Modification of Straw-based Biochar and Its Application in

Wastewater Treatment

Yujin Long

1a

, Yuan Zhou

2,3,* b

, Li Feng

1c

, Long Yang

2d

, Yangyang Chu

2e

, Min Zhang

2f

and Siyu Wang

2g

1

Beijing Key Laboratory for Source Control Technology of Water Pollution, Engineering Research Center for Water

Pollution Source Control and Eco-remediation, Beijing Forestry University, 100083, Beijing, China

2

China Urban Construction Design & Research Institute Co. Ltd, 100120, Beijing, China

3

State Key Joint Laboratory of Environment Simulation and Pollution Control, School of Environment, Tsinghua

University, 100084, Beijing, China

Keywords: Straw-Based Biochar, Agricultural Waste, Wastewater Treatment, Biochar Adsorption.

Abstract: Biochar has attracted much attention in the field of pollution control because of its cheap and easily

available raw materials and high adsorption efficiency. The pyrolysis conditions and composition of raw

materials should be taken into account when preparing biochar for specific use. Straw, as a common and

typical agricultural waste, has been paid more attention to the preparation of biochar. In this paper, the

preparation, properties, modified methods, removal of pollutants in water environment and application

prospect of straw-based biochar were reviewed. Through physical, chemical and composite material

modification, the specific surface area and surface functional groups of biochar can be increased, and its

adsorption capacity can be effectively enhanced. However, in practical application, the potential ecological

risk of biochar to the environment, application stability and large-scale production should also be

considered. This paper can provide a reference for resource utilization of agricultural wastes, and

application of straw biochar in wastewater treatment.

1 INTRODUCTION

1

Adsorption method has been considered as a suitable

way for removing pollutants such as heavy metals

and organics in wastewater for its simple and

effective operation (Khan 2021). Traditional

activated carbon material has limited adsorption

efficiency, low reproducibility and high economic

cost, which confines its practical application. In

recent years, biochar derived from the by-products

or wastes in industrial and agricultural production,

such as straw, rice husk, livestock manure and

sewage sludge, gradually become a research hotspot

for its wide sources, low cost, efficient adsorption

a

https://orcid.org/0000-0002-3379-8798

b

https://orcid.org/0000-0003-2907-3804

c

https://orcid.org/0000-0003-3871-5856

d

https://orcid.org/0000-0002-2549-5658

e

https://orcid.org/0000-0003-1079-8960

f

https://orcid.org/0000-0003-1783-8961

g

https://orcid.org/0000-0003-1185-2893

and high environmental stability (Xing 2021, Li

2014) (Zhang 2013) (Liu 2012).

Many studies have focused on the preparation of

different type and of biochar, as well as its

properties and removal of contaminants (Xing 2021,

Li 2014, Zhang 2013, Liu 2012). Nevertheless,

researches on the characterization, optimization,

mechanism, application and prospects of straw-

based biochar are still lack of comprehensive

research. In this study, the preparation, physical and

chemical properties and different modified methods

of straw-based biochar (SBC) were summarized.

Then, the removal and mechanism of pollutants after

biochar applied in water environment were explored.

Finally, the existing problems and application

prospects of straw-based biochar were also

proposed, aiming to provide a reference for resource

utilization and pollutant adsorption of agricultural

wastes.

1244

Long, Y., Zhou, Y., Feng, L., Yang, L., Chu, Y., Zhang, M. and Wang, S.

Modification of Straw-based Biochar and Its Application in Wastewater Treatment.

DOI: 10.5220/0011392000003443

In Proceedings of the 4th International Conference on Biomedical Engineering and Bioinformatics (ICBEB 2022), pages 1244-1248

ISBN: 978-989-758-595-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 DEFINITION AND

PREPARATION OF SBC

Biochar is a kind of porous carbon material with

high specific surface area and stable structure, which

is formed by pyrolysis of biomass such as

agricultural wastes, trees, sludge or animal manure

under oxygen-limited conditions at high temperature

(400

o

C-700

o

C) (Khan 2021). The unique properties

enable it to be widely used in many fields such as

carbon fixation, soil remediation, water treatment

(Xing 2021, Li 2014). Owing to simple pyrolysis

process, low cost and easily available feedstock,

researches on the preparation, modification and

application of biochar receive much attention

(Cobbina 2018).

