Towards Data-driven Production: Analysis of Data Models Describing

Machinery Jobs in OPC UA

Tonja Heinemann

a

, Marwin Gihr, Oliver Riedel

b

and Armin Lechler

c

University of Stuttgart, Institute for Control Engineering of Machine Tools and Manufacturing Units,

Seidenstraße 36, Stuttgart, Germany

Keywords:

OPC UA, Information Model, Standardization.

Abstract:

This work analyzes the Open Platform Communications Unified Architecture (OPC UA) specifications for flat

glass, plastics and rubber, machine vision, ISA-95 and machine tools regarding their job descriptions. Com-

mon contents of job models in the domain of machinery are deducted. Using a structured qualitative content

analysis, more than 70 functional elements used in OPC UA job models have been identified. While some

of these functional elements are modeled similarly in multiple domains, major differences are identified for

other functional elements. Especially those differences constitute impediments in the standardization of indus-

trial communication. The results of this work harmonize the contents and the modeling techniques regarding

machining jobs in OPC UA and provide a generally applicable method for the standardization of machine

communication throughout different domains. With this method for standardization, this work contributes

directly to the goal of OPC UA, to easily exchange data between platforms from multiple vendors.

1 INTRODUCTION

With the advent of Industry 4.0, cloud manufactur-

ing and lot size 1 in production, the data transfer of

machines between each other and between control-

ling systems like Manufacturing Execution Systems

(MES) raises in importance. A popular standard to

use for such communication today is Open Platform

Communications Unified Architecture (OPC UA).

OPC UA allows specifying data models for specific

use cases and specific domains. This opportunity is

used in the 36 Companion specifications (CS) pub-

lished today as well as in the specifications being cur-

rently developed (OPC Foundation, 2022c).

An important part of data transmission in the ma-

chinery domain is a description of jobs. A job is

considered the source of all activities, as well as data

container for all information and efforts necessary for

processing or originating from processing (Informa-

tionstechnik, 2016). Multiple of the existing CS de-

fine such jobs. These existing models have similar

intentions and overlap in content, but are different by

definition.

a

https://orcid.org/0000-0001-8601-7820

b

https://orcid.org/0000-0002-1883-6813

c

https://orcid.org/0000-0002-4073-1487

To solve such problems, especially for newly de-

veloped CS, but also in updates of the existing CS,

harmonization groups have formed (OPC Foundation,

2022b; VDMA e.V., 2022). These groups need to

know the contents of existing specifications to include

all the functionality that is already provided. Such an

overview is developed in this work.

This paper is structured as follows: In section 2,

the examined CS in this work are introduced along

with a brief description of the role of CS in OPC

UA. The content analysis used for the overview is de-

scribed in section 3. This method involves the defini-

tion of categories. These are introduced in section 4.

The resulting overview is presented in section 5, sec-

tion 6 gives context for the results. The last section 7

contains a discussion of the method used and the re-

sults generated.

2 OPC UA AND COMPANION

SPECIFICATIONS

The ISO-Standard OPC UA composes multiple exist-

ing paradigms in data transport for use in industrial

environments (IEC 62541-[1-14]:2020, 2020). These

include transport protocols, data formats, communi-

Heinemann, T., Gihr, M., Riedel, O. and Lechler, A.

Towards Data-driven Production: Analysis of Data Models Describing Machinery Jobs in OPC UA.

DOI: 10.5220/0011142900003271

In Proceedings of the 19th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2022), pages 729-736

ISBN: 978-989-758-585-2; ISSN: 2184-2809

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

729

Figure 1: Hierarchy of Information Models in OPC UA

(OPC Foundation, 2019).

cation paradigms such as server-client and publish-

subscribe and means of secure communication like

encryption algorithms. On top of this technological

foundation of data transport, OPC UA defines rules

for data representation and collaborating parties use

these rules to define data representations for differ-

ent domains (OPC Foundation, 2022c). These data

representations are called information models and are

hierarchically structured as shown in figure 1. The

main goal of information models is to describe the

structure of data and its intended usage on an OPC

UA interface. The “Core Information Models” con-

tain the most general aspects, intended to be reused

in all subsequent information models. “Companion

Information Models” are often defined by collaborat-

ing parties and contain data models for a specific use-

case or domain. The models regarded in this work are

all companion information models, described in so-

called companion specifications (CS) (40501-1, 2020;

40083, 2021; 40077, 2020; 40301, 2022; 10030,

2013; 10031-4, 2021; 30260, 2020; 40100-1, 2019).

