Biofuel Technology: Current Design Principles, Feedstocks Analysis,

Environment Impact and Future Growth

Bocheng Ouyang

1,*

, Yiling Deng

2,a

, Wuqiang Yang

3,b

and Jiaxi Yang

4,c

1

School of Engineering, Pennsylvania State University,University Park, U.S.A.

2

Roedean School, Roedean Way,Brighton, U.K.

3

Peninsula Catholic High School,Virginia 23601 U.S.A.

4

Qingdao No.2 Middle School,Shandong, China

Keywords: Biofuel, Starch-Based Feedstock, Corn: Fermentation, Dry-Grinding, Wet-Milling, Transesterification.

Abstract: This work aims to analysis the advance and disseminate knowledge in all the biofuel-related areas. The biofuel

has been researched and developed in the last two decades. Newly emerged theories and techniques has

prompted the progress of the biofuel commercial application. In this work, the histories of the development

of the biofuels were researched. The physical principle of biofuel reaction was discussed. The two major

feedstocks of producing biofuel and their cultivation technologies were discussed. The major methods of

producing the biofuels including hydrolysis, fermentation, and transesterification were introduced. This work

also analyses the economic and environmental impact of biofuel application.

1 INTRODUCTION

Biofuels, as the name implies, are fuels derived from

biomass, including crops, herbs, and other materials.

The two most common types of biofuels in use today

are ethanol and biodiesel, both of which represent the

first generation of biofuel technology. Today, fossil

fuels are still the main fuel used in most countries, but

it is recognized that fossil energy sources are limited,

and the diminishing availability of fossil fuel

resources is causing prices to skyrocket, and sooner

or later fossil fuels will be depleted, leading to the

creation of renewable energy sources, of which

biofuels are one. While fossil fuels usually take

millions of years to form, biofuels are any

hydrocarbon fuel produced from organic matter in a

short time.

2 PHYSICAL PRINCIPLES

In order to efficiently and economically produce and

apply biofuel, the physical principles of the biofuel

must be understood, which are also true for other

types of fuel.

2.1 Chemical Reactions

Generally, the released energy of the biofuel comes

from the chemical reaction. Chemical reaction, by

definition, is a process that involves rearrangement of

the molecular or ionic structure of a substance.

The rearrangement of the molecule is exhibited by

the breaking of original bonds and formation of the

new bonds. The net energy difference of the

rearrangement is required to be absorbed from or

released to the environment in a form such as internal

energy. Chemical reactions can be investigated and

represented by two different components: reaction

thermodynamics and reaction kinetics.

2.2 Reaction Thermodynamics

Reaction thermodynamics is defined as the system

needing either to absorb or to release energy to the

surrounding environment to proceed the reaction.

Endothermic reactions require absorbing energy (net

input) while the exothermic reactions result in

releasing energy (net output) (Ott, Bevan J.; Boerio-

Goates, Juliana 2000). To examine the

thermodynamic properties of a biofuel, most biofuel

will be observed under steady-state conditions during

the chemical equilibrium. To characterize the

thermodynamic entity, Gibbs free energy was

680

Ouyang, B., Deng, Y., Yang, W. and Yang, J.

Biofuel Technology: Current Design Principles, Feedstocks Analysis, Environment Impact and Future Growth.

DOI: 10.5220/0011254900003443

In Proceedings of the 4th International Conference on Biomedical Engineering and Bioinformatics (ICBEB 2022), pages 680-685

ISBN: 978-989-758-595-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

introduced, which was named after the nineteenth-

century scientist Willard Gibbs. The Gibbs free

energy was commonly presented by the following

form:

∆𝐺 ∆𝐻 𝑇∆𝑆 1

where the G represents Gibbs free energy, H

represents enthalpy, T represents temperature, and S

represents entropy. A negative Gibbs free energy

indicates that the reaction is spontaneous process and

proceeds in the forward direction of the reaction,

while a positive Gibbs free energy indicates that the

reaction is a non-spontaneous process (Li, Khanal

2017). In the equation, enthalpy and entropy can

usually be calculated by the thermodynamics

properties of the reactant and product by the

following equations.

