although chemical methods can quickly extract

high-quality chitin, such methods reduce the DA%,

thereby affecting the crystal structure (Gbenebor

2017), and it is impossible to recover value-added by-

1284

Wang, Q., Su, Z., Huang, K., Han, X. and He, M.

Recovery of Chitin from Shrimp Waste by Co-fermentation.

DOI: 10.5220/0011508700003443

In Proceedings of the 4th International Conference on Biomedical Engineering and Bioinformatics (ICBEB 2022), pages 1284-1295

ISBN: 978-989-758-595-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

products, such as proteins and pigments (García

2019). In addition, the molecular weight of the

product is low (80–800 kDa), and it cannot be used as

an ideal precursor for high-end functional materials

(Di 2019). Furthermore, these conventional chemical

extraction processes are extremely harmful to the

environment, and the high concentration of inorganic

acid that is consumed requires a large amount of fresh

water for washing after each step (Pachapur 2016,

Zhang 2018). Therefore, extracting chitin by

biological treatment became a research hotspot.

Comparing with chemical methods, chitin obtaining

by biological treatment has some advantages, such as

better antibacterial activity and biocompatibility,

higher molecular weight and crystal index,

environment-friendly, low cost (Tanganini 2020).

The biological method can recover additional

products, such as protein and pigment, and the

fermentation broth can be used as feed for

aquaculture (Younes 2016, Castro 2018). These

values demonstrate that chitin extracted by the

biological method has broader application prospects.

So far, the most studied biological method is

monomicrobial fermentation. In common bacteria,

the DP% and DM% of Bacillus subtilis,

Pseudomonas aeruginosa, Lactobacillus plantarum,

Bacillus cereus, and Lactobacillus rhamnosus were

84% and 72%, 94% and 84%, 95.3% and 99.6%,

78.6% and 73%, and 30.50% and 83.83%,

respectively (Sini 2007, Sorokulova 2009, Sedaghat

2017, Castro 2018, Liu 2020). There are a few strains

that can extract high-quality chitin alone (Nidheesh,

Suresh 2015), and precious few strains that contain

high DP% and high DM% simultaneously. For this

reason, some people combine high DM% strains and

enzymes or high DP% strains for two-step

fermentation. For example, Dun et al. (Dun 2019)

combined high-strain Bacillus coagulans and

proteinase K to ferment shrimp shells in two steps to

obtain high-quality chitin (DP% and DM% are 93%

and 91%, respectively); Yongliang Liu et al. [23]

used a high DM% (83.83%) strain Lactobacillus

rhamnoides and a high DP% strain (83.28%) Bacillus

amyloliquefaciens for joint fermentation and

obtained relatively ideal products (DP% and DM%

are 96.8% and 97.5%, respectively).

Although the fermentation efficiency (DP% and

DM%) of the two-step fermentation is higher, the re-

sterilization and replacement of the fermentation

broth for the second fermentation stage will

complicate the operation and cause a waste of

resources (Zhang 2021). Therefore, in this study, we

tried to explore if the methods of co-fermentation can

be used to extracting chitin from shrimp waste, and

its performance was compared with the

monomicrobial fermentation and two-step

fermentation under the same conditions to determine

whether this method is advantageous for producing

chitin. As far as we know, studies on the obtaining

chitin by co-fermentation have not been reported in

the literature.

2 MATERIALS AND METHODS

2.1 Materials

Fresh shrimp waste was collected from the Licun

Market, and the meat was removed, including head,

tail, and legs. The shrimp shells were dried in an oven

for 24 h and granulated with a crusher. Then, 2.00 - <

0.20 mm was extracted from it and stored in a reagent

bottle at −20℃.

2.2 Bacterial Strains and Culture

Conditions

The target strains were isolated from lactic acid

fermentation powder and soil obtained from Qingdao

University of Science and Technology, and the

culture medium was screened with protease strains

(lysogeny broth [LB] solid medium supplemented

with skimmed milk powder) and an acid-producing

strain selection medium (de Man, Rogosa, and Sharpe

[MRS] solid medium supplemented with CaCO

3

) to

screen out the strains with larger transparent circles

and to select strains, which have the best protease

activity, as well as high-yield acid strain, which can

be identified by cluster analysis on the sequence of

16S rRNA. The primers used were 27F (5′-

AGAGTTTGATCCTGGCTCAG-3′) and 1492R (5′-

ACGGCTACCTTGTTACGACTT-3′).

2.3 Fermentation Conditions and

Program Design

Depending on the literature, we chose the initial pH,

5% glucose, 4% inoculum, 3% shrimp shell, and 120

rpm as the initial fermentation conditions (Zhang

2012, Sedaghat 2017, Liu 2020) and reset the

vaccination plan on this basis: (1) the strains

producing high quality chitin in co-fermentation

method were used to explore the two-step

fermentation method and monomicrobial

fermentation method (fermentation time was 6 days);

(2) the fermentation conditions were optimized for

different fermentation methods (fermentation time

Recovery of Chitin from Shrimp Waste by Co-fermentation

1285

was 3 days); by comparing and analyzing the DP%

and DM% after fermentation, the best biological

fermentation plan was determined (fermentation time

was 6 days); (4) the small-sized shrimp shells were

fermented by the optimal fermentation method

(fermentation time was 6 days), and the products were

characterized by FT-IR.

2.4 The Analysis of Ash Content

Fresh shrimp shells were dried in a drying oven at

105℃ for 48 h, and the moisture content was

calculated by the weight difference before and after

drying ( Bellaaj 2012). The ash content was measured

by heating in a muffle furnace at 550℃ for 4 h

(Sedaghat 2017).

2.5 The Content Measurement of Total

Protein

The total protein, which in shrimp shells was

calculated by subtracting the nitrogen content in

chitin by the total nitrogen content, was measured

using a Kjeldahl Nitrogen Analyzer (JK9830; Jinan

Jingrui Analytical Instruments Ltd., China) (Liu

2020).

2.6 The Determination of Protease

Activity

The protease activity was determined according to the

method described by YaohaoDun et al. (Dun 2019).

In short, casein was used as a substrate, and

fermentation broth and phosphate buffer (pH = 7.5)

were added to induce a reaction at 30℃ for 10 min.