Pyrolysis can be further divided into two

categories according to temperature control: fast

pyrolysis and slow pyrolysis (Cobbina 2018,

Uchimiya 2015). Fast pyrolysis generally refers to

the addition of biomass to a reactor after the reactor

has reached the desired temperature, with a faster

temperature rise and generally shorter residence

time.

Slow pyrolysis refers to the process that at the

beginning of pyrolysis, biomass is added to the

reactor, while the temperature rise rate is slower

compared to fast pyrolysis, and with a longer

residence time to get biochar product. Fast pyrolysis

could facilitate the decomposition of organic

matters, resulting in a relatively low production

yield of biochar (Bridgwater, 2012), while it tends to

produce more gaseous products and oil. Slow

pyrolysis not only produces more biochar, but also

produces more carbon than fast pyrolysis. In

addition, biochar produced by fast pyrolysis and

slow pyrolysis has significantly different physical

chemistry properties (Bruun et Al., 2012), which in

turn affects the performance of biochar in practical

applications of biochar (Cobbina 2018, Kong 2014).

Straw is one of the most traditional feedstocks,

which is mainly composed of lignin, cellulose and

hemicellulose. Compared with other biochar (e.g.

sludge biochar), straw-based biochar has the

advantage in carbon sequestration, heavy metal

retention and pollutants removal, and less potential

toxic elements, which could be widely and safely

used in wastewater treatment (Zhang 2013).

Researchers found that pyrolysis process and the

properties of biochar were mainly affected by the

pyrolysis conditions (temperature, retention time,

heating rate) and components of the raw materials

(Liu 2012).

3 PHYSICAL AND CHEMICAL

PROPERTIES OF SBC

In the process of biomass pyrolysis, a variety of

comprehensive reactions occur, including physical

and chemical reactions, and these reactions were

mainly affected by both pyrolysis conditions (e.g.

pyrolysis temperature, pyrolysis residence time,

heating rate, etc.) and biomass raw material

composition (Lian et 2017, Lehmann 2015, Sun

2014, Wallace 2019). Because of the different

components of biomass, the physical and chemical

reactions will change during pyrolysis, which will

affect the formation and properties of biochar. The

composition of the raw material could have a more

significant effect on the physical and chemical

properties and function of the biochar than the

pyrolysis conditions (Hossain 2010). Therefore,

when preparing biochar for a specific use, for

example, watewater treatment or soil remediation,

the control of pyrolysis conditions and the selection

of biomass raw materials should be considered

carefully.

