Feasibility Study of Shell Powder as Biological Aerated Filter

Xiaomeng Zhang

1,2 a

, Wanjun Zhang

1,2 b

, Junwen Ma

1c

and Yubo Cui

1,2 d

1

Key Laboratory of Biotechnology and Bioresources Utilization, Ministry of Education, Dalian Minzu University, Dalian

116600, China

2

College of Environment and Resources, Dalian Minzu University, Dalian 116600, China

Keywords: Shell, Hydraulic Retention Time, Biological Aerated Filter.

Abstract: Shells are widely used as biofilm carriers for biological contact oxidation treatment because of their rough

surface and the abundance of CaCO3 on their surface. shells have the advantage of high helium and

phosphorus removal efficiency compared to conventional carrier materials. The CaCO3 in the shell provides

a source of alkalinity for nitrification. Shell fillers are used in biological aerated filter reactors. Experimental

results show that extended hydraulic retention time (HRT) can effectively improve the pollutant removal

efficiency of biofilm reactors. When the HRT was 12 h, the biofilm reactor was more effective in removing

organic matter, with the removal rate of COD increasing from 70.6% to 92.5%. the average removal rate of

ammonia nitrogen increased from 37.3% to 95.8% when the HRT was 4 h to 12 h. The highest treatment

effect for phosphorus was 74.5% when the HRT was 8 hours. At 12 hours HRT, the effluent concentration

of ammonia reached 1.5 mg/L. The pH of the treated effluent from the shell-filled biofilter was stable

between 7 and 8.5.

1 INTRODUCTION

1

Global water pollution poses an increasingly serious

threat to human survival and socio-economic

development. Wastewater treatment is an

indispensable component of economic development

and water resources. Wastewater is divided into

secondary and advanced treatment. After

conventional secondary treatment, although most of

the suspended and organic matter has been removed,

there are still traces of suspended and dissolved

harmful substances such as nitrogen and phosphorus

compounds. As plant nutrients, nitrogen and

phosphorus can help algae and aquatic life to grow

and provide nutrients for algae and aquatic life, but

excess nitrogen and phosphorus can cause

eutrophication of water and affect drinking water

sources. The most important feature of the biological

aerated filter (BAF) is the combination of biological

oxidation and interception of suspended matter,

saving the subsequent steps of settling tanks to treat

a

https://orcid.org/0000-0002-9605-4016

b

https://orcid.org/0000-0002-3342-3734

c

https://orcid.org/0000-0001-5716-9446

d

https://orcid.org/0000-0001-8950-5889

the effluent (e.g. secondary sedimentation tanks).

The BAF treatment process is characterized by high

volumetric load, high hydraulic load, small footprint,

low capital investment, high oxygen transfer rate

and good effluent quality. The reaction principle of

aeration bioreactor is that aerobic and parthenogenic

microorganisms grow on the surface of the biofilm,

and the microorganisms in the inner layer of the

biofilm are in an anaerobic state. When aerobic

microorganisms continuously react to consume

oxygen, resulting in less oxygen in the reactor and

more anaerobic reaction, when the thickness of the

anaerobic layer exceeds that of the aerobic layer, the

biofilm located on the reactor will fall off and a new

biofilm will be regenerated on the surface of the

carrier. Thus ensuring regular renewal of the biofilm

and maintaining the normal operation of the biofilm

reactor (Ding, Chu, Wang.2018).

In this experiment, shells, a waste material from

the sea, were chosen as fillers in an aeration

bioreactor. The shells not only have a rough surface

suitable for biological growth, but the surface is also

rich in CaCO

3

for removing nitrogen and

phosphorus from the wastewater. It is now widely

used in biofilm reactors for wastewater treatment in

Japan (Lei, Qing, Wen, 2020). Compared to

conventional carrier materials, biofilm reactors filled

Zhang, X., Zhang, W., Ma, J. and Cui, Y.

Feasibility Study of Shell Powder as Biological Aerated Filter.

DOI: 10.5220/0011175700003443

In Proceedings of the 4th International Conference on Biomedical Engineering and Bioinformatics (ICBEB 2022), pages 13-17

ISBN: 978-989-758-595-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

13

with shells have the advantage of high helium and

phosphorus removal efficiency. The alkalinity

source for the nitrification reaction is provided by

the CaCO

3

in the shells as an alkalinity source. The

rough surface of the shells and the large amount of

CaCO

3

can be used as a carrier for the biofilm and as

a source of alkalinity for the nitrification reaction.