∆𝐻

∆𝐻

,

∆𝐻

,

2

∆𝑆 ∆𝑆

∆𝑆

3

2.3 Reaction Kinetics

Reaction kinetics is another important field to study

for determining the physical properties of biofuels

and their related reaction. Instead of determining the

spontaneity of the reaction by thermodynamic study,

kinetics study determines the rate of process of the

reaction (Hoff, J. H. van't (Jacobus Henricus van't);

Cohen, Ernst; Ewan, Thomas 1896). To simplify the

kinetics study of the reaction, most biochemical

reactions were assumed to occur in an isothermal

environment to preserve the biological activity of the

microbial community. To determine the rate of the

reaction, rate constant k was introduced and can be

represented by the following expression:

𝑘𝐴𝑒

/

4

where the k is the first-order rate constant of the

reaction, A is the Arrhenius constant, E is the

activation energy of the reaction, R is the gas

constant, and T is the temperature. The rate constant,

or the specific rate constant, is the proportionality

constant in the equation that expresses the

relationship between the rate of a chemical reaction

and the concentrations of the reacting substances. By

specifying the rate constant, the reaction rate can be

deducted and represent by the following expression:

𝑟

𝑘𝐶

𝐶

𝐶

5

where the C is the concentration of each component

and. The exponents x, y, and z correlate with the

stoichiometric number of each component according

to the chemical equilibrium in most cases.

3 TECHNOLOGY

IMPLEMENTATION

In order to effectively produce biofuel, raw materials

or so-called feedstocks are also an important field to

study. Based on different bio-properties, the major

categories of feedstocks are starch-based, oilseed-

based, lignocellulose-based, and algae-based

feedstocks. This article will focus on the major and

massive production feedstocks: starch based.

3.1 Starch-based Feedstock

Starch-based feedstocks are grown and cultivated for

food and feed supply. The major crops of Starch-

based feedstocks are cereals (such as wheat, rice,

maize, oat, barley, rye, millet, and sorghum) and

starchy roots (such as potatoes and yams). Based on

the data collecting by FAOSTAT (Etipbioenergy EU,

2012), the total global starch product is around 3.07

billion metric tons at current. Approximately 6% of

the starch production is used for biofuel production,

and the major biofuel product from the starch

feedstock is bioethanol (40%). Corn is the major

cereal crop that produces about 98% bioethanol.

3.2 Corn

This article will use corn as an example of starch-

based feedstock to specify the technical implements

during biofuel production.

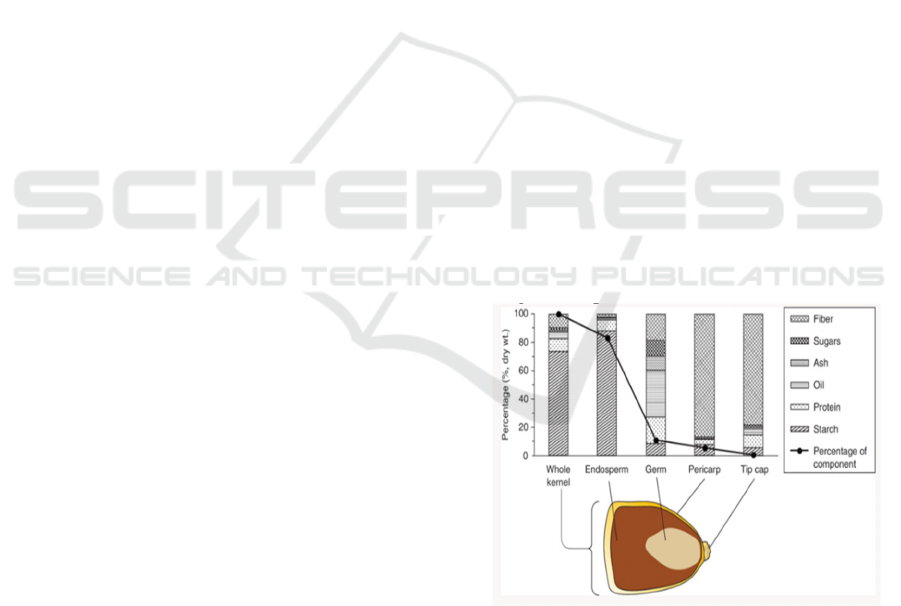

Figure 1: Percentage Components of Corn.

