Process Mining to Discover the Global Process

from its Fragments’ Executions

Minh Khoi Nguyen, Hanh Nhi Tran and Ileana Ober

Institut de Recherche en Informatique de Toulouse, Toulouse, France

Keywords:

Process Mining, Artifact-centric Process Modeling, Data-driven Process Engine.

Abstract:

Process analysis to improve performance and detect anomalies is important for process management. How-

ever, such an analysis requires a global process model that is sometimes hard to get, especially for complex

processes involving various teams. This is also an obstacle for BAPE (Bottom-up Artifact-centric Process

Environment), an artifact-centric process management environment that allows splitting a process into several

fragments which are separately modeled and enacted by different actors. Thus, the knowledge about the whole

process is distributed over the involved teams and an overview on the complete process is missing. This paper

presents the integration of process mining into BAPE in order to construct the overall process model from the

execution data of process fragments.

1 INTRODUCTION

Process Management Systems (PMSs) provide sup-

ports at the operational level to manage the execution

of processes. A PMS relies on explicit process mod-

els to coordinate and synchronize process activities

at enactment time. Mainstream PMSs embody a top-

down approach that models a process as a whole to

enable its enactment. In contrast to the conventional

PMSs, in our previous work, we proposed a bottom-

up approach that splits a process into several frag-

ments which are separately modeled and enacted by

process actors who play different roles in the process

(Hajmoosaei et al., 2017).

We have developed BAPE (Bottom-up Artifact-

centric Process Environment) for modeling and enact-

ing process fragments. BAPE use a data-driven pro-

cess engine to construct progressively, at enactment

time, the global process from different process frag-

ments. Thus, to execute a process, BAPE does not

require the model of the whole process, but accepts

a partially-defined model, i.e. one with some miss-

ing fragments. Although this feature is an advantage

of BAPE, it also makes process analyzing harder in

BAPE due to the lack of an overall process model.

Process Mining (van der Aalst, 2016) is a promis-

ing technique for diagnosing processes by mining

event logs to extract knowledge. Since its emergence,

process mining has gained important achievements in

providing techniques and tools for discovering differ-

ent process aspects (van der Aalst et al., 2004; van der

Aalst et al., 2017; Pe

˜

na and Bayona-Or

´

e, 2018; Kim

et al., 2021) and has been applied in numerous do-

mains (Rovani et al., 2015; Jokonowo et al., 2018;

Valencia-Parra et al., 2019; dos Santos Garcia et al.,

2019).

The work presented in this paper aims at improv-

ing BAPE by using process mining to discover the

global process from the execution traces of process

fragments. Integrating process mining into BAPE has

two benefits: (1) enabling the analysis of the whole

process in order to detect anomalies; (2) generating

process models of the missing fragments to enact and

control them inside BAPE in the future.

The remainder of this paper is organized as fol-

lows. Section 2 presents the current environment

BAPE with an example of a partially-defined process.

Section 3 introduces the process mining steps to ex-

ploit the execution data of process fragments for dis-

covering the global process model and process frag-

ments. Finally, section 4 concludes the paper.

2 BAPE

BAPE is a process management environment that

adopts an artifact-centric and data-driven approach to

model and enact processes. To better explain the main

characteristics of BAPE, we present first a running ex-

ample, then illustrate the propositions of BAPE on this

Nguyen, M., Tran, H. and Ober, I.

Process Mining to Discover the Global Process from its Fragments’ Executions.

DOI: 10.5220/0011044800003176

In Proceedings of the 17th International Conference on Evaluation of Novel Approaches to Software Engineering (ENASE 2022), pages 363-370

ISBN: 978-989-758-568-5; ISSN: 2184-4895

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

363

example.

2.1 Illustration Example

We take an extract of a process given by our indus-

trial partners as the running example for this paper.

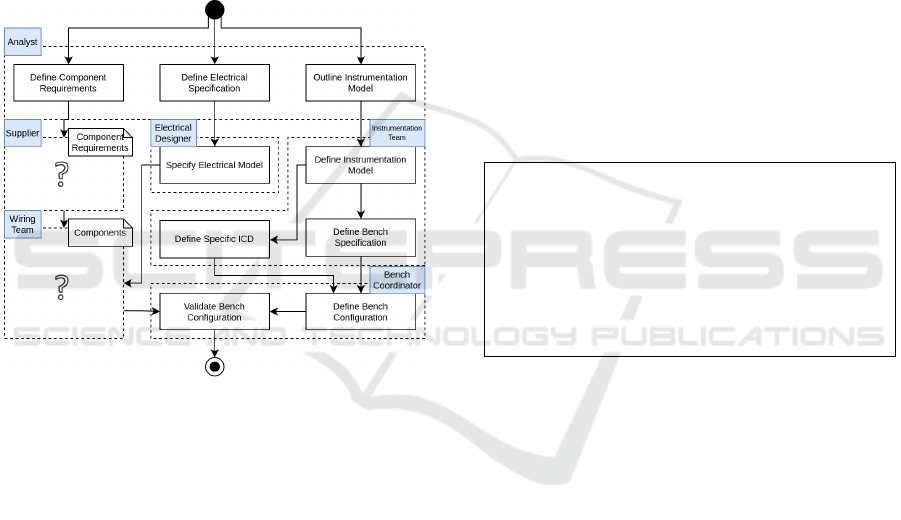

Figure 1 shows the process Modify Test-bench Wiring

which is executed to reconfigure the wiring system of

a test-bench due to an evolution of the system under

test. The process concerns several expertise domains

that can be geographically dispersed. Each role, i.e.

