Study on the Influence Mechanism of Chitosan on Two Strains of

Petroleum Hydrocarbon Degrading Bacteria

Xiuying Zhao

1a

, Jing Li

1b

, Wu Cui

1c

, Zhiyuan Wu

1d

, Chaocheng Zhao

2e

and Qiyou Liu

2,* f

1

College of Chemical Engineering, China University of Petroleum (East China), Qingdao 266580, China

2

China university of petroleum (east China) state key laboratory of oil pollution control, Qingdao 266580, China

f,*

liuqiyou@upc.edu.cn

Keywords:

Chitosan, Pseudomonas Aeruginosa, Paenibacillus, Petroleum Hydrocarbon, Environment.

Abstract: With the rapid increase of petroleum use in modern industrialization, the leakage in the process of

exploitation and transportation has caused environmental issue. In order to degrade the pollutants in a green

way, it is very important to study the properties of petroleum hydrocarbon degrading bacteria. The effect of

promising immobilized microbial material, chitosan, on the hydrocarbon degrading bacteria was studied by

plate drilling method. It was found that the acetic acid used to dissolve chitosan had a certain inhibitory

effect on the growth and development of microorganisms. Chitosan had the ability to resist such inhibitory

effect and this ability also depended on the strain itself to a certain extent.

1 INTRODUCTION

1

With the accelerating process of industrialization

and the increasing demand for petroleum and its

ancillary products, petroleum, known as the "blood"

of modern industry, will inevitably have a negative

impact on society from exploitation to use (Dai.

2014). The average annual output of oil in the world

is about 4 billion tons. According to the statistics, 2

kg of pollutants enter the environment every 1 t of

oil produced, so about 800 wt of pollutants enter the

environment every year in the world (Wei. 2020).

At present, there are a lot of remediation

technologies for oil pollution, and bioremediation

technology has great application potential because

of its safety, environmental protection, no secondary

pollution and other advantages. Compared with the

use of free cells, immobilized microorganisms have

several advantages. Chitosan, a new functional

carrier material, is the only basic polysaccharide

found in nature so far. It is the product of chitin

deacetylation. Its chemical name is polyglucosamine

a

https://orcid.org/0000-0002-2369-2391

b

https://orcid.org/0000-0001-5974-6710

c

https://orcid.org/0000-0001-8711-3611

d

https://orcid.org/0000-0002-6122-488X

e

https://orcid.org/0000-0001-7374-8448

f

https://orcid.org/0000-0002-2369-2391

(1-4)-2-amino-b-d-glucose. Its good

biocompatibility, strong adsorption and other

excellent properties have been widely studied in

textile printing and dyeing, food, papermaking,

heavy metal recovery, medical and pharmaceutical,

water treatment and other fields research (Gao et al.

2020; Ou et al. 2020). Chitin waste generated by

shrimp culture can be recycled, which is a profitable

source of income in areas with relatively developed

aquaculture industry (Barreto et al. 2010).

CTS molecular surface is rich in functional

groups but can only dissolve in weak acids. It is

reported that in acidic environment, it can adsorb

organic matter but its -NH

2

protonation into

positively charged -NH

3+

will produce certain

inhibitory effect on microorganisms. Therefore, for

chitosan, the material used by immobilized

microorganisms for degrading petroleum

hydrocarbons, we should not only stay in the study

of pollutants but also pay attention to its effects on

different petroleum degrading microorganisms. In

this paper, the effects of different concentrations of

CTS on different petroleum hydrocarbon degrading

bacteria were compared to provide a theoretical

basis for the petroleum hydrocarbon degrading in

the soil environment.

Zhao, X., Li, J., Cui, W., Wu, Z., Zhao, C. and Liu, Q.

Study on the Influence Mechanism of Chitosan on Two Strains of Petroleum Hydrocarbon Degrading Bacteria.

