Process Diagnostics at Coarse-grained Levels

Mahsa Pourbafrani

a

, Firas Gharbi

b

and Wil M. P. van der Aalst

c

Chair of Process and Data Science, RWTH Aachen University, Aachen, Germany

Keywords:

Process Mining, Event Logs, Time Series Analysis, Process Diagnostics, Performance Analysis, Coarse-

Grained Process Logs, Concept Drift.

Abstract:

Process mining enables the discovery of actionable insights from event data of organizations. Process analysis

techniques typically focus on process executions at detailed, i.e., fine-grained levels, which might lead to

missed insights. For instance, the relation between the waiting time of process instances and the current states

of the process including resources workload is hidden at fine-grained level analysis. We propose an approach

for coarse-grained diagnostics of processes while decreasing user dependency and ad hoc decisions compared

to the current approaches. Our approach begins with the analysis of processes at fine-grained levels focusing

on performance and compliance and proceeds with an automated translation of processes to the time series

format, i.e., coarse-grained process logs. We exploit time series analysis techniques to uncover the underlying

patterns and potential causes and effects in processes. The evaluation using real and synthetic event logs

indicates the efficiency of our approach to discover overlooked insights at fine-grained levels.

1 INTRODUCTION

Event data in process mining are presented in the form

of event logs, in which process executions for a pro-

cess instance are captured, such as a sequence of man-

ufacturing steps with respect to time for a product in a

production line. Event logs are the primary means of

performing performance and bottleneck analysis for

enhancing/improving processes (van der Aalst, 2016).

Current performance analyses techniques in process

mining highly rely on event-based data, and they are

mainly in a detailed manner (Leemans et al., 2014;

Mannhardt et al., 2015). For instance, the effects of

resources workload on their speed is not detectable

using fine-grained event logs, i.e., detailed event logs,

and it requires daily performance metrics.

The effectiveness of projecting processes over

time is proven. Consider for example Dotted Charts

(Song and van der Aalst, 2007) that represent the ex-

isting patterns at fine-grained levels inside the pro-

cess over time. Therefore, aggregating processes w.r.t

time is a practical approach for process diagnostics.

For instance, the idea of using the sliding window for

concept drift detection in process mining is proposed

in (Bose et al., 2011). Time-related diagnostics such

a

https://orcid.org/0000-0002-7883-1627

b

https://orcid.org/0000-0001-6849-7939

c

https://orcid.org/0000-0002-0955-6940

as dotted charts or concept drift detection as well as

anomaly detections that use time series analysis are

mainly dependent on the user for defining and extract-

ing the aggregated process variables and analyzing the

results.

In this paper, we introduce a generic framework

that benefits from both fine- and coarse-grained pro-

cess analyses. The fine-grained event logs (steps are

events) are transformed into coarse-grained process

logs, i.e., a collection of measurable aspects of a pro-

cess over steps of time when steps are time windows.

All the aspects are defined and extracted systemati-

cally on top of standard event logs, as explained in

(Pourbafrani and van der Aalst, 2021). For instance,

arrival rate is an aspect that can be measured daily,

and different aspects at every time step are consid-

ered as a process state, e.g., arrival rate, waiting time,

and the number of unique resources in one day. We

define three categories of change points in process as-

pects and a module to indicate potential cause and ef-

fects among process aspects, e.g., detecting the effects

of the number of engaged resources per week on the

idle time of a single resource after three weeks. It

should be noted that throughout the paper, we refer

to event logs and diagnostics techniques utilizing the

standard event logs in which the steps are events as

fine-grained event logs, and diagnostics to stress the

distinctions in the granularity of data and approaches.

484

Pourbafrani, M., Gharbi, F. and van der Aalst, W.

Process Diagnostics at Coarse-grained Levels.

DOI: 10.5220/0011035000003179

In Proceedings of the 24th International Conference on Enterprise Information Systems (ICEIS 2022) - Volume 1, pages 484-491

ISBN: 978-989-758-569-2; ISSN: 2184-4992

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

The designed synthetic event log of an insurance com-

pany (INS) and two public event logs, i.e., BPI Chal-

lenge 2017 (BPIC’17) (van Dongen, B.F., 2017) and

BPI Challenge 2015 (BPIC’15), are used for provid-

ing examples explaining the approach and performing

the evaluation.

We present the related work in Section 2 and Sec-

tion 3 covers the process mining and time series anal-

ysis concepts. We introduce our approach in Section

4 and evaluate it in Section 5. Section 6 concludes

this work with challenges and future work.

