Experimental Study on Adsorption of Methylene Blue in Wastewater

by Bamboo Leaves Powder

Fang Zhang

a

, Boxu Jia

b

, Huiping Xiao

c

and Fangfang Li

d

Environmental Engineering of City Construction Department, Wenhua College, No. 8, wenhuayuan Road, Wuhan East

Lake High-tech Development Zone, Wuhan, China

Keywords: Dye Wastewater, Adsorption, Bamboo Leaves, Software Simulation, Software Optimization.

Abstract: Adsorption is one of the common methods for treating dye wastewater. The existing adsorbents still have

the problems of high cost, difficult disposal and secondary pollution. Agricultural and forestry wastes with

low price and rich sources can be applied to the treatment of dye wastewater. The effect of bamboo leaf

powder on the adsorption of methylene blue was studied. The effects of particle size, dosage, temperature,

adsorption time and pH on the adsorption effect were studied. The results showed that the optimal single

factors were: the particle size is less than 0.25mm, the dosage is 0.4g/100mL, the temperature is 20 ℃, the

adsorption time is 50min and pH is 8. Study on the adsorption kinetics indicated that pseudo-second-order

kinetic model could better describe the kinetic behaviour. Comprehensively considering the interaction

among multiple factors, the optimization experiment was designed by the Optimal mode of Design-Expert

software, and the factors were optimized by the response surface method. The results showed that the

optimal conditions were: the dosage is 5.37g/L, the adsorption time is 65.47min, the temperature is 25.17

℃, and pH is 6.7. The results showed that bamboo leaf is a potential natural adsorbent for methylene blue in

wastewater.

1 INTRODUCTION

1

Most of the dyes contained in dye industrial

wastewater are synthetic dyes with stable molecular

structure and poor biodegradability. It is an

important factor causing water pollution. Fenton

oxidation, catalytic oxidation, biodegradation and

adsorption are often used in the treatment of dye

wastewater. Among them, adsorption is widely

recognized because of its low cost, simple treatment

method and high treatment efficiency (Gao 2018,

Donkadokula 2020).

Among the existing adsorbents, activated carbon

has good adsorption properties, but it is not suitable

for the primary treatment of dye wastewater because

of its high cost and difficult regeneration. Mineral

adsorbents, coal and slag adsorbents have a wide

range of raw materials and low cost, but the

subsequent disposal is difficult and the secondary

a

https://orcid.org/0000-0002-8466-4458

b

https://orcid.org/0000-0002-3508-6524

c

https://orcid.org/0000-0002-6423-6958

d

https://orcid.org/0000-0001-6793-3452

pollution is also a problem that cannot be ignored.

The adsorption resin has good effect, easy

regeneration and simple operation, but the high cost

limits its large-scale use. As a possible adsorbent,

agricultural and forestry wastes have the advantages

of low price and rich sources, and can be applied to

the treatment of dye containing wastewater.

China is the country with the most abundant

bamboo resources in the world. Bamboo can not

only be used for physical processing and making

appliances, but also for extracting chemicals from

bamboo knots, leaves, branches and roots. Bamboo

charcoal and bamboo vinegar can be prepared by

pyrolysis. Bamboo charcoal can be used as fuel, and

to make activated carbon and then applied in

environmental pollution control, and as conductive

materials (Zhang 2020, Isa 2016, Jiang 2021).

Bamboo vinegar can be used as soil disinfectant,

composting accelerator, feed additive and plant

growth regulator (Zhang 2021). As a kind of forestry

waste, bamboo leaves have the potential to adsorb

dye molecules in wastewater. At present, there are

few reports on the adsorption of dyes in wastewater

by bamboo leaves (Wu 2019, Yang 2017).

166

Zhang, F., Jia, B., Xiao, H. and Li, F.

Experimental Study on Adsorption of Methylene Blue in Wastewater by Bamboo Leaves Powder.

DOI: 10.5220/0011192800003443

In Proceedings of the 4th International Conference on Biomedical Engineering and Bioinformatics (ICBEB 2022), pages 166-174

ISBN: 978-989-758-595-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

In this study, bamboo leaves were used as raw

materials and methylene blue aqueous solution was

used to simulate the wastewater containing

methylene blue. The effects of adsorption conditions

such as bamboo leaf powder particle size, dosage,

temperature and pH on the adsorption effect of

methylene blue in wastewater were studied, and the

mechanism of adsorption process was explained by

fitting the adsorption kinetics. Finally, the Optimal

model of Design-Expert was used to optimize the

experimental design of response surface, and the

optimal reaction conditions of bamboo leaf powder

adsorbing methylene blue were obtained.

2 MATERIALS AND METHODS

2.1 Materials

The Moso bamboo leaves were collected from the

campus and washed with tap water, then rinsed with

distilled water, and dried in an oven at 60 ℃. The

dried bamboo leaves were then grinded into powder,

screened to obtain powder with particle sizes of <

0.25mm, 0.25-0.4mm, 0.4-0.5mm, 0.5-0.8mm and

0.8-1.0mm, and then stored in sealed bags. The main

reagents used in the experiment are methylene blue

(analytical purity), HCl (analytical purity) and

NaOH (analytical purity).

2.2 Instruments

Main instruments used in this study contains

thermostatic oscillator (SKY-200B), ultraviolet

spectrophotometer (UV2450) and pH meter (PB-10).

2.3 Methods

2.3.1 Effect Evaluation of Bamboo Leaf

Powder Adsorbing Methylene Blue

Title

(1) Standard curve of absorbance and methylene

blue solution concentration

Methylene blue solution with concentration of

100mg/L was prepared and diluted to 2, 4, 5, 6 and

8mg/L, respectively. After zeroing with distilled

water at 662nm on the ultraviolet spectrophotometer,

the absorbance of the diluted solutions was

measured. The standard curve was drawn with the

concentration of methylene blue solution as the

abscissa and the absorbance as the ordinate, and the

standard curve equation was obtained.

