Application of Enzyme in Pharmaceutical Engineering

Ouyang Tu

YK PAO School, Shanghai, 200333, China

Keywords: Biocatalyst, Enzyme, Pharmaceutical Engineering, Drugs, Lipase.

Abstract: Enzymes have found massive applications as every industry is becoming more environmentally friendly. In

recent decades, the pharmaceutical industry has successfully applied enzymes in drug manufacturing as

catalysts and as a part of API. Biocatalytic progress is mild and green compared to the chemical catalytic

process. This paper discovers the new pharmaceutical engineering progress from three aspects: the

development of biocatalysts, potential risks of biocatalytic process, and a significant biocatalyst-lipase. This

paper also explores the process through recent experiments and achievements, discusses the advantages and

disadvantages of enzyme-catalyzed processes through comparisons with the original chemical catalysts. The

research on biocatalysts helps more scientists and students to learn about the latest techniques and

achievements in pharmaceutical engineering. It’s possible to solve problems associated with complex

molecules and pollutions created by chemical catalyzed processes. The application of enzyme is a crucial

improvement in developing drugs.

1 INTRODUCTION

The enzyme has become an important part of the

food, feed, chemical, biological and pharmaceutical

industries. The application and development of

recombinant DNA and bioengineering using various

enzymes in the past decades (Goutam, 2016), such as

using genetically engineered bacteria to make human

insulin, made huge progress in manufacturing drugs.

As enzymes are environmental-friendly,

biodegradable, and sustainable, biocatalysts are

established as a better alternative to original chemical

catalysts (Liang et al. 2016). Therefore, enzymes are

not only applied in API, multiple kinds of enzymes

are useful in the chemical synthesis of complex

molecules and the improvement of drug qualities. The

conditions of producing enzyme are mild

temperature, normal pressure, and neutral pH level,

which saves cost, energy, and improves the stability

and safety of the production comparing to the

chemical catalytic process. The catalytic efficiency is

100 times higher at least (Andrew et al. 2016). With

these advantages, many biocatalytic and enzymes

have been used for commercial benefits. It’s one of

the reasons for the fast development of

biopharmaceutics. However, it’s still a niche tool in

the whole pharmaceutical engineering. This paper

focused on three aspects of recent achievements and

risks in utilize biocatalysts and enzymes, including

one of the most special hydrolytic enzymes, lipase.

The importance of lipases exceeded the status of

proteases and amylases as the complexity of API

continuously increases, according to the enzyme’s

advantage in chemical synthesis (Saxena et al. 1999).

Different types of medicine required specific

biocatalytic as they have unique chemical functions

of API. Sophisticated compounds can be achieved by

late-stage modification, which requires biocatalysts.

Discovering the suitable biocatalyst through the

process of biocatalytic retrosynthesis followed by

engineering is the basic route. The theory of how to

form multi-functional compounds while ensuring

their reactivity is important (Elvira et al. 2021). Even

though it seems like a time-consuming and expensive

process, it’s still much quicker and cheaper than

finding a new chemical synthesis for the catalytic

process (Andrew et al. 2016).

In the recent development, biocatalysts are

usually used during producing small molecule

intermediates and APIs. Biocatalysts are efficient in

the entire process of developing new medicines,

especially with complex drug targets. Despite the

benefits, there are several risks to be considered.

Investigating potential hazards in the process of API

synthesis using biocatalysts is crucial, as the quality

of drugs should be ensured. There will be some

Tu, O.

Application of Enzyme in Pharmaceutical Engineering.

DOI: 10.5220/0011196900003443

In Proceedings of the 4th International Conference on Biomedical Engineering and Bioinformatics (ICBEB 2022), pages 231-237

ISBN: 978-989-758-595-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

231

residual enzymes in the drug, and these might be

harmful to certain patients. It’s essential to develop

appropriate residual enzyme control strategies when

the drug enters clinical trial to assure the quality by

raising the purity of API (Andrew et al. 2016).