DOI: 10.5220/0011199400003443

In Proceedings of the 4th International Conference on Biomedical Engineering and Bioinformatics (ICBEB 2022), pages 265-268

ISBN: 978-989-758-595-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

265

2 MANUSCRIPT PREPARATION

2.1 Materials

The soil samples used in this study were obtained

from the soil that was not contaminated by oil in

Dongying, China. All other chemicals were of

analytical grade and commercially available. The

chitosan solution is prepared by dissolving powder

CTS in different concentration of HAC.

2.2 Bacterial Strains and Culture

Media

Mineral salt medium was used for sieve bacteria, the

composition was as follows: 1.0 g of (NH

4

)

2

SO

4

, 1.0

g of K

2

HPO

4

, 1.0 g of KH

2

PO

4

, 0.2 g of

MgSO

4

·7H

2

O, 0.02 g of CaCl

2

, 10.0 g of NaCl, 0.3

g of Crude oil in per liter of deionized water. Beef

extract peptone liquid medium was used for inocula

preparation and maintenance, and the composition

was as follows: 5.0 g of NaCl, 5.0 g of beef extract,

10.0 g of tryptone in per liter of deionized water.

Adjust pH to 7. Sterilization for 20 min at 121 ℃.

After 4 weeks of domestication, absorb 1.0 mL of

the supernatant and placed it in a glycerin tube and

stored in the refrigerator for subsequent use.

2.3 Analytical Techniques

The DNA of strain was extracted from the high

efficient petroleum hydrocarbon degrading bacteria

by using universal primers 27f and 1492r. PCR

amplification of 16S rRNA gene was carried out

according to the corresponding system and

procedure. PCR products were sequenced by Beijing

Qingke Biotechnology Co., Ltd. According to the

results of homology comparison, the genus was

preliminarily identified.

2.4 Experimental Design

The CTS was dissolved in 2.0% and 1.0%HAC to

prepare CTS solution with the concentration of

0.1%, 0.25%, 0.5%, 0.75%, 1.0% and 1.5%. The

solution was mixed uniformly by ultrasound and

sterilized at 105 ℃. Add 200 μL of target bacteria

into 20 mL beef agar medium to be solidified, mix

well, and

make a plate. After the plate was

solidified, three uniform holes were made on the

plate with a 6.5 mm diameter punch as parallel

holes. 50 μL CTS solution with different

concentrations was injected into the holes, and 1.0%

and 2.0% HAC was injected into the holes as

control. The diameter of transparent circle was

measured after 24 h cultivation at 37 ℃.

3 TEST RESULTS AND

DISCUSSIONS

3.1 Experimental Results

Six strains of bacteria were screened from oil

contaminated soil, and the oil reduction rate of each

strain was determined. Two different strains were

selected, one was Pseudomonas aeruginosa (TL-1)