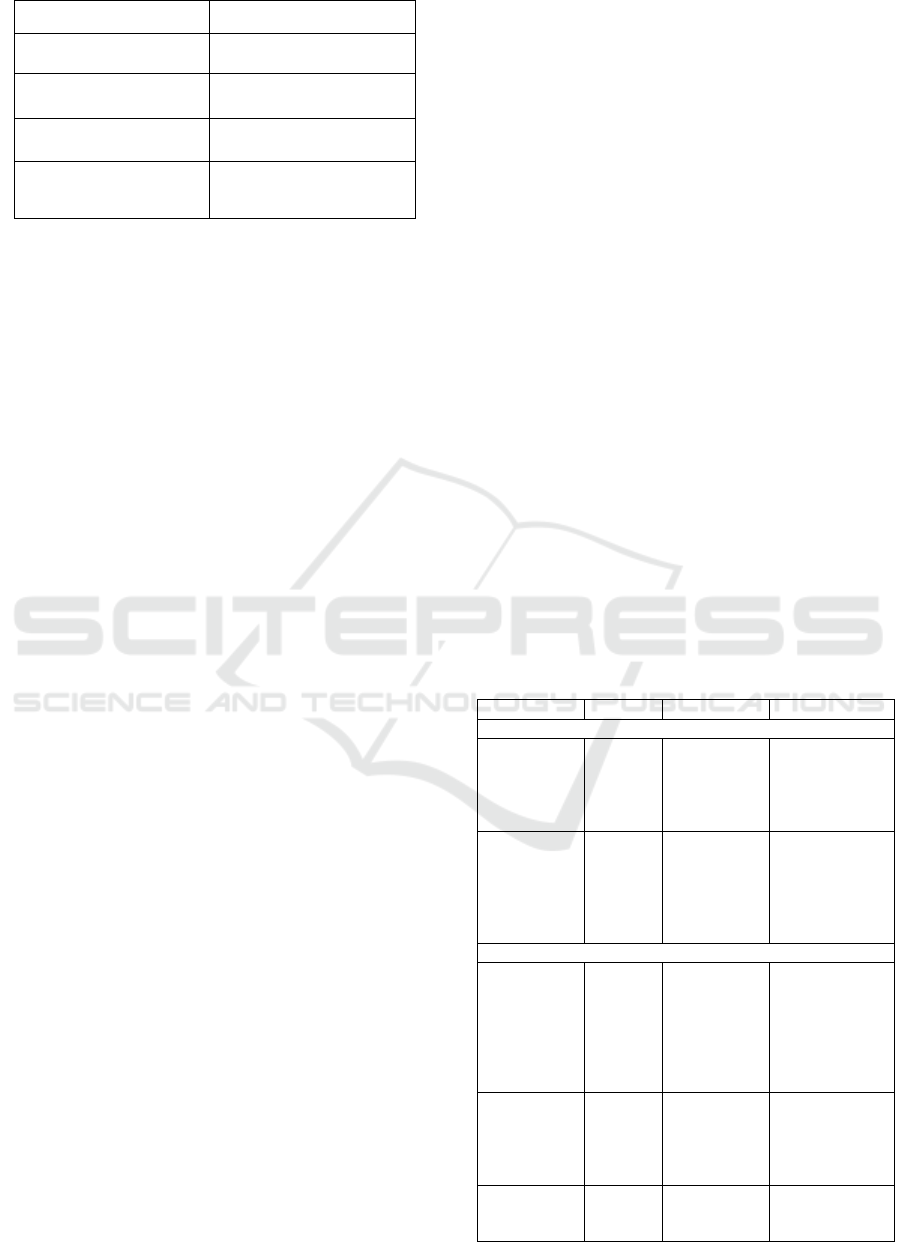

The main physical and chemical properties of

SBC and analysis methods were shown in Table 1.

The properties include pH, particle distribution and

porosity, specific surface area, morphology,

elemental composition, components such as volatile

matter and ash, as well as functional groups. Organic

components in raw materials can be decomposed

and recombined at high temperature to form C=C,

C-O, C-N, aromatic hydrocarbon and other

functional groups during pyrolysis, which can

increase the adsorption capacity and improve the

fertility of biochar (Liu 2012).

Table 1. The main properties and analysis technology of

SBC.

Physico-chemical

properties

Analysis technology

morphology SEM, SEM-EDX

ash contents Gravimetric method

volatile matter Gravimetric method

particle distribution and

surface area

BET

structure or

morphology of atoms

XRD

element composition

and formula

XPS

Modification of Straw-based Biochar and Its Application in Wastewater Treatment

1245

C, H, O, N, S ratios Elemental analysis

Heavy metals ICP-MS

Functional groups FTIR/FTIS

Surface potential Zeta potential analyzer

Acidic and basic

functional groups

Boehm titration

4 MODIFICATION OF BIOCHAR

Aiming to solve the problem of biochar properties

and limited adsorption, different modification

methods were adopted to adjust and control biochar

in order to enhance its structure and function and

reach the expected effect. It often include three

modification methods of biochar: physical modified

method, chemical modification and composite

modification.