Lastly, lipase is one of the most outstanding

micro-origin enzymes that is known for its massive

contributions and wide application as a biocatalyst

(Rohit et al. 2013). The reason behind this is its

unique attributes. Microbial lipases can be

biocatalytic in both aqueous and non-aqueous

reactions, which differentiates lipases from proteases

and amylases. Its huge potential in organic synthesis

determines its remarkable importance. A magnificent

usage of lipases in the production of chiral drugs,

anticholesterol, and anti-Alzheimer’s are two

examples (Ramesh et al. 2001). As lipase is a micro

origin enzyme, it can be easily extracted from bacteria

with unlimited supplies at any time. Also, it’s

relatively cheap. Lipases are suitable for commercial

applications (Rohit et al. 2013).

The job content of developing medicines with

biocatalysts is using biocatalytic retrosynthesis to

identify suitable synthons, then design the

corresponding biocatalysts. This process needs to be

repeated for every enzyme because each one of them

has unique and distinct composition (Elvira et al.

2021). The details of the process will be discussed in

the next section. The application of biocatalysts is

significant in two perspectives: sustainable

development and medical development. Firstly,

the enzyme-catalyzed process saves an enormous

amount of energy and costs comparing to chemical

catalytic progress. Most enzymes are fairly cheap to

purchase, and the reaction only requires mils

conditions (Andrew et al. 2016). Enzymes are also

biodegradable, so zero pollution is released from the

production. Recently, scientists discovered that when

enzymes are conjugated to stimuli-responsive

polymers, they can protect enzymes by changing their

structures and manage enzymes’ activities when

facing external stimuli. Therefore, enzymes can be

extracted from the reaction mixture effortlessly and

be reused in later reactions (Truppo, 2017). Secondly,

as enzymes are basically proteins from the human

body, they usually have better therapeutical effects.

Protein, hormone, and polypeptide’s molecular

weight is over 10000u, which exceeds the most

advanced techniques of organic chemistry.

Biocatalysts are exquisitely selectivity in protein

engineering, which lead to the success in

manufacturing new drugs with complicated formulas

and solving the bottlenecks in organic chemistry

(Truppo, 2017). By decreasing the price of drugs,

more people can afford the treatment. Overall, the

health condition of the whole population will

increase.

2 LITERATURE REVIEW

2.1 Development and Advantages of

Biocatalyst and LSMs

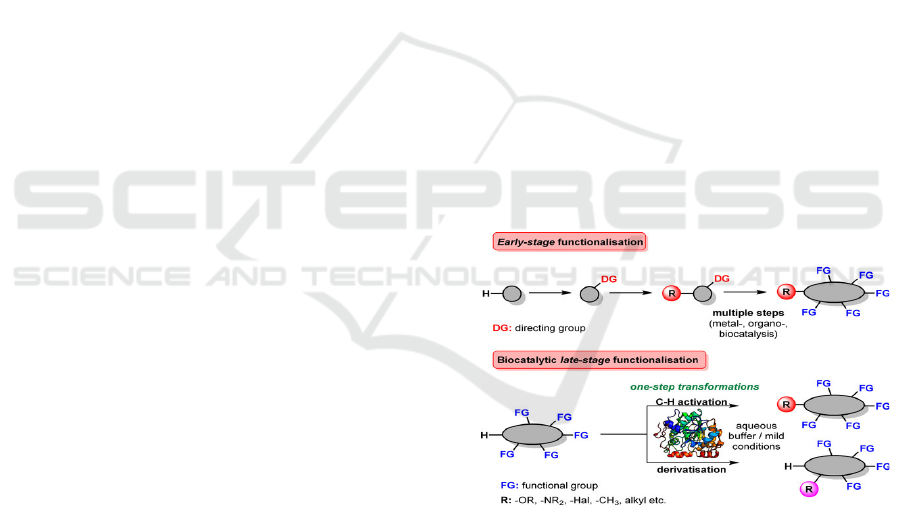

In organic chemistry, the C-H bond is the

fundamental of all compounds. Before enzymes

emerge, the selective modification of the C-H bond is

the top challenge. In early-stage functionalization, the

modification starts from a nonfunctionalized

compound. After multiple steps, the compound is

attached to the same functional group (Figure 1).

There’s no diversification. In late-stage

functionalization with biocatalyst, targeted

modification of C−H and C−heteroatom bonds

becomes realistic. The site-specific transformations

with functional groups on the compound offer

diversification at the final synthetic step. With

various possibilities of multi-functional compounds,

many new drugs are discovered. However, the main

drawbacks of this method are cross-reactivity and

incompatibility due to the different chemical

properties of different atoms (Elvira et al. 2021).

