Analyses on Human Fatigue and Posture Risk of Demolishing Task

Kun Yu

1a,*

, Yunping Sun

2b

, Jie Huang

1c

, Cannan Yi

3d

and Fan Tang

3e

1

China Ship Development and Design Center, Wuhan, 430064, China

2

Department of Critical Care Medicine, Union Hospital, Tongji Medical College, Huazhong University of Science and

Technology, Wuhan, 430022, China

3

School of Safety & Management Engineering, Hunan Institute of Technology, Hengyang Hunan, 421102, China

Keywords: Demolishing Task, Human Fatigue, Posture Risk, Maximum Endurance Time (MET).

Abstract: Safety plays a key role in ensuring the efficiency of demolition operation. Exploring the fatigue

development of demolition operators in the operation process at the view of safe man-machine and risk

control is not only conducive to improving the safety and humanization of operation design, but also in

favor of ensuring the physical and mental health of operators. This research aimed to explore the law of

development and influencing factors of demolishing task that are contribute to prevent WMSDs and design

assignment for demolishing task. A simulated demolishing task was designed and 10 male college students

were recruited as participants. Then the pushing and griping strength before and after demolishing and

MET, were measured, and the RPE for four limbs and waist after demolishing were collected to explore the

influence of the size of demolition equipment, demolishing height on fatigue for demolishing task. In

addition OWAS was employed to analyze poor working postures and evaluate the risk on demolishing task.

The results show that the decrease degree of pushing strength was significantly greater than that of griping

strength, and the risk of fatigue accumulation was greater. The size of the demolition equipment did not

affect the development of human fatigue in the process of demolition operation. Furthermore demolishing

height had a great impact on MET, which would affect the accumulation of fatigue. The posture risk shows

that the posture risk of 115cm is lower than 65cm, but it also needs to be corrected as soon as possible.

1 INTRODUCTION

1

Demolition equipment is an indispensable tool to

building engineering, road and bridge engineering,

disaster rescue and so on, being used to dismantle

solid reinforced concrete or obstruction (Li 2019).

Demolition equipment is partially automated man-

machine operation system, and it needs human assist

to accomplish a task (Nordmand 2013). As the

clunky of demolition equipment, the complex

components of architectural structures and

equipment vibration and so on, there are many

influence factors contribute to human overload and

operating fatigue, such as high degree of applying

force, strong vibration, repetitive operation and

a

https://orcid.org/0000-0002-5072-8070

b

https://orcid.org/0000-0002-4821-0061

c

https://orcid.org/0000-0003-0338-9106

d

https://orcid.org/0000-0001-9103-3921

e

https://orcid.org/0000-0002-3957-3493

awkward position (squat or creep). The operating

fatigue, which has been accumulated for long, were

likely to cause work-related disorders, this not only

decreases effectiveness, frequent safety accidents,

and brings personal injury accidents, and led to a lot

of business and social damage to property (Prati

2010, Xu 2019). Early research confirmed that long-

term use of demolition equipment can lead to a

greater risk of Work-related musculoskeletal

disorders (WMSDs) (Xu 2017, Phairah 2016). At the

same time, the decreased response and restricted

physical exercise when workers work under the state

of fatigue have a directly impact on the

concentration level and the accuracy level of

operating which are mostly contributed to human's

unsafe behaviors (Zhang 2019). Therefore, it is very

importance to investigate the fatigue of the workers

used demolition equipment for ensuring the work

safety.

The inappropriate man-machine and man-work

assignment match are major cause of WMSDs

(Miller 2007, Wu 2013). The careful reasonable

272

Yu, K., Sun, Y., Huang, J., Yi, C. and Tang, F.

Analyses on Human Fatigue and Posture Risk of Demolishing Task.