Cron was an original tropical plane only after

centuries of modification, cron was well adapted to

and effectively grown at temperature climates.

Globally, the U.S. is the largest corn producer

providing 35% production, followed by China (21%)

and Brazil (8%). For bioethanol production, Yellow

dent corn (Zeamays var. indentata) is the commonly

Biofuel Technology: Current Design Principles, Feedstocks Analysis, Environment Impact and Future Growth

681

used corn at present. Figure 1. illustrates the profile

of the corn and its composition.

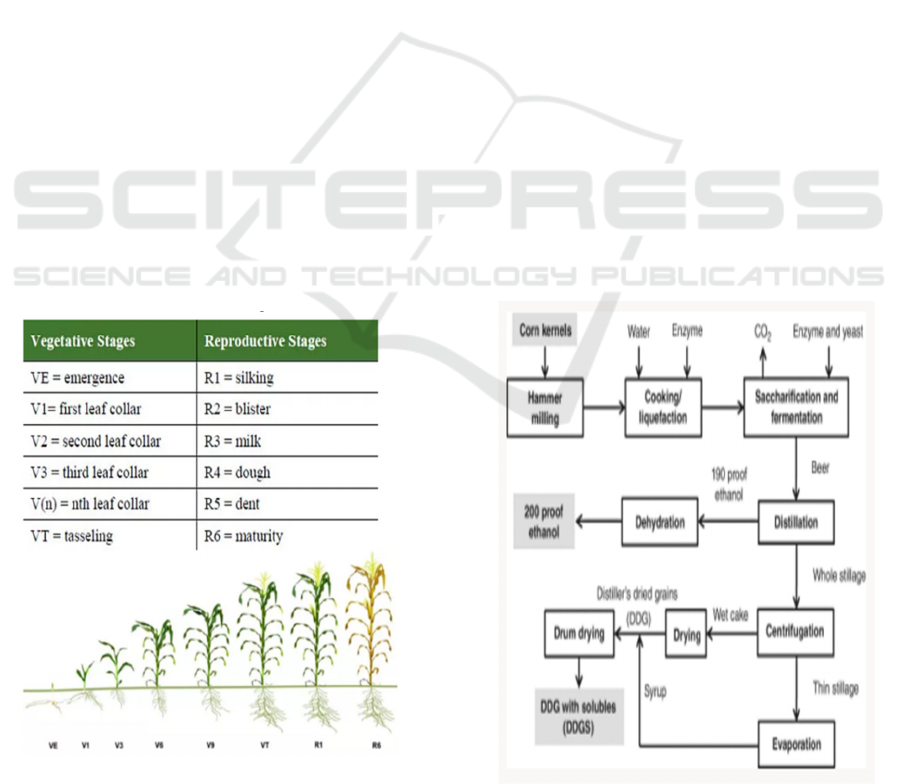

3.3 Growth Cycle of Corn

After selecting cultivars, the corn will be planted to

absorb water and nutrients in the endosperm. The

growth cycle of corn was typically divided into three

stages: emergence, vegetative and reproductive. The

VEG stage is further designated numerically to

represent the highest leaf and visible collar. Such

numerical designation is also applied to the REP

stage representing kernel development. Figure 2.

illustrates the corresponding observation of each

stage.

