Study on Gelatinization Behavior of Aging Rice Starch Granules at

High Temperature

Rui Song

a

School of Biological and Food Engineering, Anhui Polytechnic University, Wuhu, China

Keywords:

Rice Aging, Starch Granules, Gelatinization Behavior, Quality Deterioration.

Abstract:

Rice starch is one of the most important nutrition sources worldwide. In the current study, we prepared,

characterized and evaluated gelatinized glutinous rice starch. The main purpose of this study was to

investigate the effect of 95℃ slurry on the separation and functional properties of rice endosperm cells

granules aged for 12 months. Our results showed that during high temperature treatment, particle size

analysis observed that the degree of separation for endosperm cells granules decreased, morphology

examination suggested that the protein distribution was uneven, and starch granules was more difficult to

swelling. Morever, The texture of cooked aged rice was higher hardness, chewiness and gumminess while

lower adhesiveness, also higher setback value whereas lower breakdown value. Thus, different methods

have been proposed to classify that why the n vitro weight loss rate diminished for aged rice starch granules

at at high temperatures. These results provide a new basis for understanding aging mechanisms from the

pasting behavior of rice flour particles at high temperatures.

1 INTRODUCTION

1

More than half of the world’s population consumes

rice and rice products, rich in starch, as their main

staple food (Lamberts, De, Vandeputte, 2007). To

product flour for various food items, the quality of

aging rice needs to be increased. Aging is the most

common phenomenon in rice storage, but its

mechanism is still not fully understood. Starch is the

main ingredient of rice, since it is its most important

component. Rice products are mainly processed by

starch entities such as cooking, gelatinization, and

retrogradation properties, which are important

factors to consider when commercializing rice

products (Likitwattanasade, Hongsprabhas, 2010)

At present, most rice products, such as rice

cakes, baby food, and instant rice milk, are made

from rice noodles. Thus, there are many domestic

and overseas countries to improve the quality of rice

products through heat-moisture treatment, like the

superheated steam modifying wheat flour (Hu, Guo,

Liu, 2018), food crop starches (L, Y, X, 2019) and

potato starches (Hu, Guo, Liu, 2018), add functional

polysaccharides and enzyme preparations, etc (Heo,

Jeon, Lee, 2014). And China mainly from the

a

https://orcid.org/ 0000-0002-1911-5292

improvement of production process, delaying aging,

improving nutrition and other aspects of rice flour

(Advances on fermentation in rice noodle

production, 2013). During the storage process, the

microcrystal bundle structure of starch strengthens,

the molecular weight decreases, the content of

insoluble amylose increases. Due to these changes,

water molecules are contained in the cell so that

water absorption expansion force is too weak for the

aging starch granules to disperse, reducing the

amount of dissolved starch molecules and

consequently the texture. The current study

investigates the influence of high temperature on its

morphology and functional properties to validate the

theory and observations.

The aim of this paper is to clarify the separation

of high temperature starch granules by using inner

rice flour for endosperm cells aggregates. The

purpose is to study the gelatinization behavior under

the effect of high temperature gelatinization

treatment on the separation of new and aged rice

starch granules as well as the changes in functional

properties of aging rice, for understanding the

mechanism of rice aging and improve the process of

commercial manufactures of rice products.

Song, R.

Study on Gelatinization Behavior of Aging Rice Starch Granules at High Temperature.

DOI: 10.5220/0011375500003443

In Proceedings of the 4th International Conference on Biomedical Engineering and Bioinformatics (ICBEB 2022), pages 1007-1012

ISBN: 978-989-758-595-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

1007

2 MATERIALS AND METHODS

2.1 Materials

This study used freshly milled non-waxy japonica

rice harvested in Jiangsu Province, China with an

initial water content of 14.30±0.01%. All chemicals

and reagents used in the study were of analytical

grade.

2.2 Preparation of Endosperm Cell

The rice was first divided into two samples and

sealed in a bottle, with one sample stored at 4℃ as a

control and the other in a 37℃ incubator for 12

months to obtain the aged rice sample for further

testing (Zhou, Robards, Helliwell, 2010). The rice

samples were then milled using a fine rice machine.

