Improved Assessment of Offshore Helideck Marking Standards’

Compliance using Optimized Machine Learning Principles in

the U.S. Gulf of Mexico

Mitchell Bosman, Kazim Sekeroglu and Ghassan Alkadi

Department of Computer Science, Southeastern Louisiana University, 500 W University Ave, Hammond, U.S.A.

Keywords: Machine Learning, Helidecks, CAP 437, HSAC RP 161, U.S. Gulf of Mexico, Convolutional Neural Network,

Deep Learning.

Abstract: There is an unknown number of offshore helidecks in the U.S. Gulf of Mexico that comply with a specific

marking standard. This is a direct result from the lack of national regulations enforced. The purpose of this

research is to improve the assessment of offshore helideck marking standards’ compliance using optimized

machine learning principles. Using two different phases and employing the transfer learning approach, an

optimized machine learning algorithm is generated to classify offshore helidecks from photographs into CAP

437, HSAC RP 161 or None. Results show that this model can identify marking standards being used with an

accuracy of 95.7 percent. Therefore, demonstrating that the machine learning principles used can improve the

assessment of offshore helideck marking standards’ compliance.

1 INTRODUCTION

Across the world, energy industry workers must be

transported to offshore facilities. Originally, this

transportation was performed by ship, yet this

presented issues such as individuals getting seasick,

hazardous transition from the ship to the facility, and

wearisome travel times. Now, with the use of

helicopters, these legacy issues have been mitigated.

Helicopter travel decreases passenger illness, eases

transition from the helicopter to the facility, and

significantly reduces travel time compared to travel

by ship. Due to these benefits, helicopters have been

used since 1947 to perform tasks like offshore

transportation of personnel, cargo, and parts. To

execute offshore helicopter operations, a safe landing

area should be guaranteed on these offshore facilities,

referred to as helidecks (HSAC ~ Helicopter Safety

Advisory Conference - Home, 2016).

A helideck is defined as “a heliport located on a

fixed or floating offshore facility such as an

exploration and/or production unit used for the

exploitation of oil and gas” (International Civil

Aviation Organization, 2018).

Many offshore facilities, and their helidecks, were

built prior to the introduction of any applicable design

standard. Therefore, the underlying design

parameters and associated safety aspects for these

facilities remain unknown. In the past two decades,

design standards and guidance material have been

developed and became more readily available;

however, compliance with these standards or

guidelines for newly built helidecks, as well as the

gaps in compliance with those previously built

(legacy) helidecks remain an industry concern. This

results in a plethora of issues that offshore helicopter

pilots must face when attempting to safely land a

helicopter on a helideck. For example, the lack of,

incorrect, or ambiguous markings force the pilots to

adapt and draw their own conclusions as to whether it

is safe to land or not during the final stages of landing.

To clarify the various interpretations of these

markings, standardization of helideck markings is

crucial to improve landing safety.

It takes time for a helideck to be inspected and

verify compliance with applicable standards or

industry guidelines. A trained and competent helideck

inspector will need to be transported to the facility by

helicopter, leading to significant additional costs.

These costs also include travel labor costs of the

inspector, offshore room, and board for the inspector,

as well as the potential disruption of the daily

activities at the facility due to the inspection of the

helideck. With the vast number of active helidecks in

234

Bosman, M., Sekeroglu, K. and Alkadi, G.

Improved Assessment of Offshore Helideck Marking Standards’ Compliance using Optimized Machine Learning Principles in the U.S. Gulf of Mexico.

DOI: 10.5220/0011108800003209

In Proceedings of the 2nd International Conference on Image Processing and Vision Engineering (IMPROVE 2022), pages 234-241

ISBN: 978-989-758-563-0; ISSN: 2795-4943

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

the U.S. Gulf of Mexico, this presents an immense

challenge. It will take considerable sum of money and

resources to inspect and subsequently improve

marking standards’ compliance for all helidecks in

the U.S. Gulf of Mexico.

1.1 Helidecks in the U.S. Gulf of

Mexico

Oversight of platform structures is being handled by

the Bureau of Safety and Environmental Enforcement

(BSEE) and the U.S. Coast Guard (USCG), where

floating facilities and vessels are under the USCG, the

fixed-leg facilities on the U.S. Continental Shelf in

the Gulf of Mexico are overseen by BSEE. BSEE has

a database that maintains the number and details of

active and non-active offshore facilities in the U.S

Gulf of Mexico, excluding vessels. The number of

offshore facilities that are currently active can be

derived from this BSEE database. Using the available

dataset as of 1/23/2021, a pivot table can be created

to identify those facilities that may potentially be non-

compliant and in need of inspection to assess if they

need to be re-marked to become compliant with

current available guidelines. The resulting pivot table

shows that there are 1311 facilities that need to be

assessed and might be candidates for re-marking.

1.2 Helideck Design

Offshore helideck safety starts with a safe design. In

this section, the available standards and guidance

material regarding design will be introduced. Design

criteria include the application of markings as visual

cues to help the helicopter pilot interpret safety

related information.