Figure 1: Progress of Early-stage functionalization VS

Late-stage functionalization

Another advantage of applying enzymes is that

enzymes are functional for the synthesis of complex

metabolites in aqueous media with no requirements

of extra costs on protection. An example of metal

catalysis is catalytic metallodrugs, which contain

artificial nucleases and artificial proteases. With a

catalytic metal center and a targeting domain,

catalytic metallodrugs can overcome the limitation of

normal drugs binding reversibly to their targets

(Joyner et al. 2013). This development can

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

232

significantly improve the effectiveness and reduce the

toxicity of drugs (Robinson et al. 2004).

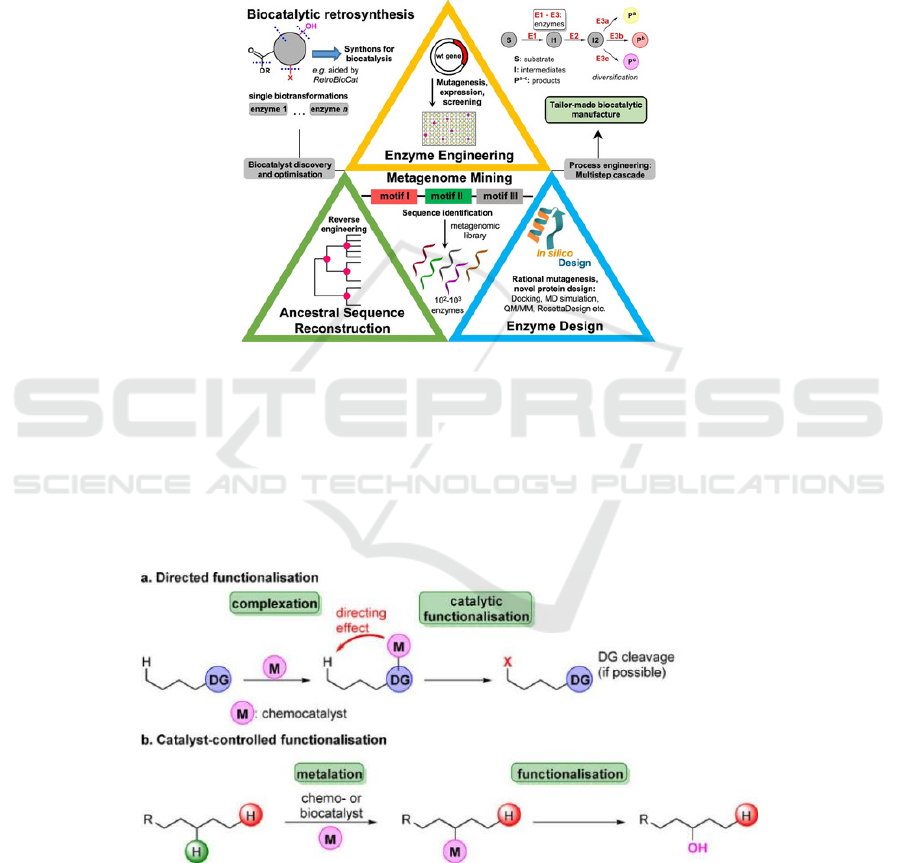

Before the usage of biocatalysts, every substance

requires specified biocatalysts. Using biocatalytic

retrosynthesis on target molecules, which is

disconnecting chemical bonds to identify reasonable

synthons for biocatalysis. The results can be verified

by computer-aided synthesis planning. There are four

ways in the pyramid to screen, design, discover or

engineer the suitable enzyme in order to satisfy the

tailored biocatalytic manufacture (Figure 2). Genetic

engineering, rational mutagenesis, and detect unseen

biocatalysts from nature are three common, potent

methods to increase biocatalyst diversity. Ancestral

sequence reconstruction is a new method. The

artificial ancestors of known enzymes are likely

endued with higher robustness and can accept

extended types of substrates (Elvira et al. 2021).

Figure 2: Process of developing tailored biocatalysts.

Even though the bond energy of C-H does not

always have a positive correlation with the reactivity

of the compound, the bond strength still decides the

selectivity of activation in most of the reactions. The

C-H bond is directed functionalization is affected by

a metal ion. Comparing to catalyst-controlled

functionalization, biocatalyst protects the C-H bonds

by using a site-specific modification (Figure 3).