DOI: 10.5220/0011292200003438

In Proceedings of the 1st International Conference on Health Big Data and Intelligent Healthcare (ICHIH 2022), pages 272-277

ISBN: 978-989-758-596-8

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

designs of work assignment and workload have

significant preventive effect on WMSDs, and that

need to be analyzed the influencing mechanism

between the physiological function and operating

mission (Ma 2009). So exploring the progression of

fatigue for demolishing task is the essential method

for reducing physiological overhead and preventing

WMSDs. The mechanism of operating fatigue is

more complicated and involves physiological fatigue

and psychological fatigue. The measure of fatigue

involves multiple discipline knowledge such as

biology, psychology and human factors engineering,

and the concrete method includes subjective

evaluation, biomechanical analysis, biochemical

analysis and operational evaluation (Yi 2018). The

combination of several methods to measuring

fatigue will help to more comprehensive

understanding of the progression of operating

fatigue. Studies have shown a good coherence

between these approaches (Hu 2018). The present

research related development of fatigue for manual

demolishing task have concentrated principally on

localized muscle fatigue (Xu 2019, Widia 2009,

Fattorini 2016, Jacquelyn 2016), force distribution in

different positions (Li 2019, Xu 2017, Alabdulkarim

2017), the effects of the human body’s

characteristics to muscle fatigue (Xu 2017, Su 2013,

Bast 2017). However, the above researches mainly

used a single approach to recruit operating muscle

fatigue, focused on the fatigue of the body parts and

particular body postures, and lack of in-depth

research on the development tendency of muscle

fatigue on demolishing task.

The field observation method is the important

assessment tool to research the risk of WMSDs, and

can be used to identify the bad factors associated

with the workplace in the view of human

engineering (Tzu 2013, Wahyudi 2015). In order to

adopt more comprehensive analysis on the

development of fatigue and assessment of risk in

performing a demolishing task, a demolishing task

was designed and arranged. The objectives of this

study were to i) compared the strength of griping

and strength of pushing before and after performing

a demolishing task; ii) explore the influence of the

size of the demolition equipment and the height of

demolishing on operating fatigue, and evaluate the

risk of working posture for demolishing task; and iii)

provide advices on how to lower the risk of WMSDs

for performing a demolishing task.

2 METHODOLOGY

An experiment was conducted in the laboratory to

simulate demolishing task. The temperature and

humidity were 19.21°C (±1.83) and 62.17%

(±14.66), respectively.

2.1 Subjects

Ten male adults volunteered as subjects in the

demolishing task experiment without payment. All

subjects were right-handlers. All of them did not

have a history of WMSDs. They read and signed an

informed consent for participating in the study. The

age, stature, body weight, body mass index were

19.64(±0.7) yrs, 70.85(±8.15)kg, 172.05(±4.85) cm,

and 23.91(±5.92) kg/m

2

, respectively. All subjects

were requested to refrain from strenuous physical

exercise a day before joining the experiment.