For individual information models, often defined by a

single company, there is the information model group

of “Vendor Specific Extensions”.

The CS are defined by a so-called joint working

group consisting of OPC Foundation members of the

respective domain. This working group defines the

applications and use cases for the CS, develops the

information model and edits the CS documentation.

Resulting CS do include concepts, that are similar in

principle, but handled differently in various CS. Such

a concept is the representation of production jobs.

Based on the description of all CS published by the

OPC Foundation (OPC Foundation, 2022a), the CS

for Machine Tools, Plastics and Rubber Machinery,

Flat Glass, OPEN-SCS, ISA-95 and Machine Vision

contain an information model describing jobs (40501-

1, 2020; 40083, 2021; 40077, 2020; 40301, 2022;

10030, 2013; 10031-4, 2021; 30260, 2020; 40100-1,

2019).

In OPC 40501, the CS for machine tools, the job

model focuses on times spent per program, part and

job for a communication for systems like MES (Man-

ufacturing Execution Systems). The individual enti-

ties, programs, parts and jobs, have key indicators like

a unique identifier. However, more complex proper-

ties like identification of material lots used in parts or

a detailed representation of subprogram structures is

not included. The machine tools model is represent-

ing the job without providing an interface to control

it. (40501-1, 2020)

Two of the specifications for plastics and rubber

machinery contain information about jobs, namely

OPC 40083 and OPC 40077. In combination, they

provide a communication interface between machines

and MES systems. The job description contains the

planned jobs and related information as well as a man-

agement interface for production data like programs.

Using this interface, some aspects of production like

enabling and disabling automatic runs, can be con-

trolled by an OPC UA client. (40083, 2021; 40077,

2020)

The model of OPC 40301 aims to provide a com-

munication interface between MES or ERP (Enter-

prise Resource Planning) and glass processing ma-

chines. It represents jobs, instructions used for pro-

duction and the material used in production. In addi-

tion to representing the state of jobs, the model also

allows to manage jobs by e.g. adding, deleting, sus-

pending and releasing jobs. (40301, 2022)

The specifications OPC 10030 and 10031-4 are

mappings of the ISA-95 standard defined by the ISA

(International Society of Automation) to communi-

cate between MES and diverse manufacturing soft-

ware systems. OPC 10030 contains models for man-

agement of material, personnel and components. In

OPC 10031-4, these models are extended by means

to control machine jobs. The jobs are connected to

the related material, equipment, physical assets and

personnel. In addition, the interface allows to control

jobs. (10030, 2013; 10031-4, 2021)

The specification of OPC 30260, representing the

Open Serialization Communication Standard (OPEN-

SCS) in OPC UA, utilizes the ISA-95 standard and is

thus implicitly represented in this work, but not ex-

plicitly analyzed (30260, 2020).

In OPC 40100-1, communication among machine

vision systems and between vision systems and con-

trollers or MES is specified. Machine vision systems

are used e.g. to gain information about production

quality and to identify products. In the OPC UA

model, jobs are displayed as “recipes”, and can be

modified over the interface.

Even though the different models exist and are

known to the specification groups, no comparison or

comprehensive overview has been developed so far.