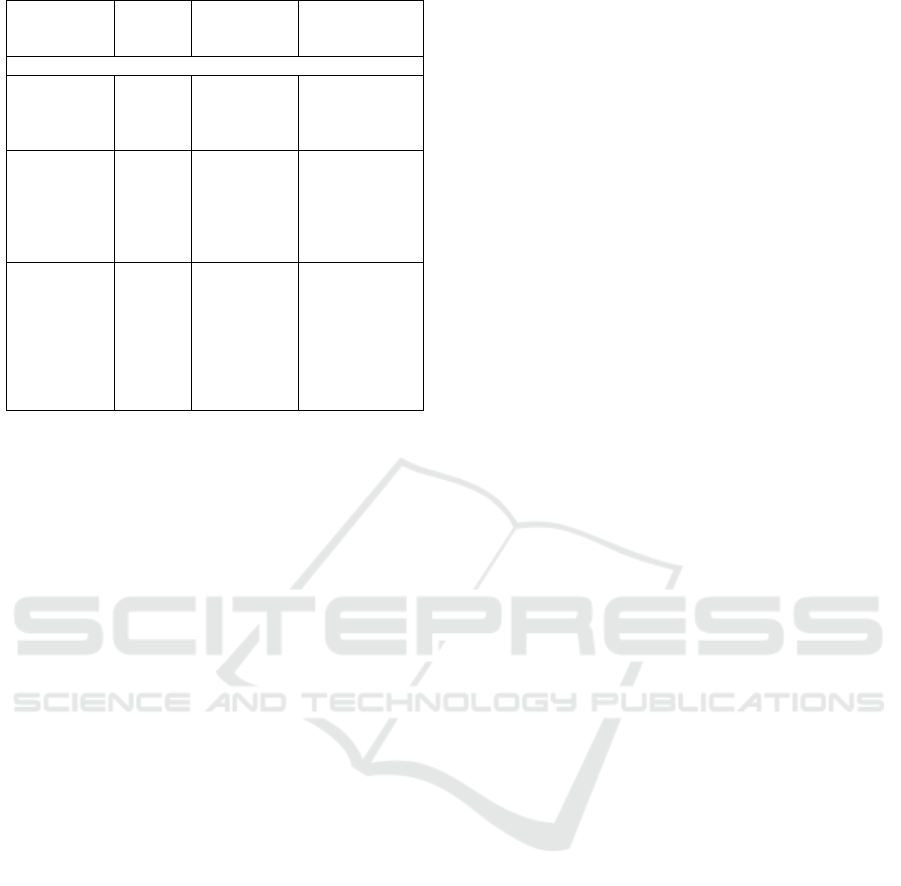

4.1 Physical Modification

The common methods of biochar modification

mainly include physical, chemical and composite

ways. The preparation, effect and mechanism of

modified biochar were shown in Table 2. The

physical modification mainly adopts heat or

gasification treatment such as steam, nitrogen,

oxygen, ammonia, carbon dioxide, or some other gas

during biomass pyrolysis process. Physical

modification can optimize the pore structure and

improve the hydrophilicity of biochar by promoting

the formation of crystalline carbon (Li 2014, Zhang

2013).

4.2 Chemical Modification

Chemical modification methods include acid-base

modification, oxidant modification and metal

modification (adding metal salt or metal oxidant).

Acid-base modification can optimize the properties

of biochar by increasing the number and variety of

functional groups and increasing the specific surface

area on the surface of biochar (Cazetta 2011, Feng

2018, Li 2014, Liu 2012, Jin 2014, Peng 2016).

Oxidants modified biochar by increasing the number

and type of oxygen-containing functional groups

(Huff 2016). The modification of biochar by oxidant

depends on the type and amount of oxygen-

containing functional groups in biochar. Besides,

metal modification can improve biochar adsorption

and endow biochar with magnetism, which is

beneficial for its recovery (Fang 2015, Tan 2016,

Wang 2018, Yang 2014).