Currently, there are three prevailing guidance

documents available for use in offshore helideck

design. These three documents are the International

Civil Aviation Organization (ICAO) Doc 9261 Part 1

- Heliport Manual (International Civil Aviation

Organization, 2018), United Kingdom Civil Aviation

Authority (UK CAA) Publication 437 Standards for

offshore helicopter landing areas (CAP 437), and The

Code for the Construction and Equipment of Mobile

Offshore Drilling Units, 2009 (2009 MODU Code

(International Maritime Organization, 2010)).

ICAO Doc 9261 Part 1 is approved by and

published under the authority of the Secretary

General of the United Nations. Within ICAO, the 191

Member States and several global aviation

organizations work together to develop international

Standards and Recommended Practices (SARPs).

These SARPs are the references countries utilize to

develop their national civil aviation regulations,

which then become enforceable. This is an important

aspect: ICAO SARPs are not legally binding by

themselves. Instead, they form the basis of national

regulations which have legal status. As such, ICAO

Document 9261 provides global guidance regarding

the design of offshore helicopter landing areas,

including helidecks, and should be used by civil

aviation authorities to develop their own regulations.

CAP 437 is a similar standard created by the UK

CAA and is a mandatory standard for all the helidecks

under their regulatory oversight. CAP 437 has been

applied in the North Sea since 1981 and has since

undergone several amendments. “CAP 437 presents

the criteria required by the CAA in assessing the

standards of offshore helicopter landing areas for

world-wide use by helicopters registered in the UK”

(International Civil Aviation Organization, 2018) . As

international vessels and drill ships with helidecks

move around the globe, several of those vessels have

been in the operating region of the U.S. Gulf of

Mexico. As a result, this document has started to

influence helideck design guidelines for other

platforms and installations in the U.S. Gulf of

Mexico. In addition, the CAP 437 design guidelines

are considered an equivalent design standard to the

design requirements mentioned in the U.S. Code of

Federal Regulations for Helideck design by the

USCG (Hawkins, 2015).

The 2009 MODU Code is a document that

addresses requirements for drilling ships and vessels;

it does provide a section regarding helideck design

guidelines. It facilitates their international movement

and operation, plus it ensures a level of safety for such

units and for personnel on board. However, as the

MODU code only focuses on ships and vessels, and

not all platform facilities, it is outside of the scope of

this thesis, so this concludes the introduction and use

of the 2009 MODU Code.

Due to the limited number of design criteria

specifications in the United States Code of Federal

Regulations, the energy industry in the U.S. Gulf of

Mexico started developing their own guidance

material in the form of Recommended Practices

(RPs). In 1978, the Helicopter Safety Advisory

Conference (HSAC) was created as a conference

composed of over 115 members. This conference

creates RPs for the industry in the U.S. Gulf of

Mexico. In 2008, they started their process of

developing RPs for helideck markings. The RPs were

influenced by CAP 437, but not fully identical in

every aspect of the document, such as the system of

measurement (imperial units versus metric). HSAC

decided to combine relevant elements of onshore

Improved Assessment of Offshore Helideck Marking Standards’ Compliance using Optimized Machine Learning Principles in the U.S. Gulf

of Mexico

235

helideck markings from the Federal Aviation

Authority (FAA) Advisory Circulars and from CAP

437. They merged these elements, along with their

own innovative ideas, into RP 2008-1 Offshore

Helideck Markings in the U.S. Gulf of Mexico. Since

2008, an additional document, RP 2013-1 regarding

Helideck Parking Area Markings was developed, and

ultimately all helideck marking guidance was

absorbed into the HSAC RP 160-series of helideck

design guidance between 2016 and 2019.

For a pilot to safely land on the intended helideck,

the pilot needs to be able to correctly identify the

helideck, know the size and weight capacity of the

helideck he is going to land on, and any obstacles he

needs to avoid (Bosman, 2021).

To ensure that the pilot safely lands on the

helideck of the intended platform, the identification

marking on the helideck must be recognizable.

Guidance material depicts this identification marking

as white lettering in a specific location of the

helideck. In HSAC RP 161 (Helicopter Safety

Advisory Conference, 2021) and CAP 437

(International Civil Aviation Organization, 2018), the

identification marking locations are identical. Both

identification markings are white, and while minor

differences in size of font may occur, overall, these

documents provide similar guidance for pilot

recognition.

Secondly, the pilot needs to be able to verify the

weight limitations and size of the helideck. A

helideck is designed for a specific model helicopter,

which is the largest helicopter type the helideck is

intended to serve. This design helicopter determines

the maximum weight and size of the helideck. Once

designed for this largest envisioned helicopter to be

operating to the helideck, the helideck can safely

accept that helicopter type and all smaller and lighter

helicopter types. The weight capacity is therefore

capped to the maximum allowable take-of mass

(MTOM) of the design helicopter, which is available

in the rotorcraft flight manual of the design

helicopter. The helideck size is determined by the D-

value of the design helicopter. The d-value is defined

as “The largest overall dimension of the helicopter

when rotor(s) are turning, measured from the most

forward position of the main rotor-tip-path plane to

the most rearward position of the tail rotor-tip-path

plane or rearward extension of the helicopter

structure” (Helicopter Safety Advisory Conference,

2021). The markings for weight and size between

HSAC RP 161 and CAP 437 differ due to separate

units of measurements used. CAP 437 documentation

and marking standards are fully based on the metric

system, whereas HSAC RP 161 is based on the

imperial system while also providing some metric

system options. CAP 437 (International Civil

Aviation Organization, 2018) displays weight

markings in metric tons in one specific location on the

helideck. Size limitations are displayed on the

helideck perimeter line using the applicable D-values.