2 RELATED WORK

Presenting processes over time will reveal process be-

havior, including compliance and performance prob-

lems. Time perspective is considered for diagnos-

tics at various levels, fine- or coarse-grained lev-

els. General time-related diagnostics such as (Hornix,

2007) are at aggregated levels, where they calculate

a set of predefined KPIs, e.g., average waiting time

in processes, for the whole process. Dotted charts

are fine-grained process diagnostics techniques (Song

and van der Aalst, 2007) that depend on the user to

spot the insights over time. Time series analysis is

used in existing process behavior analysis for a vari-

ety of objectives. In (Pourbafrani et al., 2020a), we

use the time series models such as ARIMA for detect-

ing the best window size to extract process variables

for the purpose of simulation. Concept drift in pro-

cesses, their type, and the use of time series for their

detection are proposed in (Bose et al., 2011). The

concept drift detection in (Bose et al., 2011) is based

on using different periods of time inside processes.

Detecting anomalies in processes is the other pur-

pose of utilizing time series as presented by (Bez-

erra et al., 2009). Moreover, in (Pourbafrani et al.,

2020b), the relations between process aspects are dis-

covered to form a simulation model which (Adams

et al., 2021) used the same idea to detect the cause and

effect relations among process variables. The purpose

is to capture new insights using time series. Authors

in (Yeshchenko et al., 2019) propose to employ the

time series for concept drifts by applying the PELT

algorithm. The results are clustered and are visually

prepared for the user. We refer to (Sato et al., 2021)

as a survey of concept drift detection in process min-

ing. In the causal and relation detection between pro-

cess variables, multiple researchers exploited time se-

ries analyses. In (Hompes et al., 2017), cause and

effect relations between a business process character-

istics and process performance are detected. Authors

in (Adams et al., 2021) employ time series analysis

to determine the potential cause and effects between

process variables. However, similar to previous ap-

proaches, they are rather too much reliant on the user,

or the variables are extracted in an ad hoc manner.

The user domain knowledge is used to define the vari-

able, which makes the approach process specific.

Fine- and coarse-grained analyses are required to

detect process behavior. As a result, there is a gap

in providing an integrated and general framework for

defining and extracting process measurable aspects

while also having a comprehensive approach for ap-

plying time series analysis to processes. By increas-

ing the granularity of process event data, we can rep-

resent a process from various perspectives using its

aspects over time, as presented in (Pourbafrani and

van der Aalst, 2021) and implemented in (Pourbafrani

and van der Aalst, 2020).

3 PRELIMINARIES

In this section, we define coarse-grained process logs

and introduce time series concepts used in our ap-

proach.

Process Mining.

Definition 1 (Event Log). An event e=(c, a, r, t

s

,t

c

),

where c∈C is the case identifier, a∈A is the activ-

ity in e, r∈R is the resource, t

s

∈T is the start time,

and t

c

∈T is the complete time of the event e. ξ=C ×

A × R × T × T is the universe of events. We de-

fine projection functions for e as follows: π

C

: ξ → C ,

π

A

: ξ → A, π

R

: ξ → R , π

T

S

: ξ→T and π

T

C

: ξ→T .

Event log L⊆ξ is a set of events in which events are

unique.

The start and complete timestamps of an event

log L⊆ξ, are obtained using p

s

and p

c

, respec-

tively. p

s

(L)=min

e∈L

π

T

S

(e) and p

c

(L) = max

e∈L

π

T

C

(e).

A sequence of events w.r.t. timestamp with the

same case identifier represents a process instance,

i.e., a trace. In the event log of a production line,

the first event e=(c, a, r,t

s

,t

c

) is for the first item

with c=1, the activity is a=welding which was

started at timestamp t

s

=08:30:25 02.01.2021 by re-

source r=employee1 and was completed at times-

tamp t

c

=10:02:47 02.01.2021.

Coarse-grained Process Logs. Coarse-grained

process logs are the collections of measurable aspects

of a process over a specific time window, e.g., Table 1

shows a sample coarse-grained log. The time window

is δ=1 day. Each column describes the process in a

time step (process state), e.g., 1 day, and each row

Process Diagnostics at Coarse-grained Levels

485

Table 1: A sample coarse-grained process log in which the time window is one day. It includes six process aspects that values

are represented in the cells.

Process aspects

Time window (day)

1 2 3 4 5 6

Arrival rate 180 147 160 116 94 ...

Finish rate 180 147 160 116 94 ...

Num of unique resources 6 6 6 6 6 ...

Avg service time 0.35 0.41 0.40 0.44 0.52 ...

Avg time in process 0.96 0.95 0.99 0.93 0.82 ...

Avg waiting time 0.60 0.54 0.59 0.49 0.32 ...

