Intelligent Control of Construction Manufacturing Processes using

Deep Reinforcement Learning

Ian Flood

1

and Paris D. L. Flood

2

1

Rinker School, University of Florida, Gainesville, FL 32611, U.S.A.

2

Dept. of Computer Science and Technology, University of Cambridge, Cambridge, U.K.

Keywords: Construction Manufacturing, Construction Simulation, Decision Agents, Deep Artificial Neural Networks,

Precast Reinforced Concrete Production, Reinforcement Learning, Rule-of-thumb Policies.

Abstract: This paper is concerned with the development and evaluation of a reinforcement learning approach to the

control of factory based construction operations. The unique challenges associated with controlling

construction work is first discussed: uneven and uncertain demand, high customization, the need to fabricate

work to order, and a lack of opportunity to stockpile work. This is followed by a review of computational

approaches to this problem, specifically those based on heuristics and machine learning. A description is then

given of a model of a factory for producing precast reinforced concrete components, and a proposed

reinforcement learning strategy for training a neural network based agent to control this system. The

performance of this agent is compared to that of rule-of-thumb and random policies for a series of protracted

simulation production runs. The reinforcement learning method was found to be promising, outperforming

the two competing strategies for much of the time. This is significant given that there is high potential for

improvement of the method. The paper concludes with an indication of areas of proposed future research.

1 INTRODUCTION

Achieving operational efficiency in construction is

challenging, more so than most other manufacturing

industries. This results in part because construction

work does not lend itself to the methods of mass

production. The arrival of work is random and

sporadic, the work can be diverse and extensive in

scope, and the products are rarely reproduced.

Consequently, work has to be made to order with little

or no potential for stockpiling, and with large

fluctuations in resource demand.

These complexities make it difficult to derive a

simple policy for controlling construction operations

that is likely to be near optimal. A potentially

promising approach to this problem is assisted control

of operations by artificial intelligence (AI) agents.

These agents would act like an advisor (in a human-

in-the-loop system) or a controller (in an automated

environment) offering solutions whenever an

operational decision is needed.

The use of AI based decision agents to control

operations in the field of construction is limited.

Shitole et al. (2019) developed an agent for

optimizing a simulated earth-moving operation based

on artificial neural networks (ANNs) and

reinforcement learning (RL), and found it worked

better than previously published hand-designed

heuristics. RL is a broad class of learning techniques

based on discovery and rewards that has

demonstrated much success in recent years (Sutton

and Barto, 2018). Their earth-moving system

comprised two excavators serving a fleet of dump-

trucks. The function of the agent was to direct the

trucks to one or other of the excavators at a junction

in the return road, with the goal of optimizing the

overall production rate of the system. An issue with

this approach to control is its lack of extensibility.

That is, the agent can only be applied to the earth-

moving system considered in the study. Applying the

agent to a new situation with a different site layout

and/or equipment combination would require its

redevelopment. Although this could be achieved prior

to the start of the new construction operation, it would

nevertheless be a significant burden on planning.

Clearly, there is a need for more work in the area of

ANN extensibility.

An alternative application area to site-based

construction, with more immediate application given

current technology, is factory based manufactured

112

Flood, I. and Flood, P.

Intelligent Control of Construction Manufacturing Processes using Deep Reinforcement Learning.

DOI: 10.5220/0011309600003274

In Proceedings of the 12th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2022), pages 112-122

ISBN: 978-989-758-578-4; ISSN: 2184-2841

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

construction. In this situation, the life-span of an

agent should be relatively long, lasting at least until

any reconfiguration of the factory system is required

or a change occurs in its operating environment. This

study will be focused on factory based construction

manufacture, specifically for precast reinforced

concrete (PRC) component production.

Optimization of customized PRC component

production has been considered by several

researchers (Leu & Hwang, 2001; Chan & Hu, 2002;

Benjaoran & Dawood, 2005), using genetic

algorithms (GAs) to improve production

performance. Although the approach was shown to

be successful, heuristic search methods such as GAs

are computationally expensive. Therefore, they are

not well suited to situations where decisions have to

be made quickly.

RL solutions based on a learned model, such as

that developed by Shitole et al. (2019), will generate

rapid solutions to a decision problem, once trained. A

number of authors have applied this method to the

control of factory operations (Waschneck et al., 2018;

Zhou et al., 2020; Xia et al., 2021) and found results

to be promising when compared to more conventional

approaches such as rules-of-thumb. Unfortunately,

applications have been outside construction

manufacturing, and therefore do not address many of

the challenges of this industry, although Waschneck

et al. (2018) did address the problem of customization

within the semiconductor industry.

The objective of this paper is to explore the

potential of RL based modelling as a means of

controlling factory based construction

manufacturing, given the unique demands of

construction projects.

2 DYNAMIC SYSTEM CONTROL

2.1 Decision Agents

The future path of a construction manufacturing

system is determined by both controllable and

uncontrollable events. The controllable events

provide an opportunity to steer this path along a line

that is favourable to the manufacturer, optimizing

performance in terms of, say, productivity and/or

profit. This is achieved through the selection of an

appropriate sequence of decisions wherever options

exist. Examples of such decisions include prioritizing

jobs in a queue, deciding when to take an item of

equipment offline for maintenance, and selecting the

number of machines to allocate to a process.