The reaction was terminated immediately with

trichloroacetic acid, and a color reaction with Folin

reagent was induced at 40℃ for 20 min. The

absorbance was measured at 680 nm. The protease

activity unit, which was expressed in U/ml, was

defined as the amount of 1 µg tyrosine produced by 1

ml liquid enzyme hydrolyzing casein in 1 min.

2.7 The Determination of DP% or DM%

The DP% or DM% was calculated by the equation:

Y% = ((C

1

× W

1

) − (C

2

× W

2

))/(C

1

× W

1

)

Y% is DP% or DM%; C

1

is the protein or ash

content before fermentation; W

1

is the protein or ash

dry weight before fermentation; C

2

is the protein or

ash content after fermentation; and W

2

is the protein

or ash dry weight after fermentation.

2.8 Characterization of Chitin

A Fourier transform infrared spectrometer (FT-IR)

was used to study chitin, and the DA% of chitin was

calculated based on the FT-IR (Knidri 2016).

The FT-IR was calculated by the equation:

DA%=

(

A

1655

/A

3450

)

×100/1.33

2.9 Statistical Analysis

All experimental data are observed in triplicate, and

the means ± standard deviations were reported.

Statistical analysis was conducted using SPSS

version 17 software. Statistical significance was

determined at P < 0.05.

3 RESULTS AND DISCUSSION

3.1 Strain Screening

Nine protease-producing strains and three acid-

producing strains with relatively large transparent

circles were selected from the screening medium of

the protease strain and the acid strain.

Protease activity and pH were measured 24 h after

fermentation in LB and MRS broth.

Three strains (2, 4, and 7) with higher protease

activity were selected and named B1, B2, and B3,

respectively (Table 1). Homologous strains were

searched in the NCBI library using 16S rRNA. The

homologies of strains B1, B2, and B3 with Bacillus

mobilis, Bacillus zanthoxyli, and Bacillus proteolytic

strains is as high as 99% or more. The three acid-

producing strains that were identified as the same

strain and have more than 99% homology with

Streptococcus thermophilus strain were named L.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

1286

Table 1: Protease activity of enzyme-producing strains and pH of acid-producing strains.