Rice flours of both new and aged rice grains were

obtained by grinding the inner layer of rice grains,

which accounted for 15% in the whole rice grains.

20 g of kernel rice was crushed in the shredder for

20s The crushed powder further went through a 150-

mesh sieve, and then passed a120-mesh sieve. The

sieved powder (approximately with sizes finer than

100-125μm) were stored in a self-sealed pocket at

4℃ for later use.

2.3 Particle Size Analysis

Using a laser light scattering particle size analyzer,

we determined the particle size distribution of rice

flour particles. Then 0.2 g of samples was added to

the tube, followed by 10 mL of distilled water

vortexing for 1 minute to prevent the sticky wall

from dispersing the samples, which then pasted in a

95℃-water bath for 5 min. The sample was removed

and placed in a bath for 50℃ to prevent aging.

Particle size analysis was performed 5 times and

averaged using an ultrasound dispersion using water

as the dispersant at 1800 r/min, and the shading

between 10%-20% (Odeku, Itiola, 2007).

2.4 Light Microscope Observation

After completely dispersed using a vortex for 1 min,

rice flour particles were dispersed in distilled water

and heated in a water bath at 95 °C for 5 min. Then

the sample was kept in 50 °C before further testing.

After removed from water bath, the samples were

briefly vortexed for 1 min, dripped on slides with

0.02% iodine fluid, and covered with cover glass.

The particles were then observed and imaged under

a light microscope to observe its morphological

properties.

2.5 Scanning Electron Microscope

Observation

Following the same sample preparation method as

above, the sample was vortexed for 20s and set still

for 2 min. Supernatant was removed using a pipette

and the residues were washed three times through a

5 mm filter film using 10 mL of 50℃ distilled

water. The filter residue on the filter membrane was

dispersed into a petri dish. After the sample freeze-

dried, it was grinded and bagged, followed by

mounting to a circular aluminum stub with double-

sided sticky tape. After coating with gold to form a

thickness of 10 nm, the sample was examined and

photographed using a cold field emission scanning

electron microscope at an accelerating voltage of 15

kV.

2.6 Determination of the Textural

Properties

We implemented similar textual analysis method

similar to Huo et al., etc (Huo, Yuan, Tang, 2019)

methods with slight modifications. 2,000 g samples

were taken with 8 mL distilled water supplemented

to form a rice slurry suspension of 20%. The mixture

was stirred evenly in a 40 mm diameter small

aluminum box, heated at a constant temperature to

95℃ water bath for 15 min, and then cooled to room

temperature and stored in an upper 4℃ refrigerator

for 12 h. Each starch gel sample in the canister was

pressed to form distances of 30 mm (trigger force =

5.0 g) with a cylinder probe with 0.5 inch in

diameter at the speed of 1.0 mm/s during two

replication. The bite speed, pre-speed and post-speed

were all set at 1.0 mm/s, compressing the original

sample to 50% and residence time of 4s.

2.7 Determination of the Pasting

Properties

A 0.5g sample of rice flour was added to 4mL of

distilled water and stirred ten times quickly to

prevent sticking to the wall, and the starch pasting

viscosity measurement instrument (FDV-E) was

used to set the programmed temperature control: 50-

50℃, 5min; 50-95℃, 6min; 95-95℃, 4min; 95-

51℃, 6min; 51-51℃, 5min. peak viscosity (PV),

final viscosity (FV), Holding strength (HS) and

pasting temperature (PaT).

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

1008

2.8 Determination of the in Vitro Mass

Loss Rate

We following the produced according to Li et al

(LI, YANG, XU, 2019) with slight modifications.