Therefore, in this example, the reactivity of the

hydrocarbon compounds manufactured by directed

functionalization is probably lower than hydrocarbon

compounds manufactured by catalyst-controlled

functionalization (Elvira et al. 2021).

Figure 3: Directed functionalization and catalyst-controlled functionalization.

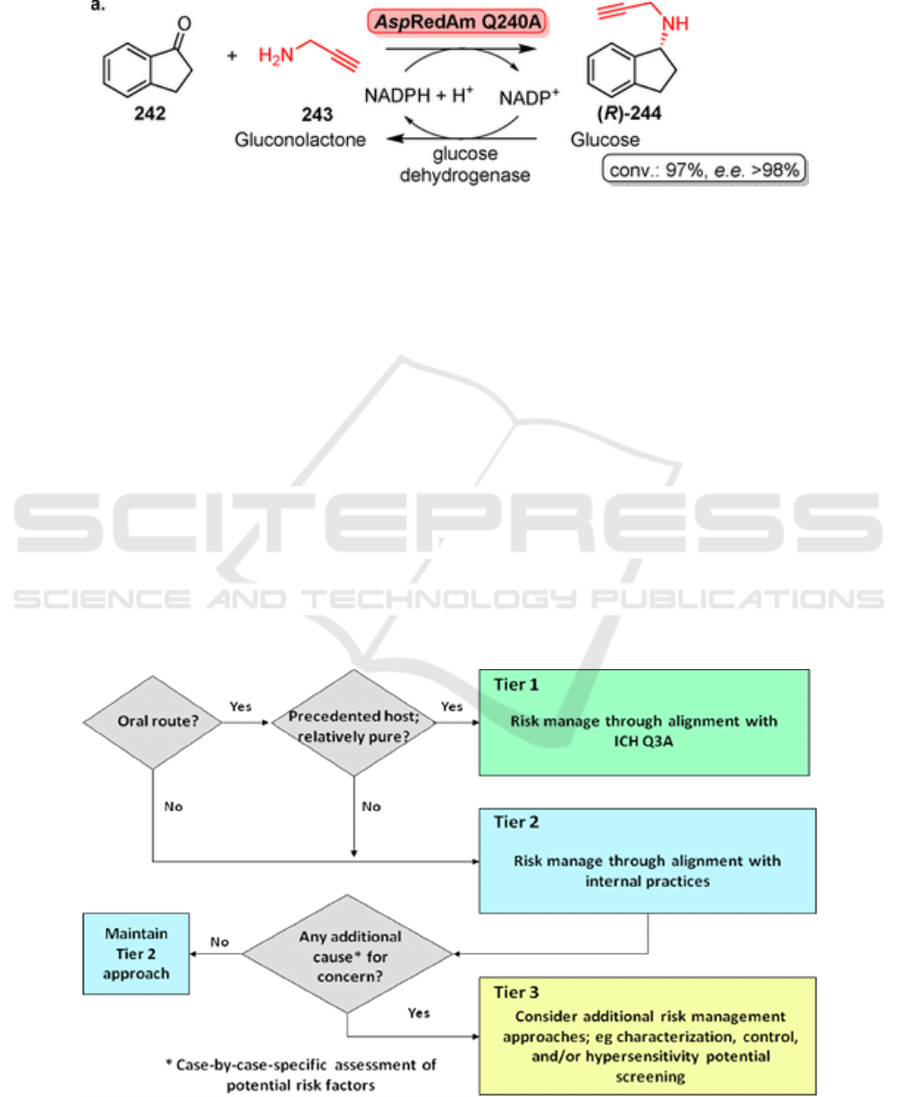

The development of enzyme makes the

manufacture of complex compounds with high yields

possible. In 2011, a survey shows that amide

couplings are applied to 16% of all reactions in

medicinal chemistry. As one of the most commonly

used motif, the improvement in biocatakysts are

crucial. The biosynthesis of tabtoxin discovers a

miscellaneous ATP-grasp enzyme, TabS. It is able to

constitute variety of dipeptides from unprotected

amino acids. The suitable dipeptides including 136

Application of Enzyme in Pharmaceutical Engineering

233

types of amino acid combinations is a supreme

challenge for chemical engineering. The original

method to produce 244 is by the usage of different

biocatalytic approaches on prochiral ketone precursor

(242) or the racemic amine (rac-244). The application

of AspRedAm, which produce 244 from 242 and

propargylamine (243), has the conversion of 97% in

Figure 4 (Elvira et al. 2021).