(2) Evaluation of adsorption effect

The absorbance of methylene blue aqueous

solution before and after adsorption was determined

by ultraviolet spectrophotometer, the concentration

of methylene blue was calculated according to the

standard curve, and the adsorption effect was

evaluated by the removal efficiency:

0

0

= 100%

i

cc

c

η

−

×

(1)

Where: η is the adsorption removal efficiency; c

0

and c

i

are the concentration of methylene blue in

solution before and after adsorption, mg/L.

2.3.2 Effect of Adsorption Factors on the

Adsorption

Several conical bottles with volume of 250mL were

prepared, 100 mL methylene blue solution with a

certain concentration and bamboo leaf powder with

a certain quality were added into each conical bottle,

and then stirred at a speed of 150r/min for a certain

time at a certain temperature. After stirring, the

mixture in the conical flask was filtered with 0.45

μm filter membrane to obtain filtrate. The original

methylene blue solution and the filtrate were diluted

and their absorbance were determined by the

ultraviolet spectrophotometer at the wavelength of

662nm, the concentration of methylene blue were

calculated and the adsorption effect was evaluated.

Factors such as particle sizes and dosage of bamboo

leaf powder, temperature, adsorption time, pH and

the initial concentrations of methylene blue solution

were taken into consideration when discuss the

effect of adsorption conditions on the adsorption.

2.3.3 Adsorption Kinetics

The concentration of methylene blue in the solution

at different times of adsorption reaction was

determined, and the results were fitted by the

pseudo-first-order kinetic equation and the pseudo-

second-order kinetic equation (Travin 2019, Francis

2021), then the kinetic equation most suitable for the

behaviour of bamboo leaf powder adsorbing

methylene blue in water is obtained by comparison.

The pseudo-first-order kinetic equation:

1

ln( - )=ln

et e

qq q kt−

(2)

The pseudo-second-order kinetic equation:

2

2

1

tee

tt

qkqq

=+

(3)

Experimental Study on Adsorption of Methylene Blue in Wastewater by Bamboo Leaves Powder

167

Where: q

e

is the equilibrium adsorption capacity

of bamboo leaf powder for methylene blue, mg/g; q

t

is the adsorption capacity of bamboo leaf powder for

methylene blue at time t, mg/g; t is the reaction time,

min; k

1

is the adsorption rate constant, min

-1

; k

2

is

the adsorption rate constant, g/mg · min.

2.3.4 Response Surface Optimization Test

Four factors of bamboo leaf powder dosage,

adsorption time, temperature and pH were selected

in the response surface optimization test. The range

of each factor level included the corresponding value

with the highest removal efficiency in the test results

in 2.3.2. The removal efficiency of methylene blue

by bamboo leaf powder was taken as the response

value, the response surface test was designed by

Design-Expert 8.0.6 software. The factors were

optimized through the test results, and the best

process parameters were obtained.

3 RESULT AND DISCUSSION

3.1 Effect of Adsorption Conditions on

the Adsorption

3.1.1 Effect of Bamboo Leaf Powder Particle

Size on the Adsorption

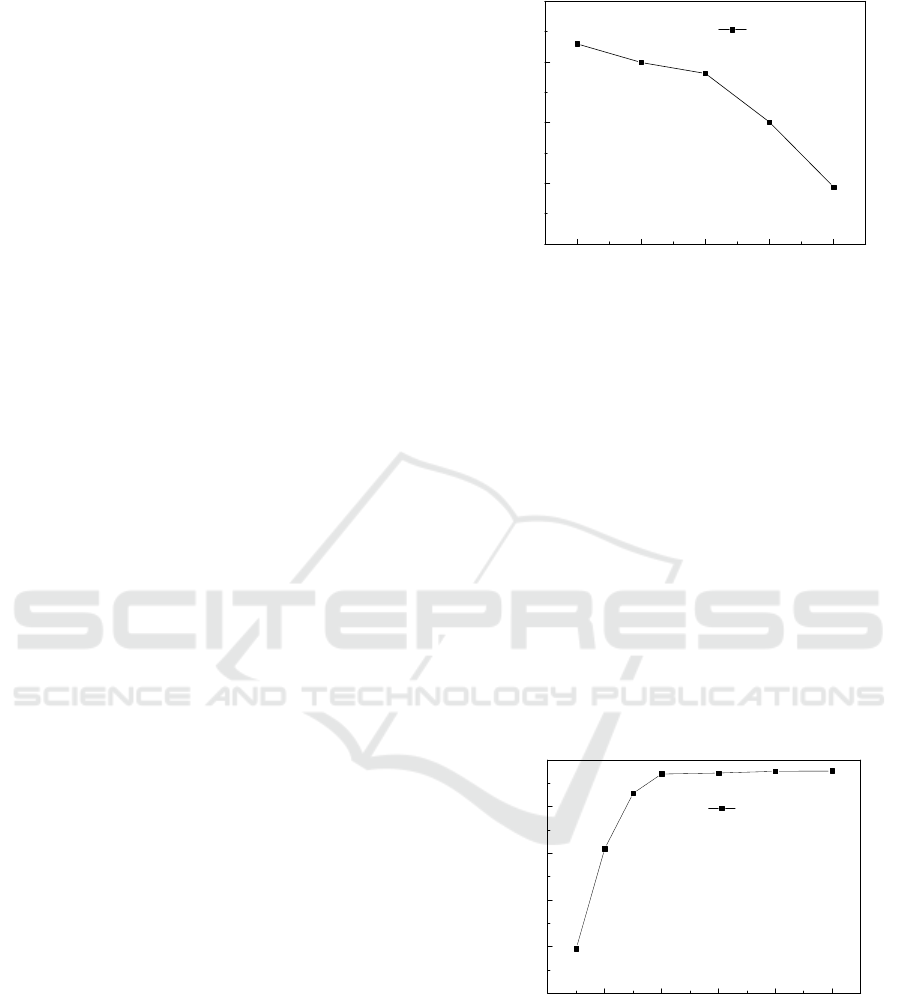

The effect of bamboo leaf particle sizes on the

adsorption is shown in Figure 1. The particle sizes

were determined as <0.25mm, 0.25-0.4mm, 0.4-

0.5mm, 0.5-0.8mm and 0.8-1.0mm, respectively, the

dosage is 0.5g, and the initial concentration of the

methylene blue solution was 100mg/L. As shown in

Figure 1, as the particle size gradually increases, the

removal efficiency gradually decreases. When the

particle size is less than 0.25mm, the removal

efficiency reaches 93% and removal effect is the

most significant. When the particle size increased to

0.8-1mm, the removal efficiency was only 69.4%.