200 ± 0.1mg rice paste sample was added to 10ml of

distilled water in centrifuge tubes, heated up to 95℃

for 5min, added 6mL of artificial gastric juice, and

then digested at a constant temperature of 37℃ for 4

hours. After 10 min- centrifugation at 10,000 r/min,

the supernatant was discarded, and the precipitation

was washed three times with anhydrous ethanol. The

precipitation was dried at 105℃, and the the mass

loss rate of artificial gastric juice was calculated as

W1:

𝑊1 =

×100%

The above digested samples were combined with

6mL of artificial intestinal fluid and digested at a

constant temperature for 5h. Then the mixer was

centrifuged at 10,000 r/min for 10min, and the

supernatant was discarded, washed three times with

anhydrous ethanol and dried at 105℃. The mass loss

rate of artificial intestinal fluid, W2, was measured

and calculated as the following:

𝑊2 =

×100%

3 RESULTS AND DISCUSSION

3.1 Starch Particle Size Analysis

Figure 1: Starch granule particle size distribution of native

and gelatinized starch at 25℃and 95℃. (Black curve:

fresh rice; red dashed curve: aging rice).

It is obvious from the above figure that the new

rice particle distribution after 95℃ compared that

with room temperature. Three particle size peaks are

shown in the figure. The peak of middle particles

with most of it concentrating near 7 um, which

belongs to the range of single starch (JANE,

KASEMSUWAN, LEAS, 2010). The peaks of small

particle sizes are concentrated around 1 um and fall

within the range of protein bodies. (COFFMAN,

JULIANO, 1987) Large particle size peaks are

concentrated in the range of 40 um and found in

endosperm cells (PAN, ZHAO, LIN, 2017). At room

temperature, in addition to the easy dissociation

between the endosperm cells, the starch granules

also disaggregated easily between the fresh rice;

while the aged rice only dissociated easily between

the endosperm cells, but it was difficult to

disaggregate between starch granules, which was

reflected by the higher peak of the endosperm cells

than the starch granules in the aged rice, indicating

that aging had little effect on the dissociation

between the cells, but mainly affected the tightness

of the bond between the starch granules. When aged

rice is pasted at 95℃, the small particle size peak

decreases to a certain extent, while the large particle

size peak increases. Moreover, fresh rice peak

position shifted to the right. It appears that even the

native rice has difficulties in endosperm cells, and

endosperm cells between starch granules separate

more completely,

Rice flour granules can be sorted into small

starch granules, swelling, and unbroken rice flour

particles. Aged rice becomes difficult to separate

between starch granules within endosperm cells,

which decreases the volume fraction of small

particle size peaks. In aged rice, gelatinization at

high temperatures inhibits the depolymerization of

starch granules while promoting slightly their

swelling. Due to uneven water absorption and

swelling of rice noodle particles, the edge of larger

particles scatters and falls off, and then the internal

particles absorb water and dissolve. Water is more

easily absorbed and swollen by thinner particles.

Consequently, the amount of small and middle

particle granules decrease while glued at 95℃, and

the amount of larger particle gradually increases.

3.2 Light Microscope

The new rice disaggregated more smaller particles at

95°C than the old rice. There is less cracking on the

aged rice starch granules, because the edges of the

rice flour particles, are dissociated, and there are

fewer granules in the cell wall. There is high edge

dissociation in rice flour particles, a small swelling

of starch granules, and the boundaries between the

cell walls is. The degree of fresh rice flour is

0.1 1 10 100 1000

0

6

12

18

24

Volume(%)

Particle diameter (μm)

Fresh rice flour at 25℃

Aging rice flour at 25℃

Fresh rice flour at 95℃

Aging rice flour at 95℃

Study on Gelatinization Behavior of Aging Rice Starch Granules at High Temperature

1009

uniform, most of which is higher than that of old

rice. the starch granules are larger and the cell wall

boundary is clear and thick. The aging rice shows

more protein body in the grain rim, meaning that the

body has expanded; the protein body in the new rice

is evenly distributed throughout the rice flour

particles, indicating that it is more likely to dissolve.

Figure 2: Light microscope images of fresh (A) vs. aged

rice particles (B) at 400× resolution.