Figure 4: Biocatalytic approaches for (R)-rasagiline (244) synthesis.

2.2 Quality of Drug Manufactured by

Biocatalyst

For the procedure of selecting appropriate enzymes,

biocatalytic retrosynthesis and a reliable database can

be helpful. Publishing detailed rules and guidelines of

biocatalytic retrosynthesis can require chemists to

have a deeper understanding of the structures and

properties of the molecule as they need to investigate

the potential transformations and applicable

intermediates for the biocatalytic process. The

support of computer-aided synthesis planning can

ensure the enzymes are viable. A database containing

information on identified and practiced biocatalytic

reactions are also extremely conducive to chemists. If

they can check the safety, scalability, substrate scope,

conversions, and productivity of a range of suitable

biocatalysts before the real experiment, so time and

money can be saved. As engineering, a workable

biocatalyst is already more cost-effective and less

time-consuming than chemical catalysts without the

database, the positive effect on the whole

manufacturing process’ efficiency, sustainability, and

safety will assure the drug quality (Andrew et al.

2013).

After the usage of biocatalysts, some residue

enzymes are possibly left in API. The property and

safety data of the protein residues should be

considered in science-based risk assessment. For

example, amino acids and peptides are not toxic.

Furthermore, ease patients should fill an individual

risk assessment according to their condition to clarify

their endurance to protein residues (Andrew et al.

2013) (Figure 5).

Figure 5: Basic tiered risk assessment.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

234

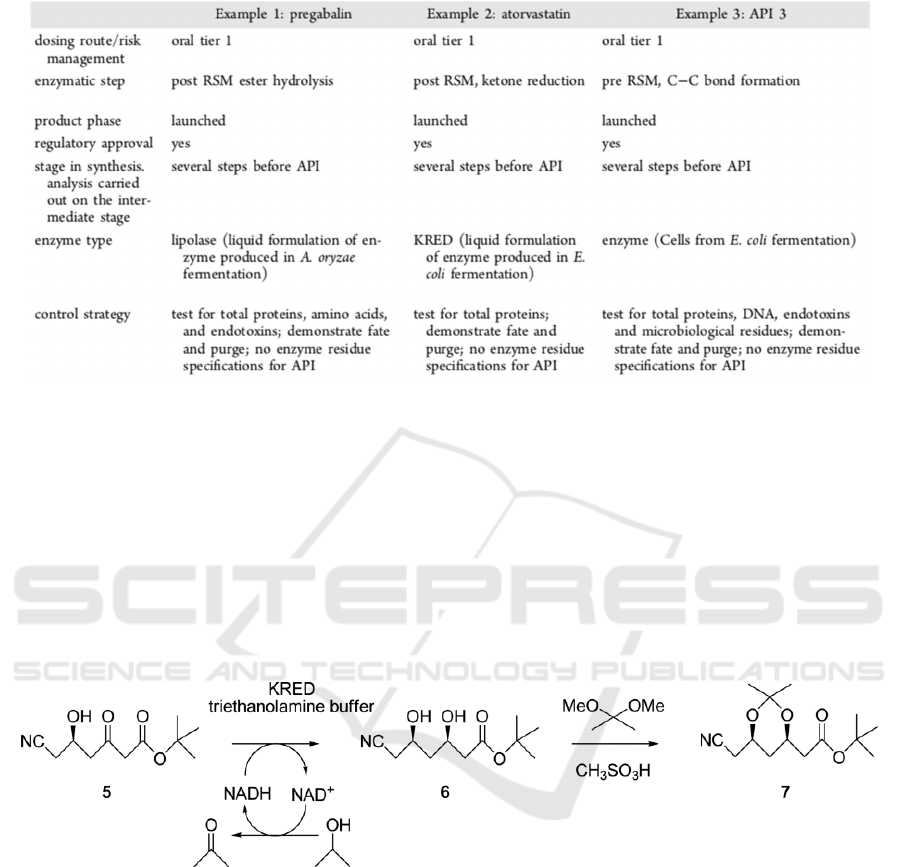

Table 1: Enzyme Fate Across Three API Projects.