3.4 Growing Degree Day

Environmental temperature is an important factor

influencing Plant growth. Most plants including corn

can only grow at a temperature above their base

temperature, while the growth rate of the plant

generally increases with the increasing temperature

with sufficient light, water, and nutrients. However, a

ceiling temperature exists for most plants, and the

growth rate will decrease as the temperature reaches

the ceiling temperature. The growing degree day

(GDD) was introduced to reflect the accumulated

heat of a given period of time and predict the plant

growth rate (Prentice, I. Colin et al 1992). Following

expression is the calculation of ht GDD and the

prediction of the GDD for corn growth:

Figure 2: Growth Stage of Corn.

3.5

Bioethanol from Starch-based

Feedstock

To produce bioethanol, two types of processes, wet

milling and dry milling, have been designed and

developed. Both of the processes were able to utilize

the starch-based feedstock to produce while

simultaneously produce co-products.

3.5.1 Fermentation Process

In the fermentation process, the essential step is

hydrolysis since starch-based feedstock cannot be

directly fermented by yeast directly. The upstream

feedstock of starch will be cooked at a high

temperature (90-100℃) with the enzyme alpha-

amylase for gelatinization and liquefaction, which is

able to dissociate the intermolecular bond of starch

feedstock and breaks down to the long-chain

molecule. Then, the liquified feedstock will be

cooked at a low temperature (55℃) to proceed the

saccharification. In most cases, the saccharification

process can be proceeded prior to the fermentation or

simultaneously with the fermentation (Li, Khanal

2017). Recently, a newly designed and developed

enzymes, STARGEN, commence its industry

operation, allowing the starch hydrolysis process to

occur at a low temperature and targeting to reduce the

energy consumption of the fermentation.