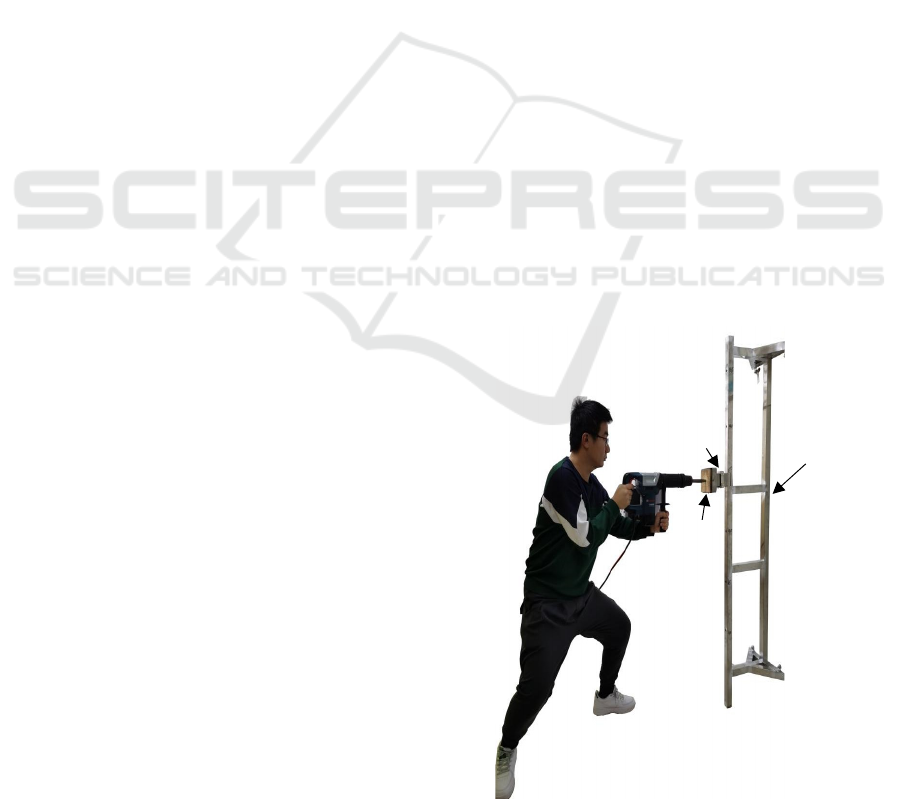

2.2 Apparatus

An apparatus to measure the push strength was

employed. This apparatus encompassed a height-

adjustable fixed mount, a loadcell (FH3D-45), and a

panel (see Fig.1). The panel was made from wood

and had one centimeter of hole in the middle for

determining the position of the bit. Demolition

equipment includes the larger (BOSCH, GSH 9VC,

8.9kg) and smaller (BOSCH, GSH 500, 5.6kg)

size models. Hand grip strength was measured using

a dynamometer (EH101, CAMRY).

Figure 1: Simulated demolishing task.

height-

adjustable fixed

loadcell

panel

Analyses on Human Fatigue and Posture Risk of Demolishing Task

273

A Borg CR-10 rating scale was employed to

measure perceived physical exertion of the subject at

the end of each trial (Gunnar 1990). The Ovako

Working Posture analysis System (OWAS) (Karhu

1977) was employed to analyze poor working

postures and evaluate the risk.

2.3 Experimental Procedure

Before each trial, the subject was requested to do

warm up exercise for five minutes. The isometric

pushing and griping strength were measured at 65cm

and 115cm altitude, respectively. The pushing and

griping strength were MVC

push

and MVC

grip

separately. In this measurement, the postures are

consistent with the experiment.

For the simulated demolishing task, the subject

was instructed to perform a push-forward task

simulating the operation of a wall demolition. One

stood and grasped the demolition equipment using

his both arm and maintained this push until he could

not do so any longer (see Fig. 1). The time of

performing the task was the maximum endurance

time (MET). After demolishing task, the pushing

and griping strengths were assessed once again

which were marked as F

push

and F

grip

. The CR-10

rating of bodily fatigue on the participant’s right and

left upper limb, waist, right and left lower limb were

recorded after each trial. In the trial, OWAS was

employed to encode and grade the demolishing

postures of black, arm, leg and loading.

2.4 Experiment Design & Data

Analysis

Each subject needs to complete four sessions (2

height conditions × 2 device models) of the

experiment. Microsoft

®

Excel was employed for

data analysis and figure preparation. The SAS

®

9.4

was used for statistical analyses.

3 RESULTS

3.1 Strength & MET Statistics

The ANOVA results indicated that the pushing

(p<0.0001) and griping (p<0.0001) strength before

and after the demolishing test were significantly

different. The decreasing degrees of pushing

strength and griping strength were 46.90% and

24.26%, respectively. To account of individual

differences, the average drops of pushing strength

and griping strength were normalized and marked as

FD (FD= (MVC-F)/MVC). The FD of pushing and

griping were 0.23(±0.09) and 0.48(±0.17),

respectively. The t-test results indicated that the FD

of pushing and griping was significantly difference

(p<0.001). The ANOVA results shown that only the

size of the demolition equipment was significant

(p<0.05) to the FD of pushing strength, and the FD

of the larger (0.36±0.16) was significantly lower

compared with the smaller (0.45±0.16). The size of

the demolition equipment was also significant

(p<0.01) to MVC

push

, and the MVC

push

of the larger

(103.15±24.75N) was significantly lower than the

smaller (117.10±28.61N). The ANOVA results

indicated that demolishing height was significant to

MET (p<0.01). The mean (±SD) MET of 115cm

(85.29±37.54s) was significantly higher than that of

65cm (64.64±33.51s). However, the size of the

demolition equipment was insignificant.

3.2 CR-10 Ratings after the Trial

The CR-10 scores among body segments were

statistically significant (p<0.001). Duncan’s multiple

range test results showed that the CR-10 of right

upper limb was significantly higher than other body

parts (p<0.05) (see tab.1). The ANOVA results

indicated that demolishing height was significant to

CR-10 of right upper limb (p<0.05) and waist

(p<0.05). And the size of the demolition equipment

was insignificant to CR-10 of five body parts.