With such a comparison, the individual concepts and

aspects of each model can be compared and be used

as groundwork for a harmonized model containing all

ICINCO 2022 - 19th International Conference on Informatics in Control, Automation and Robotics

730

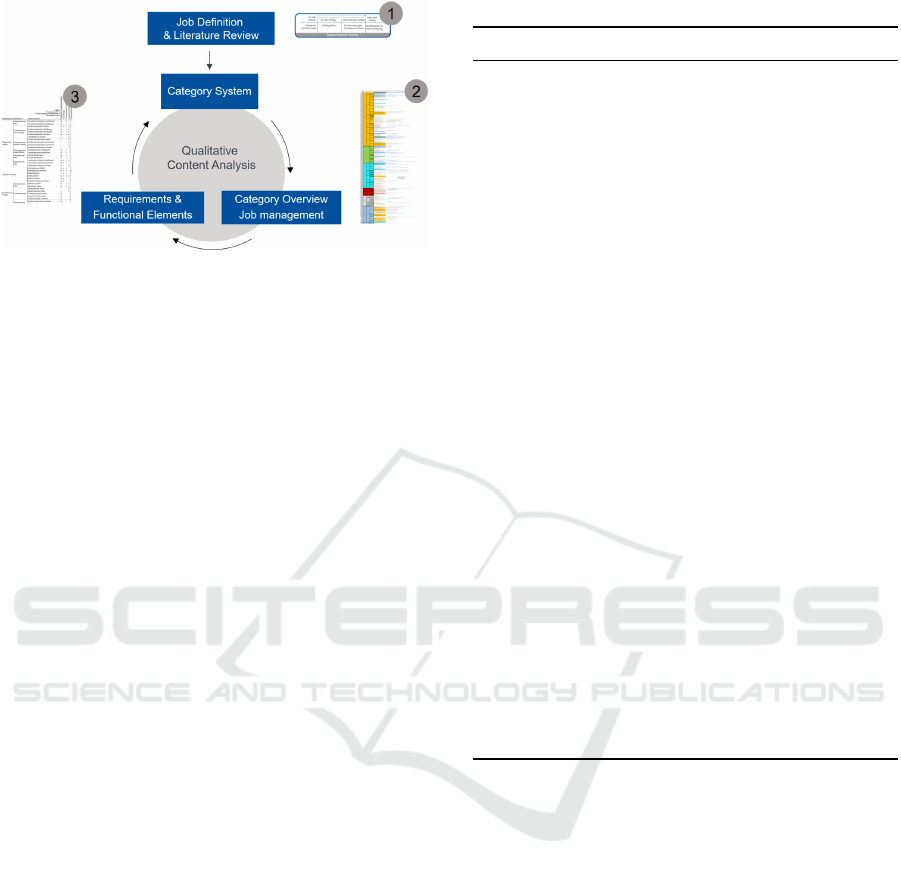

Figure 2: Qualitative Content Analysis for OPC UA CS.

aspects. For such a harmonized model, all informa-

tion needed for production and thus also the informa-

tion contained in the job model, needs to be included.

In addition, the tasks in job management that are cur-

rently contained in the individual specifications need

to be portrayed. The analysis shown in this work

aims to find the information contained in job mod-

els as well as the tasks in job management necessary

to transmit between communication partners as indi-

cated by the existing OPC UA job models.

3 METHOD

To identify the information contained in existing OPC

UA job models as well as the tasks in job management

displayed in these OPC UA job models, a structured

qualitative content analysis is performed.

This kind of analysis strives to generate a detailed

understanding of the models in the specifications. For

this analysis, first a set of main categories is defined.

The first set of categories is defined a-priori by means

of a literature review. In Figure 2 this is depicted as

step 1. Individual elements of the OPC UA models

are then categorized according to the category set; in

the end all elements need to be included in a category.

This is shown in step 2 in Figure 2. The category

overview in the sketch contains all elements with their

sources and additional information. By analyzing the

elements in each category, finding similarities and dif-

ferences, sub-categories can be deducted based on the

evaluated contents. In figure 2 this is represented by

step 3. The result is an overview of functional ele-

ments in CS, that can be used as requirements for the

generation of new specifications or for harmonization

of existing CS. In this step, the previous categories

can be modified if needed. If so, the elements in the

specification are assigned to the new categories again.

For this reason, the process is drawn as a circle in fig-

ure 2. In the end, all delimitable elements are assigned

to at least one category. (Kuckartz, 2012)

Table 1: Categories for Job Models Defined in OPC UA CS.