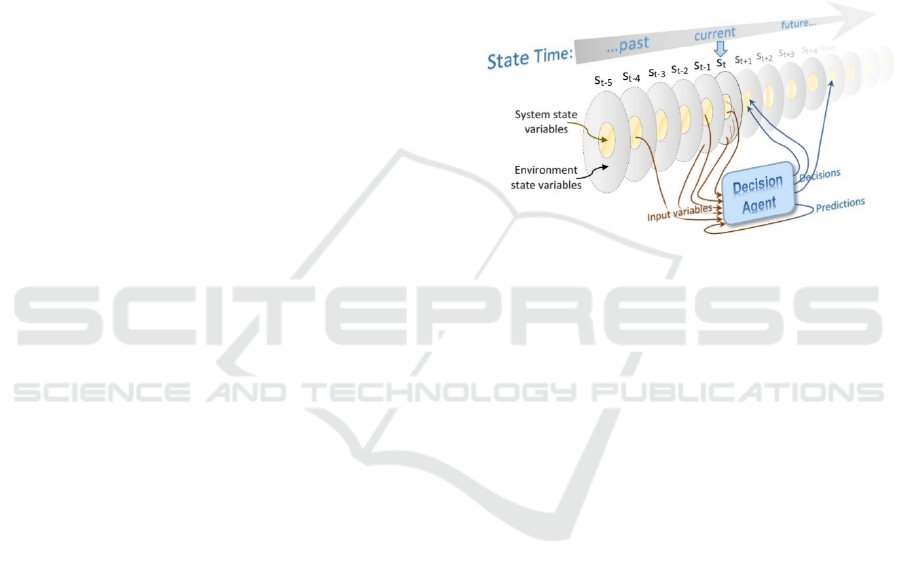

These decisions are made by one or more agents,

as illustrated in Figure 1, which operate dynamically

throughout the life of the system. An agent monitors

relevant variables defining the state of the system and

its environment (both current and possibly past states,

and even predictions about future states) then uses

these insights to decide on appropriate future actions

to implement. Typically, these actions will concern

events in the immediate future (given that the most

relevant, accurate, and valuable information is

available at the time of the decision) but can also be

applied to events later in the future for decisions that

have a long lead time.

Figure 1: Decision agent control of dynamic system.

An important dichotomy of decision agents is

search based versus experience based systems.

Search based agents, which include blind and

heuristic methods, use a systematic exploration of the

solution space looking for the best action attainable.

They tailor a solution to the specific instance of the

problem at hand. As such, they may find better

optimized solutions than experience based agents,

although that needs to be tested. Search based agents

are also highly extensible, meaning they can be easily

adapted to new versions of the problem. On the

downside, they can be computationally expensive and

thus not suited to situations requiring rapid decision

making.

In contrast, experience based agents, which

include rules-of-thumb and artificial neural networks

(ANNs), make decisions based on exposure to similar

situations from the past. Once developed, an

experience based agent can output decisions rapidly.

However, because the solutions they offer are generic

rather than tailored to each situation, their decisions

may not be as well optimized as those of search based

agents. Furthermore, experience based agents tend to

lack extensibility; each new version of the problem

requires redevelopment of the agent, which in turn

requires the acquisition and assimilation of large

volumes of new information on system behaviour.

Intelligent Control of Construction Manufacturing Processes using Deep Reinforcement Learning

113

A hybrid of these agent types is also possible. For

example, an experience based agent can be used to

make the first attempt at a solution and then a search

based agent can be used to improve on this result.

Conversely, a search based agent could be used to

acquire examples for development of an experience

based agent.

A longer term objective for this study is to

quantify and compare the benefits of search and

experience based approaches to controlling

construction production systems. This paper,

however, focuses on experience based approaches

applied to construction manufacturing. Two

experience based methods will be considered, a rule-

of-thumb and a deep artificial neural network

(DANN), representing two extremes in functional

complexity. DANNs are variants of ANNs that

include multiple hidden layers or recursion between

units. The additional structure offers a corresponding

increase in functional complexity, although model

development has additional challenges. Although a

DANN is an experience based approach, its

development will involve the use of search techniques

to gather good training solutions, specifically using

RL techniques.

2.2 DANN Agent Development

Strategies

For a construction manufacturing environment,

optimal solutions to decision problems are not easily

attained a priori or from direct observation of the real

system. Simulating the manufacturing system has the

potential to explore a broader range of scenarios than

direct observation of the real system, but it similarly

fails to provide good labels (near optimal solutions)

to problems. This excludes the direct use of

supervised training techniques for development of the

DANN. There are many ways around this problem,

including using a strategy of hindsight whereby the

agent explores alternative decision paths (through

simulation), then selects those that are most

successful, effectively learning by trial-and-error.

For DANNs, there are two broad approaches to

hindsight model development. The first is to explore

adjustments to the structure and/or weights of the

DANN model (such as random perturbations), and to

select those that result in a better performing decision

path. This was the strategy investigated by Flood

(1989) for selecting sequences for construction jobs

in an offline optimization problem. The second

approach is to explore adjustments to the values

generated at the output from the DANN model, then

to evaluate their impact on the performance of the

decision path and to feed this back to the model in a

supervised manner. A method for implementing this

is detailed in section 3.3.3 below. This is in essence

the RL method.

3 MODELLING

A key function of RL is the exploration of alternative

decision paths and their impact on the performance of

the system. This experience is used to shape the

decisions made by the agent, mapping from system

state to action. This mapping is referred to as the

decision policy.

In construction production (including factory-

based construction manufacturing) it is not

practicable to experiment with alternative decision

policies using the real system. Construction work is

rarely reproduced making it almost impossible to

compare the effectiveness of alternative strategies.