numbers Protease activity (U/ml) pH

1 1.01 ± 0.22

2 6.55 ± 0.58

3 1.01 ± 0.63

4 3.22 ± 0.58

5 2.54 ± 0.15

6 2.77 ± 0.1

7 4.15 ± 0.63

8 1.46 ± 0.29

9 2.19 ± 0.19

10 4.97 ± 0.02

11 4.72 ± 0.02

12 4.9 ± 0.01

3.2 Screening of Fermentation Strains

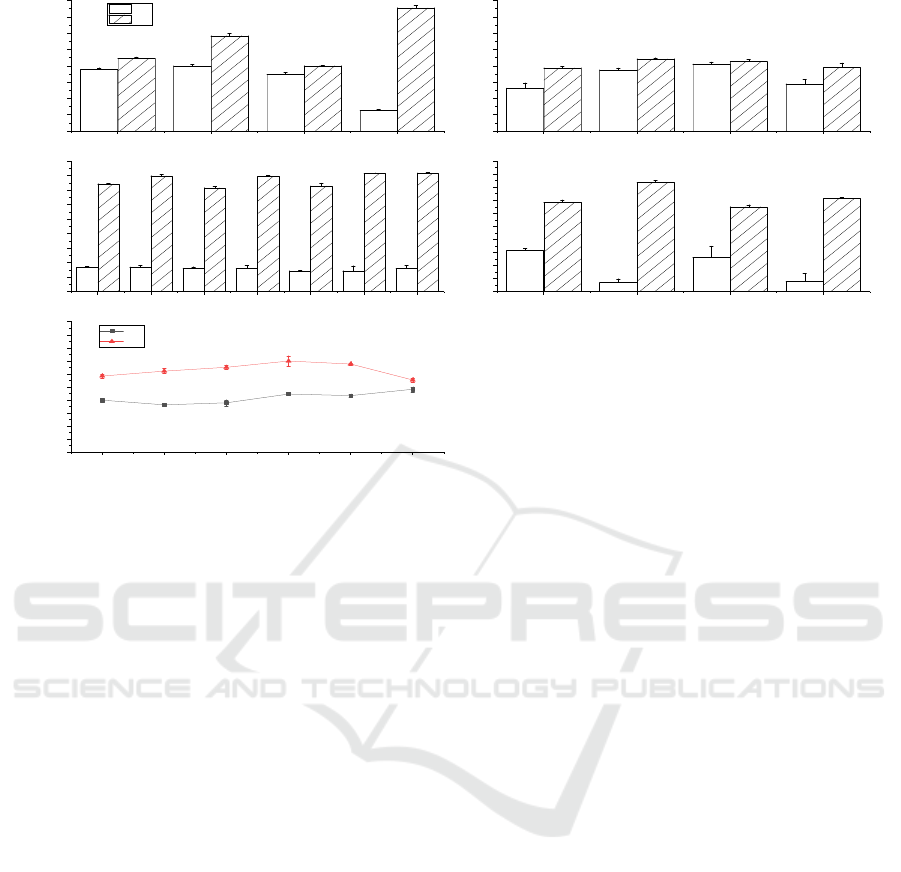

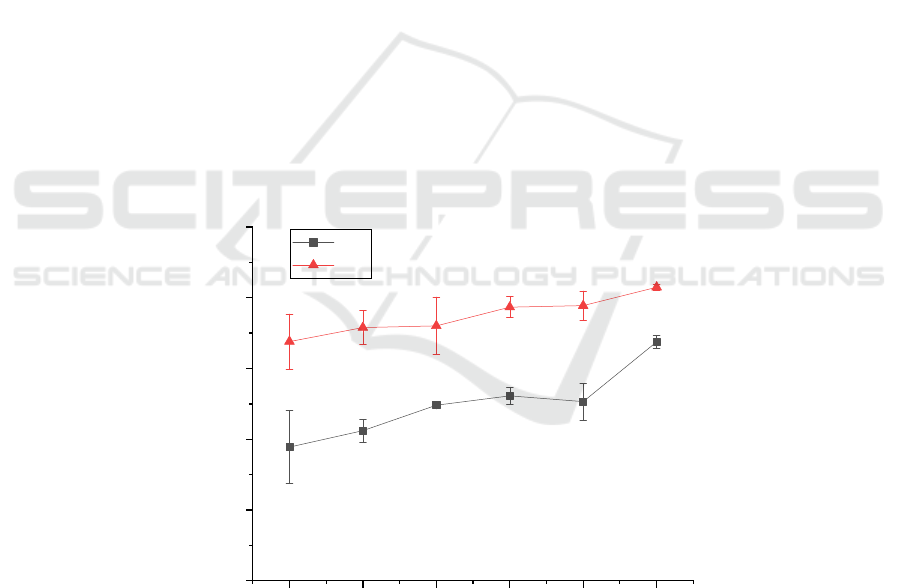

We found that the fermentation efficiency of all

screened strains was relatively lower than previously

reported (Sini 2007, Castro 2018). In our study, the

highest DP% and DM% of the B2 strain were only

39.95% and 58.46%, respectively (Figure 1. A). It

may be that the size of our shrimp shells will not

allow acids and proteases to completely contact the

reactants (Abdelmalek 2017). To verify this

conjecture, we used the B2 strain to ferment shrimp

shells of different sizes. The result shows that the

fermentation efficiency in shrimp shells gradually

increased with the decreasing shrimp shell size and

reached the maximum at 0.45–0.3 mm (Figure 1. E).

The reason for the lower fermentation efficiency of

less than 0.3 mm is that the smaller size of the shrimp

shells facilitates aggregation in the triangular flask

during the fermentation process. In addition, the

smaller the shrimp shell size, the greater the loss

during washing. Therefore, shrimp shells with a

particle size of 2.00-1.43mm were used in the

fermentation exploration stage.

In the process of co-fermentation (Figure 1. B, C),

the DM% of the group with L bacteria was higher

than that of other groups (P < 0.05), but the DP% was

not significantly different (P < 0.05). The DP% and

DM% of B2-L were the best, at 17.04% (P < 0.05)

and 79.89% (P < 0.05), respectively. In the three-

strain and four-strain group, B1-B2-B3-L showed the

highest DM%, which was 81.82%, but the

fermentation conditions were more regulated than

those of B2-L. The other groups (excluding L) had

lower fermentation removal efficiency than had B2,

which did not show the potential to justify further

research. After comprehensive consideration, we

chose B2 and L as the fermentation strains for co-

fermentation.

The performance of B2 and L strains in two-step

fermentation were further explored. Figure 1.D shows

that fermentation efficiency of the replacement broth

group (C) was higher than that of the non-

replacement broth group (NC), and the results of

B2→L were more balanced than those of L→B2. We

found that the fermentation efficiency of during two-

step fermentation tends to depend on the strain used

in the first fermentation stage, which deviated from

the results of Liu, Y et al. (Liu 2020). The reason for

this phenomenon may be that the fermentation broth

of the second fermentation stage cannot provide

sufficient growth for bacteria or that the exposed

chitin in the shrimp shells inhibits the growth of

bacteria. In summary, we chose the B2→L-C group

for the two-step fermentation method for comparison

with the B2-L fermentation method.

Recovery of Chitin from Shrimp Waste by Co-fermentation

1287

Figure 1: Selection of fermentation strains.

A, B, C, D, E: Residual protein and mineral

content of chitin after fermentation; D: C means

replacing the fermentation broth, NC means using the

fermentation broth of the previous strain for

fermentation

We chose B2 and L strains as the research objects

of co-fermentation, which can be compared with the

fermentation results of B2, L, and B2→L-C. Under

the initial conditions, we determined that the

fermentation of the B2 strain was the most balanced,

and the DM% of B2-L was the best.

3.3 The Optimization of

Monomicrobial Fermentation and

Two-step Fermentation

There are two indicators that the extracted chitin

needs to satisfy during the final evaluation process:

residual protein content and residual mineral content.

In the regulation of fermentation conditions, some

values have only the highest DM% or DP%. As

shows in Figure 3. D, DP% was the highest at 2.5%

sucrose content, but its DM% was the lowest, which

leaded to conflicts when we chose a certain

fermentation condition. We could not guarantee that

DM% and DP% were both at the optimal highest

proportion. Therefore, when selecting DP% and

DM%, it was not only required to have a relatively

small difference, but also a relatively high value, as

shows in Figure 5. B.