This is because the specific surface area of solid

adsorption materials increases with the decrease of

particle size. Therefore, bamboo leaf powder with

particle size less than 0.25mm was selected as the

material for subsequent tests.

<0.25 0.25-0.40 0.40-0.50 0.50-0.80 0.80-1.00

60

70

80

90

100

removal efficiency (%)

particle sizes (mm)

removal efficiency

Figure 1: Effect of particle size on the removal efficiency.

3.1.2 Effect of Bamboo Leaf Powder Dosage

on the Adsorption

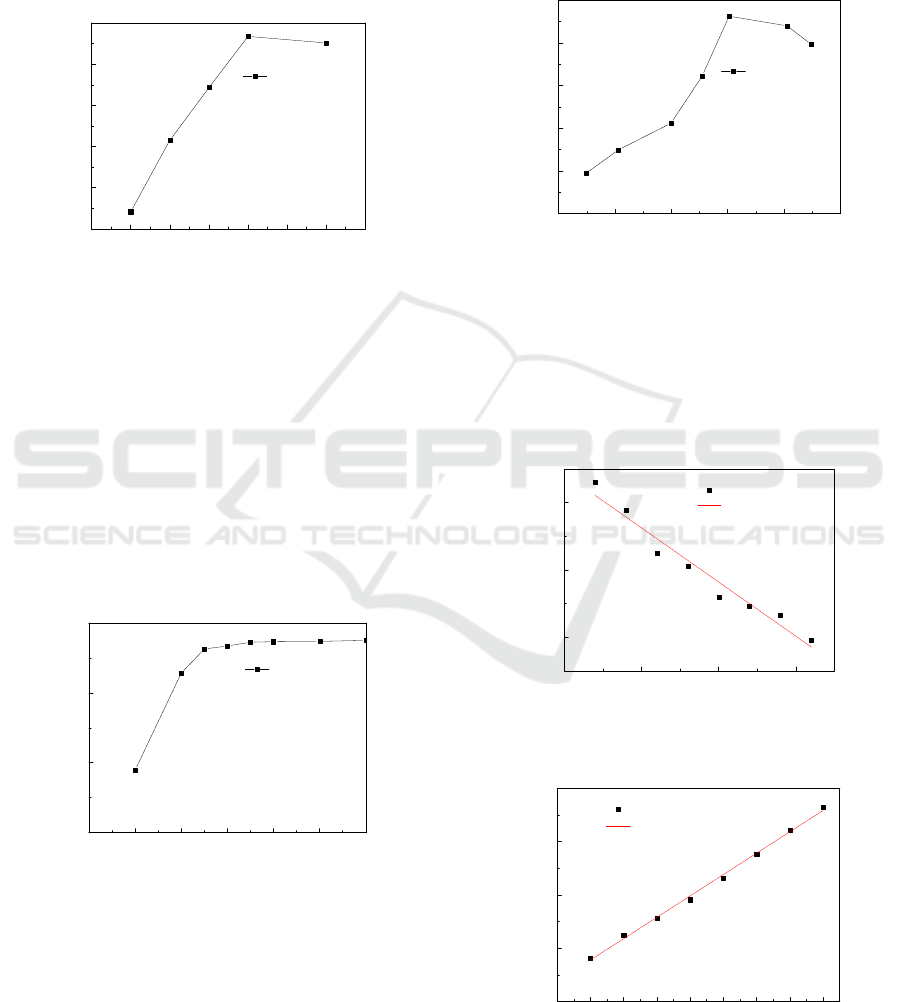

The effect of bamboo leaf powder dosage on the

adsorption is shown in Figure 2. In this test, different

dosage of bamboo leaf powder with particle size less

than 0.25mm was added into methylene blue

solution with initial concentration of 100mg/L, and

the dosage was determined as 0.1, 0.2, 0.3, 0.4, 0.6,

0.8 and 1.0g/100mL, respectively. It can be seen

from Figure 2 that the removal efficiency increases

with the increase of the dosage. When the dosage

increases from 0.1 to 0.4g/100mL, the removal

efficiency increases obviously. Then, when the

dosage increases furtherly, the removal efficiency

changes little and the adsorption tends to be

saturated. Therefore, the optimum dosage of bamboo

leaf powder under this condition is 0.4g/100mL.

0.00.20.40.60.81.0

50

60

70

80

90

100

removal efficiency (%)

dosage (g/100mL)

removal efficiency

Figure 2: Effect of dosage on the removal efficiency.

3.1.3 Effect of Temperature on the

Adsorption

The effect of temperature on the adsorption is shown

in Figure 3. In this test, 0.4g bamboo leaf powder

with particle size less than 0.25mm was added into

the methylene blue solution with concentration of

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

168

100mg/L. The temperatures were determined as 5,

10, 15, 20, 30, 40, 50 and 60 ℃ respectively. In

Figure 3, with the increase of temperature, the

removal efficiency increases in the range of 5-20 ℃,

and then decreases slowly with the increase of

temperature, and reached a maximum of 96.8% at 20

℃. Therefore, the optimum temperature for the

adsorption is 20 ℃.

0 5 10 15 20 25 30 35

50

60

70

80

90

100

removal efficiency (%)

temperature (℃)

removal efficiency

Figure 3: Effect of temperature on the removal efficiency.