Artificially reproducing work is also not viable given

the cost and time required to manufacture a

construction component. One way around this

problem is to build a simulation model of the

construction production system, and then to use this

to experiment with alternative policies. This concept

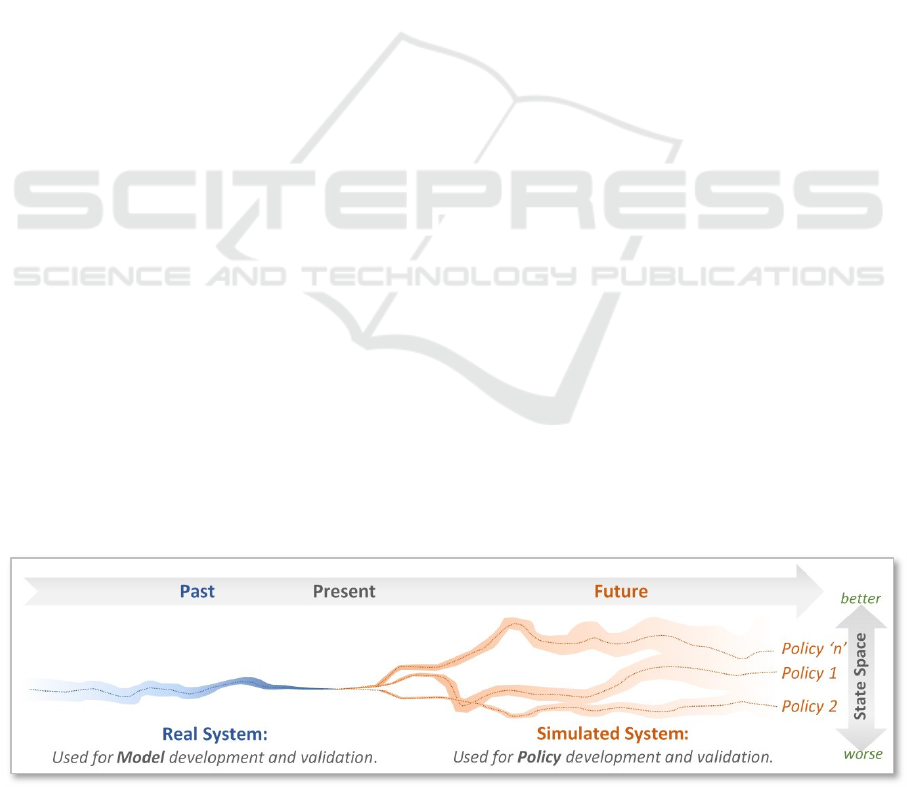

is illustrated in Figure 2, where the blue line

represents the historic path taken by the real system,

and the orange lines represent alternative future paths

Figure 2: Historic path of the real system followed by alternative future paths of a simulated version of the system.

SIMULTECH 2022 - 12th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

114

explored by different policies in a simulated version

of the system. The horizontal axis shows the state of

the system through time. Information about the real

system and its past behaviour would be used to

develop and validate the simulation model. The

information gathered from the simulated system is

used to develop and validate the policy, as described

in section 4.1. For this study, a conceptual design was

chosen for the simulation model, as specified in

section 3.1, designed to test the feasibility of the

approach.

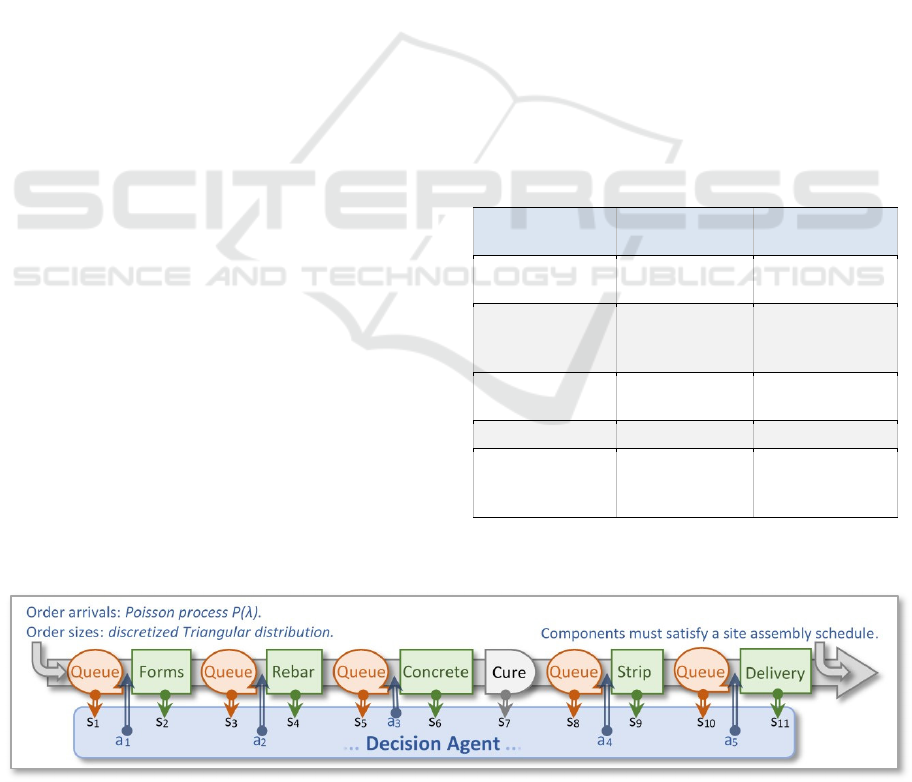

3.1 Production Simulator

Figure 3 shows the production model of the system

considered, representing the manufacture of precast

reinforced concrete (PRC) components such as walls,

floors, beams, and column units. The system is

designed to capture the challenging and somewhat

unique features of construction manufacturing,

namely:

•

orders arrive in a sparse random manner, must be

made to order and cannot be stockpiled;

•

each order consists of a batch of components

variable in number;

•

many if not all components are unique in design

both within a batch and between batches, and

therefore have variable handling times at each

process;

•

all components have uncertainty in the handling

times at each process; and

•

all components must be delivered by a given date

in accordance with a site assembly schedule.

In addition, the study includes the following

assumptions about the logic of the PRC

manufacturing system:

•

the processes are executed sequentially by all

components, in the order shown in Figure 3;

•

the order in which components are served can

change between processes; and

•

each process has only sufficient resources to serve

one component at a time, except the Cure process

which can handle an unlimited number of

components.

The stochastic time related data adopted for this

study, including their distribution types, are given in

Table 1. The dynamics of the system are given by the

relative values of these data (rather than by their

absolute values) and therefore units not included. The

triangular distribution was adopted because it is

computationally inexpensive and yet provides a

versatile way of approximating a wide range of

distribution shapes, including those with skew.

Incoming orders consist of a batch of PRC

components. The number of components in a batch is

sampled from a positively skewed triangular

distribution, rounded to a positive integer. The arrival

of orders is considered to be a Poisson process, with

an arrival rate, λ, selected so that the work demand

and the productivity of the system would balance over

time. Each PRC component is considered to have a

different design and therefore their process durations

(for Forms, Rebar, Concrete, Strip, and Delivery) are

sampled separately. Curing time is considered to be

the same for all PRC components.