3.3 Scanning Electron Microscope

In scanning electron microscope (SEM)

observations, fresh rice flour after swelling has a

loose structure, the particles are small, and aging

rice has a small swelling degree. as Along with the

overall swelling, compact structure, which is

consistent with those of the particle distribution

analysis for fresh rice paste starch compound or cell

loss left diameter larger pit. Moreover, it can be seen

that the starch shed inner wall has a smaller and

shedding pit, and the protein body is more

concentrated in the edge and more exposed. Despite

this, the starch particle shedding pit is small and

shallow, its diameter is large, the inner wall is

smooth, not as thick, and partially buried in the

starch.

Figure 3: Electron microscope images of fresh (A)vs. aged

rice granules (B) at 3000× resolutions.

3.4 Gel Texture

Table 1: Measured hardness, adhesiveness, chewiness, and gumminess of fresh and aged rice flour.

Type Hardness/N Adhesiveness/N chewiness/N

gumminess/N

Fresh 1.507±0.0084 0.373±0.031 1.326±0.081 1.328±0.081

Aging 1.840±0.016 0.548±0.064 2.101±0.218 1.537±0.070

Rice is often been characterized by the texture of

it (such as hardness, chewiness and adhesiveness).

Changes in starch gel hardness are related to the

starch colloid structure. According to studies, rice

hardness is positively related to rice protein content

(Zhu, Wu, Cheng, 2020). It can be seen that when

under 95℃ the four texture parameters of aged rice

flours are significantly higher than that of native rice

flours, higher hardness and chewing are the typical

characteristics of aging. (Table 1). It is possible that

the central part of fresh starch granules becomes

fully gelatinized during cooking because increased

soluble solids, resulting in a softer texture (low

hardness). Aged rice slurry has significantly

improved hardness and chewiness compared with

new rice. their because fresh endosperm cells are

50μm

A

50μm

B

A

B

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

1010

relatively brittle, easy to rupture and form a sticky

state. When aged rice undergoes oxidation, the rice

protein located around the starch granules becomes

cross-linked, preventing them from absorbing water

and swelling, resulting in insufficient gelatinization.

Additionally, the disulfide bond increases during

heating, and the stronger binding effect of protein

and starch promotes the formation of gel network

structures. Aged rice becomes harder, gummier, and

chewier as the gel strength and force needed to grow

stronger when chewing. For rice grains, the hardness

is increased after the aging, but its adhesiveness is

reduced; and for rice glue, the hardness and

adhesiveness of the aged increase (Wu, Li, Bai,

2019), maybe since the aged rice particles in glue

are large and the clearance space is small, the

surface solids of the unit particles are relatively

large, or the small amount of aged starch particles

dissociated are more likely to rupture.

3.5 Determination of the Pasting

Properties

Table 2: Measured PaT, PV, HS, and FV of fresh and aged

rice flour.

Type Fresh rice flour Aging rice flour

PaT/℃ 71.467±0.702 72.667±1.457

PV/cP 1424.167±37.942 1080.833±27.651

HS/cP 639.167±5.774 685.000±17.321

FV/cP 1395.000±70.134 1415.833±13.769

From Table 2, it can be seen that aging increases

the FV, the PV decreases significantly, and the HS

does not change much and increases slowly a little.

The breakdown (BD) value decreases and the

setback(SB) value increases. BD value is the most

sensitive indicator in pasting properties, the decrease

in BD value indicates that the less starch particles

are released in heating. The smaller the decreases,

the smaller the taste (Zhang, Xu, Jiang, 2021) The

SB value represents the stability and aging trend of

starch cold paste, the larger value, the more prone to

aging, the worse the quality of eating. Moreover, the

increase of pasting temperature indicates that the

pasting ability of starch is inhibited, the degree of

water absorption and dissociation and dispersion of

starch gradually decreases, and the energy required

for gelatinization increases. It can be seen that aging

increases the degree of swelling of rice flour but it is

difficult to break the granules, the number of

remaining starch granules is smaller, the viscosity

and the eating quality decreases.