2 MATERIALS AND METHODS

2.1 Materials

In this experiment, The main water quality index of

artificially prepared domestic sewage is TP 3~6 mg

TP 3~6 mg/L, NH

4

-N 33~50 mg/L, COD 480~500

mg/L. The amount of trace elements added was

CuSO

4

·5H

2

O 0.8 mg/L, MnCl

2

·4H

2

O 5 mg/L,

CoSO

4

·7H

2

O 0.3 mg/L, MgSO

4

·7H

2

O 50 mg/L.

Using marine waste shells as aeration bioreactor

filler, many small equal holes were made on the

surface of the shells and two shells were tied

together to form an anoxic environment in the

middle of the two shells and an aerobic environment

on the surface of the shells. The nitrification

denitrification pattern and phosphorus removal

characteristics of the shell-filled bioaeration filter

were investigated by varying the hydraulic retention

time (HRT).

2.2 Experimental Equipment

The test set-up is shown in Figure 1. The aeration

biofilm reactor is made of polyethylene with a

column height of 0.8 m. The aeration biofilm reactor

is filled with a shell layer of 0.6 m height (porosity

of 90.7%). An aeration head is set at the bottom for

aeration to keep the whole reactor in an aerobic state

(DO>4mg/L). The raw water enters at the bottom of

the column and the treated water exits at the top. The

hydraulic retention time of the aerated biofilm

reactor is set by adjusting the influent, effluent and

overflow volumes. The treatment effect at different

hydraulic retention times is investigated by varying

the hydraulic retention time.

Figure 1: Aeration biofilm reactor installation diagram.

3 RESULTS AND DISCUSSION

3.1 Film Hanging Process and

Phenomenon

In order to promote biofilm formation, the sludge

used in the experiment was the return sludge from

the secondary sedimentation tank of the First

Wastewater Treatment Plant in Dalian Economic

and Technological Development Zone. The return

sludge was filled into the aeration biofilter reactor

with a water content of 98.90% in the feed sludge

and suspended solids (SS) of 9757 mg/L. Aeration

started the day after the return sludge was placed and

lasted for 24 hours with a water temperature

between 11℃ and 15℃ more suitable for microbial

growth. During the hanging period it could be

observed that a sticky substance was slowly

produced on the surface of the filter media. After the

7th day some greyish-white spots were observed,

which then continued to spread. By day 10, a thin

brownish-yellow biofilm was attached to the shells

in the aeration biofilm reactor. It was the lack of

oxygen to the biofilm due to uneven aeration that

caused some of the biofilm to turn dark brown.

(Chen, Zeng, Ma, 2019).