Analyst, Electrical Designer, Instrumentation Team,

Supplier, Wiring Team and Bench Coordinator, per-

forms specifics tasks to produce the required artifacts

in order to configure the test-bench.

Figure 1: Process of Modify Test-bench Wiring.

The process starts when the Analyst receives the

change requirement. Afterwards, he performs the

tasks Define Component Requirement, Define Electri-

cal Specification and Outline Instrumentation Model

to specify the required modifications or acquisitions

on wiring, electrical and instrumentation components

of the test-bench. These modifications are realized

in the next steps respectively by the Wiring Team,

Electrical Designer and Instrumentation Team. Af-

ter installing and wiring all required components in

the test-bench, process finishes when the Bench Co-

ordinator validates the configured test-bench.

2.2 Fragmented Process Model

In BAPE, a Process is comprised of several process

fragments. A Process Fragment encapsulates the ac-

tivities performed by a specific Role. An Activity de-

scribes a work composed of enactable tasks corre-

sponding to different sub-objectives. A Task, Manda-

tory or Optional represents an undivided work per-

formed by a process actor to put an Artifact, i.e. a

tangible work product, into a specific State. To avoid

being prescriptive about the way enacting processes,

BAPE does not define explicitly the work-sequence

relations between tasks. However, if two tasks work

on the same artifact, the artifact’s demandedState in

the tasks’ preconditions and post-conditions define

the order to execute these two tasks.

Figures 2 illustrates a fragment of the process in

Figure 1 corresponding to the role Analyst. The pro-

cess fragment includes an activity Detail Change Re-

quirement composed of three tasks. The two manda-

tory tasks Define Component Requirements and De-

fine Electrical Specification are always realized but

the optional task Outline Instrumentation Model will

be executed only if the option instrumentation is ac-

tivated. The mandatory task Define Electrical Spec-

ification requires two input artifacts Wiring Change

Demand and FICD in states defined. The later ar-

tifact, produced by the Instrumentation Team, is re-

quired only if the instrumentation option is activated.

Process Modify Test-bench Wiring options instrumentation, interface

ProcessFragment Analyst

Activity Detail Change Requirement options instrumentation

MandatoryTask Define Component Requirements

Artifact Wiring Change Demand(in, defined)

Artifact Component Requirements(out, defined, collection)

MandatoryTask Define Electrical Specification

Artifact Wiring Change Demand(in, defined)

Artifact FICD(in, defined, toFinish) ifOption instrumentation

Artifact Electrical Specification(out, defined)

OptionalTask Outline Inst. Model ifOption instrumentation

Artifact Wiring Change Demand(in, defined)

Artifact FICD(out, outlined)

Figure 2: Process Fragment of Analyst.

A process actor can use the process modeling lan-

guage of BAPE to model the process fragments of the

roles that he plays in a project. Each process fragment

can be modeled independently of the other fragments

but using the shared company assets.

BAPE does not require all the defined process

fragments to execute the whole process because it co-

ordinates the tasks in different fragments by the states

of exchanged artifacts. For instance, in our running

example, the process fragments of Analyst, Electrical

Designer, Instrumentation Team, and Bench Coordi-

nator are provided but those of Supplier and Wiring

Team are not defined. Thus, when the Modify Test-

bench Wiring process is executed, only the tasks of

Analyst, Electrical Designer, Instrumentation Team,

and Bench Coordinator are controlled by BAPE, but

they can be synchronized with those of Supplier and

Wiring Team thanks to the exchanged artifacts Com-

ponent Requirements and Component Specifications.

ENASE 2022 - 17th International Conference on Evaluation of Novel Approaches to Software Engineering