3.6 Determination of the in Vitro

Weight Loss Rate

Studies reveal that the degree of gelatinization of

rice flour is closely related to its in vitro digestibility

(Molecular disassembly of rice and lotus starches

during thermal processing and its effect on starch

digestibility, 2016). Investigate the influence of rice

flour particle size on the degree of gelatinization

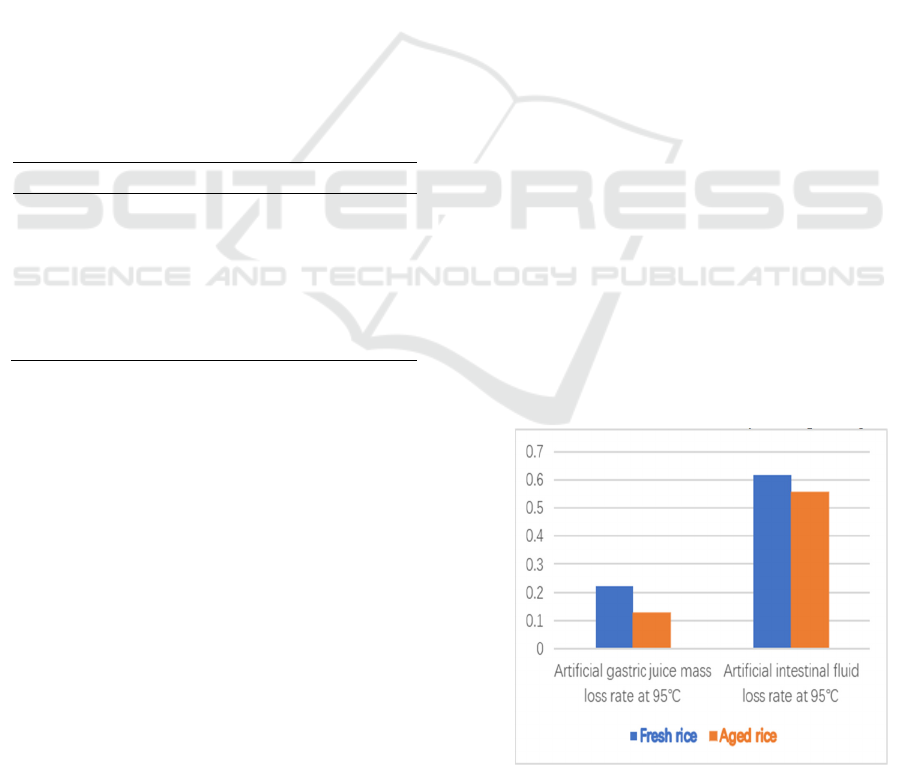

using in vitro digestibility studies. In Figure 5,

which simulates in vitro digestion of artificial gastric

juice and artificial intestinal juice. It is shown that

gelatinized rice at high temperatures is also

digestible in artificial gastric juice and artificial

intestinal juice, and new rice noodles can be digested

at higher temperatures than old rice noodles.

Therefore, after high-temperature gelatinization, rice

starch granules are more prone to absorbing water,

swelling and can be more easily hydrolyzed by

digestive enzymes. Leading to the increase of the

rate of the digestibility in aged rice starch granules

expand with temperature. The higher the aged rice

paste, the greater the degree of gelatinization of aged

rice noodles, the greater the degree of swelling in

aging rice flour. Moreover, compared with new rice

starch, the old losses less weight in vitro.is still

decline. It is possible that aged rice flour particles

are difficult to dissolve and highly gelatinized under

high temperatures, which impedes enzymes from

entering the particles and slow digestion. Therefore,

the digestion rate of new rice noodles is affected by

both rate dispersion and rate of gelatinization.

furthermore, aging rice slurry are mainly affected by

gelatinization due to their difficulty in dispersing.

Figure 3. Calculated simulated gastric juice mass loss rate

and artificial intestinal fluid loss rate of fresh vs. aged rice.

Study on Gelatinization Behavior of Aging Rice Starch Granules at High Temperature

1011

4 CONCLUSIONS

In this study, we investigated the effect of high

temperature on the gelatinization behavior and

functional properties of fresh and aged rice in non-

waxy rice flour. After gelatinization at 95 ℃. Aging

endosperm cells are harder to separate into

individual starch and protein bodies. Aged rice

starch particles has difficulty swelling and

dissociation, and dispersion outside the particles.