3.1.4 Effect of Time on the Adsorption

The effect of time on the adsorption is shown in

Figure 4. This test was carried out with temperature

of 20 ℃, bamboo leaf powder dosage of 0.4g with

particle size less than 0.25mm, and with an initial

concentration of 100mg/L. The adsorption reaction

time was 20, 40, 60, 80,100,120, 140 and 160 min,

respectively. It can be seen from Figure 4 the

removal efficiency increases obviously in the first 50

min during the process and then tends to be stable,

and the adsorption basically reaches the saturation

state.

0 20406080100120

85

90

95

100

removal efficiency (%)

time (min)

removal efficiency

Figure 4: Effect of adsorption time on methylene blue

removal efficiency.

3.1.5 Effect of pH on the Adsorption

The effect of pH on the adsorption is shown in

Figure 5. The test was carried out with temperature

of 20 ℃, bamboo leaf powder dosage of 0.4g with

particle size less than 0.25mm, and with an initial

concentration of 100mg/L. The pH of the reaction

system was adjusted by diluted HCl and diluted

NaOH solution. It can be seen from Figure 5 that the

removal efficiency increases with the increase of pH

in the range of pH 3-8 and reaches the maximum at

about pH 8. After that, the removal efficiency

decreased gradually with the increase of pH.

24681012

50

60

70

80

90

100

removal efficiency (%)

pH

removal efficiency

Figure 5: Effect of pH on the removal efficiency.

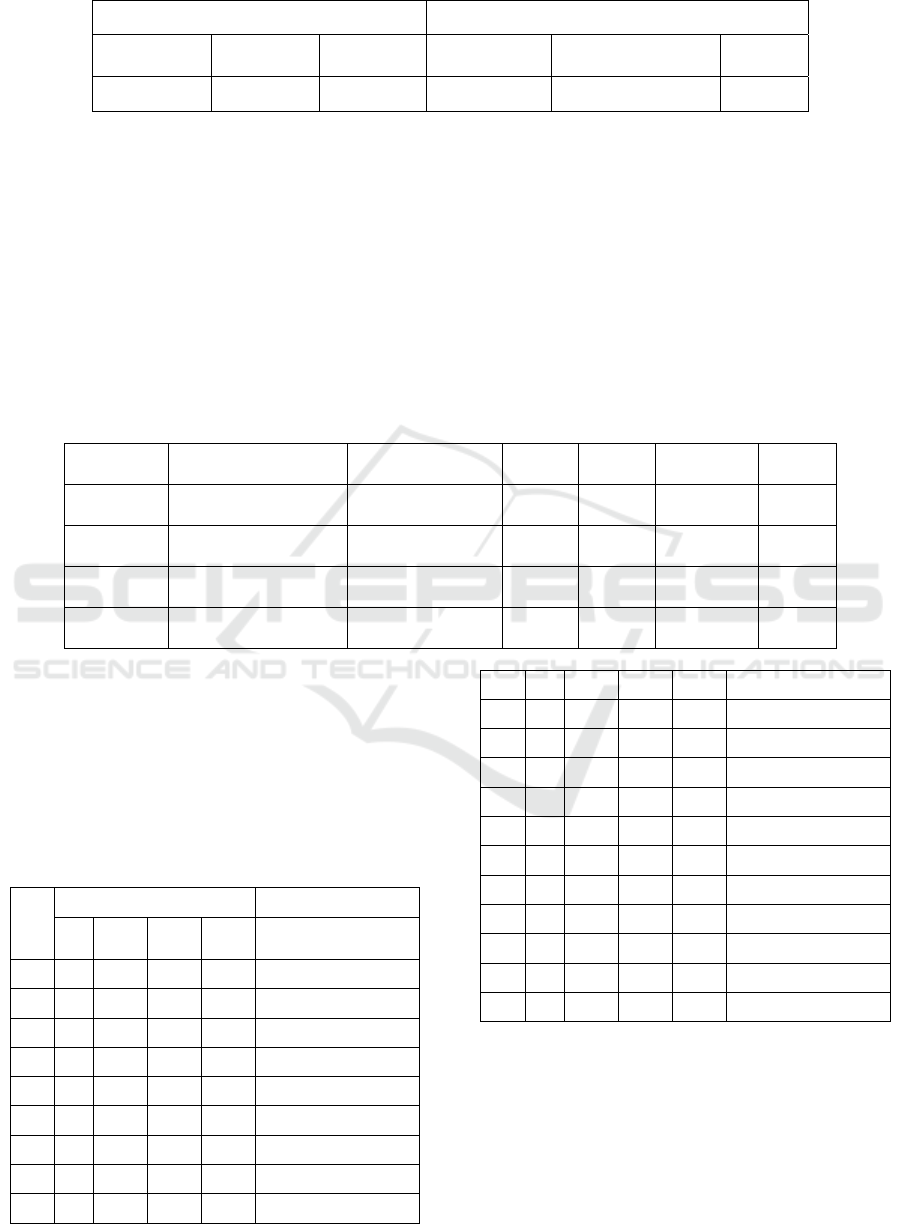

3.2 Adsorption Kinetics

The relationship between adsorption capacity and

adsorption time in pseudo-first-order kinetic

equation and pseudo-second-order kinetic equation

is shown in Figure 6 and Figure 7. The parameters of

the kinetic equation are shown in Table 1.

0 50 100 150

-2

0

2

ln(q

e

-q

t

)

Linear Fit of ln(q

e

-q

t

)

ln(q

e

-q

t

)

t (min)

Figure 6: Fitting for the pseudo-first-order kinetic

equation.

0 20 40 60 80 100 120 140 160

0

2

4

6

8

t/q

t

Linear fit of t/q

t

t/q

t

t (min)

Figure 7: Fitting for the pseudo-second-order kinetic

equation.

Experimental Study on Adsorption of Methylene Blue in Wastewater by Bamboo Leaves Powder

169

Table 1: Parameters of the kinetic equation.