To better explored the fermentation of co-

fermentation, we first needed to explore the

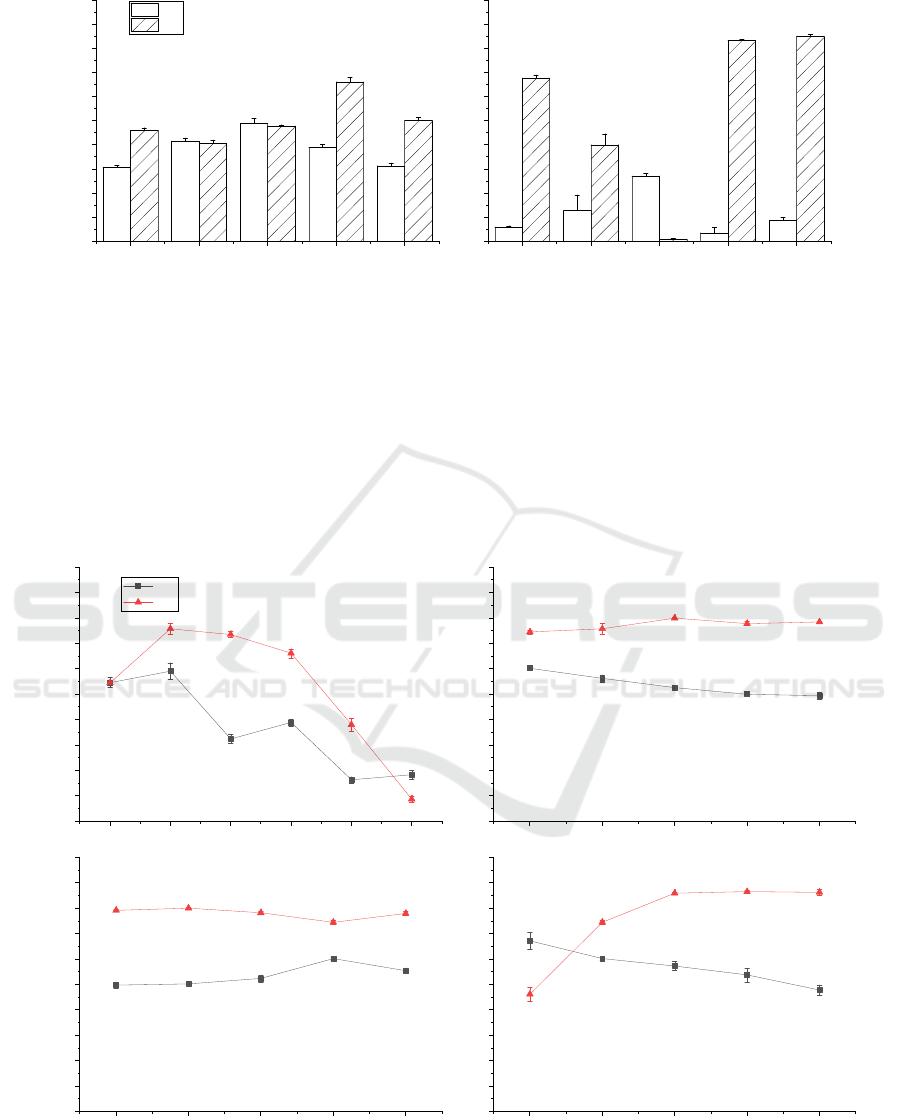

fermentation conditions of single bacteria. Figure 2.

shows that carbon (C)/nitrogen (N) sources have a

greater impact on monomicrobial fermentation.

Among them, after sucrose was added, the DP% of

the B2 and L strains increased significantly (P <

0.05), but the decrease of the DM% of the L strain

from 67.73% to 0.63% (P < 0.05) was not suitable for

use as a C source. Tryptone and yeast extract powder

were suitable for B2 and L strains, respectively. In

summary, the B2 strain uses sucrose and tryptone as

C/N sources, whereas the L strain uses glucose and

yeast extract powder.

2.00-1.43 1.43-0.60 0.60-0.45 0.45-0.30 0.30-0.20 <0.20

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

B1 B2 B3 L

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

()

Removal %

Monomicrobial fermentation

DP

DM

A

B1-B2 B1-B3 B2-B3 B1-B2-B3

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

()

Removal %

Co-fermentation

B

B1-L B2-L B3-L B1-B2-L B1-B3-L B2-B3-L B1-B2-B3-L

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

()

Removal %

Co-fermentation

C

B2→L-C L→B2-C B2→L-NC L→B2-NC

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

()

Removal %

Two-step fermentation

D

()

Remova l %

()

Shrimp shell size mm

DP

DM

E

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

1288

A: B2 strain; B: L strain

Figure 2: Optimization of C/N sources for B2 and L.

After the C/N source was determined, the B2

strain was optimized for temperature, inoculum, pH,

and sucrose content. The results show (Figure 3. A,

D) that the temperature and sucrose content have a

greater impact on the B2 strain. We chose relatively

high and balanced conditions of DP% and DM% for

the fermentation conditions of B2, and the

fermentation conditions of high DP% were used for

the conditions of the B2 strain in two-step

fermentation. Therefore, the optimized result of strain

B2 was 7.5% sucrose, 2% tryptone, 30℃, 2%

inoculum, and pH 7.5, and the optimized result of the

first fermentation as part of a two-step fermentation

process was 2.5% sucrose, 30℃, 2% inoculum, and

pH 7.5.

Figure 3: Optimization of fermentation conditions of B2 strain.

Glucose Maltose Sucrose Tryptone Yeast Extract Powder

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

()

Removal %

C/N Source

DP

DM

A

Glucose Maltose Sucrose Tryptone Yeast Extract Powder

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

()

Removal %

C/N Source

B

25 30 35 37 40 45

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

246810

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

6 6.5 7 7.5 8

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

2.5 5 7.5 10 12.5

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

()

Removal %

)

Temperature(℃

DP

DM

A

()

Removal %

Inoculation Amount(%)

B

()

Removal %

PH

C

Removal(%)

Sucrose Content(%)

D

Recovery of Chitin from Shrimp Waste by Co-fermentation

1289

Only the temperature of the L strain had a greater

influence on DM% (Figure 4. A). The selection of

fermentation conditions was the same as that for the

B2 strain. Therefore, the optimized result of the L

strain was 5% glucose, 2% yeast extract, 30°C, 4%

inoculum, and pH 6.0; as the second fermentation

strain in the two-step fermentation process, the

fermentation conditions were 10% glucose, 2% yeast

extract powder, 30℃, 4% inoculum, and pH 6.0.

According to previous reports in literature (Zhang

2021), the two strains in the two-step fermentation

play different roles, one of which is responsible for

DP and the other is responsible for DM. In this

experiment, B2 with high DP% fermentation

conditions was mainly responsible for the

deproteinization of shrimp shells, and the L strain

with high DM% fermentation conditions was used to

demineralization. The final fermentation conditions

of B2→L-C were as follows: The first stage (B2

strain: 2.5% sucrose, 30℃, 2% inoculum, pH 7.5), the

second stage (L strain: 10% glucose, 30℃, 4%

inoculum, pH 6.0, 2% yeast extract powder).

Figure 4: Optimization of fermentation conditions of L strain.