3.2 Removal of Organic Matter by

Biological Aerated Filter

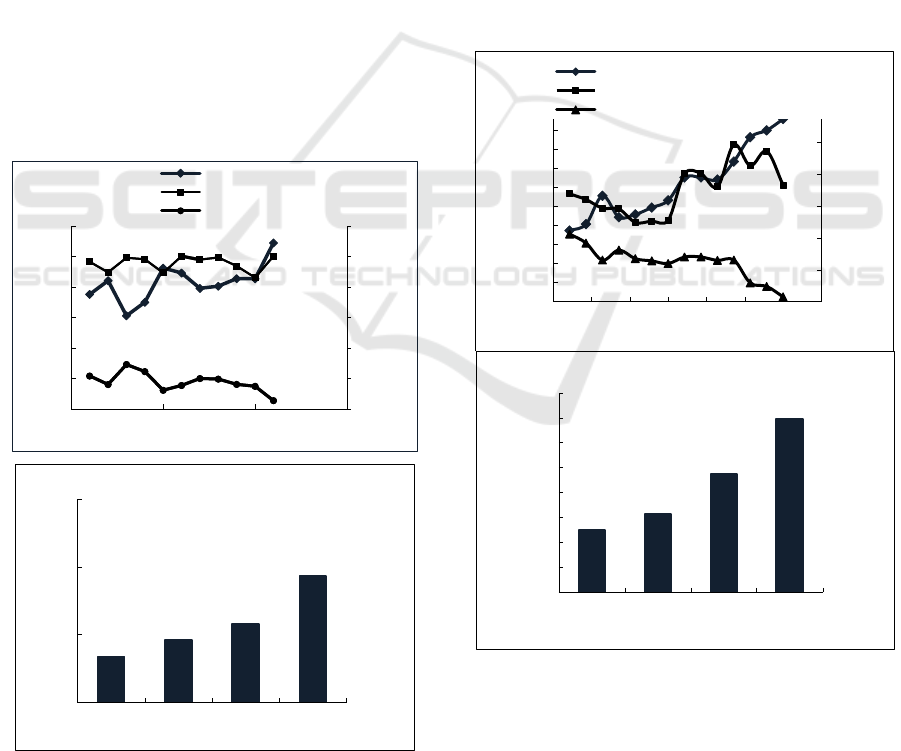

As can be seen from Figure 2, the average removal

rate of COD by the aeration bioreactor gradually

increased with the increase of HRT. The COD

removal rate is not high and the effluent COD

concentration is high when the HRT is 8 hours for

one week, which proves that the inoculation of

sludge has just started at the beginning of the

experiment, resulting in the CaCO

3

on the surface of

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

14

the shells just contacting with the microorganisms in

the sludge, the operation of the aeration bioreactor is

not stable, and the biofilm generated by the reaction

is not completely attached to the shell packing,

resulting in the COD removal rate was not high. But

the removal effect increased after a period of stable

operation compared to before. From 4hr to 12hr, the

removal rate of CODcr increased from 70.6% to

92.5% and the removal rate of organic matter

increased. From the overall trend, it seems that the

longer the HRT time the better the removal effect of

COD and the lower the concentration of COD at a

more stable feed water concentration.

Figure 2 illustrates the treatment effect of the

shell-filled aeration filter. However, it was found

that the blackening of the bottom of the aeration

bioreactor occurred in the latter part of each

filtration cycle due to the large volume of dirt

intercepted in the bottom area of the aeration

bioreactor, rapid biofilm growth, thicker biofilm and

insufficient oxygen supply inside the membrane.

Shortening the HRT increases the hydraulic load and

correspondingly increases the organic load, which

inevitably affects the treatment efficiency (Lei,

Qing, Wen. 2020).

Figure 2: Effectiveness of aeration biofilm reactor on

COD removal after adding shell-filled (up) Relationship

between average COD removal and HRT (down).

3.3 Aeration Biofilter Nitrogen

Removal Efficiency

As can be seen from Figure 3, the ammonia nitrogen

removal rate and average removal rate for the HRT

initiated at a residence time of 8 hours in the test

were not high. Furthermore, the effluent

concentrations of ammonia nitrogen ranged from

21.3 to 13.7 mg/L. This indicates that the biofilm did

not fully adhere to the biological treatment during

the test start-up and was ineffective. However,

Figure 3 shows that the average removal of

ammonia nitrogen ranged from 37.3% to 95.8%

from HRT 4 hours to HRT 12 hours, while the

lowest effluent concentration of 1.5 mg/L of

ammonia nitrogen was reached at HRT 12 hours,

indicating that extending the HRT significantly

improved the nitrification and denitrification of the

reactor and that the shell-filled aeration biofilm had

a significant effect on the nitrification process.

Figure 3: Removal of ammonia nitrogen by aeration

biofilm reactors with shell filling (up) Mean ammonia

nitrogen removal versus HRT (down).

At a hydraulic retention time of 4 hours, for an

aeration biofilter that removes both organic matter

and ammonia nitrogen, shortening the HRT will

0

100

200

300

400

500

600

40

50

60

70

80

90

100

0 204060

COD concentration(mg/L)

COD removal rate(%)

Running time(d)

COD removal rate

Feed water COD concentration

Effluent COD concentration

70

80

90

100

84812

Average COD removal rate (%)

Hydraulic retention time (HRT)

0

10

20

30

40

50

60

0

10

20

30

40

50

60

70

80

90

100

0 7 14 21 28 35 42 49

Concentration of ammonia nitrogen

(mg/L)

Average ammonia nitrogen removal

rate (%)

Running time (d)

ammonia nitrogen removal rate

Feedwater ammonia nitrogen concentration

Effluent ammonia nitrogen concentration

20

30

40

50

60

70

80

90

100

84812

Average removal rate of total

nitrogen (%)

Hydraulic retention time (HRT)

Feasibility Study of Shell Powder as Biological Aerated Filter

15

have an impact on the biofilm micro-ecology in the

reactor, making ammonia oxidizing bacteria and

nitrifying bacteria easily eluted in the backwash

process, thus reducing the nitrification capacity of

the whole reactor ammonia nitrogen removal rate is

low (Ding, Chu, Wang, 2018). And with the increase

of hydraulic retention time, the removal rate of

ammonia nitrogen significantly increased, and the

effluent concentration of ammonia nitrogen

significantly decreased. This indicates that the

aeration biofilter with shells as filler has a

significant effect on the removal of ammonia

nitrogen.

