Removal of Nitrate from Water by Reed Straw Biochar with

Different FeCl

3

Modification Method

Zhongwei Zhang

1,2 a

, Peijing Kuang

1,2,* b

, Junwen Ma

1c

, Yubo Cui

1,2 d

and Zhaobo Chen

1,2 e

1

Key Laboratory of Biotechnology and Bioresources Utilization, Ministry of Education, Dalian Minzu University,

Dalian, China

2

College of Environment and Resources, Dalian Minzu University, Dalian 116600, China

*

Corresponding author

Keywords: Reed Straw, Biochar, Nitrate Nitrogen, Modification.

Abstract: Nitrate contamination became an ever-increasing serious environmental problem and some conventional

methods had the higher operating costs and the lower efficiency. In order to develop low-cost technology for

aqueous nitrate treatment, various agro-forest residuals have attracted a great deal of research attention to

preparing biochar adsorbents for nitrate adsorption. In our study, reed straw biochar was prepared from

wetland plant residuals at different pyrolysis temperatures (300ºC, 400ºC, 500ºC, 600ºC and 700ºC).

Meanwhile, biochar was modified by FeCl

3

with different methods to optimize their adsorbent performance.

The results show that the optimal preparation conditions could achieve at carbonization temperature of 600ºC

for 2 h, followed by soaking in FeCl

3

solution for 24 hours in alkaline condition, for which the highest

adsorption capacity could reach at 1.97 mg/g after modification. SEM images show that a large amount of

iron oxides were loaded on the surface of biochar, as well as in the pores of biochar, promoting the removal

of nitrate. This study can provide a theoretical basis for the comprehensive utilization of agro-forest waste

and nitrate removal.

1 INTRODUCTION

1

Unreasonable discharge of industrial nitrogen-

containing wastewater, random stacking of solid

wastes such as domestic waste and nitrogen-

containing waste residue, unreasonable use of

nitrogen-containing pesticides and fertilizers will

lead to a large number of NO

3

-N into the water

environment, resulting in NO

3

-N pollution in water

environment (JesúsGarcía-Fernández, 2018). Due to

the limited self-purification capacity of water and the

natural degradation capacity of microorganisms,

NO

3

-N gradually accumulates in the environment,

and the concentration continues to increase (Liu

2021). Enriched NO

3

-N makes the water

eutrophication, a large number of algae cover the

water surface so that sunlight can not be transmitted,

a

https://orcid.org/0000-0001-5413-554X

b

https://orcid.org/0000-0003-1838-4252

c

https://orcid.org/0000-0001-5716-9446

d

https://orcid.org/0000-0001-8950-5889

e

https://orcid.org/0000-0003-2786-6173

the photosynthesis of aquatic plants is weakened, and

the respiration is enhanced, resulting in the death of a

large number of aquatic organisms such as fish, and

the deterioration of water quality (Huang 2017). In

order to reduce the damage of NO

3

-N pollution to the

water environment and human health, it is of great

significance to seek economical and effective

technology to control the concentration of NO

3

-N in

water.

In recent years, the use of low-cost and effective

adsorbents to adsorb pollutants is the focus of

scholars (Cao 2019). As a new type of environment-

friendly adsorbent, biochar has strong adsorption

capacity for heavy metals and organic pollutants

because of its easily available raw materials and rich

surface functional groups. Biochar has become one of

the main ways of resource utilization of agricultural

26

Zhang, Z., Kuang, P., Ma, J., Cui, Y. and Chen, Z.

Removal of Nitrate from Water by Reed Straw Biochar with Different FeCl3 Modification Method.