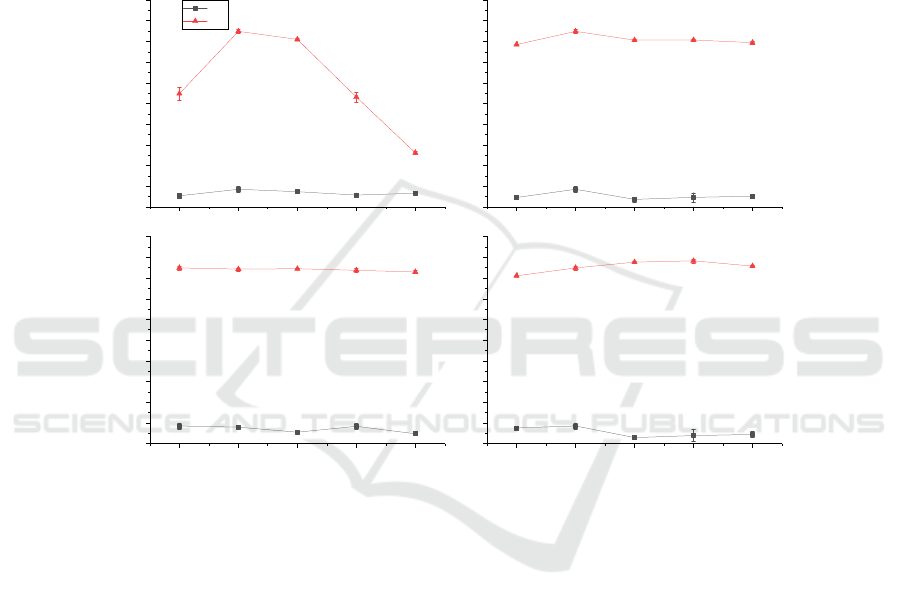

3.4 The Optimization of the

Co-fermentation Conditions

Co-fermentation explores the ratio of each strain and

then considers how different strains may be adapted

to C sources. The DP% of B2-L (1:1) was too low, so

we attempted to increase the DP% of co-fermentation

by adjusting the ratio of B2 strains. Interestingly, as

the proportion of B2 strains increases, DP% gradually

increases and then stabilizes after 1:4. At 1:6, the

fermentation efficiency of chitin was optimal and

most balanced, although it was the same as that of B2

(P < 0.05). We think there is no value in continuing

to explore, so we continued to use 1:1. We mentioned

in Section 3.3 that the B2 strain prefers sucrose,

whereas the L strain prefers glucose. On this basis, we

adjusted the ratio of sucrose and glucose. The results

show (Figure 5. B) that when the ratio of glucose to

sucrose was 1:1, the fermentation efficiency (DP% =

52.49%, DM% = 43.93%) was better than the

fermentation effect of the B2 strain.

Since the optimal temperature of strain B2 and

strain L was the same, and the additional N source

would reduce the DP% (figure 3 and figure 4), we

only discussed changes in the inoculum, pH, and C

source content. Interestingly, the amount of

inoculation also had a huge impact on the results.

After the inoculation amount reached 6%, the

fermentation efficiency was similar to the

unoptimized result (P < 0.05). It is very likely that the

increase of the L strain inhibited enzyme production

of the B2 strain or inhibited the deproteinization of

protease. The final fermentation conditions of B2-L

were B2:L inoculated at a ratio of 1:1, a ratio of

glucose to sucrose of 1:1, 4% inoculation, and pH 7,

temperature 30℃.

25 30 35 40 45

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

246810

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

6 6.5 7 7.5 8

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

2.5 5 7.5 10 12.5

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

()

Removal %

)

Temperature(℃

DP

DM

A

()

Removal %

Inoculation Amount(%)

B

()

Removal %

PH

C

()

Removal %

Glucose Content(%)

D

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

1290

Figure 5: The optimized fermentation conditions of B2-L and the optimized results of three fermentation methods.

3.5 Comparison of Three Fermentation

Methods

Figure 6: The optimized results of the three fermentation methods.

Although the optimized L had the highest DM%

(89.19%, P<0.05, figure 6.), its DP% was only

19.55%. There are too many protein residues in

chitin, so the L strain was not suitable for extracting

chitin from shrimp shells by fermentation alone.

1:1 1:2 1:4 1:6 1:8

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

:10 :10.5 :11 :0.5 1 :01

0.1

0.2

0.3

0.4

0.5

0.6

0.7

246810

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

66.577.58

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

2.5 5 7.5 10 12.5

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

()

Removal %

Inoculation ratio of B2: L

DP

DM

A

()

Removal %

Glucose: Sucrose

B

()

Removal %

()

B2-L inoculation volume %

C

()

Removal %

PH

D

()

Removal %

()

The content of Glucose: Sucrose %

E

B2 L B2-L B2→L-C

0.0

0.2

0.4

0.6

0.8

1.0

()

Removal %

Fermentation methods

DP

DM

Recovery of Chitin from Shrimp Waste by Co-fermentation

1291

The DP% (76.64%) of the B2→L-C group was

the highest (figure 6.), which was different from the

initial fermentation results (figure 1. D). The reasons

for this phenomenon were that we purposely

increased the deproteinization efficiency of B2 strains

by optimization of fermentation conditions. Although

additional nutrients (C/N sources) could be added to

make up for the second stage fermentation of the

strain, this would also increased the cost of chitin

extraction. In addition, wastewater discharge and

energy consumption would also occur when the

fermentation broth was replaced (Zhang 2021).

Therefore, the B2 and L strains in this experiment

were not suitable for the production of chitin from

shrimp shells using the two-step fermentation

method.

The DP% and DM% of the optimized B2 strain

were 61.78% and 87.41% (figure 6.), respectively,

and there was a big difference between the DP% and

DM% (25.63%). Nevertheless the difference between

the DP% and DM% of the B2-L group (the DP% and

DM% is 68.89% and 83.80%) was the smallest

(14.91%), so its quality of fermentation product was

the highest when comparing the monomicrobial

fermentation and the two-step fermentation.

Although the regulation process of co-

fermentation (B2-L) is complicated, there are more

fermentation conditions that can be regulated than

monomicrobial fermentation. For example, co-

fermentation can optimize the ratio of different strains

and the ratio of different carbon sources. Therefore,

there are more opportunities to find suitable

fermentation conditions, and its potential to produce

high-quality chitin is higher. Compared with the two-

step fermentation method, the co-fermentation

operation was simple, and it only needed to complete

the whole fermentation in one step (Zhang 2012).

Therefore, the co-fermentation method for preparing

chitin is a potential fermentation method.