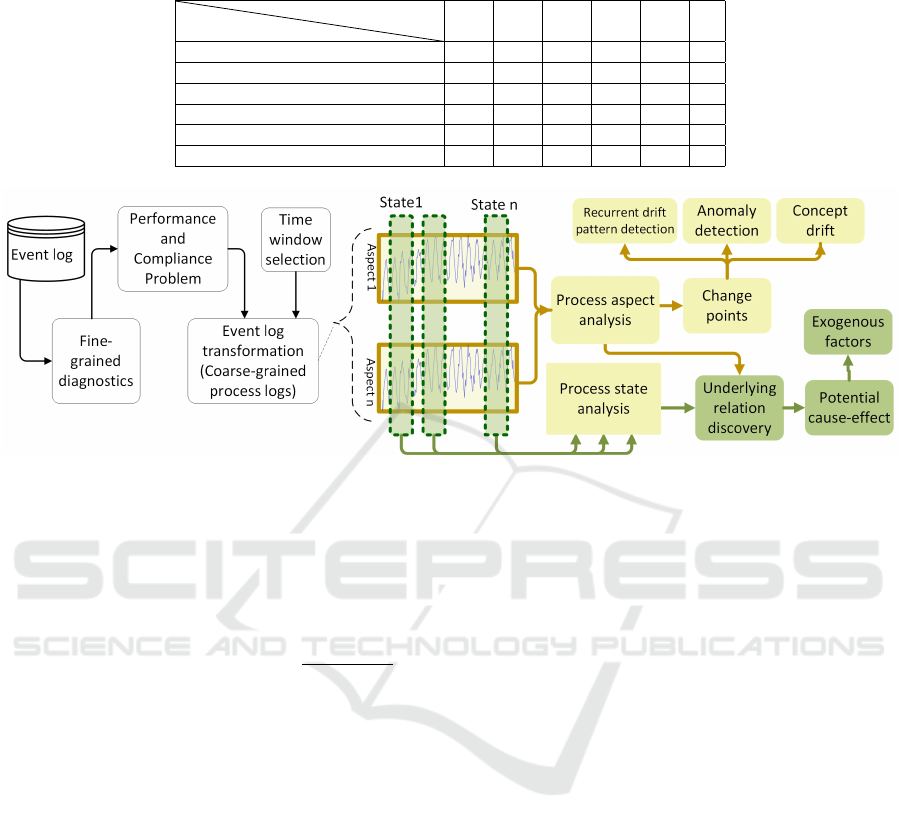

Figure 1: The proposed coarse-grained process diagnostic framework and the main modules.

is a process aspect. Cells are the values of process

aspects, e.g., at the second time window, the value of

process aspects Arrival rate is 147, which means in

this time window, 147 cases arrived.

Definition 2 (Coarse-Grained Process Log). Let L ⊆

ξ be an event log, V be a set of process aspects, δ∈N

be the selected time window, and k=d

(p

c

(L)−p

s

(L))

δ

e be

the number of time steps in the event log w.r.t. δ.

The coarse-grained process log of given L and δ is

PL

L,δ

:{1, ..., k}×V → R

≥0

, such that PL

L,δ

(i, v) rep-

resents the value of aspect v∈V in the i

th

-time win-

dow (1≤i≤k).

We use PL throughout the paper instead of PL

L,δ

when it is clear from the context. We also de-

fine Π

v

(PL)∈R

∗

to return the sequence of values

hx

1

, ..., x

k

i for aspect v∈V . To access each value of

the process aspect over time, we define π

i

that returns

the i

th

value in a sequence, i.e., π

i

(Π

v

(PL))=x

i

.

Time Series. The analysis of sequences of real val-

ues and/or sequences of tuples of real values is often

referred to as time series analysis (Hamilton, 1994).

Pattern detection, next value prediction, or relation

detection are the examples of time series analysis.

Given a time series σ=hx

1

, ..., x

k

i∈R

∗

with length of

k ∈ N, i.e., |σ|=k, S ∈ R

∗

is a subsequence of con-

tinuous values of σ with lengths m ≤ k. For instance,

S=hx

i

, x

i+1

, ..., x

i+m−1

i is a subsequence of σ where

1 ≤ i ≤ k − m + 1.

Consider the given example in Table 1 as PL,

where Finish rate is process aspect v. Apply-

ing function Π

v

(PL) results in a time series, i.e.,

Π

v

(PL)=h180, 147, 160, 116, ...i where h180, 147i is

a subsequence of that.

4 APPROACH

Figure 1 presents the introduced coarse-grained pro-

cess diagnostics approach. First, in Section 4.1, the

existing process mining techniques are applied to

event logs. Given the results, e.g., a specific activity

or a set of resources, and the time window, coarse-

grained process logs including process aspects and

states are generated, e.g., times series presenting the

process. Afterward, in Section 4.2, we explain the

techniques designed for process diagnostics given the

process logs. Considering multiple aspects in a simi-

lar window of time in relation to each other provides

the process states analysis. Discovering the relation-

ship between different aspects over time is the pur-

pose of process state diagnostics.