On site delivery of a PRC component is measured

as a contingency time beyond the sum of the

component’s process durations, and is also sampled

from a triangular distribution.

Table 1: Modelling the time-related variables.

SYSTEM

VARIABLE

FORM OF

UNCERTAINTY

PARAMETERS

Order arrival time Poisson process

Arrival rate (λ)

1

/

5,000

Batch size

Discretized

triangular

distribution

Min Mode Max

1 20 100

Processes

d

urations

Triangular

distribution

Min Mode Max

50 100 150

Cure

d

uration Fixe

d

~

Contingency time

relative to site

assembly time

Triangular

distribution

Min Mode Max

0 100 200

Figure 3: Production model for precast reinforced concrete (PRC) components.

Intelligent Control of Construction Manufacturing Processes using Deep Reinforcement Learning

115

3.2 Policy Types Considered

The control of the system is undertaken by a decision

agent as shown in Figure 3. Whenever a vacancy

arises at a process, the agent will select a PRC

component for processing from the corresponding

queue, using its current policy. Three alternative

types of policy were considered:

1. A DANN based policy developed using the RL

method described in section 4. The selection of a

PRC component is based on the current state of

the system and predictions about the handling

times for all the PRC components at each of the

processes.

2. A rule-of-thumb policy in which the PRC

component with the least remaining contingency

time in the queue is selected. Note, negative

contingencies (delays) are possible. This type of

policy was included as a performance benchmark

for comparison with the DANN based policy.

3. A random policy strategy in which the PRC

component is selected from a queue using a

uniformly distributed random variate. Again,

this was included as a benchmark for comparison

with the DANN policy.

3.3 DANN Structure

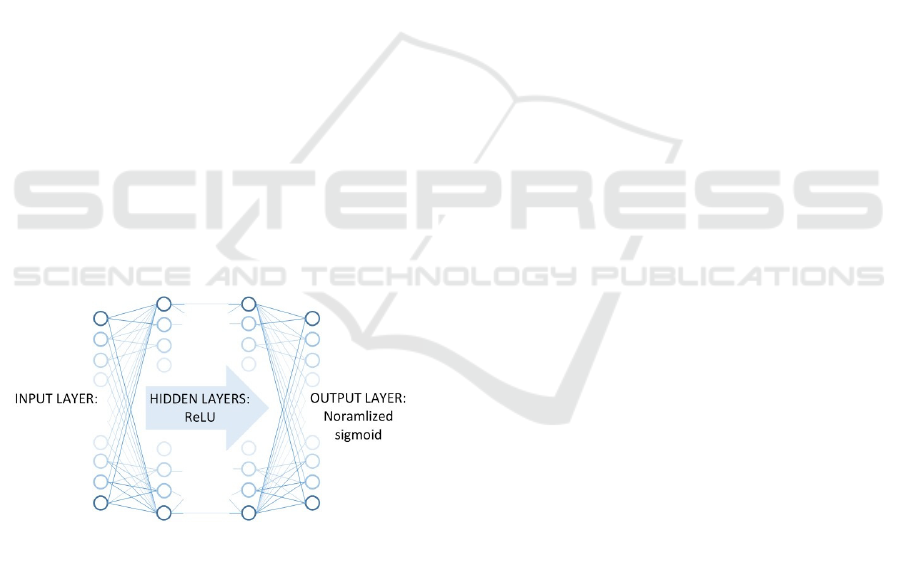

The DANN has a layered feedforward structure as

shown in Figure 4.

3.3.1 Input Layer

The input layer receives both temporal and spatial

information about the state of the system and the work

to be completed. The input values specify the

remaining process durations and the remaining

contingencies for the PRC components currently in

the system. These data are normalized for each

process, so that the values range between 0.0 and 1.0

for each input variable. The location of the values at

the input indicates the relevant queue, the position in

the queue, and the relevant process.

An issue with this approach stems from the fact

that the structure of the inputs to the DANN is fixed

(DANNs are structurally rigid) yet the number of

PRC components in the system that need to be

evaluated is variable. To get around this, the DANN

was designed to allow up to a stipulated number (N)

of PRC components to be evaluated in each queue: if

the number of PRC components in a queue is less than

N then the spare input values are set to 0.0; and if the

number of PRC components in a queue is greater than

N then only the first N PRC components will be

evaluated. Furthermore, the N PRC components

evaluated are those with the least contingency (or

greatest delay), and in this sense this the DANN is a

hybrid with the rule-of-thumb policy. For this study,

N was set to 20 PRC components since the queue

lengths were rarely found to extend beyond this value

for the systems considered. Future work will treat this

as an experimental parameter.

3.3.2 Hidden Layers

The number of hidden layers was set to 6 and the

number of hidden units per layer was set to 64. These

values were found to have the best performance in the

DANN training phase (see section 4.2) in a

preliminary search. A more thorough sensitivity

analysis ranging these parameters is planned for

future work.

All hidden units adopted the ReLU (rectified

linear unit) activation function due its computational

efficiency and avoidance of the vanishing gradient

problem (Glorot et al., 2011).

3.3.3 Output Layer

The DANNs output layer is where the PRC

components are selected from the queues for

processing. All output units use a sigmoid activation

function, thereby limiting their activation to values

between 0.0 and 1.0. The output units are arranged

into groups, with each group representing a different

queue, and with each unit in a group representing a

position in the queue. The number of units in a group

is limited to N, the number of PRC components to be

evaluated in each queue (see section 3.3.1 above).

The current length of a queue or N, whichever is

smallest, determines the number of units that are

active in its group. The values generated at the active

output units in a group are normalized to sum to 1.0.

This allows the output values to be treated as

probabilities for selecting PRC components from a

queue.

Figure 4: Policy implemented as a DANN.