HSAC RP 161 (Helicopter Safety Advisory

Conference, 2021) displays the D-value in a location

marked inside of the bottom three-tiered box outlined

in red preceded by the letter “D”.

Finally, the pilot needs to be aware of any

obstacles that might surround a helideck. Obstacle

related markings are divided into three individual

sectors: a 210 degree Obstacle Free Sector (OFS), a

150 degree Limited Obstacle Sector (LOS) and a “No

Nose” sector. The OFS is “An area free of all

obstacles above helideck level outwards to a distance

that will allow for an unobstructed arrival and

departure path to/from the helideck for the

helicopter(s) it is intended to serve” (Helicopter

Safety Advisory Conference, 2021).The opposite side

of the chevron marking is the LOS. As opposed to the

OFS where n obstacles are allowed, the LOS allows

some obstacles to be present, as long as they remain

smaller in size than the preset profile. Obstacles in the

colored areas shall remain below the associated

height profile for the helideck to be considered

compliant, providing a safe operating area for

helicopters. If an object protrudes from the labeled

sections, the helideck is not considered safe to land.

The “No Nose” sector is a sector where the location

of the helicopter’s nose is not allowed to go over to

avoid the tail rotor to strike any obstacle or prevent

the tail rotor to be maneuvered over a helideck access

point.

According to Table 1 (Composed from the BSEE

database) there are 1194 facilities that were built

before 2008. Resulting in 91.1 percent of the

facilities in the U.S. Gulf of Mexico with the

potential of being non-compliant to HSAC RP

helideck marking guidelines. Additionally, the U.S.

Coast Guard did not approve CAP 437 for use within

the U.S. Gulf of Mexico until 2015 (Hawkins,

2015). Cross referencing the BSEE database to filter

out the number of facilities before 2015

demonstrates that 98.8 percent of helidecks in the

U.S. Gulf of Mexico might not follow the CAP 437

guidance materials.

Seeing as a staggering 98.8 percent of helidecks

have not yet been verified as compliant with marking

standards and therefore cannot be positively

confirmed to be safe for landing, it is imperative that

arrangements are made to further ensure offshore

helideck operations safety. With the use of an image

IMPROVE 2022 - 2nd International Conference on Image Processing and Vision Engineering

236

Table 1: Percentage of helidecks in the Gulf of Mexico.

Number of

Helidecks

Percentage of all

Helidecks in

U.S. Gulf of

Mexico

1311 100.0%

Helidecks

before 2015

1295 98.8%

Helidecks

before 2008

1194 91.1%

classification program, this issue of quickly verifying

if helideck markings are applied using an available

and acceptable standard can be easily resolved with

much less hassle and cost.

2 METHODS

2.1 Marking Standard Comparison

To properly identify helidecks and categorize them

accordingly, a comparison needs be made between

HSAC RP 161 and CAP 437. Both helidecks are

painted green, have a yellow circle (Touch

Down/Positioning Marking), an identification name,

the letter ‘H’, and a chevron in a relative location of

the ‘H’. HSAC RP 161 helidecks have a distinguished

three-tiered red box to display the size, dimensions,

and weight specifications of the helideck, where CAP

437 helideck size markings are located within the

perimeter line and the weight marking is identified in

the top left corner. These are the key elements that the

machine learning algorithm needs to be able to

identify to distinguish between HSAC RP 161 and

CAP 437 helidecks. Moreover, a third option will be

added for the algorithm to use if the helideck is not

able to be classified as either HSAC RP or CAP 437,

it will be categorized as None. The third option is the

most important option in this regard, as it will show

which helidecks are non-compliant to either marking

standard or will therefore have to be re-marked using

one of the acceptable standards.

2.2 Assessment of Helidecks Utilizing

Deep Convolutional Neural

Networks

The main goal for the proposed convolutional neural

network model is to identify if the helideck is

compliant or not based on an image. Since there are

limited options in obtaining photographs of offshore

helidecks, the use of the guidance material can aid in

creating self-developed (artificial) compliant

imagery. This will demonstrate to the convolutional

neural network how each helideck is supposed to look

when following the HSAC RP 161 guidance material,

the CAP 437 material, or None at all. Secondly, a

convolutional neural network model with initial

parameters is needed to provide a base and from there

build an optimized model. While the parameters will

change within the convolutional neural network

through training, certain parameters such as kernel

size, pooling size, and the size of the fully connected

layer must be set manually. Based on the results of

the initial configuration of the model, the accuracy

might not be acceptable, therefore layers might need

to be added, removed, or modified to adjust the model

and increase the desired accuracy.