4.1 Fine-grained Diagnostics

We defined and implemented the problem detection

techniques w.r.t. deviation and performance, where it

can be considered for activity flow, resources, and or-

ganizations. These problems are identified based on

ICEIS 2022 - 24th International Conference on Enterprise Information Systems

486

Time Window (Day)

Arrival Rate (INS)

Process Aspect

Change Point

Detection

Subsequence

Clustering

Regular Pattern

Anomaly

Concept Drift

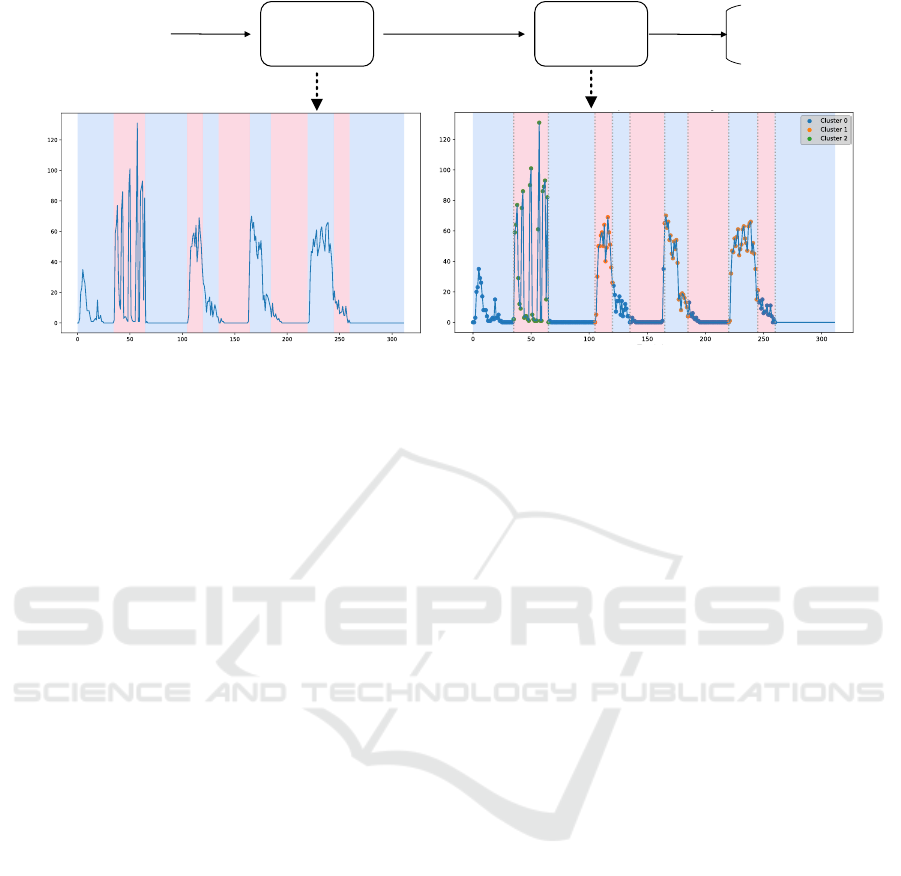

Figure 2: The overview of our process aspect analysis for the arrival rate of activity Review request for rejection in the INS

event log.

performance and bottleneck analysis, deviation detec-

tion, or social network analyses. We form the prob-

lematic part of the process in the form of a set of

activities A, resources R, or cases C. Note that or-

ganizations with performance and compliance issues

can be shown as a set of resources. Consider that in

event log L, bottleneck analysis as one of the fine-

grained diagnostics returns activity a as a process bot-

tleneck, i.e., long execution time. Therefore, A = {a},

R = {π

r

(e) ∈ R |e ∈ L}, and C = {π

C

(e) ∈ R |e ∈ L}.

Another example can be the detected role, which is

the set of resources performing activity a as a po-

tential bottleneck in the process using social network

analysis.

In the event log transformation step, in Fig. 1,

event logs are projected using the provided sets of

resources, activities and cases. For instance, for

event log L, the projected event log is L

0

= {e ∈

L|π

A

(e)=a ∧ π

R

(e) ∈ R ∧ π

C

(e) ∈ C}. The coarse-

grained process logs are created for the time window

δ=1 day by using PL

L

0

,δ

in Definition 2. The descrip-

tion of defining and extracting all possible aspects of

the process over time is derived from (Pourbafrani and

van der Aalst, 2021).

4.2 Diagnostics in a Process Aspect

By focusing on a single aspect of a process with

event log L over time in the generated PL, e.g.,

Π

arrival rate

(PL), we are able to identify the existing

change points. Given the fact that we are looking

for the behavior of process aspects over time, there

are three types of change points that we are inter-

ested in discovering: regular patterns (recurrent con-

cept drifts), anomaly behavior, and concept drifts. To

do so, we define the change point detection function

in Definition 3, where the input is a process aspect and

the output is change points in the values over time.