SIMULTECH 2022 - 12th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

116

The DANN based policy has two modes of

operation:

• Exploration. This mode is used to steer the

simulation through alternative partially-random

paths, to gathering high-reward input-output

pattern pairs for training the DANN. Monte Carlo

sampling is used to select PRC components based

on the values generated at the relevant output

units. The higher the value generated at an output,

the more likely the corresponding PRC

component will be selected. The broader strategy

adopted for learning is given in section 4 below.

• Implementation. This mode operates by selecting

a PRC component from a queue based on the

output unit that generates the highest value within

its group. The operation is entirely deterministic.

It is used to control the simulated system in non-

training mode, to validate the performance of the

current policy. In addition, this is the mode that

would be adopted when using the policy to control

the real system.

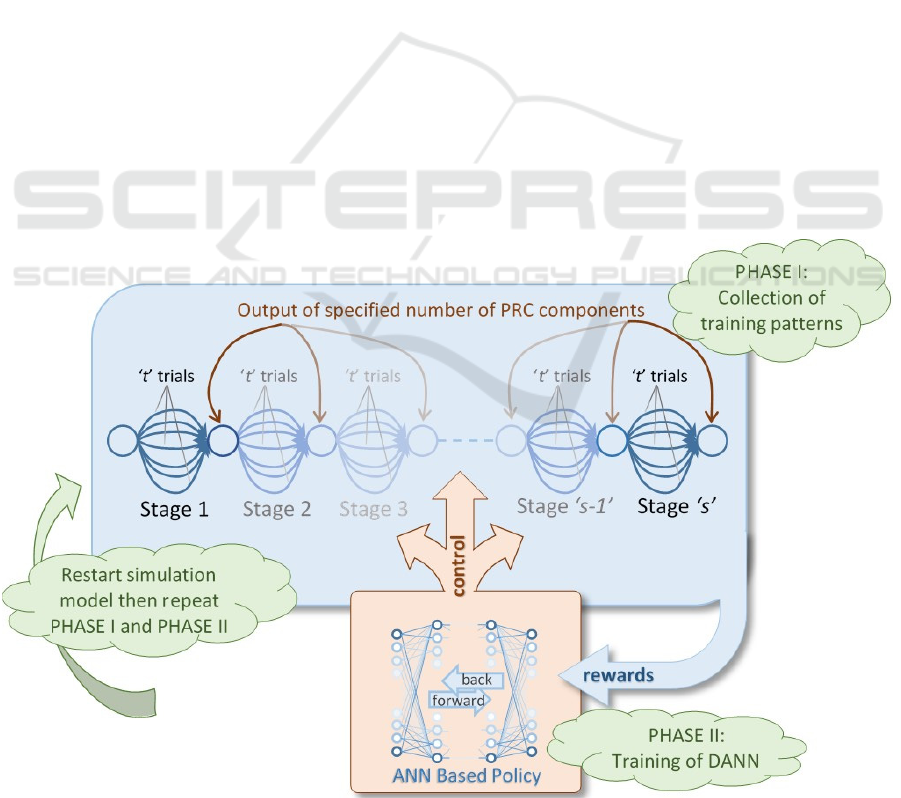

4 DANN LEARNING STRATEGY

DANN development is a deeply nested process, as

shown in Figure 5. The outer level of this process

comprises two main phases: the collection of training

patterns through the exploration of alternative

decision paths; and the training of the DANN. These

phases are cycled through a number of times until

learning converges, each occasion using the most

recent version of the DANN to control the simulation.

Each time the system cycles back to Phase I, the

simulation is reset to the beginning using a new seed

for the random number generator. These phases are

described in detail in the following two sections.

4.1 Collection of Training Patterns

Collecting training patterns is undertaken in a series

of stages ‘s’, as illustrated in the upper blue section of

Figure 5. Each stage experiments with a predefined

number of trials ‘t’ simulating the fabrication of a set

of PRC components. The trial with the best

production performance (see section 4.1.1 below) is

selected for later training of the DANN, and as the

lead-in for the next stage in the simulation. The

training patterns collected are the mappings from

input to output for each state transition in the selected

trial.

This process continues until a specified number of

stages have been completed, each time collecting

training patterns from the best performing trial. For

future studies, parameters that can be investigated in

terms

of optimizing performance are the number of

Figure 5: DANN Development Cycle.

Intelligent Control of Construction Manufacturing Processes using Deep Reinforcement Learning

117

trials per stage, the number of PRC components to be

fabricated per trial (this could be variable between

stages), and the number of stages in the phase.

After completion of this phase, the system moves

to DANN training before returning for another round

of collecting training patterns. The intent is that by

cycle between Phases I and II in this manner, the

policy will move towards a better solution

incrementally.

4.1.1 Production Performance

Production performance is measured in terms of

delays to the delivery of PRC components. The delays

are offset relative to a base value in the cost function

to account for the square component which would

otherwise treat early and late deliveries the same. The

basis of the cost function is the root-mean-square

(RMS) of these delays:

𝑐𝑜𝑠𝑡 =

∑

𝑑

−𝑏

𝑛

(1

)

where:

d is the delay for the i

th

PRC component at its

completion;

n is the number of PRC components completed

at the current trial;

b is the base value against which the delays are

offset - this value is the maximum

contingency time possible for a PRC

component.

4.1.2 Rewards

The learning strategy presented here collects training

patterns based on their success in improving system

performance. For this reason, a training pattern’s

output values are modified from that produced by the

DANN to increase the probability of making the same

selection in a similar circumstance. The modification

(a reward) is to move the selected output value closer

to 1.0, and to move the other relevant output values

closer to 0.0, remembering that the output values are

treated as probabilities of selecting an RC component

from the queue. The extent of the modification will

be treated as an experimental hyper-parameter,

although for this study the rewards will be set to 0.0

and 1.0 without any discount.

4.2 DANN Training

The training patterns collected in Phase I are used to

train the DANN, or to further train it in repeat cycles,

as illustrated in the lower orange section of Figure 5.