3.5.2 Wet Milling and Dry Milling

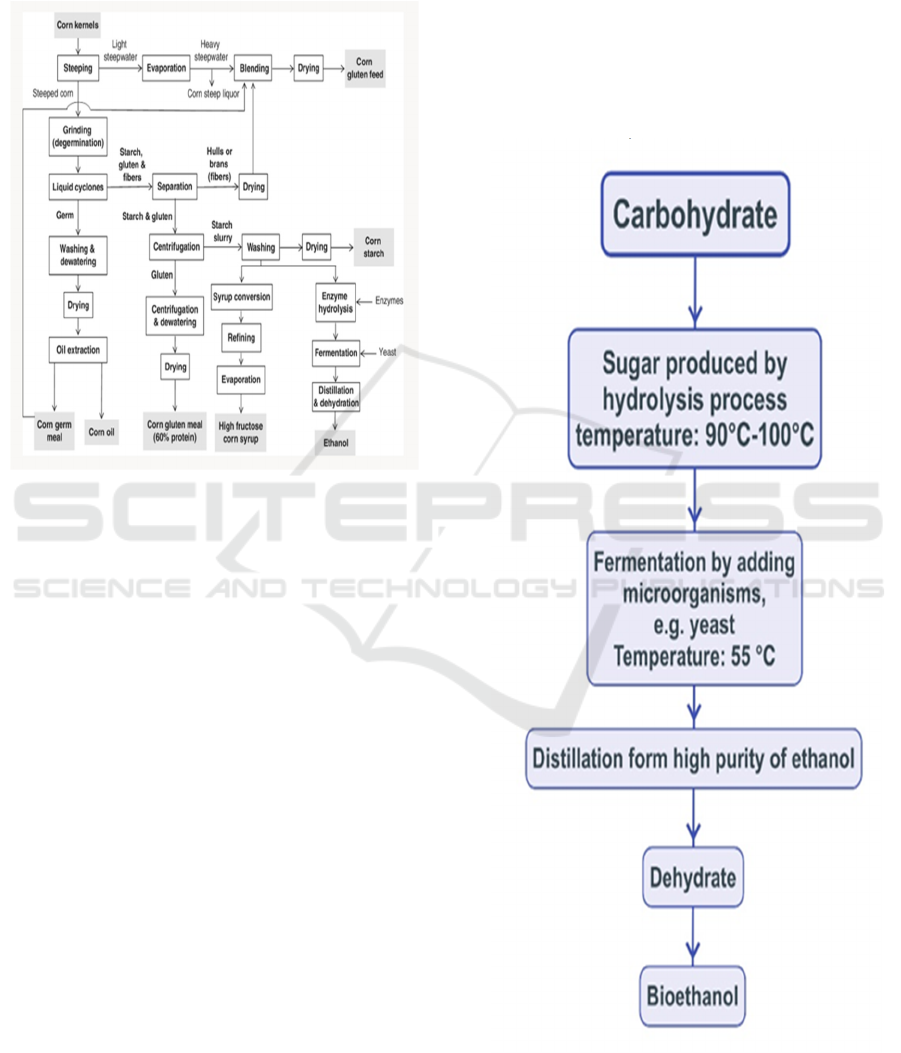

Figure 3: Flow Diagram of Dry Milling.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

682

As aforementioned, two different types of technical

(wet milling and dry milling) were applied. The

following process flow diagrams indicate two typical

fermentation processes of using corn as the starch-

based feedstock.

Figure 4: Flow Diagram of Wet Milling.

The dry milling or dry grind technique is the

major method of producing bioethanol production.

During the dry milling, the whole corn kernel was

ground and mixed with water and enzymes forming a

mash. After gelatinization and liquefaction, the mash

was cooled and mix with more enzymes to proceed

with saccharification and fermentation (Stock 2000).

Figure 3 shows the process of the dry milling.

Instead of grinding corn kernel directly, the wet

milling process allows the corn to steep for 48 hours

and separate into different parts. The germ of the

kernel can be further separated into fiber, starch, and

gluten by processing slurry separation. The wet

milling process produces multiple high value-added

co-products, while also enables “food and fuel”

production. Figure 4 shows the process of the wet

milling.

4 TYPICAL SYSTEM

DESCRIPTION

4.1 Bioethanol

Bioethanol is mainly derived from star-based and

sugar-based and lignocellulose-based natural

materials, such as wheat starch and crops. The

ethanol is produced through several processes, firstly,

those carbohydrates will convert into sugars by

hydrolysis process, those feedstocks would be cooked

under high temperature of 90-100℃. And then, under

the action of microorganism and carbon dioxide,

usually yeast, the feedstock is being fermented at a

low temperature of 55 ℃ which turn into a liquid that

contains ethanol. Finally, the liquid is going to be

refining into high purity bioethanol through

distillation and dehydration.

Figure 5: Production of ethanol with starch-based materials.

Biofuel Technology: Current Design Principles, Feedstocks Analysis, Environment Impact and Future Growth