Pseudo-first-order equation Pseudo-second-order equation

q

e

(mg/g)

k

1

(min

-1

)

R

2

q

e

(mg/g)

K

2

(g/mg·min)

R

2

17.52 0.0322 0.959 24.94 0.0021 0.997

Table 1 reveals that the linear correlation of

pseudo-first-order and pseudo-second-order kinetic

model fitting are relatively good, and the

coefficients are 0.959 and 0.997, respectively. In

terms of the linear correlation coefficient, pseudo-

second-order kinetic model can better describe the

kinetic behaviour of the adsorbing.

3.3 Response Surface Test

3.3.1 Test Scheme and Results

In order to determine the best combination of

experimental variables through fewer experiments,

the response surface method (RSM) was applied.

The coupling effect of main reaction factors on

removal efficiency was studied by test designed by

the Optimal mode in Design-Expert software, and

the value of independent variables was optimized.

The optimum conditions were obtained by

optimization with the highest adsorption removal

efficiency as the goal. The resume of RSM

experimental design is shown in Table 2.

Table 2: Parameters of the kinetic equation.

Factor Name Dimension min max Mean value Std. Dev.

A Dosage g/L 3 7 5.278 1.738

B Time min 40 80 59.31 15.75

C Temperature ℃ 10 40 24.56 13.05

D pH

4 10 6.952 2.556

The tests are carried out with an initial

concentration of methylene blue of 100mg/L, a

particle size of bamboo leaf powder of less than

0.25mm and a stirring speed of 150r/min. The test

scheme and result are shown in Table 3. The tests

are carried out three times, and the experimental

results are expressed as the average value.

Table 3: RSM test scheme and result.

No.

Independent variable Response variable

A B C D

Removal efficiency,

%

1 7.00 72.80 40.00 4.00 82.78

2 5.06 40.00 20.80 10.00 88.78

3 7.00 80.00 20.80 6.89 89.84

4 3.00 60.60 25.60 9.57 88.37

5 6.80 52.00 24.90 6.50 92.53

6 7.00 60.80 10.00 10.00 86.93

7 3.00 40.00 10.00 7.09 72.09

8 3.00 80.00 10.00 10.00 74.23

9 3.00 59.20 20.97 4.00 78.86

10 4.60 64.00 40.00 7.64 91.12

11 3.00 40.00 40.00 10.00 79.12

12 3.74 40.00 40.00 4.00 72.72

13 7.00 40.00 10.00 4.00 75.3

14 7.00 80.00 40.00 10.00 69.34

15 7.00 40.00 10.00 4.00 74.63

16 4.90 80.00 10.00 4.00 87.53

17 3.00 80.00 40.00 4.00 86.18

18 7.00 72.80 40.00 4.00 86.28

19 7.00 40.00 40.00 8.95 83.62

20 7.00 60.80 10.00 10.00 84.12

21 4.74 62.60 12.70 7.36 92.37

3.3.2 Parametric Model and Analysis of

Variance

The main parameter data of the model fitted for

response variable and the analysis of variance are

shown in Table 4 and Table 5, respectively.

According to the results, the quadratic model is

selected. The significant coefficient p of the model is

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

170

0.0001, and the p of the lack of fit term is 0.6848

(>0.05), indicating that the model is significant, but

the lack of fit is not significant. The determination

coefficient R

2

is 0.9500, which shows that the model

fits well with the actual situation and the error is

small. It can accurately analyse and predict the

removal efficiency. The F value of the model is

28.13, while the F value of the lack of fit is 0.5449,

indicating that the model is significant, the mismatch

term is not significant, and 68.48% of the F value of

the mismatch term may be caused by noise. The

coefficient of variation of the model is 1.9689%

(<5%), indicating that the model has high reliability

and sufficient experimental data. The precision is

17.31 (>4), which shows that the signal of the fitting

model is sufficient and the fitting is reasonable.