4.3 Composite Modification

The modification methods mainly change the

physical properties and structural characteristics of

biological carbon. At present, some researches adopt

different modification methods by adding another

carbon-containing material as modifier in the

preparation of biochar during pyrolysis. Biochar can

be modified by adding different carbon-containing

composite materials as modifying agent during co-

pyrolysis. This modification method often choose

some biomass as substrate, then find another carbon

containing materials as additives, thus modified

biochar was obtained (Ghaffar 2014, Inyang 2014,

Jing 2014, Wang 2019). Carbon containing materials

can be materials such as carbon nanotubes, organic

solvents, MgAl hydrotalcite, bentonite, sludge,

sawdust and other organic wastes (Lyu 2020, An

2020). Carbon nanotubes is expensive and the

preparation process is pretty complex, while biochar

modified with organic wastes is more applicable,

while wastes can be utilized as resources at the same

time (Lyu 2020).

Table 2. Preparation, effect and mechanism of modified

biochar.

Method Material Effect Mechanism

physical modification

heat bamboo

remove

furfural from

water

improve the

pore structure

and the

hydrophilicity

of biochar

NH

3

/CO

2

cotton

stalk

CO

2

capture

improve

specific surface

area and

physical/chemi

cal adsorption

capacity

chemical modification

HCl/HNO

3

,

NaOH

rice

husk

remove

tetracycline

from

aqueous

solution

increase surface

area, oxygen-

containing

functional

groups, and π-π

bond

interactions

load Ca/Mg

corn

straw

recover

phosphorus

from biogas

fermentation

wastewate

r

add functional

groups and

nano MgO

particles

amino sawdust

enhance

adsorption of

copper ions

enhance amino

functional

groups combine

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

1246

from

synthetic

wastewate

r

more stable

with Cu

2+

composite modification

MgAl

hydrotalcite

composite

ramie

remove

crystal violet

from

wastewate

r

increase pore

volume and

functional

groups

wood

/bamboo

polyethylene

pine

sawdust

improve the

tensile and

strength of

material

enhance the

thermal barrier

and delay

thermal

reaction of

wood fiber

bentonite

cotton

stalk

improve

sustained-

release

nutrients

bentonite can

be used as a

slow-release

phosphorus

source and

improve

nutrients of

b

iocha

r

5 APPLICATION OF SBC IN

WASTEWATER TREATMENT

Biochar has important effects on the removals of

heavy metal ions, organic and inorganic pollutants in

wastewater treatment in recent years. Yang studied

that sawdust biochar prepared at high temperature

(800

o

C) enhanced amino functional groups and had

good adsorption effect on Cd

2+

(Yang 2014). The

biochar prepared from wheat straw and peanut shell

could adsorb more than 30 mg/g of

Pentachlorophenol (PCP) in water (Khan 2021).

Deng found that the adsorption capacity of modified

straw biochar with phosphoric acid was significantly

higher than that of original biochar, the removal

rates of phenol and dimethyl disulfide could reach

above 80%, which had great potential in black and

odorous water treatment (Deng 2021).

The adsorption capacity of biochar can be

affected by its surface functional groups. For

example, biochar containing amino groups can

enhance the adsorption of Cu

2+

through

complexation. Oxygen-containing groups on the

surface of ball milled biochar improved the

adsorption of Methylene blue by electrostatic

attraction and ion exchange. Lyu considered that the

adsorption mechanism of Fe-loaded biochar mainly

included pore filling, electrostatic attraction,

precipitation, surface complexation, ion exchange

and oxidation-reduction (Khan 2021, Lyu 2020, An

2020).

6 CONCLUSION AND PROSPECT

Biochar is a carbon-rich material with low cost and

wide sources, which could be widely used in water

treatment. Through physical, chemical and

composite material modification, the adsorption

ability of biochar can be improved, which is due to

its high functional groups, large specific surface area

and strong ion exchange ability. When biochar is

applied in wastewater treatment, attention should

also be paid to its potential risk to the environment,

and following aspects need to be studied deeply in

future: (i) identify the potential impact of biochar on

ecological environment and reduce its toxicity; (ii)

explore the mechanism of biochar for emerging

organic pollutants (e.g, PPCPs, EDCs) in

wastewater; (iii) consider the batch production,

large-scale application and recycling of biochar.