3.4 Phosphorus Removal Effect of

Shell-filled Biofilters

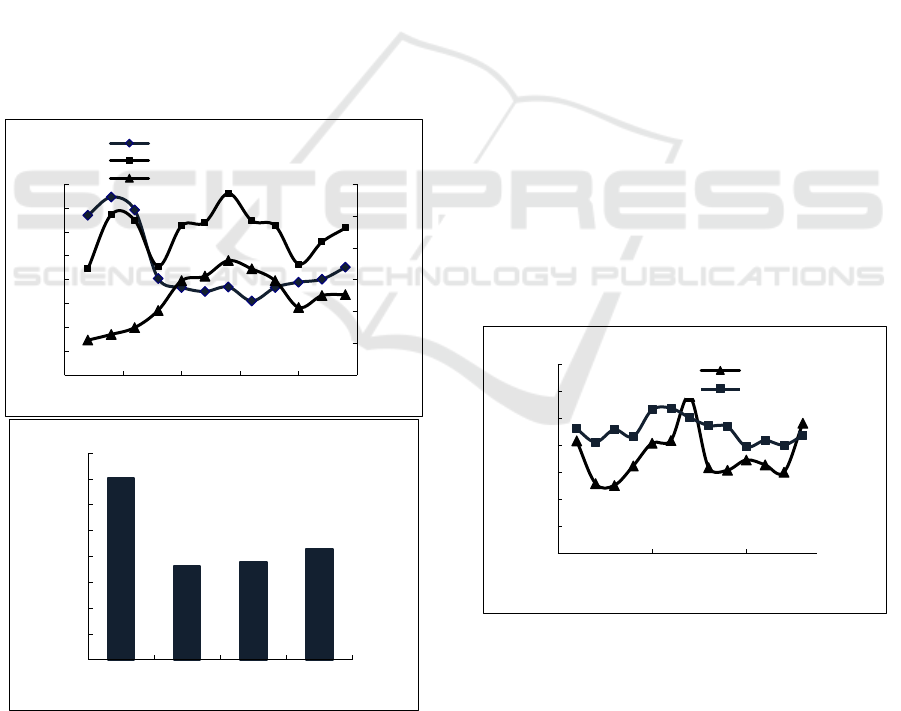

Figure 4 show that the highest phosphorus treatment

effect of 74.5% was achieved at the beginning of the

experiment, i.e. when the HRT was 8 hours. The

reasons for this are, firstly, that phosphorus removal

is good under acidic conditions with low pH,

secondly, chemical phosphorus removal dominates

Figure 4: Effectiveness of aeration biofilm reactor on total

phosphorus removal after adding shell-filled (up)

Relationship between average total phosphorus removal

and HRT (down).

and the generated biofilm does not completely

encase the shells, and the Ca

2+

that precipitates in the

shells helps to remove phosphorus, so the

phosphorus removal effect is significant at the

beginning of the test. As the residence time varied,

the change in hydraulic load also had an effect on

the phosphorus removal.

Combined with Figure 4 it can be seen that at an

HRT of 4 hours, biological phosphorus removal

dominates due to the increase in pH. The shell filler

was wrapped by the biofilm and could not

precipitate Ca

2+

, resulting in a poor phosphorus

treatment effect and a decreasing trend. When the

HRT was shortened to 4h, the phosphorus removal

rate did not decrease significantly. It can be seen that

when the HRT was controlled above 4h, the

biodegradation and the acidity level of the system

were sufficient to ensure that the chemical

precipitation for phosphorus removal by bioinduced

action could be carried out properly.

3.5 Effect of pH on Shell-filled

Aeration Biofilters

The Figure 5 demonstrates that the effluent pH of

the aeration biofilm reactor was stable between 7

and 8.5. The slight drop in pH at the beginning of

the hook-up is caused by the instability of the

system, and effluent indicators for this period

indicate that the system is unstable at the beginning

of the hook-up, with rebound fluctuations at a later

stage and then gradual stability.

Figure 5: Changes in pH of aeration biofilm reactors after

addition of shell fillers.