During the manufacture of API, continuous

operations are enabled to remove residue enzymes.

E.g., filtration, distillation, and pH adjustment. None

of the residue proteins from enzyme preparations are

expected to pass through the operations with the API.

Therefore, the anticipation is the absence of residue

enzymes in intermediates and APIs in Table 1. The

production of atorvastatin is a piece of supportive

evidence. A biocatalytic process is carried out for the

synthesis of Acetonide 7, which is a crucial

intermediate in the formation of atorvastatin as can be

seen from Figure 6. The procedure was implemented

by adding acetone to recombinant E, an organic layer

containing diol 6, and an aqueous phase containing

the enzyme are formed. The analysis of crude 6

samples and isolated intermediate 7 both from 4 lots

have the result of no perceivable protein (Bradford

protein assay, LOD < 0.01%). This data demonstrates

that separating aqueous and organic phases can

practically remove residue enzymes, which proves

the absence of residue enzymes in atorvastatin. All

agencies responsible for drug registration approved

the strategies of not assaying residue enzymes in APIs

(Andrew et al. 2016).

Figure 6: Chemoenzymatic synthesis of pregabalin.

Pregabalin, which is the API in Lyrica, is also

manucfactured through a chemoenzymatic process.

as can be seen from Table 1. 3 samples form 10 lots

are tested with Bradford protein assay, and 20 lots are

tested with the Micro BCA assay for total proteins.

The result is no residue protein are perceived with

LOD 0.04% w/w and LOD < 0.1). After

derivatization with EZfaast, 24 commercial lots of

pregabalina are also analyzed with LC/MS/MS. None

of the samples have amino acidsabove the LOD

(0.05%) (Andrew et al. 2016).

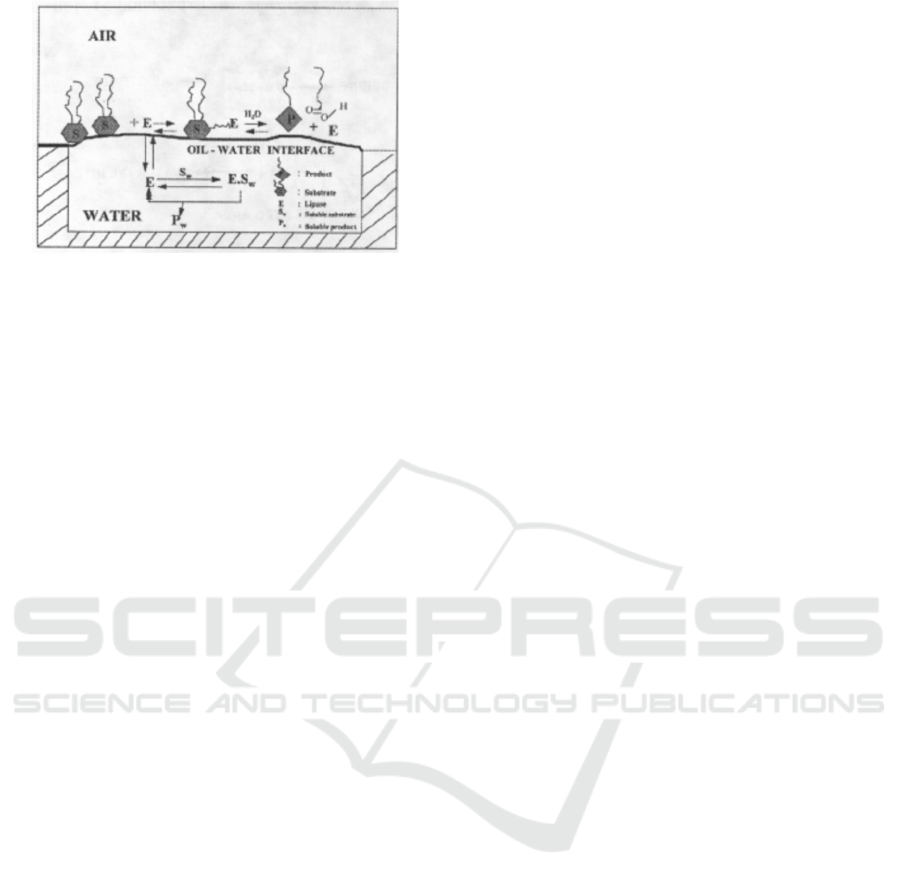

2.3 Contributions of Lipase

Lipases have become the top choice in enzymes for

organic chemists, pharmacists, and other professors

because of their unique properties. The activity of

lipases can be easily controlled as it only works at the

oil-water interface in Figure 7. Fats are only

hydrolyzed in this certain condition. By adding an

emulsifier, followed by stirring, the interface area

will increase constantly until its limitation (Saxena et

al. 1999). Therefore, the efficiency of API

manufacturing and the efficacy of drugs containing

lipases can reach the optimum.