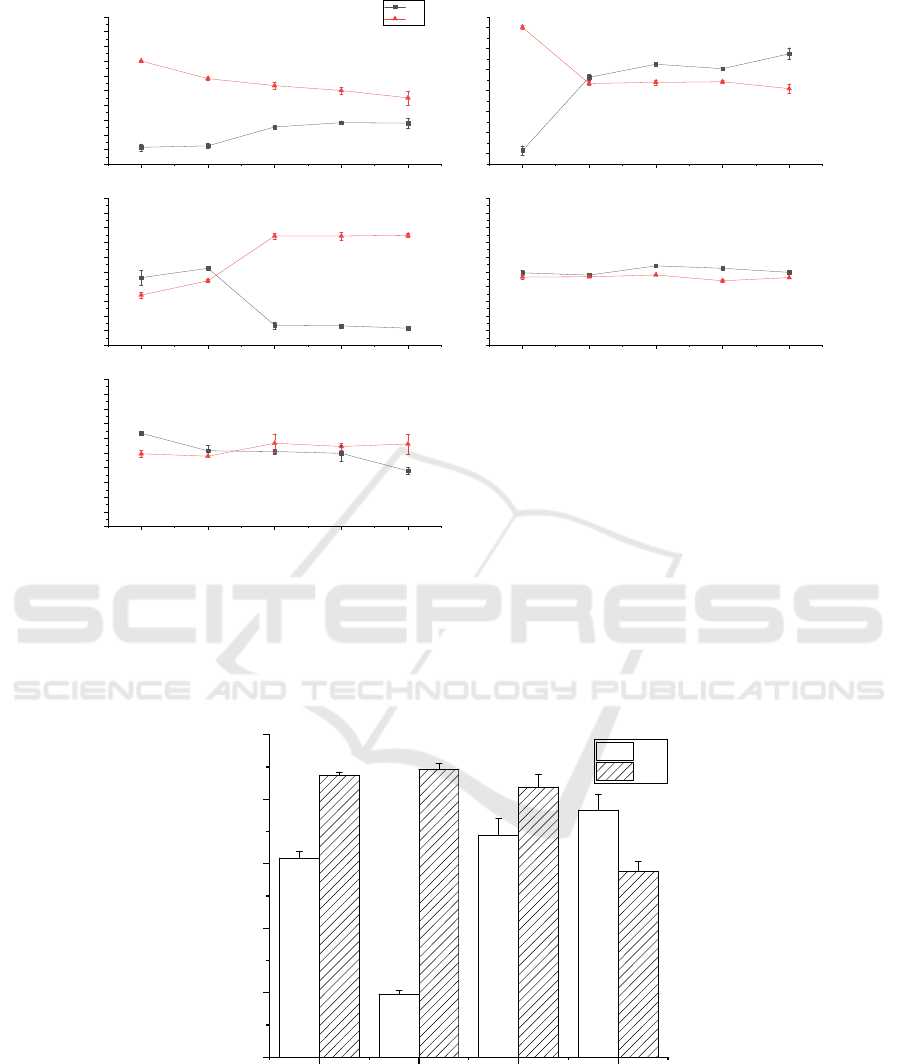

3.6 The Optimal Fermentation Results

for B2-L

Co-fermentation (B2-L), compared with the other two

fermentation methods, was considered to be the best

fermentation method. In order to further improve the

quality of its product, the effect of shrimp shell size

was studied (figure 7). The fermentation bottle was

vigorously shaken once a day in view of the tendency

of small-size shrimp shells to aggregate. The results

shows that the DP% and DM% could reach to 83.76%

and 91.48%, respectively when reduced the size of

shrimp shell (<0.2mm, figure 7), which indicated the

great potential of co-fermentation.

Figure 7: The fermentation efficiency of different sizes of shrimp shells in B2-L.

Sini T K et al. (Sini 2007) showed that the DP%

and DM% of chitin obtained from the fermentation of

shrimp shells by Bacillus subtilis were 84% and 72%.

Compared with it, the DM% increased by 19.48%

after co-fermentation of B2 and L (DP% = 83.76%,

DM% = 91.48%). The latest report showed that the

two-step fermentation of Bacillus subtilis and

Acetobacter pasteurianus can produce chitin with

DP% and DM% of 94.5% and 92.0% (Zhang 2021).

The DP% in this trial was 10.5% lower than the

2-1.43 1.43-0.6 0.6-0.45 0.45-0.3 0.3-0.2 <0.2

0.5

0.6

0.7

0.8

0.9

1.0

()

Removal %

DP

DM

()

Shrimp shell size mm

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

1292

former report. The DP% and DM% of Bacillus

subtilis, Bacillus cereus, and Bacillus mojavensis

reported by Hajji, S et al. (Hajji 2015) were 81.6%

and 76.6%, 83.1% and 81.8%, 80.4% and 73.2%

respectively, which were lower than the DP% and

DM% of chitin in this experiment. This showed that

the co-fermentation is a potential and effective

method for preparing chitin. The reason why their

fermentation result is lower than the former report

may be the weak DP ability of L strain. Therefore,

when selecting dominant strains, we must pay

attention to selecting strains with better acid-

producing ability and protease-producing ability.

3.7 Fourier Transform Infrared (FT-IR)

Spectra Analysis and Determination

of the Degree of Acetylation

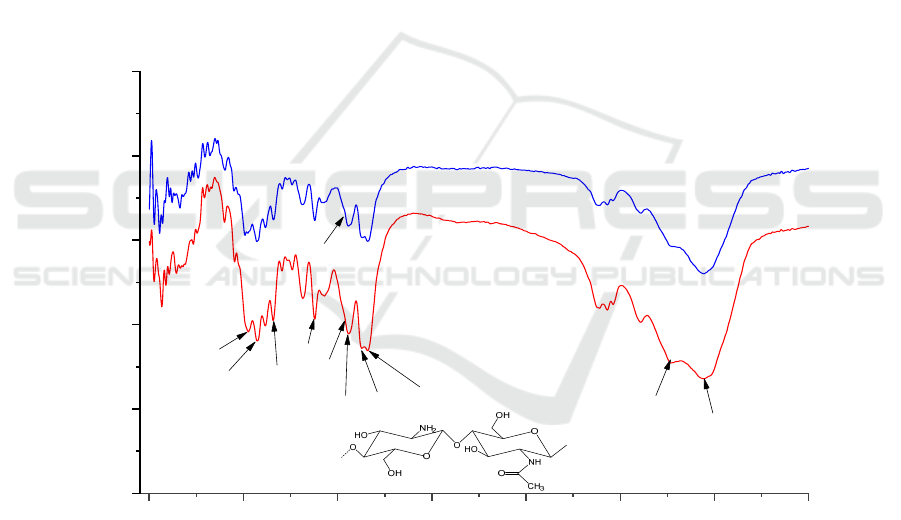

Figure 8. showed that the FT-IR of chitin prepared

from shrimp shells (<0.2mm) by co-fermentation of

B2 and L was similar to that of commercially

available chitin. The prepared chitin had the typical

characteristic peaks of α-chitin, including amide I

bands about 1659 cm

-1

and 1627 cm

-1

(C=O stretching

vibration), amide II bands at 1556 cm

-1

(N-H bending

vibration), and amide III at bands 1378 cm

-1

(C-N

stretching vibration). The stretching vibrations of -

OH and -NH appeared at 3441 cm

-1

and 3265 cm

-1

.