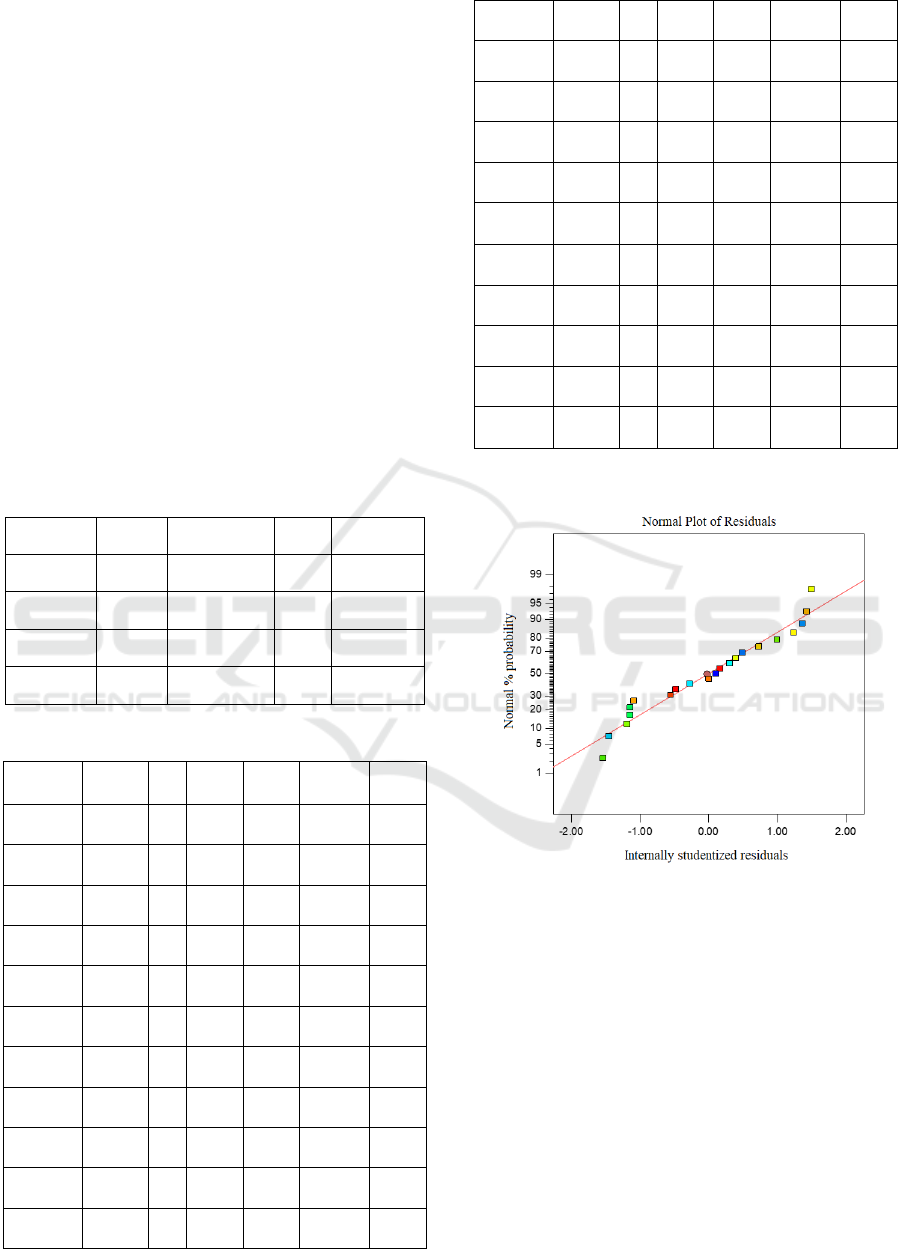

Figure 8 shows that the normal distribution linearity

of the residual and the fitting effect of the model are

good. The above results show that the fitting model

has high reliability and precision.

Table 4: The main parameter data of the model.

Resource p p(Lack of fit) R²

Linear 0.8300 0.0139 0.1455

2FI 0.2563 0.0154 0.0515

Quadratic 0.0001 0.6848 0.9500 Suggested

Cubic 0.6848 - 0.9352 Aliased

Table 5: The analysis of variance.

Variance

source

Sum of

S

q

uares

DF

Mean

S

q

uare

F

p

(p

rob>F

)

Signifi

cance

Model 1044.09 14 74.58 28.13 0.0003 **

A 69.66 1 69.66 26.27 0.0022 *

B 54.89 1 54.89 20.70 0.0039 **

C 5.08 1 5.08 1.91 0.2157 *

D 3.46 1 3.46 1.30 0.2969 **

AB 47.70 1 47.70 17.99 0.0054

*

AC 63.19 1 63.19 23.83 0.0028

AD 21.86 1 21.86 8.24 0.0284

*

BC 4.77 1 4.77 1.80 0.2283

BD 216.79 1 216.79 81.76 0.0001

*

CD 13.66 1 13.66 5.15 0.0637

A

2

55.43 1 55.43 20.91 0.0038

**

B

2

57.27 1 57.27 21.60 0.0035

**

C

2

56.60 1 56.60 21.35 0.0036

**

D

2

86.49 1 86.49 32.62 0.0012

**

Residual

15.9091 6 2.65

Lack of

Fit

5.6116 3 1.87 0.5449 0.6848

Pure Error

10.30 3 3.43

Cor Total

1060.00 20

R

2

0.9850

C.V. %

1.9689

Adeq.

Precision

17.31

Note: *p<0.05, significant, **p<0.01, extremely

significant.

Figure 8: Normal distribution diagram of residual

probability.

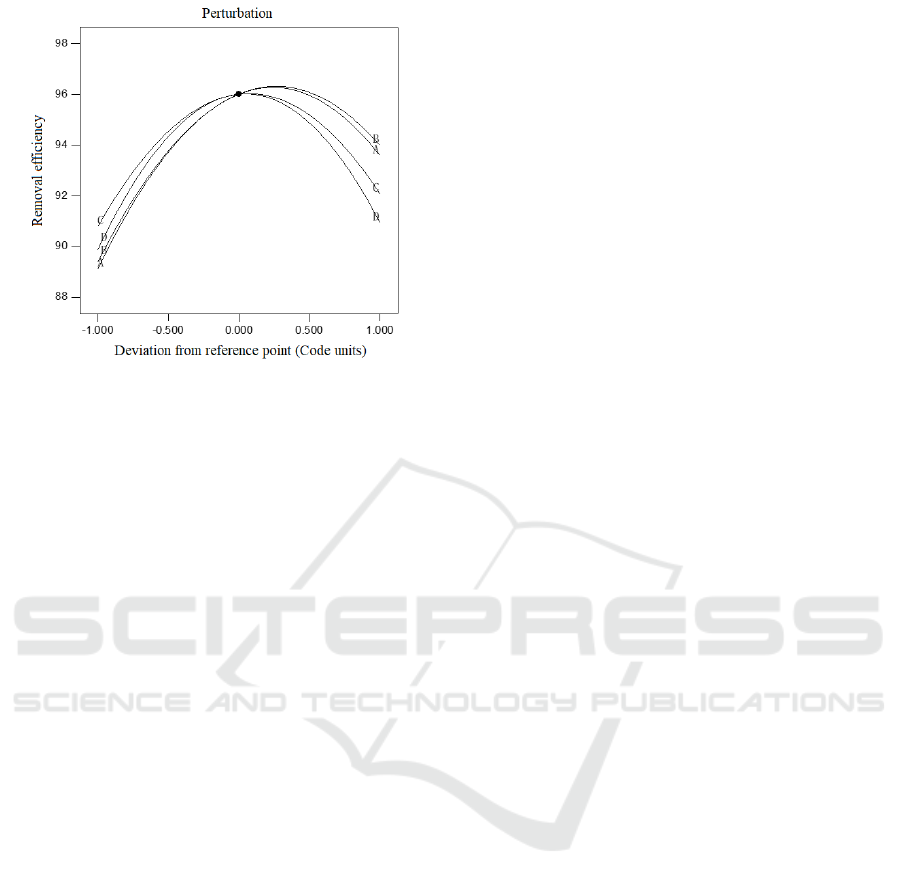

3.3.3 Single Factor Effect Analysis

In RSM test, the fluctuation diagram of A (dosage),

B (time), C (temperature) and D (pH) factors is

shown in Figure 9. The independent variables in this

experiment have square effect, linear effect and

interaction with the response variables. With the

increase of factor level, the response value first rises

and then decreases slowly. From the fluctuation

range of response variable, the fluctuation of each

factor from high to low is A, B, D, and C. Therefore,

the influence of various factors on the removal

efficiency is A, B, D and C from high to low.