Table 1: Duncan’s multiple range tests for subjective ratings.

Bod

y

p

arts ri

g

ht u

pp

er limb left u

pp

er limb waist ri

g

ht lower limb left lower limb

Mean ±SD 5.88±1.13 3.21±1.33 3.73±1.15 4.25±1.47 2.54±1.48

Duncan’s grouping A D C B E

Different letters in the Duncan’s grouping indicate that they are significantly different at = 0.05.

3.3 Posture Observation

The OWAS are widely used in a variety of tasks and

have well adaptive degree with demolishing task.

The action rankings of demolishing postures were

AC3 (obvious harm) and AC4 (serious harm) (see

tab.2). The action ranking of 115cm posture was

below

65cm, and the urgency of improvement was

ICHIH 2022 - International Conference on Health Big Data and Intelligent Healthcare

274

Table 2: The OWAS’s results for demolishing postures.

Equipment Height Low back Arm Leg Loading

Code of Working

Postures

Action ranking of

Working Postures

The larger

65cm 4 1 4 1-2

4141、4142

AC4

115c

m

3 1 4 1 3141 AC3

The smaller

65cm 4 1 4 1-2

4141、4142

AC4

115cm 3 1 4 1-2 3141、3142 AC3

“as soon as possible to improve” and “immediately

improve”.

4 DISCUSSIONS

Two actions including griping and pushing are

needed to complete the task when using the

demolition equipment, therefore, the changes of

muscle strength in demolishing operation can be

obtained by measuring pushing strength and griping

strength (Xu 2017, ISO 2001). In the experiment, the

decrease of pushing strength (p <0.001)was

significantly higher than griping strength. Li et al.

also showed that pushing fatigue rate (0.056) higher

than griping fatigue rate (0.018)

(Li 2019).

Therefore, it can be seen that the accumulation of

human fatigue caused by the pushing is greater than

that caused by the griping in the demolition

operation under the experiment conditions.

The size of the demolition equipment did not

cause a significant decrease in griping strength but it

related to the MET experimental design. Regardless

of the loading value, the operator continues to work

until he can no longer hold, the muscle strength will

be approximately equal at the end of the trial, and

this result is also illustrated by the fact that the size

of the equipment have no obvious effect on RPE.

The size of the demolition equipment has a distinct

effect on the value of the FD of pushing, which is

mainly dominated by the time factor. After adding

the time factor, the value of pushing strength

reduction per unit time (FD/MET) can be calculated,

which is 0.37 (± 0.19) / min for larger size and 0.37

(± 0.14) / min for smaller size and that was

insignificant difference. The ANOVA result shows

that the size of the demolition equipment has no

significant effect on MET. Therefore, in the

demolition task under the experiment conditions, the

equipment sizes did not lead to a difference in the

development of human fatigue, which may be due to

the smaller weight difference (3.3kg) between the

two sizes of equipment. However, the size of

equipment has a remarkable effect on the value of

MVC

push

, which indicates that the size of the

equipment has an impact on the generative capacity

of pushing strength. The larger the equipment size is,

the heavier the load is, and the worse the generative

capacity of pushing strength is.

Although the demolishing height has no

significant effect on the decrease of muscle strength,

it has a significant effect on the value of MET. At

65cm height, the value of MET is lower than that of

115cm, and the risk of fatigue accumulation is

greater compared with 115cm. The OWAS results

also validated this view from a perspective of

posture risk. The posture code of 65cm is 4141 and

4142, and the risk level is AC4 (serious harm). The

posture code of 115cm height is 3141, and the risk

level is AC3 (obvious harm). The risk level of 65cm

is higher than that of 115cm, which is due to the

different bending degree of waist and right limb

caused by different heights. The results showed that

the bending degree of right lower limb and waist at

65 cm was greater than that at 115 cm, which was

consistent with the striking effect of height on RPE

of right lower limb and waist. The RPE of right

lower limb and waist at 65cm height were 4.68 (±

1.19) and 4.12 (± 1.08) respectively, which were

extremely higher than those at 115cm height of 3.82

(± 1.61) and 3.34 (± 1.20).