Convolutional neural networks are like traditional

neural networks in that they are both able to optimize

their weights by learning. They also end the same way

by receiving the outputs of earlier nodes and use loss

functions to classify the object (O’Shea & Nash,

2015). Where traditional neural networks and

convolutional neural networks differ is that in

traditional neural networks, the data is composed of

text or numbers, such as a database, whereas

convolutional neural networks perform their

operations based on imagery and find information

within images to recognize patterns.

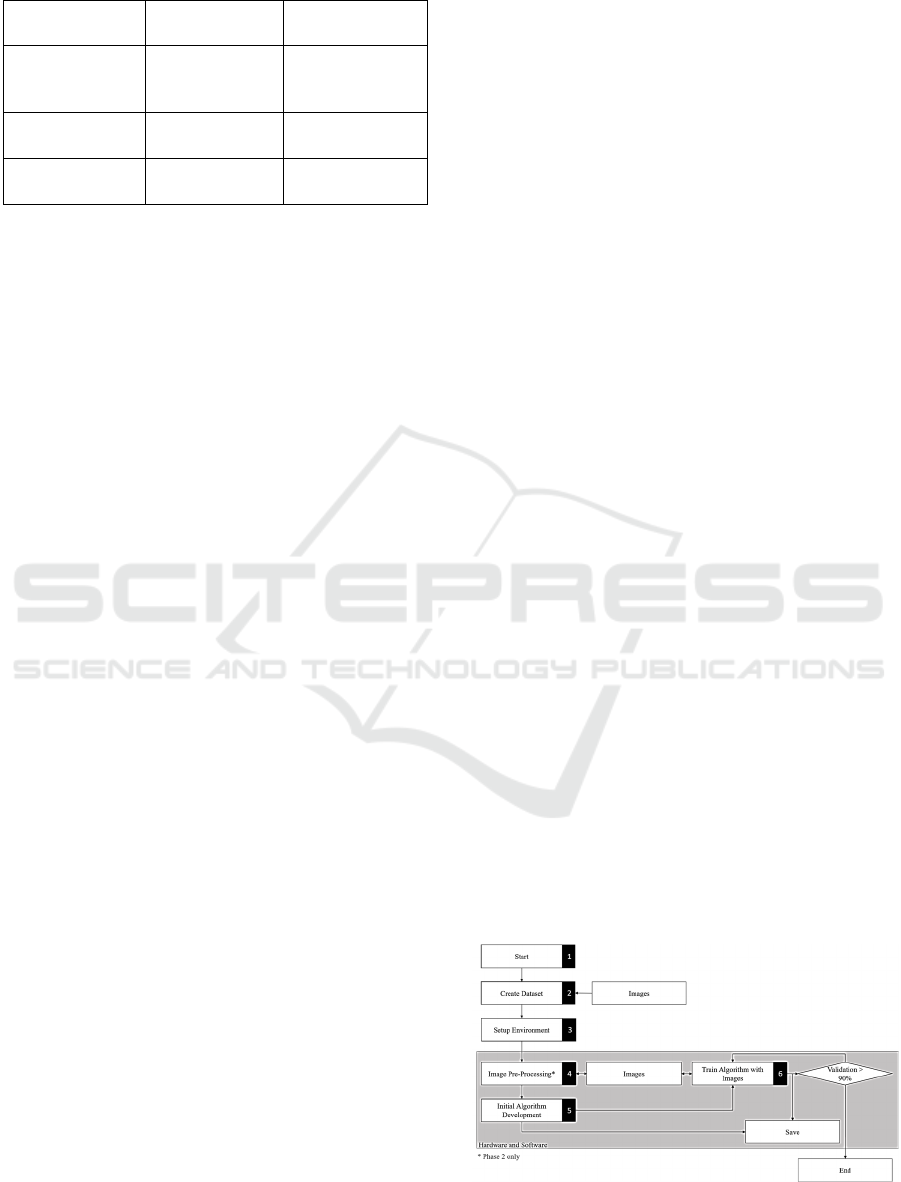

The proposed framework can be explained using

the diagram in Figure 1 below. For each block in the

process, a brief explanation is available to explain

each specific process and the associated activities that

were performed. The process will run in two different

phases: phase one being composed of images that

were self-developed (artificial) using the guidance

materials, and phase two being composed of

photographs from offshore facilities in the U.S. Gulf

of Mexico. One key difference is the Image Pre-

Processing stage, as it is not performed in phase one,

while in phase two, each photograph will need to be

pre-processed before entering the convolutional

neural network.

Figure 1: Flowchart of methodology.