DOI: 10.5220/0011176000003443

In Proceedings of the 4th International Conference on Biomedical Engineering and Bioinformatics (ICBEB 2022), pages 26-30

ISBN: 978-989-758-595-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

waste (HussainLAHORI 2017). The adsorption

performance of biochar can be improved by

modifying biochar

(Chen 2014). Ordinary biochar has

large specific surface area and high porosity. Biochar

can be modified to change its surface structure

(Zhu

2017), increase surface functional groups, enhance

the adsorption capacity of biochar to NO

3

-N and

improve the removal rate of NO

3

-N. Some studies

have shown that iron oxides have high affinity and

adsorption selectivity for oxygen-containing anions

in water (Namasivayam 2005). Wheat straw biochar

was prepared by Li et al and modified with FeCl

3

. The

results showed that when the mass ratio of Fe/C was

0.7, the maximum NO

3

-N adsorption capacity of iron

modified biochar was 2.47 mg/g fitted by Langmuir

isothermal adsorption model, while that of

unmodified biochar was only 0.13 mg/g (Li 2015).

Dewage et al prepared Douglas fir biochar and

modified it with FeCl

3

. It was found that Fe particles

in the form of α-Fe

2

O

3

and Fe

3

O

4

could lead to

magnetization of biochar and produce a large number

of adsorption sites

(Dewage 2018). However, few

people have studied the treatment of pollutants in

water by FeCl

3

modified reed straw biochar.

As a kind of wetland aquatic plant, reed straw was

made into biochar to explore its adsorption capacity

to nitrate nitrogen in water environment. reed straw

biochar was modified by FeCl

3

to determine the

modification conditions with the best adsorption

capacity. The related properties of biochar (modified

biochar) were analyzed by scanning electron

microscope (SEM) and X-Ray diffraction (XRD).

The purpose of this study is to provide a scientific

basis for the resource utilization of aquatic plants in

wetlands and the pollution control of nitrate nitrogen

in water.

2 MATERIALS AND METHODS

2.1 Preparation of Biochar from Reed

Straw

In this study, the reed was defoliated, washed and

crushed into powder with a powder mesh of about 60-

80 mesh. The reed straw powder was washed with a

large amount of deionization and dried in an oven at

105°C. Under the conditions of 10°C/min heating

gradient, 120 min combustion residence time and

oxygen limitation, reed powder was prepared at five

operating temperatures of 300ºC, 400ºC, 500ºC, 600

ºC, 700 ºC respectively, and BC300, BC400, BC500,

BC600 and BC700 were obtained.

2.2 Preparation of Biochar from

Different Modified Reed Straw

Different preparation methods are as follows:

(a) Reed straw was pre-modified with FeCl

3

solution and rotated in shaker for 24 hours, then

carbonized at 600°C for 2 hours in muffle furnace

under oxygen-limited condition;

(b) Reed straw was carbonized at 500°C for 1

h, soaked in FeCl

3

solution for 24 h, then washed with

deionized water for five times (filtrate Ph was about

4.3), then dried;

(c) Reed straw was carbonized at 600°C for 2

h, soaked in FeCl

3

solution, adjusted to alkaline

solution, soaked 24 h, washed with deionized water

for five times (filtrate Ph was about 4.5);

(d) Reed straw was pre-soaked with Hcl

solution for 24h, then rinsed with deionized water for

five times (filtrate Ph was about 4), carbonized at

600°C in muffle furnace under oxygen limitation for

2 h, removed and soaked with FeCl

3

for 12 h, then

dried;

(e) Reed straw was carbonized at 600°C for 2

hours, soaked in Hcl solution for 24 hours, then

washed with deionized water for five times (filtrate

Ph = 5.5), then dried, soaked in FeCl

3

solution for 12

hours, and dried.

2.3 Preparation of Nitrate Solution

Accurately weigh KNO

3

(analytical purity) 0.14436 g

in the beaker, add appropriate amount of deionized

water to dissolve, fix the volume to 1 L, obtain the

NO

3

-N reserve solution of 20 mg/L, avoid light and

store at 4°C.