In the implementation, we used Pruned Exact Lin-

ear Time Method (PELT) since it has a linear com-

putational time. PELT detects change points by re-

cursively splitting the time series into subsequences

(Killick et al., 2012).

Definition 3 (Change Point Detection). Function

CPD : R

∗

→ N

∗

such that for σ=hx

1

, x

2

, ..., x

k

i∈R

∗

if CPD(σ)=hτ

1

, ..., τ

m

i∈N

∗

then for all 1 ≤ j ≤ m,

1 < τ

j

< τ

j+1

< k.

Figure 2 depicts the general steps of the process

aspect analysis module in our approach, as exem-

plified by the values of the daily arrival rate for

activity review request for rejection in an insurance

company’s generated synthetic event log (INS). The

activity is identified as a deviation in the fine-grained

diagnostic module, i.e., a low fitness value. Func-

tion CPD(Π

arrival rate

(PL))=h43, 65, ...i, returns 10

change points. Given the detected change points for

process aspects, the corresponding subsequences are

generated. For instance, in Fig. 2, Π

arrival rate

(PL)

is transformed into 11 subsequences, e.g., s

1

=

hπ

1

(Π

arrival rate

(PL)), ..., π

43

(Π

arrival rate

(PL))i, and

s

2

= hπ

44

(Π

arrival rate

(PL)), ..., π

65

(Π

arrival rate

(PL))i.

We refer to the set of corresponding subsequences of

a process aspect as S

(CPD(σ))

.

The ultimate goal in single process aspect analysis

is to discover aspects’ behavior over time. Having the

subsequences of an aspect, we investigate the similar-

ities of these subsequences to find whether there is re-

current concept drift, anomaly, or concept drift in the

process. To do so, we cluster these subsequences us-

ing the defined function in Definition 4. To implement

Process Diagnostics at Coarse-grained Levels

487

the module, our technique is based on (Niennattrakul

and Ratanamahatana, 2007). Since our clustering is

based on k-means, the silhouette metric (Shahapure

and Nicholas, 2020) is used for automatic selection

of k. For other potential clustering techniques of time

series, we refer to (Warren Liao, 2005).

Definition 4 (Subsequence Clustering). Let

σ=hx

1

, x

2

, ..., x

k

i∈R

k

be a time series, CPD(σ)

be the detected change points, and S

CPD(σ)

be the set

of the subsequences of σ w.r.t. change points. We

define function C S(S

CPD(σ)

) ⊆ 2

S

CPD(σ)

such that it

returns the set of clusters including the subsequences

inside.

In Fig. 2, for the set of subsequence

S

CPD(Π

arrival rate

(PL))

, the output of function sub-

sequence clustering CS is presented. There are 3

clusters, where s

4

, s

7

, and s

9

belong to one cluster,

and s

2

belongs to a second cluster. Afterward, the

detected behaviors using the change points and

clustering results are categorized such that:

• Regular Pattern (Recurrent Concept Drift): when

a cluster has at least two subsequences that

are not consecutive, there is a potential for

regular patterns in the aspect. For cluster

C={s

1

=hx

i

, ..x

j

i, s

2

=hx

p

, ..., x

q

i}, and p 6= j + 1,

i.e., s

1

and s

2

are not consecutive. Note that if

there is a period of time between every two sub-

sequences in the cluster that does not match them,

then, there is a regular pattern in the data. For in-

stance, cluster 0 and 1 in Fig. 2 represent regular

patterns that appear over time in the arrival rate.

• Anomaly: when a cluster has only one subse-

quence and the aspect has more than one subse-

quence, the time duration in the cluster is a poten-

tial anomaly. For cluster C = {s

1

=hx

i

, ..x

j

i}, s

1

indicates an anomaly in the period of time steps i

until j. For instance, cluster 2 in Fig. 2 is a de-

tected period of an anomaly.

• Concept Drift: a cluster with consecutive se-

quences is a concept drift. For instance, C =

{s

1

=hx

i

, ..x

j

i, s

2

=hx

j+1

, ..., x

p

i}, then, s

1

and s

2

are matches and directly following each other over

time, therefore, x

i

shows a concept drift at time

step i. Note that an aspect with two subsequences,

i.e., one change point, and two clusters is also con-

sidered as a potential concept drift.

4.3 Diagnostics in Process States

In addition to analyzing the behavior of a single as-

pect of a process, the relationships between process

aspects provide an insight into the states of the pro-

cess through time. Performing diagnostics for process

states among the process aspects is able to reveal the

potential effects of other aspects on the identified be-

havior of a single aspect. The extracted process states

are in the form of Multivariate Time Series, therefore,

techniques such as Multivariate Time Series Analysis

and Granger Causality are applicable.