Improved Assessment of Offshore Helideck Marking Standards’ Compliance using Optimized Machine Learning Principles in the U.S. Gulf

of Mexico

237

2.3 Phase One – Developing the Model

using Artificial Images

Using the guidance material, eight individual

helideck marking images were made for each

document, 8 using HSAC RP 161 and 8 using CAP

437, resulting in 16 distinct images for the machine

learning process. These images include helidecks that

are round, rectangular, and octagonal. Based on these

16 images, the category None was created manually

by copying the images and using a photo editor to

change colors and remove key elements. This process

resulted in a folder with 23 individual images and

were categorized as HSAC, CAP 437 or None.

Before being able to create a dataset, the model

will need to distinguish individual images from each

other. To achieve this, each image has been verified

and classified manually and the filename reflects the

classification of the image. The filenames will either

start with a prefix CAP 437, HSAC, or None.

In Convolutional Neural Networks, more

available data provides better overall results. The

number of 23 images currently available is not

enough to properly train a convolutional neural

network. Data augmentation was used to

automatically generate more images for the network

to use during learning. The data augmentation

consisted of taking a single image and altering

saturation, brightness, or rotation to generate

additional images that have different properties.

Tensorflow has an ImageDataGenerator function that

can adjust the mentioned property values and save the

newly generated image to a different location (Abadi,

et al., 2015). Additionally, this function can perform

functions such as flipping the image orientation,

shifting horizontally and vertically, adjusting zoom

levels to make it appear closer or further away, and

shearing the image to make the helideck appear

angled (Abadi, et al., 2015). The augmented image

was sheared, mirrored horizontally, zoomed out, and

has an increased brightness. Repeating this step for

each image 100 times will result in over 4,343 images

as a dataset for the neural network learning.

Just as important as the algorithm itself, the

environment used to train the algorithm needs to be

taken into consideration. While the model can be

exported and be reused in other hardware, the training

process requires a more robust setting. For this

training process a desktop computer with a ZOTAC

GeForce® GTX 1070 Ti Mini graphics card was used

to train the model.

The graphics card aids in accelerating the neural

network training process by using the Tensorflow

library. This library will use the CUDA cores to allow

parallel processing (Abadi, et al., 2015). The software

used in this process was Microsoft Visual Studio

Code with the Python extension provided by

Microsoft. Libraries within Python 3.8.7 mainly

consist of Tensorflow 2.4.1 and keras 2.4.3, while

sklearn was used for metrics (Pedregosa, et al., 2011).

A base convolutional neural network model is

first created to start the process of finding an

optimized model. The base model is manually

constructed to increase productivity and a gradient

descent optimizer is selected. Based on the resulting

graphs of accuracy and loss, manual modifications

are made to add and adjust layers and create a model

that demonstrates the desired learning curve, as well

as a desired loss function curve.

This initial model will also define the compiler

used for future fine-tuning, and will be chosen

between SGD, AdaDelta, RMSprop, and Adam. The

chosen optimizer will be based on the graphs

generated after each training session and by the

performance of the model.

During the training, the model will be modified

until it has a validation accuracy above 90 percent

This number was chosen as this program is meant to

be an aid to the pilot, so in case it does misidentify,

the pilot will still be able to personally verify the

helideck. In this process, the computer uses a loop to

modify the number of convolutions per layer and the

number of nodes per dense layers to find a model that

has an accuracy above 90 percent.

The accuracy of the predictions is dependent on

the training and testing data. There are no universal

rules regarding the identification of proper ratios

between training and testing data to obtain a certain

percentage in accuracy. Also, as the size of the

training data increases, the accuracy of the model will

likewise increase (Medar, Rajpurohit, & Rashmi,

2017). Focusing on the model, rather than the number

of images it is training and testing on, will give the

program the chance to obtain accuracies of 90 percent

or higher. The training and testing ratio will be set at

75 percent training and 25 percent testing. Using this

ratio, the model will have enough images to learn and

adapt to the ratio to get accuracies above 90 percent.

In case the optimization process is not able to obtain

90 percent, the training and testing ratio will be

modified and then the process will have to be

restarted to find the proper model.

2.4 Phase Two - Developing the Model

using Real Images

Phase two of the process is similar to phase one,

except that instead of self-developed images actual

IMPROVE 2022 - 2nd International Conference on Image Processing and Vision Engineering

238

photographs are used. The photographs need to be

pre-processed before entering the neural network.

Additionally, the previously optimized model in

phase one is now being used as the initial model to

start phase 2. In other words, the model used in phase

2 benefits from the transfer learning approach. Most

of the photographs obtained had a broad range of

resolutions. Some images were as large as 4252 by

2838 pixels compared to other images which were as

small as 640 by 480 pixels in resolution. In addition,

some images included the entire facility and not just

the helideck. Therefore, some images needed to be

resized and cropped to focus on the helideck in order

to be usable in the convolutional neural network. The

image preparation was performed through a process

of segmentation, in which certain features are filtered

out of the image depending on the users’

specifications.

The similarities in HSAC RP 161 and CAP 437

work in the favor of segmentation in such a way that

the computer can focus on the helideck being green

to find it in the image. For this process to work, each

image is converted into a three-dimensional array,

this is done because each image is composed of

values for red, green, and blue, and range from zero

to 255. Unfortunately, there is a drawback, as each

pixel in an image has a green value to create its color.