2.4 Experiment on Determination of

Adsorption Effect of NO

3

-N

Configure the KNO

3

solution of 20 mg/L, adjust the

solution pH to about 7, weigh 0.2 g reed straw biochar

(modified straw biochar), add it to the 50 ml capacity

flask of KNO3 solution containing 20 mg/L, shake in

the shaker for 24 hours, and then use 0.22 μm filter

membrane to determine the concentration of NO

3

-N

in the supernatant. Thus, the adsorption effect of reed

straw biochar (modified straw biochar) on NO

3

-N

after 24 h adsorption was calculated. NO

3

-N was

detected by CleverChem Anna automatic

discontinuous chemical analyser, and the SEM

characterization of reed straw biochar was measured.

X-Ray powder diffraction (XRD) is used to scan the

crystal structure of the material in the range of 10-60

Removal of Nitrate from Water by Reed Straw Biochar with Different FeCl3 Modification Method

27

degrees using Bruker D4 Endeavor Powder X-Ray

diffractometer.

2.5

Analytical Methods

The adsorption capacity of biochar to NO

3

-N is

calculated by formula (1):

q

e

= V/M(C

0

-C

e

)

(1)

Among them, q

e

(mg/g) is the equilibrium

adsorption capacity; C

0

(mg/L) is the initial

concentration of NO

3

-N in the water sample; C

e

(mg/L) is the concentration of NO

3

-N in the

adsorption equilibrium; M (g) is the amount of

biochar added; V (L) is the volume of the water

sample.

The experimental data were plotted using Excel

2016 and Origin 2018 software.

3 RESULTS AND DISCUSSION

3.1

Effect of Biochar at Different

Preparation Temperatures on the

Adsorption Properties of Nitrate

Nitrogen

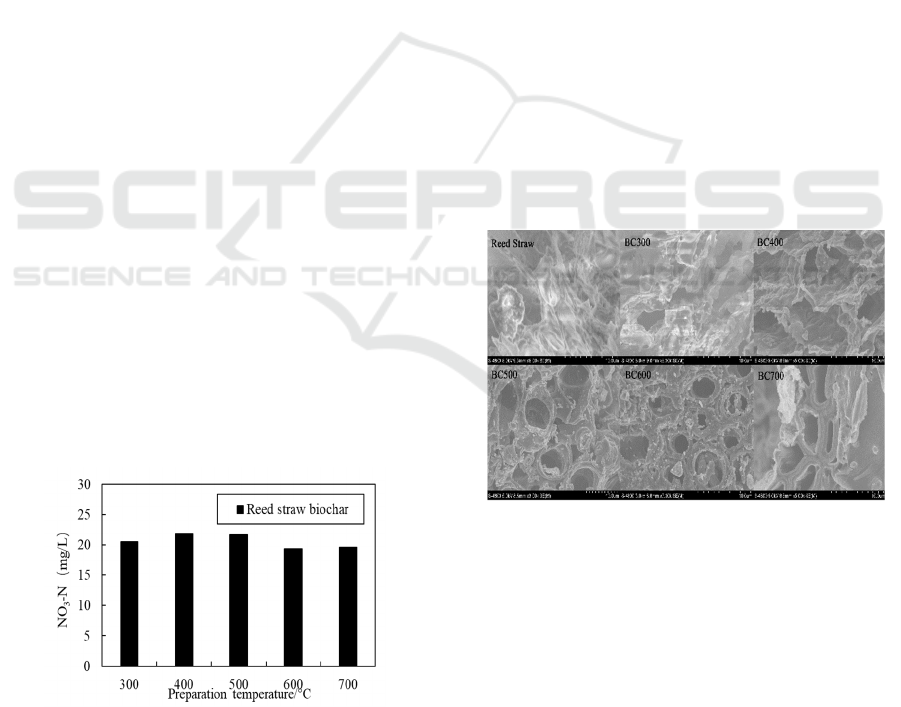

It can be seen from figure 1 that for the solution with

the same NO

3

-N concentration (20.381mg/L), the

adsorption capacity of reed straw biochar is in the

order of BC600 > BC700 > BC300 > BC500 > BC400

under the preparation conditions of 300°C, 400°C,

500°C, 600°C and 700°C. The three kinds of biochar

BC300, BC400 and BC500 had negative adsorption

effect on NO

3

-N, while under the preparation

conditions of 600°C and 700°C, the adsorption effect

of reed straw biochar on NO

3

-N was close to that of

reed straw biochar.