Analyzing whether the previous/current values

of a variable plays a role in the future values of

other variable is performed using Granger Causality

(Granger, 1988). Considering both linear and non-

linear Granger Causality, we define relation detection

function as Definition 5. The output of this function

only indicates whether there is a relation between the

current/previous values of the first process aspect and

the future values of the second process aspects.

Definition 5 (Cause and Effect Relation). Let

σ

1

, σ

2

∈ R

k

, and k ∈ N, function GC : R

k

× R

k

→

{R

k

× R

k

× N, 0}. For two time series, the func-

tion returns whether one of the time series causes

on the other one with the shift in time, i.e.,

GC(σ

1

, σ

2

)=(σ

2

, σ

1

, 2) represents that the values of

aspect σ

2

in each time window has effects on the next

value of σ

1

in the next two time windows.

For a detected bottleneck in WValidateApplica-

tion in BPI Challenge 2017 (L) with δ=1 week,

process aspects including the number of cases in

process per week (v

1

), and the number of unique

engaged resources (v

2

) per week are extracted.

GC(Π

v

1

(PL), Π

v

2

(PL))=(Π

v

2

(PL), Π

v

1

(PL), 1) indi-

cates that the change in the number of cases in the

process per week causes a drift in the number of en-

gaged resources per week within 1 time step as pre-

sented in Fig. 3.

4.3.1 Exogenous Aspects

The developed cause and effect module determines

the potential effects of aspects on the value of each

other over time. We refer to the process aspects

that are not affected by any of the aspects as exoge-

nous aspects. Consider v=arrival rate, we identify it

as an exogenous aspect if ∀v

i

∈ V , Corr(v

i

, v)=0 ∧

GC(v

i

, v)=0, where Corr is the correlation among

two aspects, and GC is the cause and effect function.

In processes, the exogenous factors are generally ig-

nored. The influence of the environment and aspects

that can (or cannot) be adjusted during the process is

a determining factor in process improvement and pre-

dictive process monitoring.

ICEIS 2022 - 24th International Conference on Enterprise Information Systems

488

Time Window (Week)Time Window (Week)

Number of Cases in the Process (BPIC’17) Number of Engaged Resources (BPIC’17)