683

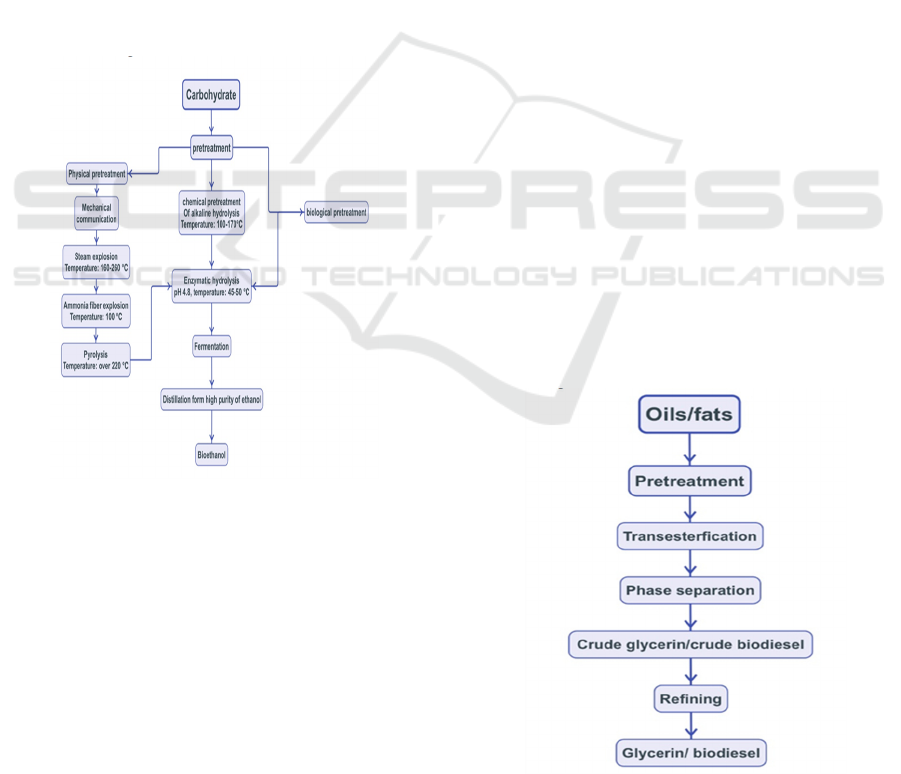

However, for lignocellulose-based feedstock, the

production process and condition required is different

compare to starch-based and sugar-based materials.

Pretreatment is used to prepare the lignocellulosic

material for enzymatic hydrolyses of cellulose and

hemicelluloses to generate fermentable sugars,

including physical, chemical, and biological

pretreatments. Firstly, chemical pretreatment is used

through alkaline hydrolysis at high temperature of

100-170℃.Or physical pretreatment is used,

including process of mechanical communication,

steam explosion (160-260℃), ammonia fiber

explosion (around 100℃) and pyrolysis (over

220℃), or biological pretreatment. After this,

enzymatic hydrolysis converts cellulose and

hemicellulose into glucose and pentose respectively

under the condition of pH 4.8 and temperature 45-

50℃.finally, ferment and distillation the feedstock to

get bioethanol. Figure 5 and 6 indicates the process

of the production of the ethanol via starch-based

materials and lignocellulos-based materials.

Figure 6: Production of ethanol with lignocellulos-based

materials.

4.2 Biodiesel

The feedstock used to produce biodiesel has two

generations, the first generation uses animal fat and

oils from vegetables. Those oils need pretreatments

like degumming, deacidification, bleaching, and

dehydration, the use of pretreatment depends on the

compositions of the materials. Degumming is used to

remove phosphatides from most feedstock;

deacidification is used to remove free fatty acids;

bleaching is used to remove pigments and trace

metals and reduce oxidation; and finally, dehydration

is to remove water from oil or fats, as it is toxic to

transesterification and can affect the efficiency of

biodiesel conversion.

After pretreatment, is the process called

transesterification which can produce glycerin and

biodiesel by using alcohol as reactants, methanol is

commonly used in this process as it is cheaper and

easier to find compared to ethanol. And to separate

glycerin and biodiesel, settling, filtration and

decantation are used to find crude glycerin and crude

biodiesel. To increase the quality of biodiesel, it can

be done through refining.

5 ENVIRONMENTAL IMPACT

The production and use of biofuels can also release

air pollutants other than greenhouse gases that can

affect people and their surroundings. Air pollutants

from biofuels include carbon monoxide, sulfur

dioxide, nitrogen oxides, and ozone; these pollutants

have a variety of effects, including damage to human

health (e.g., cardiovascular disease, and respiratory

irritation) and to the environment (e.g., reduced

visibility, water, and soil acidification, and crop

damage).

Increased biofuel production will dramatically

increase water use, measured at some locations where

corn irrigation or production facilities draw water

from depleted groundwater sources. In some large

corn grain ethanol-producing countries, agricultural

irrigation has been increasing, resulting in

competition for freshwater with other uses (USDA

Foreign Agricultural Service 2018).

Figure 7: Production of biodiesel with first generation

feedstock.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

684

6 ECONOMICS OF BIOFUEL

6.1 Introduction

Biofuel production is constantly developed

worldwide. In the U.S., ethanol production has three

times more than 5 years ago, from 2.8 billion gallons

in 2003 to over 9 billion gallons in 2008. Moreover,

Brazil produces secondly around the world with

approximately 5 billion gallons in 2007.