Figure 1: Adsorption effect of reed straw biochar prepared

at different temperatures for NO

3

-N.

As shown in figure 2, with the increase of the

pyrolysis temperature of straw biochar material, the

concentration of NO

3

-N in the target solution

decreases gradually. The higher the pyrolysis

temperature, the higher the adsorption capacity of

straw biochar to NO

3

-N, and the adsorption capacity

of BC600 and BC700 to NO

3

-N is the largest

compared with other biochar. This should be due to

the fact that the surface of biochar prepared by high

temperature pyrolysis has more pore structure than

that of biochar prepared at 300°C ~ 500°C. With the

increase of pyrolysis temperature, the porosity and

specific surface area of biochar are increasing, and the

porosity is becoming more and more perfect. In the

SEM diagram of the original reed, due to the crushing

of the reed straw, the surface of the reed straw is

rough and the electrical conductivity is poor. In the

SEM diagram of BC300, biochar is not carbonized

completely and does not form complete porosity,

which will lead to poor electrical conductivity of

biochar. In the SEM diagram of BC400 and BC500,

the porosity of biochar has been gradually formed. In

the SEM diagram of BC600, the porosity of reed

carbon is relatively complete, and the voids are larger,

and there are many small holes in the voids, which

may cause NO

3

-N to adhere to the voids more easily.

In the SEM diagram of BC700, the porosity of reed

carbon has been completely formed, and the

arrangement is relatively neat, and the inner surface

of the pore is smooth.

Figure 2: Micro-morphology pictures of SEM (10 μm)

prepared by biochar at different temperatures.