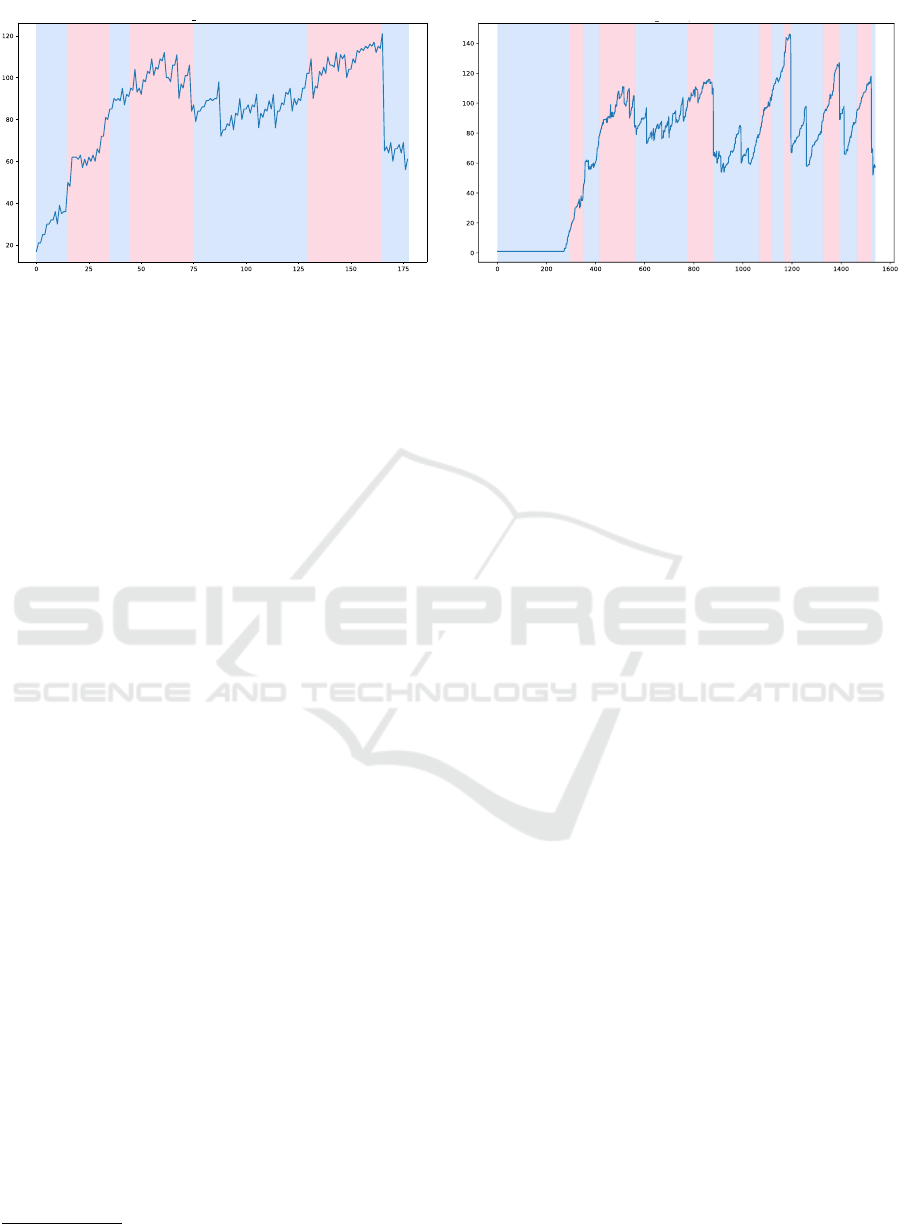

Figure 3: The change point in the number of engaged resources for activity WValidateApplication in BPIC’17 depends on the

anomaly in the number of cases in process, i.e., after one week.

Figure 4: Two aspects for activity WValidateApplication as a detected bottleneck in BPIC’17.

Avg

Duration

(Week)

Num of Engaged Resources (Week)

Figure 5: Revealed relations Fig. 4 using shifted time win-

dow of two aspects.

5 EVALUATION

To assess our approach, we used real and public event

logs such as BPI Challenge 2017 (BPIC’17), BPI

Challenge 2015 (BPIC’15), and a synthetic event log

of an insurance company (INS) generated using the

simulation tool in (Pouarbafrani et al., 2021). We be-

gin by identifying and applying performance, com-

pliance, and social network techniques to event logs.

The results show that the approach is able to identify

the patterns inside processes including the potential

cause and effect relations among process aspects with

time lags and without the user domain knowledge.

Activity WValidateApplication in BPIC’17 is detected

as a bottleneck, hence we extracted all the process as-

pects w.r.t. that activity. As shown in Fig. 4, no re-

lation can be found at the same time window. How-

ever, using our approach, we find the potential cause

and effect relations between the number of unique re-

sources per week and the average duration of the ac-

tivity with a shifted time window automatically, i.e.,

after 4 weeks, see, Fig. 5.

It should be noted that the size of the time win-

dow used to extract values of process aspects is criti-

cal in detecting process behavior. Given that we apply

a time window selection module presented in (Pour-

bafrani et al., 2020a), the approach may determine the

time window size in which the aspects have more sta-

ble behavior, such as stationary time series. However,

this does not imply that other window sizes do not

provide insights and information. For example, there

could be a pattern in the process daily arrival rate as

well as different patterns in the weekly arrival rate.

As a result, these various insights resulting from the

different time windows should be taken into account.

Process Diagnostics at Coarse-grained Levels

489

Time Window (Day)Time Window (Week)

Number of Cases in the Process (BPIC’15)

Figure 6: The number of cases in the process per day (right), and week (left) for BPIC’15. The detected patterns, change

points and general behavior of event logs are affected by the size of time window to generate coarse-grained process logs.

We take the BPIC’15 event log as an example, where

different patterns in weekly and daily values of pro-

cess aspect the number of cases in the process can be

seen. The different insights include different change

points followed by different detected behavior, as pre-

sented in Fig. 6.

All the steps including the fine-grained process

diagnostics, coarse-grained process logs generation,

and coarse-grained analysis are integrated into one

publicly available tool

1

. We also provided the used

data sets, techniques, and evaluation results.

6 CONCLUSION

One of the primary goals of process mining is to pro-

vide process diagnostics that can be used to enhance

processes. We designed a new and generic diagnos-

tic approach in this paper. The approach unifies fine-

and coarse-grained analysis by increasing the time

granularity of event logs. Our approach overcomes

the limitation of current techniques in extracting pro-

cess variables from event logs, as well as selecting the

time window for analysis, such as concept drift detec-

tion. We detect change points in process aspects and

propose the potential causes. Process state analysis

includes relation detection between process aspects

across time. Distinguishing between the types of con-

cept drifts, e.g., sudden drift or gradual drift, is one

of the challenges and open problems for future work.

Furthermore, the discovered insights in the proposed

framework allow for future analysis, e.g., prediction

and what-if analysis.