364

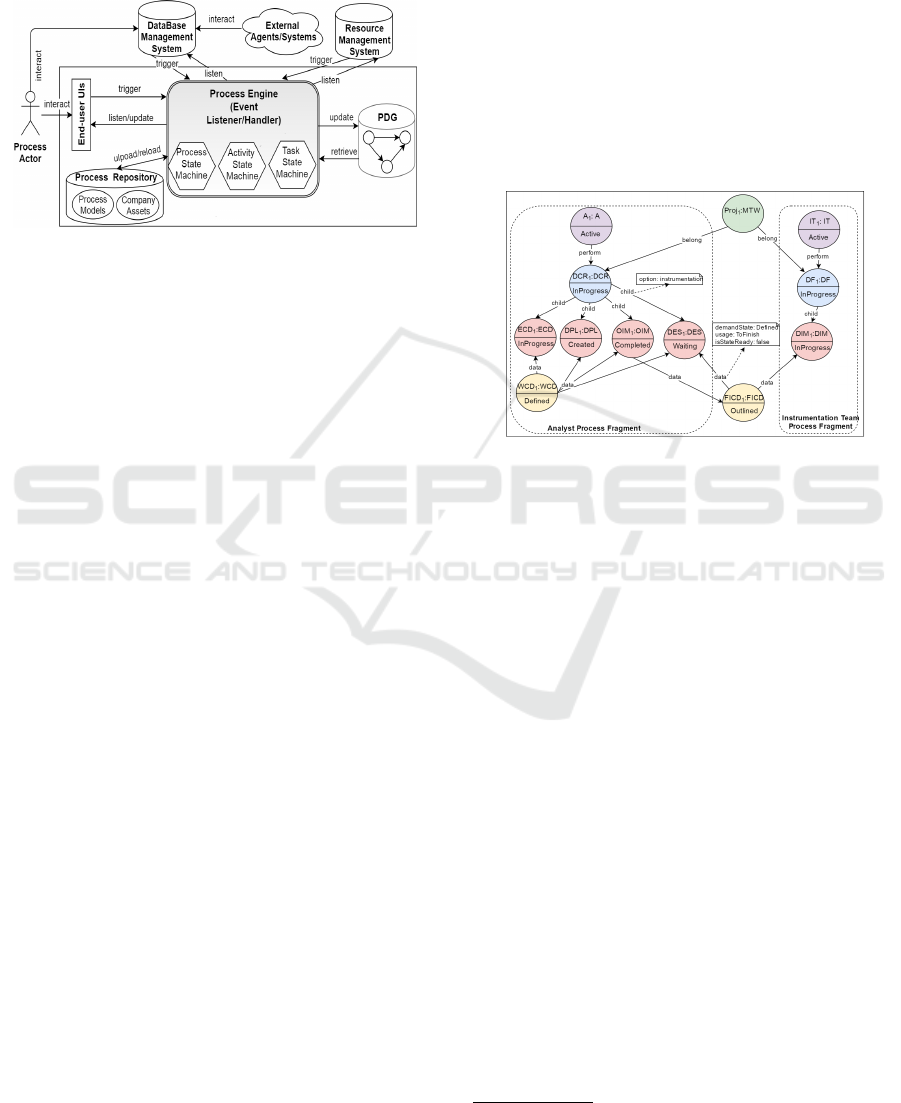

2.3 Components of BAPE

Figure 3 shows the architecture of BAPE with the

main components to control the execution of process

fragments operated by different actors.

Figure 3: Architecture of BAPE.

1. End-User UI: This component provides interfaces

that allow process actors to interact with the pro-

cess environment. Process actors define their pro-

cess fragments then store them into the Process

Repository via the modeling interface. They use

the enactment interface to manage their activities

and tasks (e.g., create, start and complete tasks).

Each user’s action triggers a specific event that is

handled by the process engine which decides if

the required action is valid to be taken.

2. Database Management System: We suppose that

resources (e.g., process actors, tools, etc.) and

working artifacts are externally managed by each

company proper tools. However, those external

tools use a central Database Management Sys-

tem (DBMS) which is connected to BAPE. This

connection makes the process environment being

aware of any events changing the state of artifacts

and resources in the external information systems

of process actors.

3. Process Dependency Graph (PDG): In BAPE, the

information of running processes is stored in a

graph-based structure called PDG, which is com-

posed of nodes representing process elements (i.e.

tasks, activities, artifacts and actors) and arcs rep-

resenting the relationships between these process

elements (e.g. links between a task and its input

and output artifacts). PDG is progressively up-

dated whenever a task from any of process frag-

ment is realized. In this way, at enactment time,

PDG shows the current state of process elements

and establishes the global view of the system.

On one hand PDG is the information source for

the process engine to coordinate and synchronize

tasks, on the other hand PDG is the source to

extract execution traces of running process frag-

ments. Figure 4 shows an example of PDG con-

taining elements of two running process frag-

ments of the roles Analyst and Instrumentation.

These teams enact their tasks separately but can

be coordinated thanks to the shared artifact FICD.

4. Process Engine: This component is in charge of

enacting and synchronizing the processes man-

aged by BAPE. It listens to events triggered by

process actors (when doing tasks in the process

fragments controlled by BAPE) or by external sys-

tems (when updating elements of the process frag-

ments that are not controlled by BAPE) and ap-

plies appropriate actions to handle these events.

Figure 4: A snapshot of the PDG.

3 PROCESS MINING IN BAPE

We integrate process mining into BAPE for process

discovery purpose, i.e. we analyze the execution data

kept in an event log to build a process model. In the

context of BAPE, getting an event log containing all

information needed for mining the overall process is

not obvious because BAPE can execute partially de-

fined processes. Concretely, a process can be enacted

with some defined process fragments which are man-

aged inside BAPE and some missing fragments which

are not controlled by BAPE. While the execution data

of defined fragments are stored inside BAPE, those of

missing fragments are located in process actors’ own

information systems. Therefore, it is necessary to ex-

tract the execution traces from both of these sources to

build an event log that enables discovering the activ-

ities of different process fragments, even the missing

ones.