3.2

Effect of Biochar Modified by

Different Methods on Adsorption

Properties of NO3-N

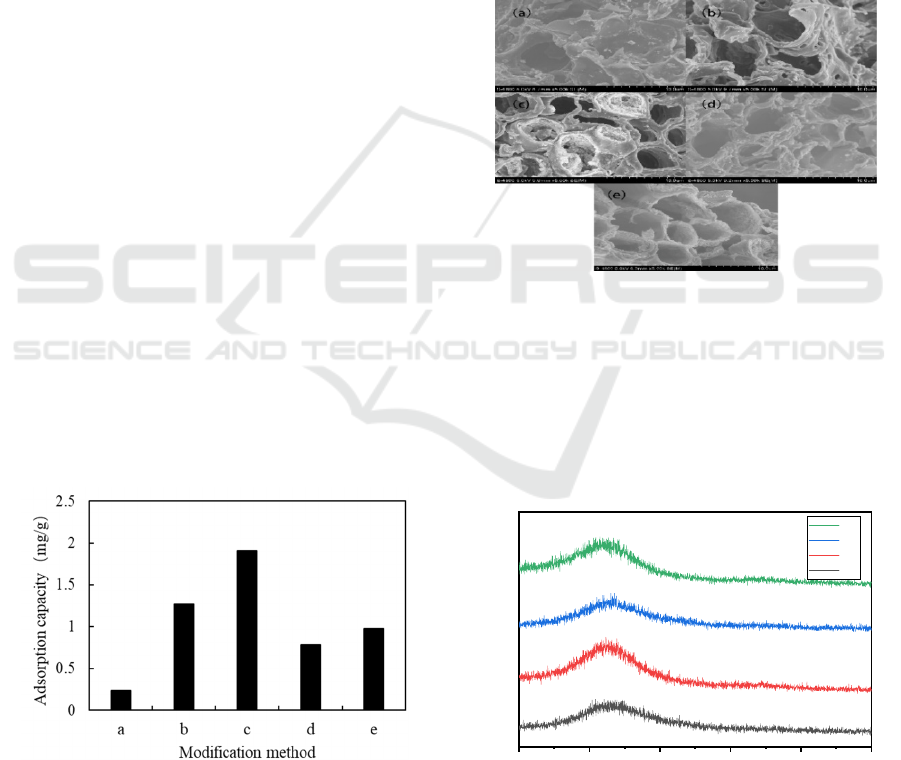

As shown in figure 3, the effect of (c) method is the

best among the five modification methods, reaching

1.97 mg /g. In (c) method, Ph, is adjusted to FeCl

3

solution to make it alkaline. NaOH can interact with

carbon matrix to increase the porosity and specific

surface area of biochar. At the same time, it can also

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

28

increase the amount of -OH, -COOH and cation

exchange capacity. FeCl

3

is easy to form iron

hydroxide under alkaline conditions. Iron hydroxide

is easier to combine with the surface functional

groups in biochar to form iron oxide, and it is easy to

be loaded in biochar. The effect of (b) is not as good

as that of (c), which may be due to the fact that the

porosity is not as good as that of (c) due to the lack of

carbonization time. Although the adsorption effect of

(d) and (e) is not as good as that of (c), they also have

better adsorption capacity, which may be due to the

effect of HCI solution, because the surface elemental

composition of biochar changes when soaked in acid

solution: on the one hand, the C content decreases and

the O content increases due to the loss of organic

carbon in biochar, on the other hand, the relative

content of C increases due to the decrease of ash

content in biochar. In addition, the increase of

oxygen-containing functional groups on the surface

of biochar can also increase its O content. Therefore,

acid modification can effectively increase the number

and variety of oxygen-containing functional groups

on the surface of biochar, and greatly increase the

porosity of the materials. In (d) method and (e)

method, the modification order of HCl solution is

different, and the reed straw treated with HCI solution

does not play a key role in carbonization. On the

contrary, the carbonized reed carbon produces a large

amount of CO and H

2

O due to soaking in HCI

solution, which makes the pore structure of biochar

more developed, increases the specific surface area

and reduces the crystallinity of cellulose in the

process of biomass carbonization. The improvement

of its pore structure leads to the increase of the

porosity of biochar, which makes the oxide of Fe

more easily attached to it.

Figure 3: Adsorption effect of NO

3

-N on biochar under

different modified methods.

As shown in figure 4, most of the biochar has a

porous structure in the (a) ~ (e) modification method.

In (a) modification method, the porous structure of

biochar and very few Fe oxide particles attached to the

surface of biochar have large and small pore structure,

which may be caused by carbonization time of only 1

h. In (c) method, the crystallization of oxides

containing a large amount of iron in the pores can be

observed, which may indicate that FeCl

3

solution

modification is more successful than the previous

methods. Due to the pre-treatment of reed straw by

HCl immersion in (d) method, the solution is slightly

acidic after washing, and the pores are destroyed and

not round, which may make the adsorption effect not

as good as that of (e) method. In the SEM diagram of

(e) method, it is obvious that the iron oxides have been

attached to the pores, which is because the carbonized

pores are amplified by HCl solution.

Figure 4: SEM (10 μm) micro-morphology pictures

prepared by different modification methods of biochar.

Figure 5 shows the XRD pattern of biochar

modified by FeCl

3

solution, which does not show the

characteristic diffraction peak of iron, indicating that

the two kinds of modified biochar are amorphous. Hu

et al also reached a similar conclusion

(Hu 2016). The

iron-bearing particles are amorphous, which may

have a good adsorption effect on NO

3

-N.

Figure 5: XRD pattern of biochar modified by FeCl

3

solution.