This results in it being more difficult for the computer

to find the green helideck. To remedy this, hue,

saturation, and value (also known as intensity) are

used to give more control over which green to look

for. Applying a range of green values, contrast values,

and intensity values, the computer can filter the image

based on the range provided. This is also known as

thresholding.

Within python, using the OpenCV (commonly

called cv2) library, the use of masks can help segment

the helideck from the rest of the image (Bradski,

2000). To develop this mask, a custom tool was

created to find the ranges of hue, saturation, and

intensity of the green helideck. The tool provides a

graphical interface where color (HSV) values can be

adjusted at will, filtering the color of the resulting

image. Once the values are identified, they can then

be used in the findContours function built into the cv2

library. This function will locate a rectangle around

the helideck and create the image that will later be

used in the neural network (Bradski, 2000).

Moreover, a total of 56 photographs of helidecks

or offshore platforms with helidecks were collected,

and these underwent the same data augmentation

process as mentioned under phase one to generate

additional photographs for the dataset. The same

parameters for data augmentation were used as in

phase one. This resulted in 4,873 photographs that the

neural network can use.

3 RESULTS

3.1 Results of Phase One

The initial model starts off with a single 200-by-200

pixel image. This image was then convoluted with 32

filters in the convolutional layer. Following this, the

ReLU activation layer was used to remove the

negative values that may appear and adjust them to

zero. After activation, a dropout rate of 50 percent

was applied; meaning that out of the 32 nodes, 16

were randomly selected to be passed onto the next

layer. The next layer is the fully connected layer, in

which the 16 nodes are then condensed into one single

vector. At the end of the network, the dense layer will

further narrow the results down to three choices. The

softmax activation layer will then use these three

choices to return a probability vector.

Using this model, different optimization

algorithms were used to find the optimum. Adam and

RMSProp show the most potential. Adam, however,

showed a more stable curve, and was therefore chosen

to be used for the rest of the development. Using the

Adam compiler and step five of the methodology, a

more complex network was created. This model was

able to reach an accuracy of 98.1 percent. Both the

confusion matrix and classification report are shown

below in Table 2 and Table 3. These show the model

tends to classify some helidecks that were None as

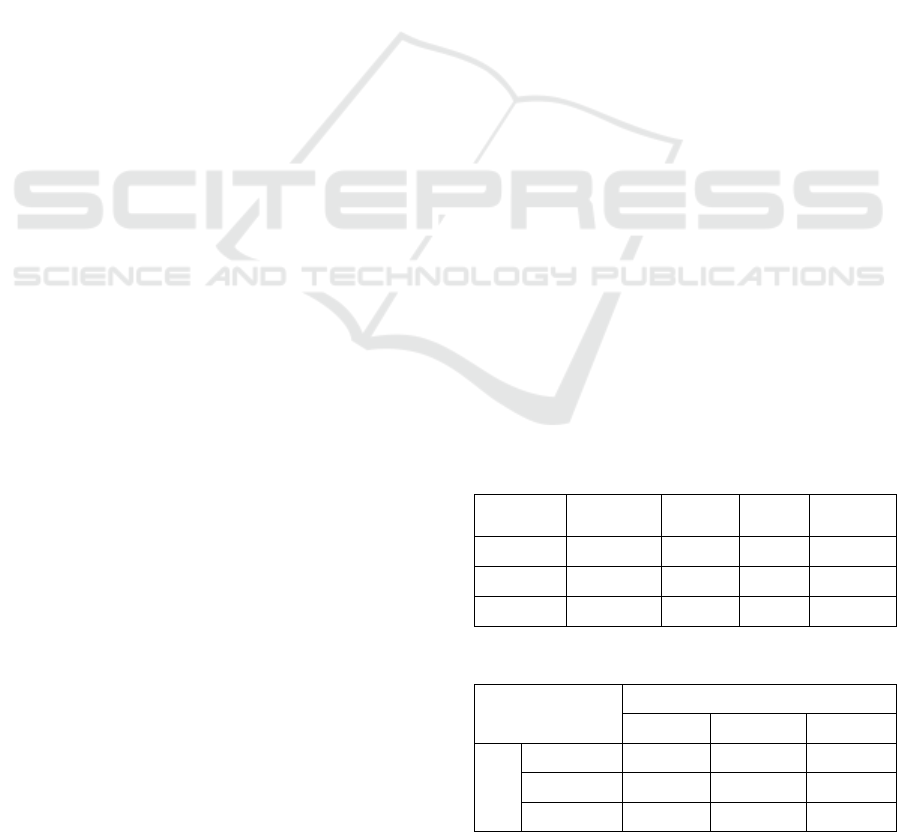

HSAC RP 161 helidecks. As seen in Figure 2, the

model was able to learn the data at a steady rate, and

both accuracy and loss remained close together

throughout the entire training process.

Table 2: Confusion matrix of final theoretical model.