The other peaks of the chitin structure were 1157 cm

-

1

(C-O-C asymmetric vibration), 1025 cm

-1

and 1072

cm

-1

(C-O stretching vibration), and 1378 cm

-1

(C-H

shear vibration). This was the same as described by

El Knidri, H. et al (Knidri 2016). The spectrum of

chitin prepared by the co-fermentation method and

commercial chitin was lacking the absorbance peak at

1540 cm

−1

, where proteins would normally give rise

to absorption (Liu 2020).

The DA% of chitin prepared by B2-Lwere

93.47%, which is higher than that of chitin prepared

by commercial (86.37%) and Manni, L et al.

(89.50%) (Manni 2010).

A: Commercial chitin.

B: Chitin prepared by mixed-bacteria simultaneous fermentation method (B2-L).

Figure 8: FT-IR spectra of chitin.

4 CONCLUSIONS

The DP%, DM% and DA% with 83.76%, 91.48% and

93.47% of chitin were co-fermentation of B2 and L,

respectively. Comparing to the monomicrbial

fermentation and the two-step fermentation, the co-

fermentation can be used to extract chitin from

shrimp waste, which provides a feasible fermentation

method for the large-scale production of chitin in the

future.

500 1000 1500 2000 2500 3000 3500 4000

0

20

40

60

80

100

()

Transmittance %

Wavenumber (cm

-1

)

3441

3265

1659

1627

1556

1540

1025

1072

1157

1378

1540

A

B

Recovery of Chitin from Shrimp Waste by Co-fermentation

1293

ACKNOWLEDGMENTS

The authors would like to thank numerous individuals

who participated in this study. This work was

supported by the National Natural Science

Foundation of China under Grant 41471279.

REFERENCES

Abdel-Mohsen, A. M., R. M. Abdel-Rahman, I. Kubena, L.

Kobera, Z. Spotz, M. Zboncak, R. Prikryl, J. Brus and

J. Jancar (2020). "Chitosan-glucan complex hollow

fibers reinforced collagen wound dressing embedded

with aloe vera. Part I: Preparation and characterization."

Carbohydrate Polymers 230: 115708.

Abdel-Mohsen, A. M., J. Frankova, R. M. Abdel-Rahman,

A. A. Salem, N. M. Sahffie, I. Kubena and J. Jancar

(2020). "Chitosan-glucan complex hollow fibers

reinforced collagen wound dressing embedded with

aloe vera. II. Multifunctional properties to promote

cutaneous wound healing." International Journal of

Pharmaceutics 582: 119349.

Abdelmalek, B. E., A. Sila, A. Haddar, A. Bougatef and M.

A. Ayadi (2017). "β-Chitin and chitosan from squid

gladius: Biological activities of chitosan and its

application as clarifying agent for apple juice."

International Journal of Biological Macromolecules

104: 953-962.

Ablouh, E. H., R. Jalal, M. Rhazi and M. Taourirte (2020).

"Surface modification of alpha-chitin using an acidic

treatment followed by ultrasonication: Measurements

of their sorption properties." International Journal of

Biological Macromolecules 151: 492-498.

Aranday-García, R., H. Saimoto, K. Shirai and S. Ifuku

(2019). "Chitin biological extraction from shrimp

wastes and its fibrillation for elastic nanofiber sheets

preparation." Carbohydrate Polymers 213: 112-120.

Balitaan, J. N. I., J. M. Yeh and K. S. Santiago (2020).

"Marine waste to a functional biomaterial: Green facile

synthesis of modified-β-chitin from Uroteuthis

duvauceli pens (gladius)." International Journal of

Biological Macromolecules 154: 1565-1575.

Casadidio, C., D. V. Peregrina, M. R. Gigliobianco, S.

Deng, R. Censi and P. Di Martino (2019). "Chitin and

chitosans: Characteristics, eco-friendly processes, and

applications in cosmetic science." Marine drugs 17(6):

369.

Castro, R., I. Guerrero Legarreta and R. Bórquez (2018).

"Chitin extraction from Allopetrolisthes punctatus crab

using lactic fermentation." Biotechnology Reports 20:

e00287.

Di Nardo, T., C. Hadad, A. N. Van Nhien and A. Moores

(2019). "Synthesis of high molecular weight chitosan

from chitin by mechanochemistry and aging." Green

Chemistry 21(12): 3276-3285.

Dun, Y., Y. Li, J. Xu, Y. Hu, C. Zhang, Y. Liang and S.

Zhao (2019). "Simultaneous fermentation and

hydrolysis to extract chitin from crayfish shell waste."

International Journal of Biological Macromolecules

123: 420-426.

Eddya, M., B. Tbib and K. El-Hami (2020). "A comparison

of chitosan properties after extraction from shrimp

shells by diluted and concentrated acids." Heliyon 6(2):

e03486.

Gbenebor, O. P., S. O. Adeosun, G. I. Lawal, S. Jun and S.

A. Olaleye (2017). "Acetylation, crystalline and

morphological properties of structural polysaccharide

from shrimp exoskeleton." Engineering Science and

Technology-an International Journal-Jestech 20(3):

1155-1165.

Ghorbel-Bellaaj, O., I. Younes, H. Maâlej, S. Hajji and M.

Nasri (2012). "Chitin extraction from shrimp shell

waste using Bacillus bacteria." International Journal of

Biological Macromolecules 51(5): 1196-1201.