and the other was Paenibacillus (YB-1). The

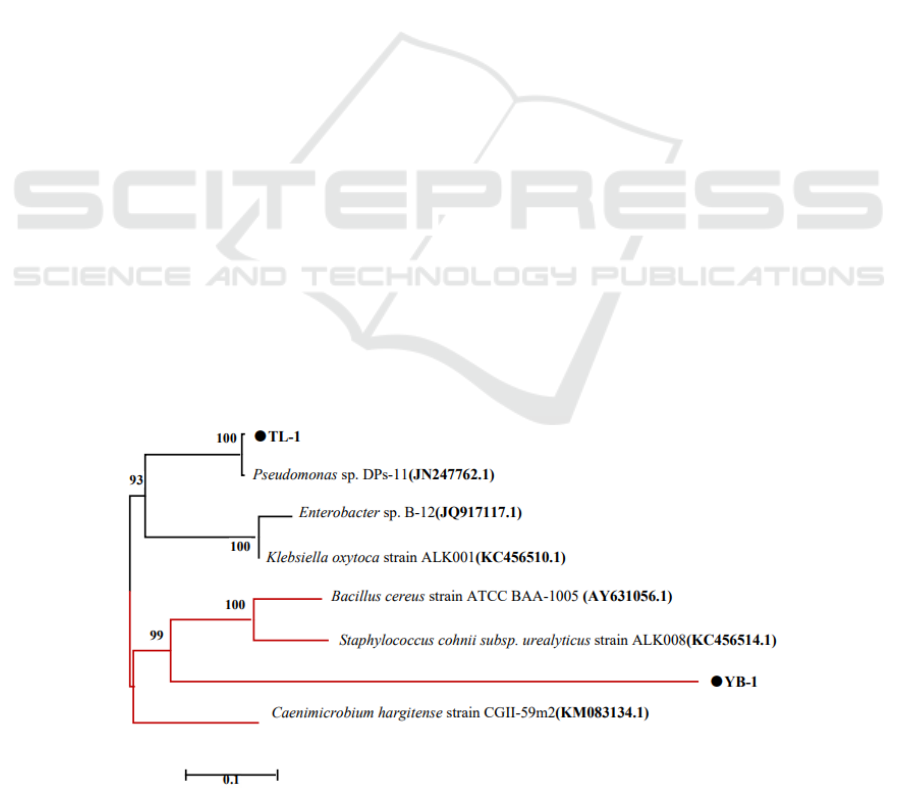

phylogenetic tree based on 16S rRNA sequence is

shown in Figure 1.

Figure 1: Phylogenetic tree based on 16S rRNA sequence.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

266

3.2 Effect of Chitosan on Bacteria

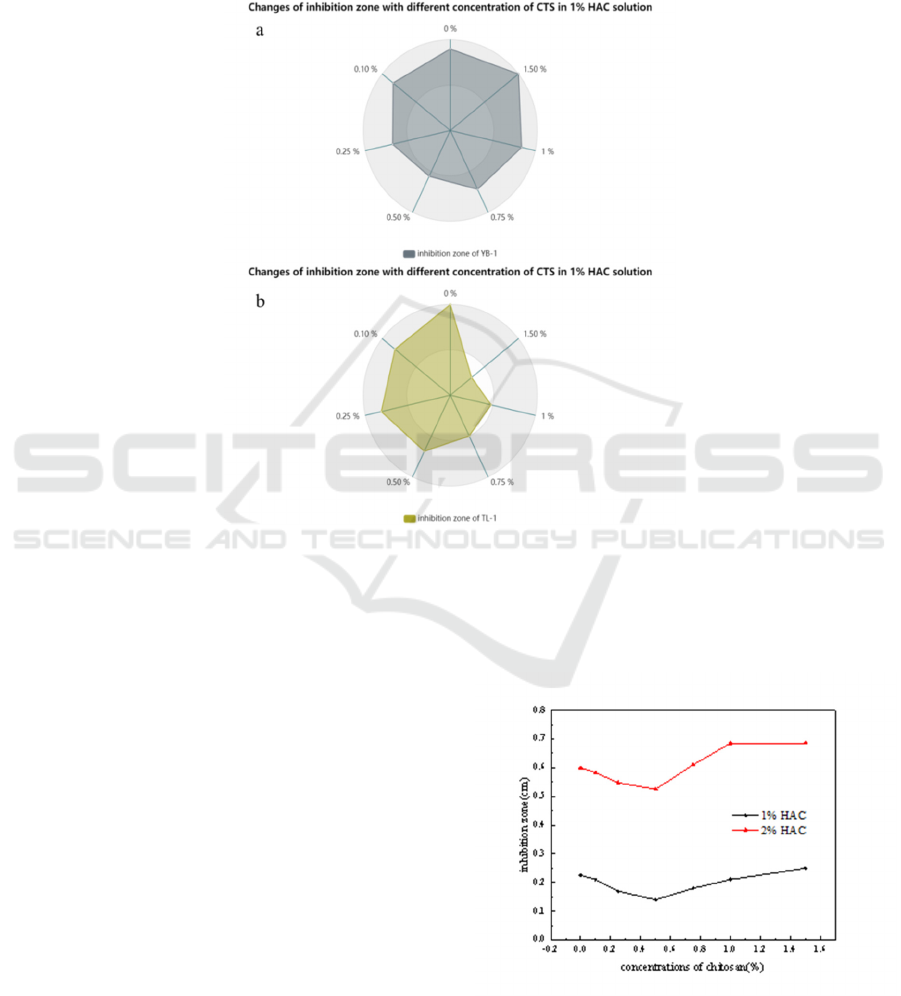

The transparent circle formed by different

concentrations of CTS dissolved in 1% HAC on the

plate of strain YB-1 and TL-1 is shown in Fig. 3.