Application of Enzyme in Pharmaceutical Engineering

235

Figure 7: lipolytic reaction at the oil-water interface.

According to the properties mentioned above,

lipases are very popular in organic synthesis. Lipases

can be applied in the discovery or development of

drugs using the method of organic synthesis.

Chemists can manage the speed of the reactions easily.

Additionally, catalysts are always expensive, so

lipases enabled more chemists to implement more

researches without worrying about costs by the

technique of crude enzyme preparation. The

regiospecificity and strong tolerance to a variety of

organic substances make lipases even more suitable

and capable for the catalyst of organic synthesis as

most of the enzymes do not have these two properties

(Saxena et al. 1999).

Lipases also have magnificent contributions to

chiral drugs due to their enantioselective and

regioselective nature. The effectiveness and efficacy

of many drugs rely on chirality. With the ability of

selective reaction at functional group and the

preference of forming enantiomers, preparing chiral

drugs intermediates using biocatalysts is well

recognized (Rohit et al. 2013). For example, one of

the key intermediates in the synthesis of an

antihypertensive drug, Diltiazem, is successfully

produced after lipases solve the hydrolysis of epoxy

ester alcohols (Saxena et al. 1999).

Most of the biocatalysts have disadvantages, such

as being easily affected by heat, poor stability, require

a neutral pH level and room temperature. It is simple

for enzymes to become denatured. Although enzymes

are relatively cheap, they should be employed for at

least 3 months or 30 batches. Any accidental denature

that happened is considered a loss. Nowadays,

scientists are trying to discover thermostable

biocatalysts as thermo stabilization is a necessary step

to improve the robustness of enzymes (Shakya et al.

2018). Robustness of enzymes is especially vital

because designing biocatalysts requires enzymes to

constantly expose in the probably unstable

environment of organic reactions, which increases the

chance of denaturing and inactivation. Normally,

thermo stabilization is achieved by accumulating

numbers of mutations in directed evolution. However,

the potential risk is to sacrifice the catalytic function

(Shakya et al. 2018). Thermophilic lipases have been

discovered in recent decades. It can endure harsh

conditions while keeping the former advantages. Also,

it is extracted from various microorganisms, for

example, escherichia coli (Rohit et al. 2013).

Microbial origin lipases then become one of the best

choices in enzymes.

3 CONCLUSION

The emerging, developssment and application of

biocatalysts in pharmaceutical industries have

effectively made the industry more advanced and

more reliable. LSF is the fundamental support of

successful drug developments. The achievement of

complex scaffolds, which stimulates the

diversification of compounds, determines the huge

progress made in modern synthetic organic

chemistry. Comparing to chemical catalytic progress,

biocatalysis is more sustainable, cost-effective, and

environmentally friendly. Testing in the API

specification is not necessary, because the basic

chemical operations can purge residue proteins.

Therefore, the possible risks of residue enzymes don't

really exist. Lipases are one of the most important

biocatalysts. The special properties of lipases solved

many crucial problems and produced many complex

intermediates that have no resolution in the chemical

industry now. It is not just applicable in various

industries, but also the best catalyst to many

pharmaceutics. Despite the significant achievements

of lipases, more researches are needed to completely

understand it.

Biocatalysts will probably be more important and

widespread in pharmaceutical engineering by

assessing the potential commercial benefits that

enzymes can create. The whole process of

engineering biocatalysts will have huge

improvements and become significant on drug

discovery. The most crucial part is to apply computer-

aided synthesis planning in recognizing possible

synthons and choose the most efficient process to

design the suitable biocatalysts (Elvira et al. 2021).

With the tremendous efforts of some drug companies

inventing drugs with enzyme-catalyzed processes, the

environment will be better when we dispose of less

toxic gases and chemical products. More complex

diseases can be treated and more people will ve cured.