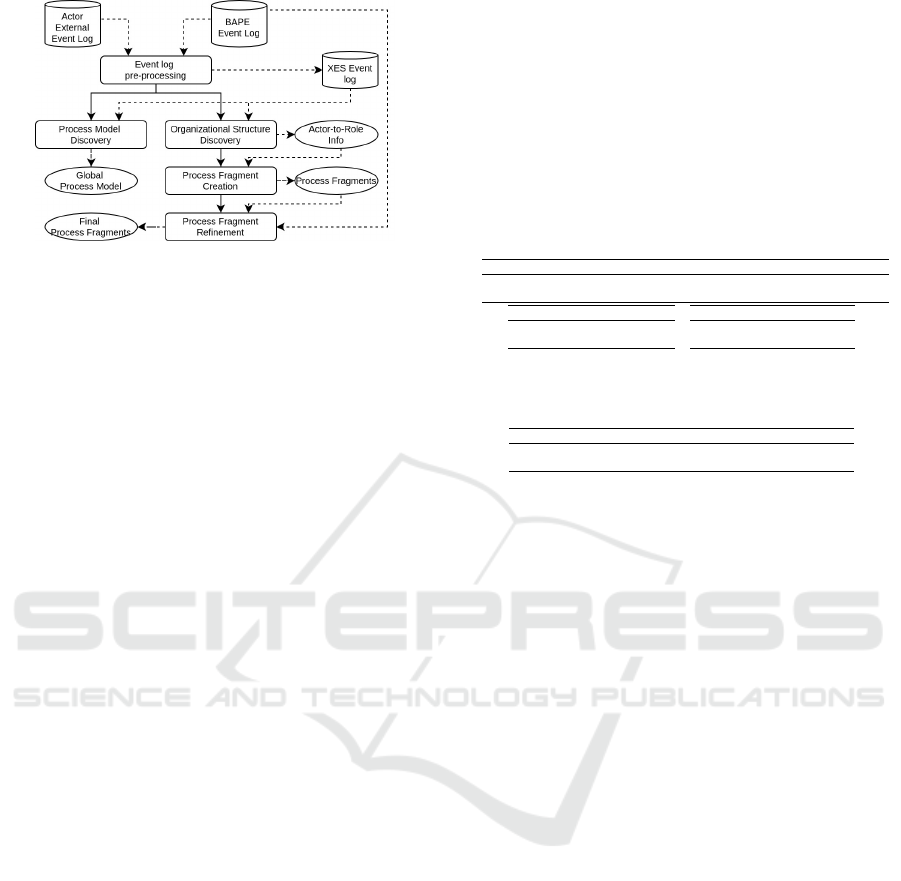

The process mining steps for BAPE are shown in

Figure 5. The first step Event log pre-processing (Sec-

tion 3.1) is for collecting the execution data from two

sources, BAPE event log and process actor’s informa-

tion systems, and building an event log in XES for-

mat

1

. Then the event log will be mined to extract

1

http://xes-standard.org/start

Process Mining to Discover the Global Process from its Fragments’ Executions

365

Figure 5: Process mining integration into BAPE.

knowledge about the global process on two aspects:

(1) Process Model Discovery (Section 3.2) establishes

the control flow between tasks executed in different

fragments and (2) Organizational structure Discovery

(Section 3.3) deduces the relationship between pro-

cess actors and the tasks they performed. The two

final steps presented in Section 3.4 are about creating

process fragment models corresponding to the identi-

fied roles of process actors.

3.1 Event Log Pre-processing

As explained earlier, we use two sources of execution

data of managed and unmanaged process fragments

to build an activity-centric event log for process min-

ing. Each event corresponds to the performing of a

task in a process instance (called case). To allow dis-

covering the control-flow between tasks as well as the

resources used by tasks (process actors and artifacts

needed for a task), each item in the even log must con-

tain the requisite information of an event: timestamp,

event name, actor relating to the event and artifacts

used in that event.

Code 1 shows an event in the event log extracted

from BAPE execution traces: actor A1 performed the

task Define Component Requirements using Wiring

Change Demand artifact at 2021-10-12 11:04:54. It

contains all necessary information, which is perfect

for process mining algorithm.

<event>

<string key="org:resource" value="A1"/>

<date key="time:timestamp" value="2021-10-12T11:03:54.032"/>

<string key="concept:name" value="Define Component Requirements"/>

<list key="artifactlifecycle:moves">

<values>

string key="artifactlifecycle:model" value="Wiring Change Demand">

<string key="artifactlifecycle:instance" value="WCD1"/>

<string key="artifactlifecycle:transition" value="in"/>

</string></values></list></event>

Code 1: An event extracted from BAPE execution traces.

In contrast to BAPE event logs, it was more com-

plicated with the execution data extracted directly

from process actors’ information systems of the miss-

ing fragments. In general, the transaction history in an

information system is created to keep traces of manip-

ulations on artifacts thus provides an artifact-centric

event logs. For example, Table 1 shows a snapshot

of the Supplier relational database in which there is

no explicit task recorded, but the history of manip-

ulations on orders and the relation between orders

and items). Table 2 shows a working history of the

Wiring Team which stores the changes made on man-

aged components: the status, the person in charge and

the timestamp of change.

Table 1: A snapshot of the Supplier’s information system.

orderId order personId receive release

o1 project1 s4 2022-01-20 12:34:56 2022-02-10 17:01:48

o2 project2 s3 2022-02-01 13:04:15

itemId name price

i1 component1 300

i2 component2 200

orderId itemId quantity

o1 i1 2

o1 i2 3

Table 2: An artifact log extracted from the Wiring Team’s

information system.

id name status personId timestamp

i1 component1 purchased p1 2022-01-30 12:00:05

i2 component2 installed p2 2022-02-05 16:40:38

In artifact-centric events logs, events of different

instances of the same artifact type can be in the same

case (divergence) or duplication of the same event can

appear into different cases (convergence). For exam-

ple, in the Supplier log, many component require-

ments from the Analyst (see Figure 1) could be the

items of the same order, which raises the convergence

issue. On the other hand, the log of Wiring Team

might have the divergence problem, since the same

installation step may appear multiple times for differ-

ent components in a case. In order to deal with such

complications, we had to apply some pre-processing

on the logs obtained from the missing fragments that

allow us to construct activity-centric logs more suit-

able for our process mining algorithm. Due to the

limit of space, the details of this pre-processing is not

presented here.