For strain TL-1, the inhibition zone was the largest

when the CTS addition was zero (1% HAC solution

control group), and then with the increase of CTS

concentration, the inhibition zone gradually

decreased to the minimum when the CTS

concentration was 1.5%.

Figure 2: Inhibition zone of YB-1 and TL-1 in different concentration of CTS and 1% HAC.

For strain YB-1, 1% HAC alone made the

inhibition zone larger, then with the continuous

addition of CTS, the inhibition zone gradually

decreased to the minimum when the concentration

of CTS was 0.5%. After that, the inhibition zone

increased gradually with the addition of CTS, and

there is a trend that the inhibition zone will be larger

than that formed when 1% HAC solution was

injected alone. We speculate that when the

concentration of CTS was less than 0.5%, the effect

of HAC on the strain was dominant and the addition

of CTS could gradually weaken the effect of HAC

on the strain. But, with the gradual progress of the

reaction, the -NH

2

on the surface of CTS in HAC is

gradually protonated into positively charged -NH

3+

,

which makes CTS become a water-soluble cationic

polyelectrolyte.

Variation of inhibition zone of strain YB-1 with

CTS dissolved in different concentrations of HAC is

as shown in Fig. 3. As for YB-1, the inhibition zone

in CTS dissolved in 2% HAC is higher than that in

1% HAC. It can be concluded that HAC is the main

inhibitor in this concentration range, and with the

increase of CTS, not only does it not have a stronger

antibacterial effect, but it can weaken the inhibitory

effect of HAC on strain TL-1.

Figure 3: Variation of inhibition zone of strain YB-1 with

CTS dissolved in different concentrations of HAC.

Study on the Influence Mechanism of Chitosan on Two Strains of Petroleum Hydrocarbon Degrading Bacteria

267

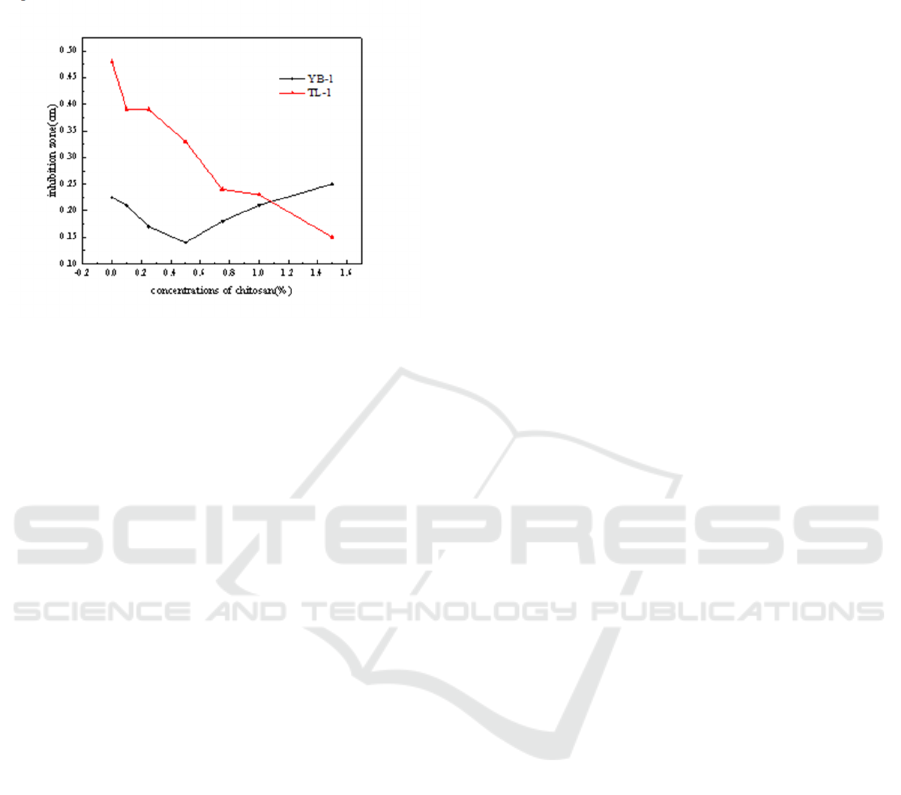

At the same time, the inhibition zone produced

by two strains at different concentrations of CTS

dissolved in 1% HAC was compared, as shown in

Fig. 4.