Precision Recall

F1-

score

Support

CAP 437 0.98 0.97 0.98 427

HSAC 0.99 0.95 0.97 603

None 0.91 0.98 0.95 189

Table 3: Classification report of the final theoretical model.

Actual

CAP 437 HSAC None

Predicted

CAP 437 200 0 2

HSAC 0 183 14

None 0 4 683

Improved Assessment of Offshore Helideck Marking Standards’ Compliance using Optimized Machine Learning Principles in the U.S. Gulf

of Mexico

239

Figure 2: Accuracy and loss of the phase one model.

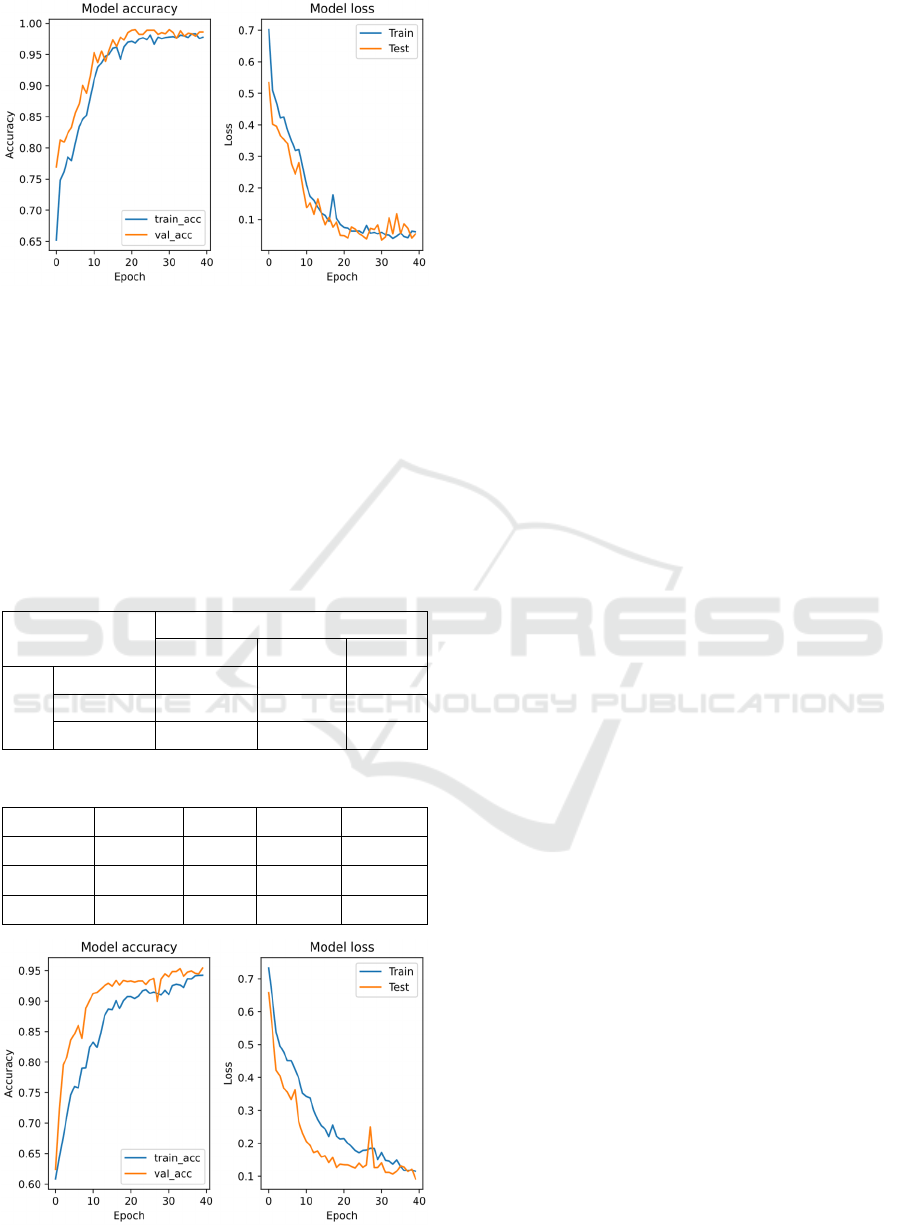

3.2 Results of Phase Two

In phase two, images are cropped and resized to the

resolution of 200 by 200 pixels in the pre-processing

stage. The same model and compiler from the

previous phase were used for this phase as well, with

the model being re-trained using the pre-processed

photographs rather than the manually created images

used in phase one. The model was able to train up to

Table 4: Confusion matrix from phase two model.

Actual

CAP437 HSAC None

Predicted

CAP437 407 7 13

HSAC 16 551 36

None 4 1 184

Table 5: Classification report from phase two model.

Precision Recall F1-score Support

CAP 437 1.00 1.00 1.00 202

HSAC 0.98 0.94 0.96 197

None 0.98 1.00 0.99 687

Figure 3: Accuracy and Loss curves of phase two model.

an accuracy of 95.7 percent. This is lower than phase

one, but it is to be expected due to the noise presented

in the photographs. The same confusion matrix,

classification report and performance graphs were

generated to evaluate the model and are shown in

Table 4 and Table 5 as well as Figure 3.