The DANN was implemented in Python (Van

Rossum, 1995) and PyTorch (Paszke et al., 2019),

using the optimizer RMSProp (root-mean-square

propagation) and the loss function MSELoss (mean-

squared-error) with reduction set to ‘mean’. Data

loading used a mini-batch size of 64 (with a training

set size typically between 2,000 and 6,000) with

shuffling switched on. The learning rate was set to

0.001.

Training was conducted until the output from the

loss function had converged, which was typically

within 1,000 epochs. Validation of the system was

undertaken after the learning cycle had plateaued.

This involved running the simulation in

implementation mode (see section 3.3.3) using a start

point not used for learning.

5 RESULTS AND DISCUSSION

A series of experiments were undertaken to evaluate

the ability of the DANN to learn, and to compare its

performance with both the rule-of-thumb and random

policies outlined in section 3.2.

The work demand (given by the batch size

distribution for orders and their arrival rate, λ) and the

system’s productivity (determined in part by the

handling times for the processes) were designed to be

in balance for these experiments. The relevant

parameters are given in section 3.1.

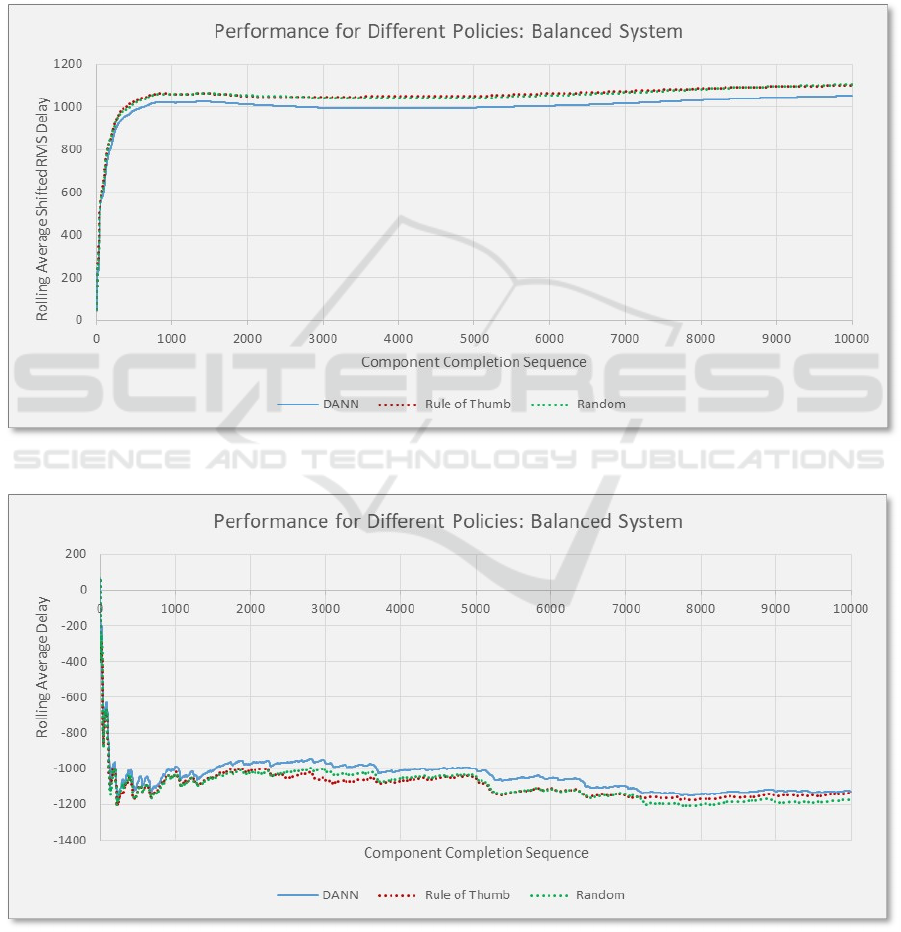

5.1 Short Term Reward Approach

The first experiment was designed to test the

performance of the DANN using a short term strategy

for collecting rewards, monitoring delivery delays in

cycles of 20 PRC components (the mode batch size

used for one order of PRC components).

Training data was collected over a 2,000 PRC

component production run, divided into 100 stages of

20 components each and with 100 trials per stage (see

Figure 5 and section 4.1). Learning was undertaken

for six cycles of Phase I and II, at which point no

further improvement in performance was found. Each

cycle generated around 2,000 training patterns.

After development of the DANN, the simulation

model was reset and run for a 10,000 PRC component

production run for validation purposes. The results of

this experiment are presented in Figure 6, plotting the

RMS of the shifted delays in the delivery of the PRC

components (the Phase I objective function, see Eq.

1) against the component sequence number. Note, the

measure of delay is presented as the rolling average

(the average delay from the first to the n

th

component)

SIMULTECH 2022 - 12th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

118

to capture the collective performance over the

production run. The initial rise in delay in the graph

(over approximately the first 700 components) is due

to start-up conditions in the production system. The

performance of the rule-of-thumb and random

policies are also shown in the figure for the same

production run.

The DANN demonstrated a slightly better

performance than the two alternative policies, settling

at approximately a 5% reduction on this measure of

delay. Interestingly, the rule-of-thumb and random

polices had very similar performance histories

throughout the run. This was found to be generally

true for all experiments undertaken.

Figure 7 presents the same results but for delays

rather than RMS delays. Noting that delays are

measured as negative quantities, a similar conclusion

is found to that drawn from Figure 6, except that the

rule-of-thumb policy becomes more competitive in

the latter stages of the experiment.

Figure 6: Validation run for a short term rewards strategy: shifted RMS delay versus PRC components.

Figure 7: Validation run for a short term rewards strategy: delay versus PRC components.