The right upper limb has the highest subjective

rating of perceived exertion (5.88±1.13) in the

demolition operation, which is mainly due to the fact

that the right upper limb not only needs to grasp the

equipment but also needs to continuously apply

pushing strength on it. Therefore, the muscle fatigue

of the right upper limb is more serious than that of

the other limbs, so the degree of fatigue of the right

upper limb is an important basis for the subjects to

decide whether to stop the experiment. During the

demolition operation, the left upper limb is mainly

responsible for grasping the auxiliary handle to

ensure that the position of the demolition equipment

remains unchanged, and the muscle force required to

be applied is smaller, and the fatigue feeling is

weaker. The fatigue of the right lower limb is second

only to that of the right upper limb, according to the

feedback from the subjects after the experiment, the

right lower limb should not only keep the trunk

posture unchanged, but also keep the forward trend

Analyses on Human Fatigue and Posture Risk of Demolishing Task

275

by pedaling against the ground in order to

continuously exert the thrust, then, the fatigue

perception of this part is also sensitive. The left

lower limb only needs to maintain the posture of

trunk during the task, so the fatigue feeling of it is

the weakest. The results show that the waist is

slightly twisted to the left and tilted forward during

the application of force, and the RPE of it is at a

medium level. The degree of lumbar fatigue is

mainly influenced by demolishing height (p<0.05).

It is worth pointing out that only two

demolishing heights are considered in the horizontal

demolition operation, and the posture of operator is

squatting posture, which is quite different from

standing posture, sitting posture and crawling

posture. Therefore, the amounts of heights and

postures need to be further increased in the follow-

up research, so as to explore the development of

muscle fatigue in the horizontal demolition

operation more comprehensively. The demolition

operation belongs to the operation of hand-held

electric equipment. In the simulation test process,

the demolition equipment is not working, so its force

application mode is different from the real operation.

Especially when the vibration factor is added to the

running equipment, the characteristics of the

development of human fatigue need be further

studied.

5 CONCLUSIONS

Based on the results and discussions presented

above, the conclusions are obtained as below:

In this study, three methods of operation task

measurement, OWAS method and subjective fatigue

method were used to measure the fatigue indexes

and risks of the operators after completing the

simulated demolition task under different sizes of

equipment and heights. The griping strength,

pushing strength, RPE and posture risk were

obtained to evaluate the WMSDs risk in the process

of demolition task.

In order to better optimize the task and load

design of demolition operators, suggestions are put

forward as follow. Considering the significant effect

of thrust on fatigue accumulation, it is suggested that

the design of the demolition equipment should add a

corresponding booster to reduce the pushing strength

load. Demolishing height has obvious effects on

fatigue accumulation and posture risk, so it is

necessary to set reasonable demolition height in

actual operation. At the same time, protective

measures should be taken to reduce the load on the

right upper limb and back during the operation to

avoid the accumulation of fatigue in these parts

which resulting in WMSDs.

The follow-up study can add more sizes of

equipment, drilling heights to carry out the research.

It is also possible to explore the development of

human fatigue and postural risks in longitudinal and

confined space operating environment. In order to

better evaluate the development of human fatigue

during demolishing operation, follow-up research

can try to build a fatigue prediction model combined

with risk factors.

ACKNOWLEDGEMENTS

This work was financially supported by the National

Natural Science Foundation of China (NSFC)

(71801089), Natural Science Foundation of Hunan

Province, China (2020JJ4263), Guidance Project

Foundation of Hengyang City of Science and

Technology Bureau, China (2020jh052793),

Research-based Learning and Innovative

Experimental Program of Hunan Institute of

Technology.

REFERENCES

Alabdulkarim S, Nussbaum M A, Rashedi E, et al. (2017)

Impact of task design on task performance and injury

risk: case study of a simulated drilling

task.Ergonomics, 60(6): 851-866.

Bast-Pettersen R, Ulvestad B, Farden K, et al. (2017)

Tremor and hand-arm vibration syndrome (HAVS) in

road maintenance workers. International Archives of

Occupational and Environmental Health, 90(1):93-

106.

Fattorini L, Tirabasso A, Lunghi A, et al. (2016) Muscular

forearm activation in hand-grip tasks with

superimposition of mechanical vibrations. Journal of

Electromyography and Kinesiology, 26:143-148.