The treatment effect of the aeration biofilm is

closely related to the pH value and has a very strong

influence on ammonia nitrogen and phosphorus in

particular. Under acidic conditions, phosphorus was

treated significantly, whereas in the middle of the

run, the pH of the influent was adjusted to around

0

1

2

3

4

5

6

0

10

20

30

40

50

60

70

80

0 1020304050

Phosphorus content (mg/L)

Phosphorus removal rate (%)

Running time (d)

Phosphorus removal rate

Feedwater phosphorus concentration

Effluent phosphorus concentration

0

10

20

30

40

50

60

70

80

84812

Average removal rate of total

phosphorus (%)

Hydraulic retention time (HRT)

3

4

5

6

7

8

9

10

02040

pH

Running time (d)

Feedwater pH

Effluent pH

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

16

8.2 due to changes in the test conditions, resulting in

a significant decrease in phosphorus removal. After

this trial, when the alkali addition was stopped, the

phosphorus removal effect increased significantly. It

can be seen that the effect of pH on the treatment

effect of biofilm cannot be ignored.

4 RESULTS AND DISCUSSION

The aeration biofilm method used in this experiment

to treat domestic wastewater investigates the

pollutant removal effectiveness of shell-filled

aeration biofilters at different hydraulic retention

times. The following conclusions were drawn from

the tests and analysis:

The rough surface of shells contains a large

amount of calcium carbonate, which can be used as

a carrier for biofilms and a source of alkalinity for

nitrification reactions (Yang, Liu, Zhang, 2019). In

the aeration biofilm reactor, CaCO

3

dissolved in the

shells provides alkalinity for the nitrification

reaction, so that the activity of nitrifying bacteria is

protected from the inhibition of acidic substances

and the nitrification reaction rate can be maintained

at a high level.

HRT has a significant effect on the treatment

efficiency of the aeration biofilter, and extending

HRT can effectively improve the efficiency of the

reactor in removing pollutants. When the HRT is 4

hours, the treatment effect of the reactor on organic

matter decreases significantly, which is due to

frequent backwashing and short time for

microorganisms to stay on the shell surface. When

the HRT is 8 hours or the HRT is 12 hours, the

reactor has a better effect on the removal of organic

matter, which is significantly higher than the effect

when the HRT is 4 hours.

The aeration biofilter with shells as filler had a

significant effect on the removal of ammonia

nitrogen, and the simultaneous nitrification and

denitrification processes occurring in the reactor

tended to increase the removal rate of nitrogen as the

residence time increased.

During the start-up phase of the experiment, the

phosphorus removal effect was obvious, which fully

indicates that chemical phosphorus removal

dominated, while Ca

2+

precipitated in the shells

helped biodegradation of phosphorus.

The aeration biofilter had a significant effect on

the degradation of organic matter, up to 90%, with

the lowest effluent concentration reaching 27.4

mg/L. The average removal rate was above 75%

during stable operation.

The effect of pH on the treatment effect is

obvious. pH between 6.5~8.5 is more suitable for

aerobic organisms. In the middle of the experiment,

the pH was changed and it was confirmed that a

slightly acidic pH was more effective for the

treatment of phosphorus.

ACKNOWLEDGEMENTS

The research was financed by the Natural Science

Foundation of Liaoning, China (2020-MZLH-02)

and Science and Technology Innovation Foundation

of Dalian, China (2018J12SN080).

REFERENCES

F. Lei, S. H. Qing, J.P Wen. (2020) Journal of Chemical

Technology & Biotechnology, A bioaugmentation

agent allowing the advanced treatment of refractory

refinery wastewater in a biological aerated filter and

analysis of its microbial community,95,1258-1269.

F. Chen, S.Y. Zeng, J. Ma. (2019) Environmental Science

and Pollution Research, Treatment of chlorpyrifos

manufacturing wastewater by peroxide promoted-

catalytic wet air oxidation, struvite precipitation, and

biological aerated biofilter, 26, 26721-26732.

Xiang Shuo, Han, Yutong. (2021) Journal of water process

engineering, Composite biologically active filter

(BAF) with zeolite, granular activated carbon, and

suspended biological carrier for treating algae-laden

raw water.

P. Y. Ding, L.B. Chu, J.L. Wang. (2018) Environmental

science and pollution research international, Advanced

treatment of petrochemical wastewater by combined

ozonation and biological aerated filter,25,9673-9682.

Y. X. Yang, J. H. Liu, N Zhang, (2019) Ecotoxicology and

Environmental Safety, Influence of application of

manganese ore in constructed wetlands on the

mechanisms and improvement of nitrogen and

phosphorus removal,170, 446-452.

Feasibility Study of Shell Powder as Biological Aerated Filter

17