Main category Sub category

Data for job

preparation

Ensure capability

Data for job execution -

Data during job

execution

Production state

Production mode

Execution information

Parameter monitoring

Data after job

execution

-

Resource capability

description

Equipment description

Production data set

description

Configuration data set

description

Variant parameter

description

Personnel description

Material description

Job management -

Production

management

Machine control

Production mode

Device control

Production parameters

Result management -

Safety Functional reliability

Security Authenticity

Availability

4 CATEGORY SYSTEM FOR

EXAMINED JOB MODELS

Table 1 shows the categories for the information and

task management elements contained in a job. The

data for job preparation concerns checking the capa-

bilities and capacities of machines needed in advance

to schedule and start production activities. As soon

as a job is scheduled, the information required by ma-

chines to execute the job is sent to the machine.

During job execution, the machine transmits in-

formation for systems to monitor the production.

This category is subdivided in information about

the state and the operation mode of the machine, as

well as in information about the job execution itself

and the monitoring of job-related parameters.

After job execution, results and information for

product tracing are transmitted.

Towards Data-driven Production: Analysis of Data Models Describing Machinery Jobs in OPC UA

731

The capabilities of machines are not only needed

in advance to start a job but also to manage it during

execution. Furthermore, they need to be adapted in-

dependent of jobs, like information about tools avail-

able on the machine. For this reason, a category for

resource capability description is considered. Subcat-

egories include the description of equipment used in

production, like tools and fixtures, personnel required

for the job, and material used in production. The pro-

duction data set description contains programs and in-

structions for production. The description of configu-

ration data sets concerns settings that can be made on

machines and production equipment. And the variant

parameter description contains all information that

changes in different variants of similar products.

The category job management contains elements,

e.g. used to add or delete jobs on machines.

All information concerning functions like starting

or stopping the job is gathered in the category pro-

duction management. The respective subcategories

further specify if actions concern the machine con-

trol, change the production mode, control additional

devices apart from the machine itself or changes of

parameters like controller settings or tolerances.

If the communication partner can control how and

how long results are available, especially independent

of active jobs, the respective elements are categorized

as result management.

For the operation of manufacturing equipment,

safety plays a crucial role. As to communication part-

ners, ensuring the functional reliability by informing

about errors and invalid system states is identified in

the OPC UA specifications.

In terms of security, OPC UA itself provides op-

tions for authentication of communication partners, as

well as methods to encrypt the data transfer. For this

reason, these aspects don’t need to be handled explic-

itly in companion specifications. Nevertheless, in the

examined specifications, aspects related to authentic-

ity and availability and thus to security are included.

5 RESULTS

Within the categories and sub-categories, the ele-

ments are evaluated and grouped using the following

common functional elements. More than 70 func-

tional elements for job models are found. The cate-

gories and the functional elements therein are shown

in table 2. In the rightmost five columns, the exis-

tence of a functional element in the specifications is

shown with an “x”. The following text will use the

abbreviations for the specifications used in the table.

In the category “Data for job preparation”, PAR,

G and V are represented. The models provide lists

of configurations and available job data like machine

programs.

Concerning the category “Data for job execution”,

MT is the only specification without elements in this

category. All other specifications’ models contain

most of the functional elements identified. For the

functional element “Production data set”, different

modeling approaches are used to link a data set to a

job. PAR, I95 and V transmit the data set ID to link

to the job, while G requires to transmit the data set

along with the job. In similar fashion, material data

is referenced by ID in PAR, I95 and V while for G

all types of material are provided wile creating a job.

I95 only makes a difference between resources and

resource classes. A resource class represents the ma-

terial properties in an abstract fashion (e.g. size) while

resources are directly linked to real material (e.g. with

lot number).

The functional elements in “Data during job exe-

cution” are apparent in all specifications. They follow

similar OPC UA modeling principles in all specifica-

tions. The same can be said for the three specifica-

tions implementing “Data after job execution”.

Each specification contains functional elements of

the category “Resource capability description”. How-

ever, MT and G only implement few functional ele-

ments while PAR, I95 and V implement the majority.

Concerning similarities and differences in modeling,

one sub category is taken as an example. As a sub

category, the material description occurs in all spec-

ifications but MT. In I95, the material is represented

in an array structure containing material IDs. In PAR

and V, a list containing entries that directly represent

the material is used. G, on the other hand, uses an

array containing references to the OPC UA represen-

tation of the material.