Another issue is that the available BAPE execu-

tion traces collected during the past project are insuf-

ficient in quantities for running a useful process min-

ing. Thus, in addition to the real execution data, we

simulated more execution traces of process fragments

of BAPE. To ensure that the simulated event log can

emulate the real one, we generated events diversify-

ing in numerous factors: workflow, human resources,

timing, etc. The constrains on work sequences be-

tween tasks in the generated events must be respected.

For example, in the Modify Test-bench Wiring pro-

cess, all the tasks of the role Analyst can be done in

parallel while those of the Wiring Team can start only

when the Supplier finishes their task. Consequently,

we can generate simultaneous events of tasks done

by Analyst but can not generate an event of a Wiring

ENASE 2022 - 17th International Conference on Evaluation of Novel Approaches to Software Engineering

366

Team task before an event of a Supplier task.

The simulated log was built to include some unex-

pected cases representing anomalies. In general, there

are two popular anomalies situations during process

enactment: (1) anomalies of the organization where

an actor executes a task that is not assigned to his role;

(2) anomalies of control-flows where an actor skips a

task assigned to him or realized the task without re-

porting its enactment.

To generate the anomalies in the event log, we use

two parameters: the parameter n for the number of

anomalies occurring in a single trace and the parame-

ter t for the type of anomalies appearing in the traces.

Each time generating a new set of event log, the posi-

tion and the number of these unexpected cases varies

randomly. Each time a trace is built, a random num-

ber r is generated to control the opportunity that the

trace has anomalies. If r ≤ t, (0 ≤ t ≤ 0.5), then we

integrate in the trace an anomaly of type (1) (an actor

does a task of another role). If r ≥ 1 − t, an anomaly

of type (2) (an actor does not performed his task) will

be added into the trace. To test the adaptation of our

algorithm to multiple anomalies in the event log, we

made some controls on the appearance rate of those

anomalies by setting the parameters n and t with the

appropriate values. We suggest setting the first pa-

rameters n = 2, which means at most 2 tasks in a trace

will be the anomalies. Also, we choose to config-

ure the second parameter t = 0.05. If we set a higher

value for one of these two parameters, the unexpected

cases are not the anomalies anymore but become nor-

mal and would emerge a new dependency in the pro-

cess model.

We could collect 320 traces of the event logs from

both BAPE system and the external information sys-

tems of the Modify Test-bench Wiring process’s ac-

tors. We simulated an event log with 680 traces. To-

gether, there are 1000 traces to perform the process

mining for the running example.

3.2 Process Model Discovery

Algorithm 1 resumes the steps based on the heuristic-

miner algorithm (Weijters et al., 2006) to discover the

process model P from an event log L.

The final process model is presented as a heuristic

net composed of tasks and the dependencies between

them. Given two tasks a and b, a is said to be followed

by b (denoted by a −−→

L

b) if the dependency measure

between a and b (denoted by D(a, b)) calculated from

the log L is greater than a given filter.

The first step is to construct the dependency mea-

sure list D

L

= {D(a, b)} for each pair of tasks in the log

Algorithm 1: Process Model Discovery.

Input: L, f ilter

Output: P

1 Construct dependency measure list D

L

// Construct dependency list X

L

2 X

L

= {}

3 forall (a, b) ∈ D

L

do

4 if D(a, b) ≥ f ilter then

5 X

L

= X

L

∪ a

D(a,b)

−−−−→

L

b

6 end

7 end

8 Build the process model P from X

L

L. For two tasks (a, b), |a ⇒

L

b| is the value of the

dependency relation between a and b and is computed

using the equation 1 where |a >

L

b| is the number of

times a is directly followed by b.

|a ⇒

L

b| =

(

|a>

L

b|−|b>

L

a|

|a>

L

b|+|b>

L

a|+1

i f a 6= b

|a>

L

a|

|a>

L

a|+1

i f a = b

(1)

D(a, b) produces a value between -1 and 1. If D(a, b)

is closer to 1 then we deduce the high possibility that

a is followed by b. In contrast, if D(a, b) is closer to

−1, there is a high possibility that b is followed by a.

When D(a, b) is around 0, there is nearly no intuitive

relation between a and b.

A threshold f ilter is used to exclude the depen-

dencies caused by noises between two tasks. Only

the dependencies a

D(a,b)

−−−→

L

b with D(a, b) ≥ f ilter are

kept and then translated to the result process model P.

At this step, only work-sequences anomalies are

detected because organizational anomalies (where an

actor enacts an unassigned task) concerns the issue of

human resources and does not affect the integrity of

the process control flow.

Table 3: Modify Test-bench Wiring process’s tasks.

Task name Decoded

Define Component Requirements a

Define Electrical Specification b

Outline Instrumentation Model c

Purchase Components d

Specify Electrical Model e

Define Instrumentation Model f

Define Bench Specification g

Define Specific ICD h

Install Components i

Wire Components j

Define Bench Configuration k

Validate Bench Configuration l

To facilitate the presentation of the mining results,

we show in Table 3 the decoded names of Modify Test-

bench Wiring process’s discovered tasks.

Table 4 gives an extract of dependency measures

Process Mining to Discover the Global Process from its Fragments’ Executions

367

Table 4: Extract of dependency measure between tasks in

Modify Testbench Wiring with n = 2, t = 0.05

c g i j l

c 0.000 0.667 -0.045 -0.197 0.000

g -0.667 0.000 0.018 -0.211 0.750

h 0.750 0.082 -0.044 -0.044 0.857

i 0.045 -0.018 0.000 0.998 0.667

j 0.197 0.211 -0.998 0.000 0.998

between tasks in Modify Testbench Wiring process.