10 20 30 40 50 60

Intensity(a.u)

Two theta

(

de

g

ree

)

(e)

(d)

(c)

(b)

Removal of Nitrate from Water by Reed Straw Biochar with Different FeCl3 Modification Method

29

4 CONCLUSIONS

The main results are as follows:

(1) The biochar of reed straw loaded with iron

oxide was prepared by the activation of FeCl

3

, and the

preparation conditions with the best adsorption

capacity of NO

3

-N were obtained, that is,

carbonization at 600ºC for 2 h and soaking in FeCl

3

solution (alkaline) for 24 h. The adsorption capacity

under the optimal conditions is 1.97 mg/g .

(2) The porosity of reed straw biochar prepared

under the optimal preparation conditions is higher

than that of biochar prepared by other methods;

biochar has a porous structure and loaded with a

variety of iron oxide components.

(3) Acid modification reagents can change the

specific surface area and pore structure of biochar,

and increase the porosity of biochar; Appropriate

amount of alkali modification not only increases the

specific surface area and porosity of biochar, but also

increases the number of -OH and -COOH of biochar.

ACKNOWLEDGEMENTS

The research was financed by the Natural Science

Foundation of Liaoning, China (2020-MZLH-02) and

Science and Technology Innovation Foundation of

Dalian, China (2018J12SN080).

REFERENCES

C. Namasivayam, K. Prathap. Journal of Hazardous

Materials. Recycling Fe(III)/Cr(III) Hydroxide, an

Industrial Solid Waste for the Removal of Phosphate

from Water, 1, 123 (2015).

Dewage N B, Liyanage A S, Pittman C U, et al.

BioresourceTechnology. Fast Nitrate and Fluoride

Adsorption and Magnetic Separation from Water on α-

Fe

2

O

3

and Fe

3

O

4

Dispersed on Douglas Fir Biochar,

263, 258-265 (2015).

Garcia M J, Pastor M M, Epron F, et al. Applied Catalysis

B Environmental. Proposed Mechanisms for the

Removal of Nitrate from Water Byplatinum Catalysts

Supported on Polyaniline and Polypyrrole, 225, 162-

171 (2018).

J.H. Li. Chinese Academy of Agricultural Sciences

Dissertation. Adsorption of Nitrate and Phosphate by

Modifned Biochar, (2015).

J.H. Cao, L.Q. Liu, Y.J. Huang, et al. Chemical Industry

Progress. Effects of Feedstock Type and Pyrolysis

Temperature on Cd

2+

Adsorption by Biochar, 38, 4183-

4190 (2019).

Lahori A H, Z.Y. Guo, Z.Q. Zhang, et al. Pedosphere. Use

of Biochar as an Amendment for Remediation of Heavy

Metal-contaminated Soils: Prospects Andchallenges,

27, 991-1014 (2017).

Q. Hu, N. Chen, C. Feng, et al. Journal of the Taiwan

Institute of Chemical Engineers. Nitrate Removal from

Aqueous Solution Using Granular Chitosan-Fe(III)-

Al(III) Complex: Kinetic, Isotherm and Regeneration

Studies, 63, 216-225 (2016)

S.H. Zhu, J.J. Zhao, L.G. Chu, et al. Journal of Agro-

Environment Science. Comparison of Copper

Adsorption onto Unmodified and Nano-

hydroxyapatite-Modified Wheat Straw Biochar, 36,

2092-2098 (2017).

W.L. Liu, Y.P. Yuan, Maxwell Bryan. Science of the Total

Environment. Letter to the Editor: Comments on

“Springs Drive Downstream Nitrate Export from

Artificially-drained Agricultural Headwater

Catchments” by Goeller et al, Part B, 783 (2018).

W.F. Chen, F. Wen, W.M. Zhang, J. Meng. Journal of

Agro-Environment Science. Biochar and

Agroecological Environment: Review and Prospect, 33,

821-828 (2014).

Y. Huang, X. Chen, P. Li, et al. Bioresour Technol.

Pressurized Microcystis Can Help to Remove Nitrate

from Eutrophicwater, 248, 140-145 (2018).

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

30