The application of biocatalysts offers something more

beneficial than engineering tanglesome molecules or

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

236

solving problems in organic chemistry. The

healthcare and life expectancy in the world will

slowly increase. Scientists and pharmaceutics have

only learned the tip of the iceberg, there are so much

to explore, expand and reinforce.

ACKNOWLEDGMENTS

Writing a paper about new techniques can be very

challenging for a high school student. I want to

appreciate Professor Axel for teaching me basic

knowledge of pharmaceutical engineering, so I have

the chance to explore this topic. My TA, Ben, also

explains and expands professor’s contents, which

enables me to understand and write about the niche

topic. Ms. Wang helps me to state and paraphrase my

ideas into a paper, so I should be thankful to her, too.

Lastly, my parents are always being supportive and

helpful. Without them, I might not have the courage

and capacity to write this paper. Once again, I would

like to express my heartfelt thanks to everyone who

helped me.

REFERENCES

Andrew S. Wells, John W. Wong, Peter C. Michels, David

A. Entwistle, Keith Fandrick, Gregory L. Finch,

Animesh Goswami, Heewon Lee, Stefan Mix, Thomas

S. Moody, Long Pang, Robert K. Sato, Nicholas J.

Turner, and Timothy J. Watson. (2016). Case Studies

Illustrating a Science and Risk-Based Approach to

Ensuring Drug Quality When Using Enzymes in the

Manufacture of Active Pharmaceuticals Ingredients for

Oral Dosage Form, pp.594-600.

Elvira Romero, Bethan S. Jones, Bethany N. Hogg, Arnau

Rué Casamajo, Prof. Martin A. Hayes, Prof. Sabine L.

Flitsch, Prof. Nicholas J. Turner, Dr. Christian

Schnepel. (2021). Enzymatic Late-Stage

Modifications: Better Late Than Never.

Eric J. Moore, Dmitri Zorine, William A. Hansen, Sagar D.

Khare and Rudi Fasan. (2017). Enzyme Stabilization

via Computationally Guided Protein Stapling, National

Academy of Sciences, Vol. 114, No. 47, pp. 12472–

12477.

Goutam Brahmachari. (2016). Biotechnology of Microbial

Enzymes, Academic Press, pp.6.

Joyner J. C., Cowan J. A. (2013). Target-directed catalytic

metallodrugs, Brizillian Journal of Medical and

Biological Research, Vol.46, No. 6.

Ramesh N. Patel. (2001). Enzymatic Synthesis of Chiral

Intermediates for Drug Development.

Robinson, Mark A., Stuart T. Charlton, Philippe Garnier,

Xiang-tao Wang, Stanley S. Davis, Alan C. Perkins,

Malcolm Frier, Ruth Duncan, Tony J. Savage, David A.

Wyatt, Susan A. Watson, Benjamin G. Davis, Robert

Langer. (2004). “LEAPT: Lectin-Directed Enzyme-

Activated Prodrug Therapy, National Academy of

Sciences, Vol. 101, No. 40, pp. 14527–14532.

Rohit Sharma, Vishal Thakur, Monika Sharma, Nils-Kåre

Birkeland. (2013). Biocatalysis Through Thermostable

Lipases: Adding Flavor to Chemistry, Thermophilic

Microbes in Environmental and Industrial

Biotechnology, Springer, Dordrecht, pp.905-927.

Saxena, R., Ghosh, P., Gupta, R., Davidson, W., Bradoo,

S., Gulati, R. (1999). Microbial lipases: Potential

biocatalysts for the future industry, Current Science,

Vol. 77, No. 1, pp. 101–115.

Shakya, Akhilesh Kumar, Kutty Selva Nandakumar. (2018).

An update on smart biocatalysts for industrial and

biomedical applications, Journal of the Royal Society,

Vol. 15, No. 139.

Truppo, Matthew D. (2017). Biocatalysis in the

Pharmaceutical Industry: The Need for Speed, ACS

medicinal chemistry letters, Vol. 8, No. 5, pp. 476-480.

Youyun Liang, Mingzi M. Zhang, Ee Lui Ang, Huimin

Zhao. (2016). Biocatalysis for Drug Discovery and

Development.

Application of Enzyme in Pharmaceutical Engineering

237