Experimental Study on Adsorption of Methylene Blue in Wastewater by Bamboo Leaves Powder

171

Figure 9: The fluctuation diagram of single factor.

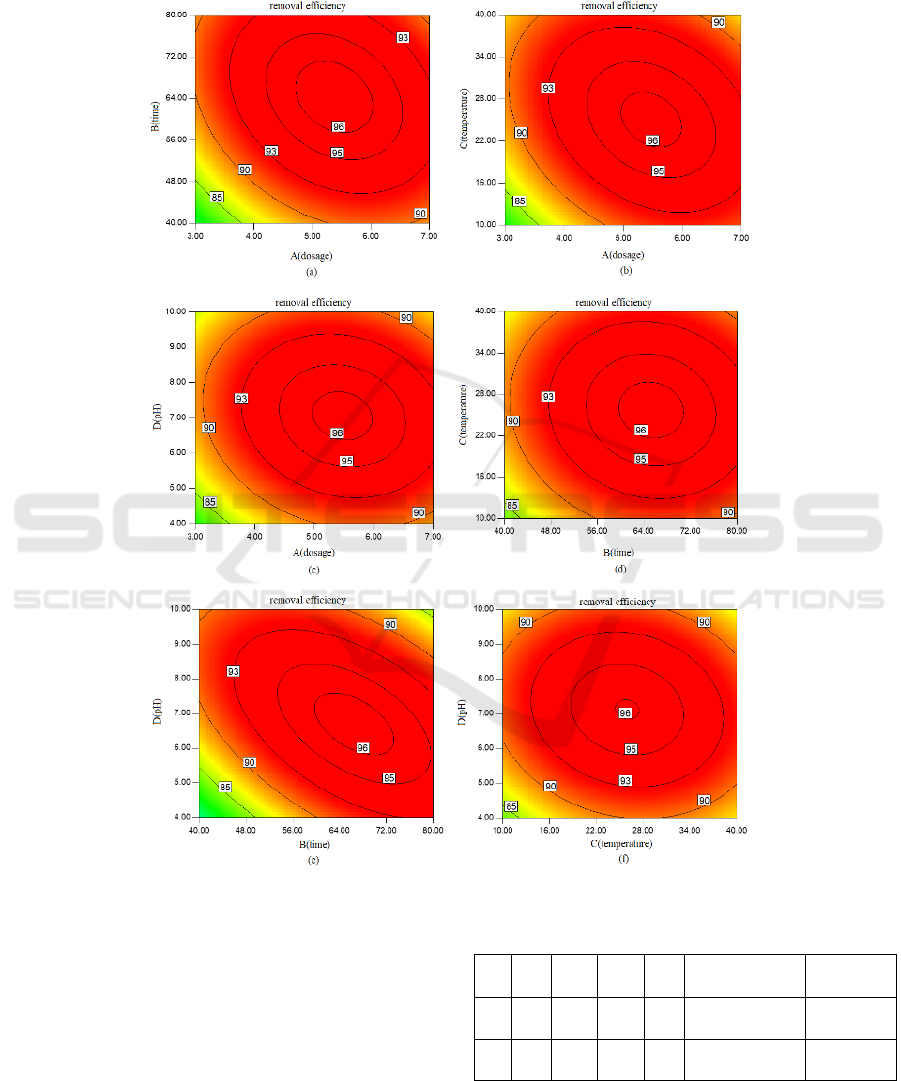

3.3.4 Analysis of Interaction among Factors

The reaction surface analysis diagram is a three-

dimensional diagram composed of reaction values

and any experimental factors, showing the influence

of the other two variables on the test efficiency when

two of the factors A, B, C and D are at the

intermediate level. However, when the two factors

interact, the influence of one factor on the other

factor is different at different levels. The response

surface of this study basically presents an open form,

that is, with the increase of factor level, the removal

efficiency shows a trend from high to low. The

contour map is a curve formed on the lower surface

with the same factor value on the surface. The closer

the contour is to the circle, the smaller the

interaction between them. The closer the contour of

the ellipse is, the greater the interaction between the

two. The density of the contour line reflects the

factors affecting the removal efficiency. The denser

the contour, the greater the effect on the removal

efficiency.

The pairwise interaction between the factors is

shown in Figure10. The contour map of the

interaction between A and B is shown in

Figure10(a). The oval contour indicates that there is

interaction between A and B. The contour density of

A is higher than that of B, indicating that A has a

greater impact on the removal efficiency than B. The

response surface showed that the removal efficiency

increased rapidly with the increase of A, and then

begins to decline slowly when the dosage exceeds a

certain value (5-6g/L). With the increase of B, the

removal efficiency increases slowly and then

decreases slowly, and reaches the maximum when

the time during 56-72 min. The contour map of the

interaction between A and C is shown in

Figure10(b). The oval contour lines indicate that

there is interaction between A and C. The contour

density of A is higher than that of C, indicating that

the impact on removal efficiency of A is greater than

that of C. The response surface diagram shows that

the removal efficiency increases slowly with the

increase of A, and then decreases slowly when the

dosage exceeds a certain value (5-6g/L). With the

increase of C, the removal efficiency first increases

slowly and then decreases slowly, and reaches the

maximum when the temperature reaches 22-27℃.

The contour map of the interaction between A and D

is shown in Figure10(c). The oval contour line

indicates that there is interaction between A and D.