Figure 4: the inhibition zone of two strains under different

concentrations of chitosan dissolved in 1% HAC.

When the concentration of CTS was less than

1%, the inhibition zone around strain YB-1 was

significantly smaller than that of strain TL-1. The

reason why we got this result is probably because

YB-1 is a Bacillus. The spores produced by YB-1

can produce certain resistance to the external

environment, so it can resist the influence of HAC

on the strain, and the inhibition zone is much

smaller than that of Gram-negative bacteria TL-1.

So the inhibition of HAC on the strain also depends

on the strain itself. Jing Yingjun (Jing et al. 2006)

also pointed out that different molecular weight, pH

value, metal ions and other external factors of CTS

have different antibacterial effects on different

strains, but the key factor of antibacterial activity of

CTS is the strain itself.

4 CONCLUSIONS

In this paper, plate drilling method is adopted to

study the effect of chitosan material on petroleum

hydrocarbon degrading bacteria. The main

conclusions can be summarized as follows:

(1) Two representative petroleum hydrocarbon

degrading bacteria Pseudomonas Aeruginosa and

Paenibacillus were successfully screened out from

oil-contaminated soil.

(2) The main inhibitory factor on strain was

acetic acid, chitosan can counteract this inhibitory

effect under certain conditions.

(3) The inhibitory effect of HAC and CTS on the

strain also depended on the strain itself.

(4) In terms of the future work, how to prepare

immobilized microbial materials by dissolving

chitosan under appropriate conditions to remove

petroleum pollutants should be carried out.

ACKNOWLEDGEMENTS

This study was supported by the Independent Project

Program of State Key Laboratory of Petroleum

Pollution Control (Grant No. PPC2018014) and the

Fundamental Research Funds for the Central

Universities (No. 16CX06008A)., CNPC Research

Institute of Safety and Environmental Technology.

REFERENCES

Barreto, R..V.G., Hissa, D.C., Paes, F.A., Grangeiro, T.B.,

Nascimento, R.F.,Rebelo, L.M., Craveiro, A.A., and

Melo, V. M. M. 2010. New approach for petroleum

hydrocarbon degradation using bacterial spores

entrapped in chitosan beads. Bioresource Technology

101(7):2121–25.

Dai, G. (2014). Analysis of the effect of different

economic management modes on the oil industry.

Economic perspective 20:401.

Gao,X., Z. Li, J. Gong., Q. Li, F. Li, and J. Zhang. 2020.

Research progress on new bio-antibacterial agents for

textiles. Journal of Textile Research 41(02): 187-92.

Jing, Y., Y. Hao, H. Qu, Y. Shan, D. Li and R. Du. 2006.

Preliminary studies on antibacterial mechanism and

analysis of antibacterial activity of chitosans. Chinese

Journal of Antibiotics 31(6):361-65. doi: 10.13461

/j.cnki .cja.003748.

Liu, H., Y. Du, and X. Wang. Liping Sun Chitosan kills

bacteria through cell membrane damage.

Internationnal Journal of Food Microbiology 95(2):

147-55.

OY, X., Sheng, Y. Wang, Y. Lin, W. Chen and Y. Shi.

2020. Preparation of Biodegradable Chitosan

Composite Film and Its Fresh-keeping Application in

Chicken Breast. Food Research and Development 41

(21): 123-28.

Wei, Y. (2020). The Harm and Present Situation of Soil

Oil Pollution. China Resources Comprehensive

Utilization 38(04):120-122.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

268