D(i, j) has the value 0.998, while D(c, g) has the

value 0.667. It means there is a higher chance that

i →

L

j but there might be a chance that c →

L

g

is a noise dependency caused by a process work-

sequences anomaly. For example there might be a

task between c and g but the actor skipped that inter-

mediate task. We can use a threshold f ilter to decide

which dependencies should be kept in the final pro-

cess model. For example, by setting f ilter = 0.9, we

only keep high reliable dependencies as i →

L

j and

mask the noise dependencies with D

(

a, b) ≤ 0.9 and

therefore eliminate c →

L

g in the discovered process

model (c.f. Figure 6).

3.3 Organizational Structure Discovery

The discovered global process model obtained in Sec-

tion 3.2 focuses only on the control flows between

tasks. To establish the performing relationship be-

tween actors and tasks, we need to execute an anal-

ysis to recognize the organizational structure of the

examined process.

For this purpose, we use a resource-activity ma-

trix M(A, T ), where A is the list of actors and T is the

list of tasks. This matrix is built when calculating the

mean number of times an actor performs a task per

trace (van der Aalst et al., 2005). Based on this ma-

trix, we can determine the similarity values among the

tasks of some actors. By heuristic evaluation, these

actors might share the same role.

For better recognizing the actor-to-role informa-

tion, we decided to use the clustering algorithm DB-

SCAN (Ester et al., 1996). Assuming that each

resource-activity value m(a,t) in the matrix repre-

sents a position in an axis of a coordinate system, thus

all the resource-activity values of an actor m(a, T ) de-

termines a multi-dimensions point at a specific posi-

tion in that coordinate system. When grouping near

points together with the euclidean distance, the actors

who perform the same tasks will be grouped into one

role C

j

. The number of points reflects the number of

actors in the event log.

The analysis process is shown in Algorithm 2.

Two parameters minPoints - the minimum number of

actors required to form a role and minDistance - the

minimum difference between the list of tasks done by

2 actors - should be considered rigorously to identify

the correct role of actors.

Algorithm 2: Organizational Structure Discovery.

Input: L =< A, T >, minPoints, minDistance

Output: PF(C

i

)

1 Compute resource-activity matrix M(A, T ) from L

2 Apply DBSCAN to M(A, T ) with

minPoints, minDistance to get R{C

i

}

3 forall t ∈ T do

4 Find a

∗

= argmax

a∈A

m(a,t)

5 PF(C

i

) = PF(C

i

) ∪ t if a

∗

∈ C

i

6 end

Analyzing the resource-activity matrix helps de-

tect organizational anomalies where actors perform

tasks not belonging to their role. The resource-

activity values of such anomalies are significantly

lower than the regular circumstance when the actor

realizes his proper tasks. By checking the value of

m(A,t), task t is identified as the task assigned to the

role C

j

of the actor who realizes task t the most fre-

quently PF(C

j

). From the list of roles found in this

step, we can reconstruct process fragments of identi-

fied roles.

Table 5 shows the resource-activity matrix of the

Modify Testbench Wiring process. From this matrix

we can deduce that BC1 and BC2 do task k and l;

WT2, WT1 and WT3 do task i and j and so on with

other actors. The values especially low around 0.002,

for example T4 with task l or A1 with task h, reveal

possible organizational anomalies where an actor per-

forms an unsigned task.

By setting minPoints = 1, minDistance = 0.1,

from the Table 5 we establish the performer relation-

ship between tasks and actors, then deduce 6 roles as

shown in Table 6.

Table 5: Resource-activity matrix.

Actor a b c d e f g h i j k l

T4 0.000 0.000 0.000 0.000 0.000 0.274 0.274 0.273 0.000 0.000 0.000 0.002

A1 0.516 0.513 0.526 0.000 0.000 0.000 0.000 0.002 0.000 0.000 0.002 0.000

BC2 0.002 0.002 0.000 0.000 0.002 0.000 0.002 0.002 0.000 0.000 0.478 0.477

A2 0.483 0.484 0.484 0.000 0.000 0.000 0.000 0.000 0.000 0.002 0.000 0.000

BC1 0.000 0.002 0.000 0.000 0.002 0.000 0.000 0.002 0.000 0.000 0.520 0.518

ED1 0.000 0.000 0.000 0.002 0.998 0.000 0.000 0.002 0.000 0.002 0.000 0.000

WT2 0.000 0.000 0.000 0.000 0.000 0.000 0.000 0.000 0.343 0.344 0.000 0.002

WT1 0.000 0.000 0.000 0.000 0.000 0.000 0.000 0.000 0.336 0.335 0.000 0.000

WT3 0.000 0.002 0.000 0.000 0.000 0.000 0.000 0.000 0.319 0.318 0.000 0.002

T1 0.000 0.000 0.000 0.000 0.000 0.277 0.275 0.274 0.002 0.000 0.000 0.000

S1 0.000 0.000 0.000 0.999 0.000 0.000 0.000 0.000 0.000 0.000 0.000 0.000

T2 0.000 0.000 0.000 0.000 0.000 0.230 0.231 0.229 0.002 0.000 0.000 0.002

T3 0.000 0.000 0.000 0.000 0.000 0.220 0.219 0.220 0.000 0.000 0.002 0.002

ENASE 2022 - 17th International Conference on Evaluation of Novel Approaches to Software Engineering