Gunnar B. (1990) Psychophysical scaling with

applications in physical work and the perception of

exertion. Scandinavian Journal of Work

Environment&Health, 16(S1):55-58.

Hu Hong, Yi Cannan, Li Kaiway, Tang Fan, et al. (2018)

Study on models for evaluating muscular fatigue of

upper extremity for pulling task. China Safety Science

Journal, 28(8) : 61-67.

ISO. ISO 5349-1:2001. (2001) Mechanical vibration -

Measurement and evaluation of human exposure to

hand-transmitted vibration- Part 1: general

requirements.

https://www.iso.org/standard/32355.html,%202001-

05/2021-1-14

ICHIH 2022 - International Conference on Health Big Data and Intelligent Healthcare

276

Jacquelyn M. Maciukiewicz,Alan C. Cudlip,Jaclyn N.

Chopp-Hurley,Clark R. Dickerson. (2016) Effects of

overhead work configuration on muscle activity

during a simulated drilling task. Applied Ergonomics,

53:10-16.

Karhu O, Kansi P, Kuorinka I. (1977) Correcting Working

Postures in Industry: A Practical Method for Analysis.

Applied Ergonomics, 8( 4) : 199-201.

Li Jiale. (2019) Research on Fatigue Test and Work

Ability Improvement of Heavy Physical Workers in

Urban Search and Rescue. Beijing: Capital University

of Economics and Business.

Ma L, Chablatt D, Bennis F, Zhang W. (2009) A new

simple dynamic muscle fatigue model and its

validation. Int. J. Ind. Ergon. 39(1): 211-220.

Miller, Geny. Parker, Christopher. (2007) Human

engineering design for marine systems.

Standardization News. 4(35).

Nordmand Andersen P. (2013) Breakting smart: The future

of hand-held demolition. Sweden: Umeå University:1-

4.

Phairah K, Brink M, Chirwa P, et al. (2016) Operator

work-related musculoskeletal disorders during

forwarding operations in South Africa: an ergonomic

assessment. Southern Forests A Journal of Forest

Science, 78(1):1-9.

Prati G, Pietrantoni L, Cicognani E. (2010) Self-efficacy

moderates the relationship between stress appraisal

and quality of life among rescue workers. Anxiety

Stress & Coping. 23(4):463-470.

Su A T, Maeda S, Fukumoto J, et al. (2013) Dose–

response relationship between hand-transmitted

vibration and hand-arm vibration syndrome in a

tropical environment. Occupational & Environmental

Medicine, 70:498-504.

Tzu Hsien Lee, Chia Shan Han. (2013) Analysis of

Working Postures at A Construction Site Using the

OWAS Method. International Journal of Occupational

Safety and Ergonomics, 19( 2) : 245-250.

Wahyudi M A , Dania W , Silalahi R . (2015). Work

Posture Analysis of Manual Material Handling Using

OWAS Method. Agriculture and Agricultural Science

Procedia, 3:195-199..

Widia M., Dawal S Z M. (2009) The effect of vibration on

muscle activity using electric drill[C]. In Technical

Postgraduates (TECHPOS), 2009 International

Conference for IEEE: 1-5.

Wu Jiabing. (2013) Survey and analysis on risk factors of

musculoskeletal disorders among automobile

manufacturing workers. Wu Han: Huazhong

University of Science and Technology.

Xu Sheng, JIN Longzhe, XU Mingwei. (2019) Study on

muscle fatigue characteristics of drilled workers in

confined space. China Safety Science Journal,

29(03):76-81.

Xu X, Yuan Z, Gong M, et al. (2017) Occupational

hazards survey among coal workers using hand-held

vibrating tools in a northern China coal mine[J].

International Journal of Industrial Ergonomics, 62, 21-

26

Yi Cannan, Hu Hong, Li Kaiway, et al. (2018) Progress in

study on muscular fatigue caused by pulling task and

prospects. China Safety Science Journal, 28( 4) :78-

84.

Zhang Yanjun, Xu Yong, Zhang Xia, et al. (2019) The

Analytical Study of Different Pedal Forces on the

Muscle Fatigue of the Driver’s Legs. Chinese Journal

of Ergonomics 25(6):1-6.

Analyses on Human Fatigue and Posture Risk of Demolishing Task

277