1

https://github.com/mbafrani/PMSD

ACKNOWLEDGEMENTS

Funded by the Deutsche Forschungsgemeinschaft

(DFG, German Research Foundation) under Ger-

many’s Excellence Strategy-EXC-2023 Internet of

Production-390621612. We also thank the Alexan-

der von Humboldt (AvH) Stiftung for supporting our

research.

REFERENCES

Adams, J. N., van Zelst, S. J., Quack, L., Hausmann, K.,

van der Aalst, W. M. P., and Rose, T. (2021). A frame-

work for explainable concept drift detection in process

mining. In Business Process Management, pages 400–

416.

Bezerra, F., Wainer, J., and van der Aalst, W. M. P. (2009).

Anomaly detection using process mining. volume 29

LNBIP of Lecture Notes in Business Information Pro-

cessing, pages 149–161.

Bose, R. P. J. C., van der Aalst, W. M. P.,

ˇ

Zliobait

˙

e, I.,

and Pechenizkiy, M. (2011). Handling concept drift

in process mining. In Mouratidis, H. and Rolland, C.,

editors, Advanced Information Systems Engineering,

pages 391–405.

Granger, C. (1988). Some recent development in a concept

of causality. Journal of Econometrics, 39(1):199–211.

Hamilton, J. D. (1994). Time series analysis, volume 2.

Princeton New Jersey.

Hompes, B. F., Maaradji, A., La Rosa, M., Dumas, M.,

Buijs, J. C., and van der Aalst, W. M. P. (2017). Dis-

covering causal factors explaining business process

performance variation. In CAISE, pages 177–192.

Springer.

Hornix, P. T. (2007). Performance analysis of business pro-

cesses through process mining.

Killick, R., Fearnhead, P., and Eckley, I. A. (2012). Optimal

detection of changepoints with a linear computational

ICEIS 2022 - 24th International Conference on Enterprise Information Systems

490

cost. Journal of the American Statistical Association,

107(500):1590–1598.

Leemans, S. J. J., Fahland, D., and van der Aalst, W. M. P.

(2014). Process and deviation exploration with induc-

tive visual miner. In Proceedings of the BPM Demo

Sessions 2014 Co-located with the 12th International

Conference on Business Process Management (BPM

2014),, page 46.

Mannhardt, F., de Leoni, M., and Reijers, H. A. (2015). The

multi-perspective process explorer. In Proceedings of

the BPM Demo Session 2015, pages 130–134.

Niennattrakul, V. and Ratanamahatana, C. (2007). On clus-

tering multimedia time series data using k-means and

dynamic time warping. pages 733–738.

Pouarbafrani, M., Balyan, S., Ahmed, M., Chugh, S., and

van der Aalst, W. M. (2021). Gencpn:automatic cpn

model generation of processes. In 3rd International

Conference ICPM 2021, Proceedings (Demo Track).

Pourbafrani, M. and van der Aalst, W. M. P. (2020). PMSD:

data-driven simulation using system dynamics and

process mining. In BPM Demo, pages 77–81.

Pourbafrani, M. and van der Aalst, W. M. P. (2021). Extract-

ing process features from event logs to learn coarse-

grained simulation models. In CAiSE, volume 12751

of Lecture Notes in Computer Science, pages 125–

140. Springer.

Pourbafrani, M., van Zelst, S. J., and van der Aalst, W. M. P.

(2020a). Semi-automated time-granularity detection

for data-driven simulation using process mining and

system dynamics. In ER, pages 77–91.

Pourbafrani, M., van Zelst, S. J., and van der Aalst, W.

M. P. (2020b). Supporting automatic system dynam-

ics model generation for simulation in the context of

process mining. In BIS, pages 249–263.

Sato, D. M. V., De Freitas, S. C., Barddal, J. P., and Scal-

abrin, E. E. (2021). A survey on concept drift in

process mining. ACM Computing Surveys (CSUR),

54(9):1–38.

Shahapure, K. R. and Nicholas, C. (2020). Cluster quality

analysis using silhouette score. In DSAA, pages 747–

748. IEEE.

Song, M. and van der Aalst, W. M. P. (2007). Support-

ing process mining by showing events at a glance. In

WITS 2007, pages 139–145.

van der Aalst, W. M. P. (2016). Process Mining - Data

Science in Action, Second Edition. Springer.

van Dongen, B.F. (2017). BPIC 2017. Eindhoven Univer-

sity of Technology.

Warren Liao, T. (2005). Clustering of time series data—a

survey. Pattern Recognition, 38(11):1857–1874.

Yeshchenko, A., Di Ciccio, C., Mendling, J., and

Polyvyanyy, A. (2019). Comprehensive process drift

detection with visual analytics. In ER, pages 119–135.

Springer.

Process Diagnostics at Coarse-grained Levels

491