The contour density of A is greater than D,

indicating that A has a greater impact on the removal

efficiency than D. The response surface showed that

the removal efficiency increased slowly with the

increase of A level, and then begins to decline

slowly when the dosage exceeds a certain value (5-6

g/L). The removal efficiency increases slowly with

the increase of D, and begins to decline slowly when

pH exceeds a certain value (6.5-7.5). The contour

map of the interaction between B and C is shown in

Figure10(d). The contours of B and C are close to

circular, indicating that the interaction between B

and C is not obvious. The density of B is greater

than C, indicating that the effect of B on adsorption

is greater than C. The response surface showed that

the removal efficiency increased slowly with the

increase of B, and then begins to decrease slowly

when the time exceeds a certain value (60-70min).

With the increase of C, the removal efficiency

increases slowly and then decreases gradually, and it

reaches the maximum when the temperature reaches

22-27℃. The contour map of the interaction

between B and C is shown in Figure10(e). The oval

contour indicates that there is interaction between B

and D. The contour thickness of B is greater than D,

indicating that B has a greater impact on the removal

efficiency than D. The reaction surface showed that

the removal efficiency increased rapidly with the

increase of B, and then decreased slowly after the

time exceeding a certain value (60-70min). The

removal efficiency increased rapidly with the

increase of D, and then begins to decline slowly

when pH exceeds a certain value (6.5-7.5). The

contour map of the interaction between C and D is

shown in Figure10(f). The contour lines of C and D

are close to circular, indicating that the interaction

between C and D is not obvious. The contour line

thickness of D is greater than C, indicating that D

has a greater impact on the removal efficiency than

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

172

C. The reaction surface showed that the removal

efficiency first increased slowly and then decreased

slowly with the increase of C. The removal

efficiency reaches the maximum when the

temperature reaches 24-28℃. With the increase of

D, the removal efficiency increased slowly and then

begins to decline slowly when pH exceeds a certain

value (6.5-7.5).

Figure 10: Pairwise interaction between the factors on removal efficiency.

3.3.5 Optimization of Adsorption

Conditions

Two adsorption schemes are recommended by RSM

optimization. The optimal adsorption conditions are:

dosage of 5.37g/L, adsorption time of 65.47min,

temperature of 25.17 ℃, and pH of 6.7. The

theoretical predicted value of the removal efficiency

is 96.5145%, and the expected value reaches 1.0, as

shown in the Table 6.

Table 6: The optimal adsorption schemes.

No. A B C D

Removal

Efficienc

y

(

%

)

Desirability

1 5.37 65.47 25.17 6.70 96.5145 1

2 5.36 65.69 25.11 6.68 96.5142 0.999989

Experimental Study on Adsorption of Methylene Blue in Wastewater by Bamboo Leaves Powder

173

4 CONCLUSIONS

(1) Bamboo leaf is a potential natural adsorbent for

methylene blue in wastewater.

(2) The best adsorption effect could be obtained

when the particle size of bamboo leaf powder was

less than 0.25mm, the dosage was 0.4g/100mL, the

temperature was 20 ℃, the adsorption time was

50min and the pH was 8, respectively.

(3) Pseudo-second-order kinetic model can better

describe the kinetic behaviour of bamboo leaf

powder adsorbing methylene blue in wastewater.

(4) Comprehensively considering the influence of

various factors on the adsorption effect, the optimal

conditions for the adsorption were as follows: the

dosage is 5.37g/L, the adsorption time is 65.47min,

the temperature is 25.17 ℃, and pH is 6.7. The

theoretical predicted value of removal efficiency is

96.5145%.

ACKNOWLEDGEMENTS

The authors acknowledge support from the Doctor

Fund Project of Wenhua College (2019Y03).

REFERENCES

Donkadokula, N. Y., Kola, A. K., Naz, I., Saroj, D.

(2020). A review on advanced physico-chemical and

biological textile dye wastewater treatment techniques.

J. Reviews in Environmental Science and

Bio/Technology. 19, 543- 560.

Francis, A. O., Zaini, M. A. A., Zakaria, Z. A.,

Muhammad, I. M., Abdulsalam, S. U., EINafaty, A.

(2021). Equilibrium and kinetics of phenol adsorption

by crab shell chitosan. J. Particulate Science and

Technology. 39, 415-426.

Gao, Y. Y., Yang, B., Wang, Q. (2018). Biodegradation

and decolorization of dye wastewater: a review. J. IOP

Conference Series: Earth and Environmental Science.

178,12-13.

Isa, S.S.M., Ramli, M.M., Hambali, N.A.M.A., Kasjoo,

S.R., Isa, M.M., Nor, N.I.M., Khalid, N., Ahmad, N.

(2016). Adsorption Properties and potential

applications of bamboo charcoal: Areview. J. MATEC

Web of Conference. 78, 35-46.

Jiang, W.Z., Zhang, W.G., Zi, X., Liu, X.M., Zhang,

W.B., Li, W. Z. (2021). Effect of Recarbonization

Temperature on conductive properties and structure of

bamboo charcoal. J. Materials reports. 8, 8023-8027.

Travin, S. O., Gromov, O. B., Utrobin, D. V., Roshchin,

A. V. (2019). Kinetic Simulation of Adsorption

Isotherms. J. Russian Journal of Physical Chemistry B.

13, 975-985.

Wu, F., Chen, Y., Ma., J. J. (2019). Adsorption of

methylene blue dyes from wastewater by bamboo

leaves powder. J. Anhui Chemical Industry. 45, 33-40.

Yang, X., Zhang, Q., Tang, C., Sun, J., Zhang, Q. L.,

Zhang, L.Q. (2017). Adsorption property of modified

bamboo leaves for the removal of congo red from

wastewater. J. New Chemical Materials. 45, 244-246.

Zhang, C. Y., Zhang, Y. R., We, J. J., Ding, X. Y., Hou,

X. Y., Wang, Q., Li, Y. (2020). Effect of bamboo

charcoal on aerobic composting of kitchen waste. J.

Chinese Journal of Soil Science. 3, 656-660.

Zhang, X., Pan, C., Zhang, Z. (2021). Effects of

Clostridium butyricum combined with bamboo

vinegar on egg quality and intestinal function in late

laying stage. J. Feed Research. 13,57-60.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

174