Morphological observation showed aged rice starch

granules contain more tightly bound protein and

starch. TPA indicated higher hardness, chewiness

and gumminess, while lower adhesiveness. FDV

revealed higher SB whereas lower BD. These can

lead to starch-protein complexes forming, which

may be difficult to disperse due to insufficient

friction between granules or surface polymerization

force, and low gelation and low degree of digestion.

The quality deterioration after high temperature

gelatinization of aging rice starch granules can be

explained by owing to the increasing gel strength of

starch-protein complexes, as well as decline of low

water absorption ability swelling, and permeability,

contributing to starch granules difficult to

dissociation, which interfere with the absorption of

internal starch. This will provide a basis for

discovering the mechanism of rice aging, and then

regulating its edible quality.

REFERENCES

Advances on fermentation in rice noodle production[J].

Food and Machinery, 2013, 29(5): 223-225.

Chengmei L, Xiaoyan Y, Xingfeng X, et al. Changes in

Granular Swelling and Rheological Properties of Food

Crop Starches Modified by Superheated Steam [J].

Starch - Starke, 2019, 71(3-4): 1800132.

Coffman W R, Juliano B O. Rice: Nutritional Quality of

Cereal Grains: Genetic and Agronomic Improvement

[M]. Nutritional Quality of Cereal Grains: Genetic and

Agronomic Improvement, 1987.

Hu X, Guo B, Liu C, et al. Modification of potato starch

by using superheated steam [J]. Carbohydrate

Polymers, 2018, 198(19-20): 375-384.

Heo S, Jeon S, Lee S. Utilization of Lentinus edodes

mushroom β-glucan to enhance the functional

properties of gluten-free rice noodles [J]. LWT - Food

Science and Technology, 2014, 55(2): 627-631.

Huo Y Q, Yuan B H, Tang S W, et al. Effect of rice gluten

on gelatinization and gel properties of rice starch[J].

Journal of the Chinese Cereals and Oils Association,

2019, 34(6):1-5

Jane J L, Kasemsuwan T, Leas S, et al. Anthology of

Starch Granule Morphology by Scanning Electron

Microscopy [J]. Starch ‐ Strke, 2010, 46(4): 121-129.

Lamberts L, De Bie E, Vandeputte G E, et al. Effect of

milling on colour and nutritional properties of rice [J].

Food Chemistry, 2007, 100(4): 1496-1503.

Likitwattanasade T, Hongsprabhas P. Effect of storage

proteins on pasting properties and microstructure of

Thai rice [J]. Food Research International, 2010,

43(5): 1402-1409.

Li Shanshan, Yang Ping, Xu Xin, et al. Preparation and in

Vitro Digestibility of Potato ResistantStarch [J]. Farm

Products Processing, 2019, 472(2): 18-22.

Molecular disassembly of rice and lotus starches during

thermal processing and its effect on starch digestibility

[J]. Food & Function, 2016, 7(2): 1188-1195.

Odeku O A, Itiola O A. Compaction Properties of Three

Types of Starch [J]. Iranian Journal of Pharmaceutical

Research, 2007, 6(1): 17-23.

Pan T, Zhao L, Lin L, et al. Changes in kernel morphology

and starch properties of high-amylose brown rice

during the cooking process [J]. Food Hydrocolloids,

2017, 66(3): 227-236.

Wu P, Li C, Bai Y, et al. A starch molecular basis for

aging-induced changes in pasting and textural

properties of waxy rice [J]. Food Chemistry, 2019,

284(11-12): 270-278.

Zhou Z, Robards K, Helliwell S, et al. Effect of storage

temperature on rice thermal properties [J]. Food

Research International, 2010, 43(3): 709-715.

Zhu L, Wu G, Cheng L, et al. Investigation on molecular

and morphology changes of protein and starch in rice

kernel during cooking [J]. Food Chemistry, 2020,

316(11-12): 126262.

Zhang D, Xu H, Jiang B, et al. Effects of ultrahigh

pressure on the morphological and physicochemical

properties of lily starch [J]. Food Science & Nutrition,

2021, 9(2): 952-962.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

1012