ACKNOWLEDGMENTS

This work was supported by the Science Foundation

of China Urban Construction Design & Research

Institute Co., Ltd. (Y09S21009) and the Science and

Technology Planning Project of Ministry of Housing

and Urban-Rural Development of the People’s

Republic of China (No. 2019-K-142) for financial

support.

REFERENCES

An X, Wu Z, Yu J, et al. (2020). Co-pyrolysis of biomass,

bentonite, and nutrients as a new strategy for the

synthesis of improved biochar-based slow-release

fertilizers. J. ACS Sustainable Chemistry &

Engineering, 3181-3190.

Bridgwater, A.V., (2012). Review of fast pyrolysis of

biomass and product upgrading. J. Biomass &

Bioenergy 38, 68-94.

Bruun, E.W., Ambus, P., Egsgaard, H., Hauggaard-

Nielsen, H., (2012). Effects of slow and fast pyrolysis

biochar on soil C and N turnover dynamics. J. Soil

Biology & Biochemistry 46, 73-79.

Cazetta, A.L., Vargas, A.M.M., Nogami, E.M., Kunita,

M.H., Guilherme, M.R., Martins, A.C., Silva, T.L.,

Moraes, J.C.G., Almeida, V.C., (2011). NaOH-

activated carbon of high surface area produced from

coconut shell: Kinetics and equilibrium studies from

the methylene blue adsorption. J. Chemical

Engineering Journal 174, 117-125.

Cobbina, S.J., Duwiejuah, A.B., Quainoo, A.K., (2018).

Single and simultaneous adsorption of heavy metals

onto groundnut shell biochar produced under fast and

Modification of Straw-based Biochar and Its Application in Wastewater Treatment

1247

slow pyrolysis. International J. Journal of

Environmental Science and Technology 16, 3081-

3090.

Deng S, Chen J, Chang J. (2021). Application of biochar

as an innovative substrate in constructed

wetlands/biofilters for wastewater treatment:

performance and ecological benefits. J. Journal of

Cleaner Production, 293, 126156.

Fang C, Zhang T, Li P, et al. (2015). Phosphorus recovery

from biogas fermentation liquid by Ca-Mg loaded

biochar. J. Journal of Environmental Sciences, 29,

106-114.

Feng, Z., Zhu, L., (2018). Sorption of phenanthrene to

biochar modified by base. J. Frontiers of

Environmental Science & Engineering,

https://doi.org/10.1007/s11783-11017-10978-11787.

Ghaffar, A., Younis, M.N., (2014). Adsorption of organic

chemicals on graphene coated biochars and its

environmental implications. J. Green Processing &

Synthesis 3, 479-487.

Hossain, M.K., Strezov, V., Chan, K.Y., Nelson, P.F.,

(2010). Agronomic properties of wastewater sludge

biochar and bioavailability of metals in production of

cherry tomato (Lycopersicon esculentum). J.

Chemosphere 78, 1167-1171.

Huff, M.D., Lee, J.W., (2016). Biochar-surface

oxygenation with hydrogen peroxide. J. Journal of

Environmental Management 165, 17-21.

Inyang, M., Gao, B., Zimmerman, A., Zhang, M., Chen,

H., (2014). Synthesis, characterization, and dye

sorption ability of carbon nanotube–biochar

nanocomposites. J Chemical Engineering Journal 236,

39-46.

Jin, H., Capareda, S., Chang, Z., Gao, J., Xu, Y., Zhang,

J., (2014). Biochar pyrolytically produced from

municipal solid wastes for aqueous As(V) removal:

Adsorption property and its improvement with KOH

activation. J. Bioresource technology 169, 622-629.

Jing, X.R., Wang, Y.Y., Liu, W.J., Wang, Y.K., Jiang, H.,

(2014). Enhanced adsorption performance of

tetracycline in aqueous solutions by methanol-

modified biochar. J. Chemical Engineering Journal

248, 168-174.