The category “Job management” again is present

in all specifications. The MT specification however

only implements one functional element, “Display

job plans”. Concerning job plans, the representations

differ: MT and G use a list, while I95 and PAR con-

tain the priority and intended start time of jobs. While

the list in MT and G represents the production order

of jobs, I95 uses an array for this information while

PAR displays the current and the upcoming job. For

the functional element “Receive job”, however, PAR,

G, I95 and V use OPC UA methods, and thus similar

modeling concepts.

ICINCO 2022 - 19th International Conference on Informatics in Control, Automation and Robotics

732

Table 2: Overview of functional elements and their occurrence in CS.

PAR: OPC 40083 and OPC 40077 (Plastics and Rubber)

G: OPC 40301 (Flat Glass)

I95: OPC 10030 and OPC 10031-4 (ISA-95)

V: OPC 40100-1 (Machine Vision)

MT: OPC 40501 (Machine Tools)

Main category Sub category Functional element PAR G I95 V MT

Data for job prepara-

tion

Ensure capability Filter and transmit capabilities x x

Prerequisites x

Add capabilities x x

Request capabilities x

Data for job execu-

tion

Job identification x x x x

Job description x x

Production data set x x x x

Variant parameters x x x

Job meta data x x x

Material data x x x x

Equipment data x x

Personnel data x

Instructions x

Data during job exe-

cution

Production state Informative x x x x x

Interaction needed (Server) x x x x x

Interaction needed (Client) x

Production mode Informative x x x

Execution information Job identification x x

Job description x

Process duration x x x x

Products x x x

Resources used x x

Parameter monitoring x x x

Data after job execu-

tion

Product data x x x

Resource capability

description

Equipment description Identify usable equipment x x x

Specify usable equipment x x x

Show inactive equipment x

Production data set de-

scription

Receive production data sets x x

Identify production data sets x x x

Specify production data sets x x x

Manage production data sets x x

Material relation x

Show inactive data sets x

Configuration data set

description

Receive configuration data

sets

x

Identify configuration data

sets

x

Specify configuration data sets x

Towards Data-driven Production: Analysis of Data Models Describing Machinery Jobs in OPC UA

733

Table 2: Overview of functional elements and their occurrence in CS (cont.).

PAR: OPC 40083 and OPC 40077 (Plastics and Rubber)

G: OPC 40301 (Flat Glass)

I95: OPC 10030 and OPC 10031-4 (ISA-95)

V: OPC 40100-1 (Machine Vision)

MT: OPC 40501 (Machine Tools)

Main category Sub category Functional element PAR G I95 V MT

Manage configuration data

sets

x

Show inactive data sets x

Variant parameter de-

scription

Identify variant parameters x x

Specify variant parameters x x

Personnel description Identify personnel x x x

Specify personnel x x x

Inform about inactive person-

nel

x

Material description Identify material x x x x

Specify material x x

Manage material x x

Job management Receive job plans x x x

Display job plans x x x x

Release job x

Receive job x x x x

Request job x x

Job management meta data x

Production manage-

ment

Machine control Start processing x x x

Stop processing x x x

Request sample product x

Production mode Set automatic mode x

Set simulation mode x

Set supervised mode x

Prevent production mode x

Device control Forward production data sets x

Inform about devices x x

Control device x

Production parameters Production settings x

Supervision settings x

Result management Provide results x

Identify results x

Specify results x

Manage results x

Safety Functional reliability Information x

Prevent undefined system

states

x

Lock processing x x

Security Authenticity Server settings x x x

Availability Limit number of clients x x

Optimize computing resources x

ICINCO 2022 - 19th International Conference on Informatics in Control, Automation and Robotics

734

Category “Production management” contains

multiple diverse functional elements that are largely

supported by PAR and V, G and I95 support individ-

ual functional elements. They are largely similar in

design if multiple specifications support a functional

element, the only exception is the sub category “Pro-

duction mode”. While V models the machine state us-

ing the concept of a state machine (displaying states

and possible transitions between them), PAR only dis-

plays possible states using an enumeration.