Intelligent Control of Construction Manufacturing Processes using Deep Reinforcement Learning

119

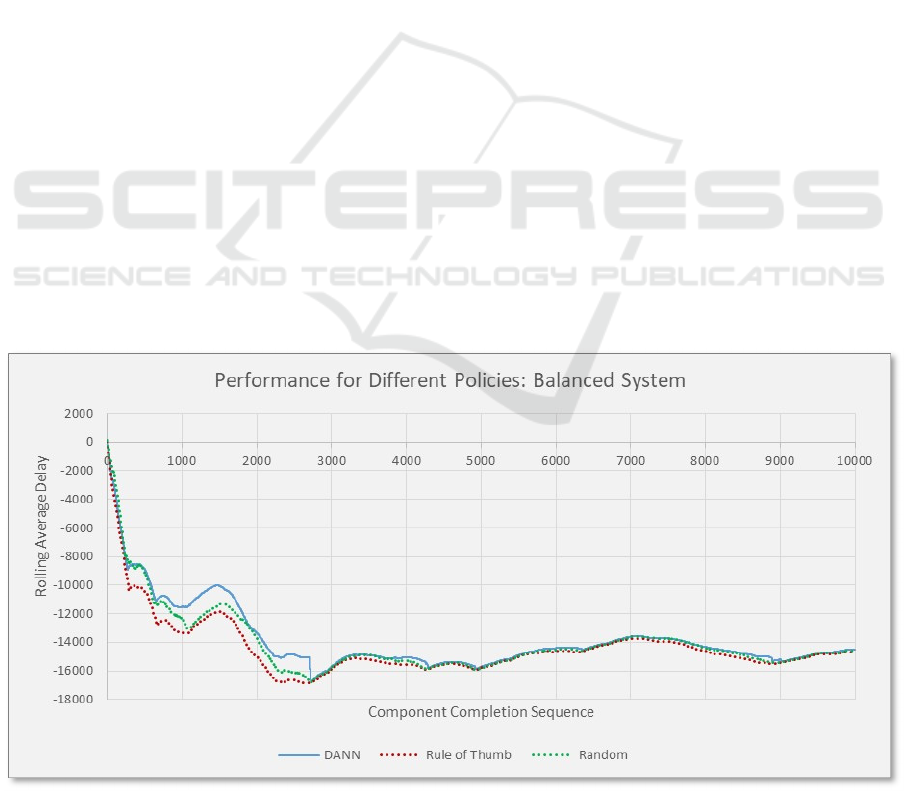

5.2 Mixed Term Reward Approach

The second experiment was designed to test the

performance of the DANN using a mixture of short,

medium, and long term strategies for collecting

rewards. In this case, delivery delays were monitored

in cycles of 20, 40 and 200 PRC components using

separate production runs which were then aggregated

into a single training set.

Training data was collected over three 2,000 PRC

component production runs, divided into stages as

follows:

•

100 stages of 20 components each, with 100 trials

per stage;

•

50 stages of 40 components each, with 100 trials

per stage; and

•

10 stages of 200 components each, with 100 trials

per stage.

Learning was undertaken for five cycles of Phase I

and II, at which point no further improvement in

performance was found. Each cycle generated around

6,000 training patterns.

As in the first experiment, the simulation model

was reset and run for a 10,000 PRC component

production run for validation purposes. The results of

this experiment are presented in Figure 8 for delays.

The DANN generally outperformed the rule-of-

thumb and random policies, except there was a period

(starting around 2,700 components) where its

performance regressed. It is not clear what caused

this, although the DANN appeared to make gains

relative to the other policies when the average delays

were increasing. The DANN does seem to be able to

learn good solutions, but this success is mixed. It

could be addressed by a broader and more

comprehensive set of training runs.

There was no obvious difference between the

learning abilities of the short and mixed term rewards

strategies. Clearly, a thorough analysis of this idea is

required for a range in the term lengths of the rewards.