Khan N, Chowdhary P, Gnansounou E, et al. (2021).

Biochar and environmental sustainability: emerging

trends and techno-ecomonic perspectives. J.

Bioresource Technology, 332, 125102.

Kong, Z., Liaw, S.B., Gao, X., Yu, Y., Wu, H., (2014).

Leaching characteristics of inherent inorganic

nutrients in biochars from the slow and fast pyrolysis

of mallee biomass. J. Fuel 128, 433-441.

Lehmann, J., Jr, J., Steiner, C., Nehls, T., Zech, W.,

Glaser, B., (2015). Nutrient availability and leaching

in an archaeological Anthrosol and a Ferralsol of the

Central Amazon basin: fertilizer, manure and charcoal

amendments. J. Plant & Soil 249, 343-357.

Li Y, Shao J, Wang X, et al. (2014). Characterization of

modified biochars derived from bamboo pyrolysis and

their utilization for target component (furfural)

adsorption. J. Energy & Fuels, 28, 5119-5127.

Lian, F., Xing, B., (2017). Black carbon (biochar) in

water/soil environments: molecular structure, sorption,

stability, and potential risk. J. Environmental Science

& Technology 51, 13517-13532.

Liu P, Liu W, Jiang H, et al. (2012). Modification of bio-

char derived from fast pyrolysis of biomass and its

application in removal of tetracycline from aqueous

solution. J. Bioresource Technology, 121, 235-40.

Lyu H, Tang J, Cui M, et al. (2020). Biochar/iron (BC/Fe)

composites for soil and groundwater remediation:

synthesis, applications, and mechanisms. J.

Chemosphere, 246, 125609.

Peng, P., Lang, Y.-H., Wang, X.-M., (2016). Adsorption

behavior and mechanism of pentachlorophenol on reed

biochars: pH effect, pyrolysis temperature,

hydrochloric acid treatment and isotherms. J.

Ecological Engineering 90, 225-233.

Sun, F., Lu, S., (2014). Biochars improve aggregate

stability, water retention, and pore-space properties of

clayey soil. J. Journal of Plant Nutrition and Soil

Science 177, 26-33.

Tan, X.F., Liu, Y.G., Gu, Y.L., Xu, Y., Li, J., (2016).

Biochar-based nano-composites for the

decontamination of wastewater: A review. J.

Bioresource technology 212, 318-333.

Uchimiya, M., Hiradate, S., Antal, M.J., (2015). Dissolved

Phosphorus Speciation of Flash Carbonization, Slow

Pyrolysis, and Fast Pyrolysis Biochars. J. Acs

Sustainable Chemistry & Engineering 3, 1642-1649.

Wang, Z., Xie, L., Liu, K., Wang, J., Zhu, H., Song, Q.,

Shu, X., (2019). Co-pyrolysis of sewage sludge and

cotton stalks. J. Waste Management 89, 430-438.

Wang, M., Zhu, Y., Cheng, L., Andserson, B., Zhao, X.,

Wang, D., Ding, A., (2018). Review on utilization of

biochar for metal-contaminated soil and sediment

remediation. J. Journal of Environmental Sciences

063, 156-173.

Wang, Z., Xie, L., Liu, K., Wang, J., Zhu, H., Song, Q.,

Shu, X., (2019). Co-pyrolysis of sewage sludge and

cotton stalks. J. Waste Management 89, 430-438.

Xing J, Xu G, Li G. (2021). Comparison of pyrolysis

process, various fractions and potential soil

applications between sewage sludge-based biochars

and lignocellulose-based biochars. J. Ecotoxicology

and Environmental Safety, 208, 111756.

Yang G, Jiang H. (2014). Amino modification of biochar

for enhanced adsorption of copper ions from synthetic

wastewater. J. Water Research, 48, 396-405.

Zhang X, Zhang S, Yang H, et al. (2013). Influence of

NH

3

/CO

2

Modification on the characteristic of biochar

and the CO

2

capture. J. Bio Energy Research, 6(4),

1147-1153.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

1248