The category “Result management” is only in-

cluded in V.

The categories safety and security show sparse oc-

currence in the specifications. In the safety category,

the functional elements contain model elements re-

porting safety relevant system states, preventing un-

defined system states and locking operations on the

interface. The G specification allows locking the pro-

duction of a job, while PAR provides the ability to

prohibit changes in data sets. Concerning security, the

specifications contain diverse measures, like requiring

a specific minimum strength of encryption algorithms

for data transmission, limiting the number of simulta-

neous service users and providing the option to delete

unused data and thus optimize computer resource us-

age.

6 ANALYSIS

When looking at the functional elements contained in

the different specifications in table 2, the PAR specifi-

cation clearly contains the most functional elements.

Compared to G, MT and V, the PAR specification is

older, with its first release in 2016 and updates to the

specification since. In addition, both PAR and I95 are

based on previous existing standards while G, MT and

V have developed the model initially for OPC UA.

The V specification stands out, being the only

specification including configuration data set descrip-

tion and result management while including fewer of

the functional elements in data during job execution

and job management than the other specifications.

This might be attributed to the difference in the type

of device: While the injection molding machines of

PAR, the glass processing machines and the machine

tools all generally use input materials to produce out-

put materials or parts, the vision systems don’t touch

the items they are processing. Moreover, a process

on a vision device is often much shorter and involves

fewer individual steps, e.g. a program for a milling

machine. In addition, parameters like temperature

and forces, that are often monitored during different

production processes, do not occur in the same con-

text for machine vision.

The G, I95 and MT specifications cover many of

the same functional elements, with the MT specifi-

cation implementing the fewest functional elements.

One reason for this is the MT specification not defin-

ing interaction possibilities on the OPC UA interface

- neither can jobs be managed (added, deleted, edited

etc.) nor can the production be managed (start, stop,

set modes, ...).

Especially in the categories “Data for job execu-

tion”, “Data during Job Execution” and “Job manage-

ment”, all specifications show similarities. Both in

the functional elements they implement, but largely

also in the way, these functional elements are im-

plemented. In cases where the specifications handle

functional elements differently, the same information

is conveyed, be it the style of reference between job

and production data set or the order of execution, if

multiple jobs are present.

Major differences between the specifications arise

in “Data for job preparation”, “Resource capability

description”, “Production Management” and “Result

Management”. In ”Data for job preparation”, V fo-

cuses on recipes, on descriptions of process steps.

PAR focuses on production data sets. G informs about

prerequisites like the allowed file format accepted in

file transfer. As the examples are this sparse, this cat-

egory seems to be less focused on than the categories

more closely related with job execution.

The whole sub category “Configuration data set

description” only appears in V. This might be due

to the different domain of vision systems and sub-

sequently to the greater significance of configuration

data. However, configuration data may still be of

value for the other domains. Similar assumptions are

true for the category “Result management”. For the V

specification, the process results are the main process

outcome, as the product is in the other four specifi-

cation domains. And the “Products” functional ele-

ment (Data during job execution), the “Product data”

functional element (Data after job execution) and the

“Material description” subcategory (Resource capa-

bility description) are implemented widely among the

specifications.

When regarding safety and security, neither CS

contains comprehensive measures. This seems odd

given the importance of those two domains in ma-

chinery and industry 4.0. However, the safety in ma-

chinery is usually ensured at controller level. So re-

gardless if a start/stop command originates from the

machine panel or the OPC UA interface, the con-

troller checks if that command can be safely executed.

For this reason, the safety functions themselves don’t

need to be included in the interface.

Towards Data-driven Production: Analysis of Data Models Describing Machinery Jobs in OPC UA

735

In case of security, the CS contain few and diverse

measures. This aspect is to be regarded with the ar-

chitecture of OPC UA in mind. Most CS don’t spec-

ify the security algorithms to be used, similar to them

not specifying the transmission protocols to be used.

This leaves all possible security algorithms described

in OPC UA Part 2 as possible choices for implementa-

tion along with the CS model (OPC, 2018). Similarly,

the number of maximum clients usually depends on

the hardware resources of OPC UA server products.