4 DISCUSSION

4.1 Conclusions

According to the literature review, the standardization

of offshore helideck marking is an important aspect

for the safety of offshore helicopter occupants. With

standardized markings in place, the pilot will be able

to identify the correct helideck, know its weight and

size limitations, and be able to find obstacle sector

markings crucial for landing safely such as the OFS,

LOS, and “No Nose” sectors. To ensure that

acceptable marking standards are complied with,

assessments of each individual offshore helideck

must be completed. Unfortunately, to do this requires

many resources due to the number of applicable

helidecks, manpower needed to perform the

inspections, and costs associated with offshore travel

for the inspectors and their hourly rate as subject

matter experts. In-person assessment of individual

helidecks will also require many years to complete.

Using machine learning, this task can be accelerated

and simplified with the use of convolutional neural

networks, where images are used to classify a

helideck into three different categories of helideck

marking standards: HSAC RP 161, CAP 437, or

None. These standards depict safety related markings

in specific locations on a helideck where the pilots

can obtain information quickly. Images were

generated based on the marking requirements in

HSAC RP 161, CAP 437, and None, and photographs

were pre-processed to focus on the helideck rather

than the entire platform.

Using the literature review results, and the

flowchart depicting the methodology, two models

were created in separate phases. Phase one to classify

manually constructed images, and phase two to

classify actual helideck photographs using the

transfer learning approach. The objective of each

phase was to create a theoretical model that had an

accuracy above 90 percent. The first phase resulted in

a model classification success rate of 98.1 percent,

while phase two had a success rate only slightly

decreased at 95.7 percent. These results show that

optimized machine learning principles can be used to

improve the assessment of compliance of offshore

IMPROVE 2022 - 2nd International Conference on Image Processing and Vision Engineering

240

helideck marking standards in the U.S. Gulf of

Mexico.

4.2 Future Work

There is potential in this model to possibly be

integrated into a helicopter, where a camera and

artificial intelligence can assist the pilot in identifying

hazards, obstacles, and destination information in

real-time. This model can also be adjusted to possibly

include other marking standards or recommended

practices, thereby furthering its reach to outside of the

U.S. Gulf of Mexico.

This model could provide a base understanding to

add additional features such as obstacle detection

around the helidecks to improve safety even more or

initiate another research to use infrared and/or radar

imagery in real time to augment pilot vision and

situational awareness.

Moreover, this model is not limited by the

offshore applications. It can also be used for onshore

applications such as hospital and rooftop heliports.

REFERENCES

Abadi, M., Agarwal, A., Barham, P., Brevdo, E., Chen, Z.,

Citro, C., . . . Zheng, X. (2015). TensorFlow: Large-

Scale Machine Learning on Heterogeneous Systems}.

Retrieved from https://www.tensorflow.org/

Bosman, P. (2021, February 10). Helicopter Safety. (M.

Bosman, Interviewer)

Bradski, G. (2000). The OpenCV Library. Dr. Dobb's

Journal of Software Tools.

Hawkins, B. J. (2015, September 3). Acceptance of CAP

437, Standards for offshore helicopter landing areas.

CG-ENG Policy Letter No. 03-15. Washington, District

of Columbia, United States of America: U.S. Coast

Guard, U.S. Department of Homeland Security.

Retrieved from https://www.dco.uscg.mil/Portals/9/

DCO%20Documents/5p/5ps/Design%20and%20Engi

neering%20Standards/docs/CG-ENG%20PolicyLetter

%2003-15.pdf

Helicopter Safety Advisory Conference. (2021). HSAC RP

161 (Second Edition ed.). Helicopter Safety Advisory

Conference.

HSAC ~ Helicopter Safety Advisory Conference - Home.

(2016). Retrieved from HSAC ~ Helicopter Safety

Advisory Conference: http://www.hsac.org/

International Civil Aviation Organization. (2018). Heliport

Manual. Montréal: International Civil Aviation

Organization.

International Maritime Organization. (2010). 2009 MODU

code: code for the construction and equipment of

mobile offshore drilling units. London: International

Maritime Organization.

Medar, R., Rajpurohit, V. S., & Rashmi, B. (2017). Impact

of Training and Testing Data Splits on Accuracy of

Time Series Forecasting in Machine Learning. 2017

International Conference on Computing, Communica-

tion, Control and Automation (ICCUBEA), 1-6.

O’Shea, K., & Nash, R. (2015). An Introduction to

Convolutional Neural Networks. eprint

arXiv:1511.08458, 10.

Pedregosa, F., Varoquaux, G., Gramfort, A., Michel, V.,

Thirion, B., Grisel, O., Duchesnay, É. (2011). Scikit-

learn: Machine Learning in Python. Journal of Machine

Learning Research, 12, 2825-2830.

Improved Assessment of Offshore Helideck Marking Standards’ Compliance using Optimized Machine Learning Principles in the U.S. Gulf

of Mexico

241