368

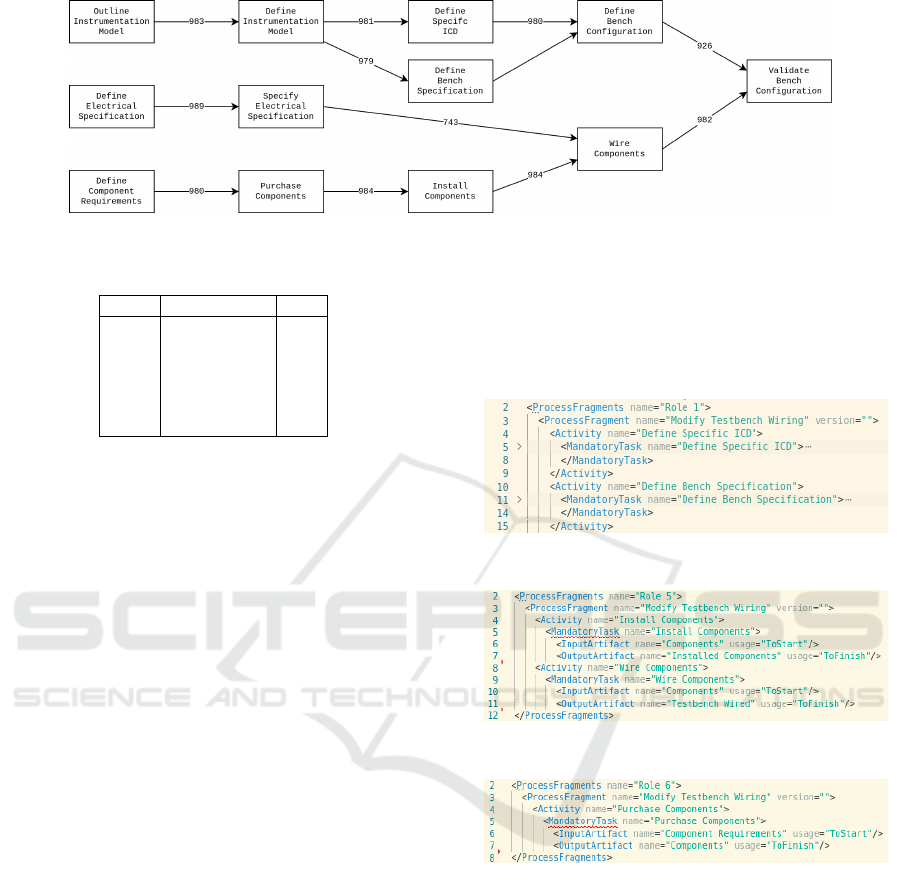

Figure 6: Process Model discover with f ilter = 0.9.

Table 6: Clusters found for actors and tasks.

Cluster Actors Tasks

Role 1 T1, T2, T3, T4 f, g, h

Role 2 A1, A2 a, b, c

Role 3 BC1, BC2 k, l

Role 4 ED1 e

Role 5 WT1, WT2, WT3 i, j

Role 6 S1 d

3.4 Process Fragment Creation

Based on the detected information about actor-role-

task relations, the process fragments of each identi-

fied role can be generated under the format of BAPE.

However, to complete these process fragments, we

need to find out the exact role names because the iden-

tified roles are just numbered.

If the reconstructed process fragments controlled

by BAPE, we can deduce the role names from the ex-

isting process fragment models in the process repos-

itory of BAPE. For the discovered fragments whose

process models were missing and thus were not con-

trolled by BAPE, the renaming of roles could be done

automatically if the role names were specified in pro-

cess actors’ execution data. If not, the renaming are

done manually.

Figure 7 shows a part of the process fragment dis-

covered for the Role 1. By comparing it with avail-

able process fragments, we found a match and could

rename Role 1 to Instrumentation Team. In the same

way, Role 2 is renamed to Analyst, Role 3 to Bench

Coordinator and Role 4 to Electrical Design.

Figure 8 and 9 display respectively the discovered

process fragments for Role 5 and Role 6. Because

there are no matched process fragments for Role 5 and

Role 6 in BAPE, we analyzed the exchanged artifact

between these fragments and the other fragments in

the process to deduce the name of the missing roles.

For example, when searching the exchanged artifact

Component Requirements (for fragment of Role 6)

among known process fragments, we found that Com-

ponent Requirements is the output artifact of Define

Component Requirements task. Recall the Figure 1,

we can deduce that Role 6 is the Supplier. Similarly,

applying the same approach, we clarified that Role 5

is the Wiring Team. Finally, we discovered the miss-

ing fragments and rebuilt the complete Modify Test-

bench Wiring process model.

Figure 7: Discovered process fragment of Role 1.

Figure 8: Discovered process fragment of Role 5.

Figure 9: Discovered process fragment of Role 6.

4 CONCLUSION

We have developed a new functionality for BAPE to

discover, from the execution traces of process actors,

the global process model as well the missing process

fragments. The overall process model enables BAPE

to do more analysis, to detect the anomalies concern-

ing the missing tasks or the mismatched role-task.

The discovered models of missing process fragments

could enable the process actors to use BAPE in the

future to manage their processes.