The handling of server resources is therefore often not

part of the CS.

7 DISCUSSION

Using a structured qualitative content analysis on

OPC UA CS yields a more profound understanding

of functional elements focused on in the group of CS.

This kind of understanding achieves the goal set in

this work: to identify the information contained in

existing OPC UA job models as well as the tasks in

job management displayed in these models. How-

ever, such a structured content analysis may produce

different results based on the initial chosen set of cat-

egories. A different set of categories used in this case

would have led to a different structure in the resulting

overview. However, it is likely that the goal of this

work would still have been achieved.

As this work only regarded existing specifications,

the job model may not be complete, including all

aspects possible. The result also does not take job

models in other representations than OPC UA into

account. Still, some models are not OPC UA spe-

cific, but rather implementations of previously exist-

ing standards in OPC UA (40083, 2021; 40077, 2020;

10030, 2013; 10031-4, 2021). The benefit of limiting

the analysis to OPC UA models is a higher compara-

bility of modeling techniques, as all models regarded

in this work have to follow the same rules.

As a result of the content analysis, the overview

presented in table 2 has been created. This overview

can now be used as a basis in extending or harmoniz-

ing the above models. The category system developed

in the analysis could even be used itself to structure

data on OPC UA interfaces. Additionally, the cate-

gory system serves as a basis to identify the elements

that are important to model. This prevents working

groups from overlooking aspects, that other specifica-

tions already contain. The additional documents gen-

erated in the analysis also serve as a guideline how

these elements may be modeled.

ACKNOWLEDGEMENT

The authors thank the German Federal Ministry of

Economic Affairs and Climate Action (BMWK) for

supporting the project ”SDM4FZI” under the funding

programme ”Zukunftsinvestitionen in der Fahrzeug-

industrie”.

REFERENCES

10030, O. (2013). Opc 10030: Opc ua for isa-95 common

object model. Standard, OPC Foundation.

10031-4, O. (2021). Opc 10031-4: Opc ua for isa-95 part 4:

Job control. Standard, OPC Foundation.

30260, O. (2020). Opc 30260: Opc ua for opcn-scs. Stan-

dard, OPC Foundation.

40077, O. (2020). Opc 40077: Opc ua interfaces for plas-

tics and rubber machinery - data exchange between in-

jection moulding machines and mes. Standard, OPC

Foundation.

40083, O. (2021). Opc 40083: Opc ua for plastics and rub-

ber machinery - general type defninitions. Standard,

OPC Foundation.

40100-1, O. (2019). Opc 40100-1: Opc ua for machine

vision part 1. Standard, OPC Foundation.

40301, O. (2022). Opc 40301: Opc ua for flat glass. Stan-

dard, OPC Foundation.

40501-1, O. (2020). Opc 40501: Opc ua for machine tools.

Standard, OPC Foundation.

IEC 62541-[1-14]:2020 (2020). Opc unified architecture.

Standard, INTERNATIONAL ELECTROTECHNI-

CAL COMMISSION, Geneva, CH.

Informationstechnik, V.-F. (2016). 5600-1: Manufacturing

execution systems (mes).

Kuckartz, U. (2012). Qualitative inhaltsanalyse. Beltz Ju-

venta.

OPC, U. (2018). Specification: Part 2–security model, ver-

sion 1.04.

OPC Foundation (2022a). Markets & collaboration - opc

foundation. https://opcfoundation.org/markets-collab

oration/.

OPC Foundation (2022b). Opc-f working groups. https:

//opcfoundation.org/about/working-groups/opcf-wg/.

OPC Foundation (2022c). Opc ua information models - opc

foundation. https://opcfoundation.org/developer-tool

s/specifications-opc-ua-information-models.

OPC Foundation (26.09.2019). Unified architecture - opc

foundation. https://opcfoundation.org/about/opc-tech

nologies/opc-ua/.

VDMA e.V. (2022). Opc ua for machinery. https://opcfou

ndation.org/markets-collaboration/opc-ua-for-machi

nery/.

ICINCO 2022 - 19th International Conference on Informatics in Control, Automation and Robotics

736