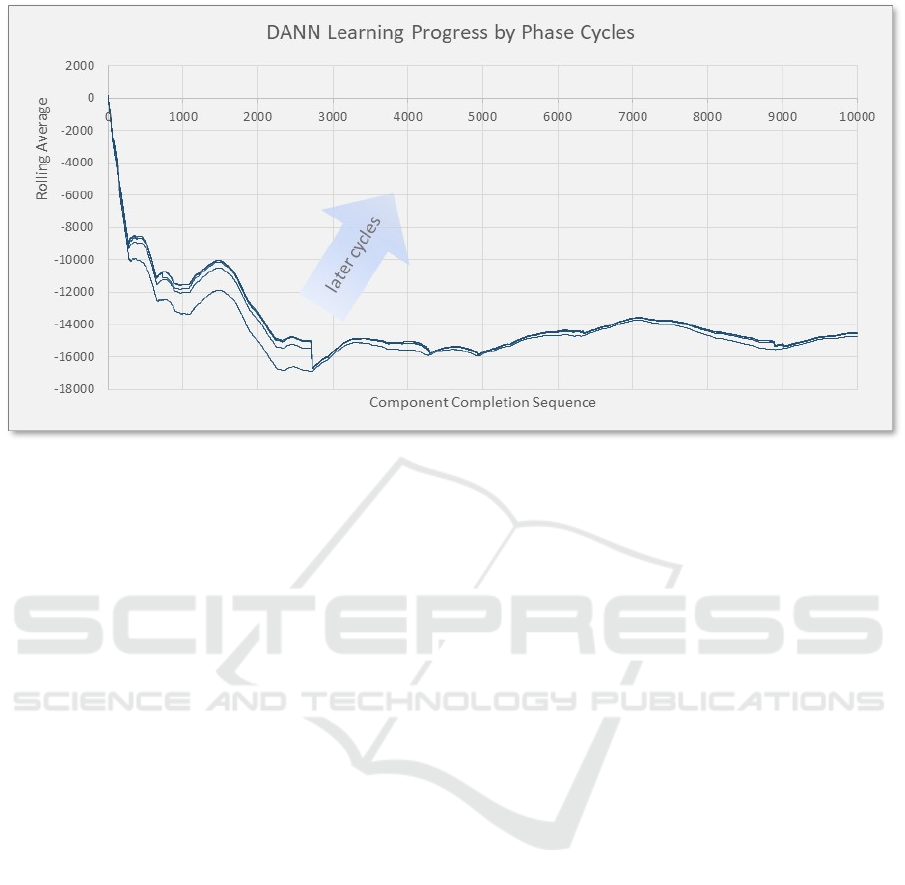

Figure 9 shows the performance of the DANN at

each of the five learning cycles in the 10,000

production run. As expected, the lines higher on the

graph were produced by the later learning cycles,

indicating convergence on a solution. An important

observation from this, however, is that most of the

learning occurred in the region where the DANN

outperformed the rule-of-thumb and random policies

(compare Figures 8 and 9). In other words, the

DANN’s superior performance over its competitors

correlates very strongly with its ability to learn. The

question to be resolved is: what gives rise to the

differences in learning? For example, there could be

a lack of training examples similar to the situation

arising at the reduced performance regions in the

production run - this could be addressed by expanding

training. Alternatively, it could be that there are

situations where improvement in performance is

unattainable, perhaps because the default solution is

already optimal or near optimal. Indeed, the DANN

seemed to learn more when the delays were

increasing in the production run.

Figure 8: Validation run for a mixed term rewards strategy: delay versus PRC components.

SIMULTECH 2022 - 12th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

120

Figure 9: DANN learning progress over the first five cycles of Phase I and II.

6 CONCLUSION AND FUTURE

WORK

The work presented in this paper was concerned with

evaluating the potential of RL trained DANNs to

provide high-performance control of factory based

construction processes. The problem is particularly

challenging given the nature of construction projects:

uneven and uncertain demand, high customization,

the need to fabricate work to order, and a lack of

opportunity to stockpile work.

A preliminary series of experiments showed the

approach to be promising. The DANN outperformed

both a rule-of-thumb policy and a random policy in

the control of long production runs. Although the

improved performance was not maintained for the

entire duration of the production runs, there are many

opportunities for significant further development of

the technique. This is in contrast to the rule-of-thumb

and random policies which have no capacity for

further improvement - they are fixed strategies.

Future work will be aimed at improving the

performance of the RL approach, and increasing the

applicability of the technique to a more diverse range

of construction manufacturing problems.

The following work is planned for performance

improvement of the approach:

•

Increasing the length and diversity of production

runs used for training, thereby increasing the size

and scope of the training dataset.

•

Undertaking sensitivity analyses on the RL hyper-

parameters such as the reward term lengths, the

rewards discount rate, the number of trials per

stage, and the number of stages in a cycle.

•

Undertaking sensitivity analyses on the structure

and architecture of the DANN, including the

number of PRC components to be sampled at the

input (N), the number of hidden layers, the number

of hidden units per layer, and the inclusion of an

ensemble of models.

•

Consideration of the use of alternative RL

algorithms, and the use of heuristic search

techniques to solve the same problem.

The following work is planned to increase the scope

of application of the approach:

•

Case studies aimed at identifying detailed

performance data, logistics, and the practical

issues associated with day-to-day control of

construction manufacturing systems.

•

Increasing the range of state data used for input

and the scope of the type of decisions made by the

decision agent.

REFERENCES

Benjaoran, V., Dawood, N., (2005). An application of

Artificial Intelligence Planner for bespoke precast

concrete production planning: a case study. (ISSN:

2706-6568), http://itc.scix.net/paper/w78-2005-a11-5-

benjaoran.

Intelligent Control of Construction Manufacturing Processes using Deep Reinforcement Learning

121

Chan, W.T., and Hu, H., (2002). Production scheduling for

precast plants using a flow shop sequencing model.

Journal of Computing in Civil Engineering, 16 (3), pp.

165-174.

Flood, I., (1989). A Neural Network Approach to the

Sequencing of Construction Tasks. In proceedings of

the 6th ISARC, San Francisco, USA, IAARC, pp. 204-

211.

Glorot, X., Bordes, A., Bengio, Y., (2011). Deep Sparse

Rectifier Neural Networks. In proceedings of the

Fourteenth International Conference on Artificial

Intelligence and Statistics, Proceedings of Machine

Learning Research, 15, pp. 315-323.

https://proceedings.mlr.press/v15/glorot11a.html.

Leu, S., and Hwang, S., (2001). Optimal repetitive

scheduling model with sharable resource constraint.

Journal of Construction Engineering and Management,

127 (4), pp. 270-280.

Paszke, A., Gross, S., Massa, F., Lerer, A., Bradbury, J.,

Chanan, G., … Chintala, S., (2019). PyTorch: An

Imperative Style, High-Performance Deep Learning

Library. In Advances in Neural Information Processing

Systems, 32, pp. 8024–8035.

Shitole, V., Louis, J., Tadepalli, P., (2019). Optimizing

Earth Moving Operations via Reinforcement Learning,

In 2019 Winter Simulation Conference (WSC), pp.

2954-2965.

Sutton, R., Barto, A. (2018). Reinforcement Learning: An

Introduction, The MIT Press. London, 2

nd

edition.

Van Rossum, G., & Drake Jr, F. L., (1995). Python

reference manual. Centrum voor Wiskunde en

Informatica Amsterdam.

Waschneck, B., Reichstaller, A., Belzner, L., Altenmüller,

T., Bauernhansl, T., Knapp, A., & Kyek, A. (2018).

Optimization of global production scheduling with

deep reinforcement learning. In proceedings of 51

st

Conference on Manufacturing Systems, CIRP, 72, pp.

1264-1269.

Xia, K., Sacco, C., Kirkpatrick, M., Saidy, C., Nguyen, L.,

Kircaliali, A., Harik, R., (2021). A digital twin to train

deep reinforcement learning agent for smart

manufacturing plants: Environment, interfaces and

intelligence, Journal of Manufacturing Systems, Vol.

58, Elsevier, pp. 210-230.

Zhou, L., Zhang, L., Horn, BKP., (2020). Deep

reinforcement learning-based dynamic scheduling in

smart manufacturing. In proceedings of 53

rd

Conference on Manufacturing Systems, CIRP, 93, pp.

383-388.

SIMULTECH 2022 - 12th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

122