The validation of this work however was limited

by the lack of real execution data that could help

Process Mining to Discover the Global Process from its Fragments’ Executions

369

to obtain more interesting insights. Another draw-

back of this work is the omission if multiple-instances

case. One challenge of process mining for artifact-

centric processes is handling with many-to-many re-

lationships between artifacts, which make it diffi-

cult to identify a unique process instance notion to

group related events. Many works have addressed

this problem, from the modeling viewpoint (van der

Aalst et al., 2001; Cohn and Hull, 2009; Lohmann,

2013), or from the process mining algorithm angle

(Schuster et al., 2021; Li et al., 2017; Li et al., 2018).

BAPE adopts a hybrid approach of artifact-centric and

activity-centric, thus does not face exactly the dif-

ficulty of the pure artifact-centric process approach.

Therefore we could still apply the traditional miner al-

gorithms when integrating process mining into BAPE

with the assumption that artifacts are manipulated by

a tasks of the same process instance. However, such

an assumption is not always true, especially for exe-

cution data extracted directly from process actor’s in-

formation systems. There are still more rooms for im-

provement of our works, especially for exploring the

possibility of multiple-instances related to a case and

for investigating other types of anomalies.

REFERENCES

Cohn, D. and Hull, R. (2009). Business artifacts: A data-

centric approach to modeling business operations and

processes. IEEE Data Eng. Bull., 32:3–9.

dos Santos Garcia, C., Meincheim, A., Faria Junior, E. R.,

Dallagassa, M. R., Sato, D. M. V., Carvalho, D. R.,

Santos, E. A. P., and Scalabrin, E. E. (2019). Pro-

cess mining techniques and applications – a system-

atic mapping study. Expert Systems with Applications,

133:260–295.

Ester, M., Kriegel, H.-P., Sander, J., and Xu, X. (1996).

A density-based algorithm for discovering clusters in

large spatial databases with noise. In Proceedings of

the Second International Conference on Knowledge

Discovery and Data Mining, KDD’96, page 226–231.

AAAI Press.

Hajmoosaei, M., Tran, H. N., and Percebois, C. (2017). A

user-centric process management for system and soft-

ware engineering projects. In 7th International Con-

ference on Industrial Engineering and Systems Man-

agement (IESM 2017), pages 123–128, Saarbr

¨

ucken,

Germany.

Jokonowo, B., Claes, J., Sarno, R., and Rochimah, S.

(2018). Process mining in supply chains: A system-

atic literature review. International Journal of Electri-

cal and Computer Engineering, 8:4626–4636.

Kim, K.-S., Pham, D.-L., and Kim, K. P. (2021). p-

algorithm: A sicn-oriented process mining frame-

work. IEEE Access, 9:139852–139875.

Li, G., de Carvalho, R. M., and van der Aalst, W. M. P.

(2017). Automatic discovery of object-centric behav-

ioral constraint models. In Abramowicz, W., editor,

Business Information Systems, pages 43–58, Cham.

Springer International Publishing.

Li, G., de Murillas, E. G. L., de Carvalho, R. M., and van der

Aalst, W. M. P. (2018). Extracting object-centric

event logs to support process mining on databases. In

Mendling, J. and Mouratidis, H., editors, Information

Systems in the Big Data Era, pages 182–199, Cham.

Springer International Publishing.

Lohmann, N. (2013). Compliance by design for artifact-

centric business processes. Information Systems,

38(4):606–618. Special section on BPM 2011 con-

ference.

Pe

˜

na, M. R. and Bayona-Or

´

e, S. (2018). Process mining

and automatic process discovery. In 2018 7th Interna-

tional Conference On Software Process Improvement

(CIMPS), pages 41–46.

Rovani, M., Maggi, F. M., de Leoni, M., and van der Aalst,

W. M. (2015). Declarative process mining in health-

care. Expert Systems with Applications, 42(23):9236–

9251.

Schuster, D., van Zelst, S. J., and van der Aalst, W. M. P.

(2021). Cortado—an interactive tool for data-driven

process discovery and modeling. Lecture Notes in

Computer Science, page 465–475.

Valencia-Parra, A., Ramos-Guti

´

errez, B., Varela-Vaca, A.,

G

´

omez-L

´

opez, M., and Bernal, A. (2019). Enabling

process mining in aircraft manufactures: Extracting

event logs and discovering processes from complex

data. CEUR Workshop Proceedings, 2428:166–177.

van der Aalst, W., Barthelmess, P., Ellis, C., and Wainer, J.

(2001). Proclets: A framework for lightweight inter-

acting workflow processes. International Journal of

Cooperative Information Systems, 10:443–481.

van der Aalst, W., Reijers, H., and Song, M. (2005). Dis-

covering social networks from event logs. Computer

Supported Cooperative Work, 14:549–593.

van der Aalst, W., Weijters, T., and Maruster, L. (2004).

Workflow mining: discovering process models from

event logs. IEEE Transactions on Knowledge and

Data Engineering, 16(9):1128–1142.

van der Aalst, W. M. P. (2016). Process Mining: Data Sci-

ence in Action. Springer, Heidelberg, 2 edition.

van der Aalst, W. M. P., Bolt, A., and van Zelst, S. J. (2017).

Rapidprom: Mine your processes and not just your

data.

Weijters, A., van der Aalst, W., and Medeiros, A. (2006).

Process Mining with the Heuristics Miner-algorithm,

volume 166.

ENASE 2022 - 17th International Conference on Evaluation of Novel Approaches to Software Engineering

370