Biodiesel production is also growing rapidly from

25 million gallons in 2004 to 700 million gallons in

2008 in the U.S, which lays a solid foundation of

maintain the increased demand of renewable energy

in the market. However, recently, markets for fuels

and feedstocks fluctuate dramatically. The prices of

Petroleum have increased from $20 per barrel in 2002

to $140 per barrel in 2008.

6.2 Corn Ethanol

As forementioned, Drys-grind and wet-milling are

two methods of producing ethanol. In the U.S., dry-

grind methods are applied to more than 80% of

ethanol production. The advantage of applying the

dry-grind method is the relatively low capital cost,

which more eco-friendly for most plants. Dry-grind

plants produce ethanol and animal feed. Wet millings,

by contrast, are able to further produce value-added

co-products. Thus, ethanol yields from dry-grind

processes are higher. Table 1 lists the cost of each

typical item of the ethanol production.

Table 1: Ethanol production cost in USDA 2002.

US average

2002 1998

Feedstock costs

($/gal)

0.8030 0.8151

By-porduct credit

($/gal)

-0.2580 -0.2806

Net feedstock

cost

(

$/

g

al

)

0.5450 0.5345

Operating cost

($/gal)

0.4124 0.4171

Total cost ($/gal)

0.9574 0.9516

7 CONCLUSIONS

In conclusion, this work discussed the

thermodynamic principles of biofuels and identified

four major feedstocks of biofuel production.

Focusing on the starch-based feedstocks, the work

introduced the cultivation of corn, which is the major

source of the starched-based feedstock. The process

of the fermentation of the corn was researched. The

typical processes of the biofuel via different

feedstock were introduced and illustrated by a flow

diagram. The economy and commercial application

of the biofuels were also analyzed and concluded as

a sustainable and growing market. In the foreseeable

future, the biofeul will continuely and increasely

replace the current fossil fuels and serves as an

important role in reducing global carbon emmsion

and enviromental impacts.

ACKNOWLEDGEMENTS

We thank Professor Nasr Ghoniem for the full

educational support. Thanks to Mr. Kai Jiang for

holding discussions and providing helpful feedback

and comments.

REFERENCES

Etipbioenergy EU, 2012, Sustainable Feedstocks for

Advanced Biofuels and Intermediate Bioenergy

Carriers Production in Europe.

https://www.etipbioenergy.eu/everyone/biofuel-

feedstocks. Accessed 2021-07-02.

Hoff, J. H. van't (Jacobus Henricus van't); Cohen, Ernst;

Ewan, Thomas (1896). Studies in chemical dynamics,

Kessinger Publishing, LLC.

Li, Y., & Khanal, S. K. (2017). Bioenergy principles and

applications. Wiley Blackwell, Hoboken.

Li, Y., & Khanal, S. K. (2017). Bioenergy principles and

applications. Wiley Blackwell, Hoboken.

Ott, Bevan J.; Boerio-Goates, Juliana (2000). Chemical

Thermodynamics Principles and Applications.

Academic Press, New Yrok.

Prentice, I. Colin; Cramer, Wolfgang; Harrison, Sandy P.;

Leemans, Rik; Monserud, Robert A.; Solomon, Allen

M. (1992). "Special Paper: A Global Biome Model

Based on Plant Physiology and Dominance, Soil

Properties and Climate". Journal of Biogeography. 19

(2): 117–134.

Stock, R. a, J. M. Lewis, T. J. Klopfenstein, and C. T.

Milton. 2000. “Review of New Information on the Use

of Wet and Dry Milling Feed by-Products in Feedlot

Diets.” Jornal of Animal Science 77:1–12.

USDA Foreign Agricultural Service. (2018). USDA

Foreign Agricultural Service Market and Trade Data.

USDA Foreign Agricultural Service.

https://data.nal.usda.gov/dataset/usda-foreign-

agricultural-service-market-and-trade-data. Accessed

2021-07-02.

Biofuel Technology: Current Design Principles, Feedstocks Analysis, Environment Impact and Future Growth

685