Hajji, S., O. Ghorbel-Bellaaj, I. Younes, K. Jellouli and M.

Nasri (2015). "Chitin extraction from crab shells by

Bacillus bacteria. Biological activities of fermented

crab supernatants." International Journal of Biological

Macromolecules 79: 167-173.

Hamed, I., F. Ozogul and J. M. Regenstein (2016).

"Industrial applications of crustacean by-products

(chitin, chitosan, and chitooligosaccharides): A

review." Trends in Food Science & Technology 48: 40-

50.

Knidri, H. E., R. E. Khalfaouy, A. Laajeb, A. Addaou and

A. Lahsini (2016). "Eco-friendly extraction and

characterization of chitin and chitosan from the shrimp

shell waste via microwave irradiation." Process Safety

and Environmental Protection 104: 395-405.

Kumirska, J., M. Czerwicka, Z. Kaczynski, A. Bychowska,

K. Brzozowski, J. Thoming and P. Stepnowski (2010).

"Application of Spectroscopic Methods for Structural

Analysis of Chitin and Chitosan." Marine Drugs 8(5):

1567-1636.

Liu, T., H. Y. Han, D. Wang, X. G. Guo, Y. Zhou, T.

Fukamizo and Q. Yang (2020). "Potent Fungal

Chitinase for the Bioconversion of Mycelial Waste."

Journal of Agricultural and Food Chemistry 68(19):

5384-5390.

Liu, Y., R. Xing, H. Yang, S. Liu, Y. Qin, K. Li, H. Yu and

P. Li (2020). "Chitin extraction from shrimp

(Litopenaeus vannamei) shells by successive two-step

fermentation with Lactobacillus rhamnoides and

Bacillus amyloliquefaciens." International Journal of

Biological Macromolecules 148: 424-433.

Manni, L., O. Ghorbel-Bellaaj, K. Jellouli, I. Younes and

M. Nasri (2010). "Extraction and Characterization of

Chitin, Chitosan, and Protein Hydrolysates Prepared

from Shrimp Waste by Treatment with Crude Protease

from Bacillus cereus SV1." Applied Biochemistry and

Biotechnology 162(2): 345-357.

Marzieh, M. N., F. Zahra, E. Tahereh and K. N. Sara (2019).

"Comparison of the physicochemical and structural

characteristics of enzymatic produced chitin and

commercial chitin." International Journal of Biological

Macromolecules 139: 270-276.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

1294

Nidheesh, T. and P. V. Suresh (2015). "Optimization of

conditions for isolation of high quality chitin from

shrimp processing raw byproducts using response

surface methodology and its characterization." Journal

of Food Science and Technology-Mysore 52(6): 3812-

3823.

Pachapur, V. L., K. Guemiza, T. Rouissi, S. J. Sarma and S.

K. Brar (2016). "Novel biological and chemical

methods of chitin extraction from crustacean waste

using saline water." Journal of Chemical Technology

and Biotechnology 91(8): 2331-2339.

Sedaghat, F., M. Yousefzadi, H. Toiserkani and S.

Najafipour (2017). "Bioconversion of shrimp waste

Penaeus merguiensis using lactic acid fermentation: An

alternative procedure for chemical extraction of chitin

and chitosan." International Journal of Biological

Macromolecules 104: 883-888.

Sini, T. K., S. Santhosh and P. T. Mathew (2007). "Study

on the production of chitin and chitosan from shrimp

shell by using Bacillus subtilis fermentation."

Carbohydrate Research 342(16): 2423-2429.

Sorokulova, I., A. Krumnow, L. Globa and V. Vodyanoy

(2009). "Efficient decomposition of shrimp shell waste

using Bacillus cereus and Exiguobacterium

acetylicum." Journal of Industrial Microbiology &

Biotechnology 36(8): 1123-1126.

Tanganini, I. C., L. D. Shirahigue, M. A. da Silva, K. R.

Francisco and S. R. Ceccato-Antonini (2020).

"Bioprocessing of shrimp wastes to obtain chitosan and

its antimicrobial potential in the context of ethanolic

fermentation against bacterial contamination." 3

Biotech 10(3): 135.

Tolaimate, A., J. Desbrieres, M. Rhazi and A. Alagui

(2003). "Contribution to the preparation of chitins and

chitosans with controlled physico-chemical properties."

Polymer 44(26): 7939-7952.

Xin, R., W. Xie, Z. Xu, H. Che, Z. Zheng and X. Yang

(2020). "Efficient extraction of chitin from shrimp

waste by mutagenized strain fermentation using

atmospheric and room-temperature plasma."

International Journal of Biological Macromolecules

155: 1561-1568.

Yan, N. and X. Chen (2015). "Sustainability: Don't waste

seafood waste." Nature 524(7564): 155-157.

Younes, I., S. Hajji, M. Rinaudo, M. Chaabouni, K. Jellouli

and M. Nasri (2016). "Optimization of proteins and

minerals removal from shrimp shells to produce highly

acetylated chitin." International Journal of Biological

Macromolecules 84: 246-253.

Zhang, A., G. G. Wei, X. F. Mo, N. Zhou, K. Q. Chen and

P. K. Ouyang (2018). "Enzymatic hydrolysis of chitin

pretreated by bacterial fermentation to obtain pure N-

acetyl-D-glucosamine." Green Chemistry 20(10):

2320-2327.

Zhang, H., Y. Jin, Y. Deng, D. Wang and Y. Zhao (2012).

"Production of chitin from shrimp shell powders using

Serratia marcescens B742 and Lactobacillus plantarum

ATCC 8014 successive two-step fermentation."

Carbohydrate Research 362: 13-20.

Zhang, Q., L. Wang, S. Liu and Y. Li (2021).

"Establishment of successive co-fermentation by

Bacillus subtilis and Acetobacter pasteurianus for

extracting chitin from shrimp shells." Carbohydrate

Polymers 258: 117720.

Zhang, W. C., Y. Zhao, L. Xu, X. Q. Song, X. X. Yuan, J.

Y. Sun and J. S. Zhang (2020). "Superfine grinding

induced amorphization and increased solubility of

alpha-chitin." Carbohydrate Polymers 237: 116145.

Recovery of Chitin from Shrimp Waste by Co-fermentation

1295