Value Creation Patterns for Industry-relevant Model-based

Cyber-Physical Systems

Nicolas C. Egger

a

and Emanuele Laurenzi

b

School of Business FHNW University of Applied Sciences and Arts Northwestern Switzerland,

4600 Olten, Switzerland

Keywords: Cyber-Physical Systems, Enterprise Modelling, Value Proposition.

Abstract: Recent development in technology brought Cyber-Physical Systems (CPS) to innovate across many industry

fields. However, given the heterogeneous nature of the different integrated components from the virtual and

physical spaces, creating a CPS requires high expertise in both engineering and the addressed application

domain. Hence, a CPS is complex and time-consuming to design, deploy and test. A model-based approach

can tackle this problem by enabling conceptual models to control physical objects and fostering the quick

creation of Cyber-Physical Systems. The process logic and decision logic are implemented in re-usable

graphical models instead of software code, which makes possible to involve domain-experts early in the

design of the CPS. Given the relatively young approach, this paper explores the various model-based CPS

that are relevant across industry and how they create value, respectively. For the investigation, a case study

research strategy was adopted, which included both literature and a workshop targeting several industry

experts. Finally, a pattern matching technique was applied to detect value proposition elements across the

created cases.

1 INTRODUCTION

The digitalisation and technological advancement are

in the top agenda of industries, governments, and

society. This is particularly the case for companies

associated with production of high-tech products such

as cars, aircrafts, medical devices, computers,

processors as well as military and space equipment.

The vision of higher competitiveness, higher value-

added and increased productivity motivates

businesses to pursue research and development of

highly advanced industrial technology and

applications (Vyshnevskyi, 2020).

Recent applications of Cyber-Physical Systems

(CPS) shown to be driving force for innovation in

various application domains (Acatech, 2011). CPSs

are engineered systems that integrate physical part

(i.e., IoT devices or robots) with the cyber part (i.e.,

the digital representation of the physical part) and

offer close interaction between the two parts (Tao et

al., 2019). The integration between the two parts

a

https://orcid.org/0000-0001-8912-1164

b

https://orcid.org/0000-0001-9142-7488

allow to achieve a higher level of control intelligence,

automation, and communication (Acatech, 2011).

However, the development of reliable automated

Industrial Cyber-Physical Systems is a challenge for

the high-tech industry (Kravets et al., 2020, p. 198).

According to Lee & Seshia (2017), the

heterogenous nature of Cyber-Physical Systems is the

major challenge to be addressed. Cyber-Physical

Systems are harder to model, harder to design, and

harder to analyse than homogeneous systems. The

key challenge is to conjoin abstractions about an

addressed application domain, e.g. a particular core

process of a company, with abstractions that have

evolved over decades in computer science, such as

programs, algorithms and data structures.

Consequently, the creation of Cyber-Physical

System artifacts requires high expertise and

specialized knowledge in engineering and in the

addressed domain. Numerous engineering loops are

required between the engineers and the domain

experts, which is a time-consuming engineering

practice.

364

Egger, N. and Laurenzi, E.

Value Creation Patterns for Industry-relevant Model-based Cyber-Physical Systems.

DOI: 10.5220/0010984400003119

In Proceedings of the 10th International Conference on Model-Driven Engineering and Software Development (MODELSWARD 2022), pages 364-370

ISBN: 978-989-758-550-0; ISSN: 2184-4348

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

A way to address this problem is through

conceptual models. They abstract away from a certain

complexity and conceptually represent relevant

aspects of a “system under study” for a specific

purpose (Benyon, Green, & Bental, 2012). In the

Enterprise Modelling discipline, conceptual models

serve as basis for discussions, analysis,

improvements, and for the support of decision-

making (Giachetti, 2011; Hinkelmann, et al., 2016).

Considering that, a model-based approach that makes

use of conceptual models promises to support the

closing of the gap between the engineering and the

domain expertise for the quick creation of Cyber

Physical Systems.

However, given the early stage of the approach in

CPS, the extend of which CPSs are embedded into

successful business models is debatable and can vary

from case to case. Since the fundamental basis of

innovative business models is the value proposition,

this research work investigates the value propositions

that emerge from industry-relevant model-based

Cyber-Physical Systems. The contribution of this

paper is, therefore, a list of model-based CPS use

cases that are currently relevant in the industry. The

list aims to serve as a basis for experiments in

development environment such as OMiLAB

3

, thus

for the continuous prove about the validity of the

model-based approach in the creation of CPSs.

The structure of the paper is as follows: in Section

2 the methodology that was applied to conduct this

research is outlined. Next, in Section 3 cases about

industry-relevant and model-based Cyber-Physical

Systems are described and analysed. Then, in Section

4 patterns are identified through the application of the

pattern matching technique and finally a conclusion

is drawn in Section 5.

2 METHODOLOGY

This section describes the methodology that was

adopted to conduct the research. Respectively, the

below sub-section elaborates on the adopted research

design and data collection.

2.1 Case Study Research Strategy

The creation of value creation patterns for industry-

relevant and model-based CPS was carried out by

embracing a case study research strategy. As stated in

(Yin, 2003), a case study research strategy is an

empirical inquiry that investigates the case or cases

3

https://www.omilab.org/

by addressing the “how” or “why” questions

concerning the phenomenon of interest. It allows

gaining a rich understanding of the context of the

research and is well compatible with explanatory

research (Saunders, Lewis, & Thornhill, 2019), thus

fitting the objective of this research work.

A rigorous design for the case study comprising

of the following five proposed components by Yin

(2003) has been followed:

1. Question. The question refers to the query that the

case should address. In our case, the main research

question was the following:

- What are the value creation patterns of model-

based CPS that are currently relevant in the

industry?

2. Proposition. The proposition highlights the issues

that should be examined within the scope of the

case study. In our case the proposition refers to the

value creation elements that are associated to the

industry-relevant model-based CPS.

3. Units of analysis. It specifies what should be

analyzed elucidating what the case is; it is related

to the way the research questions are defined. Unit

of analysis is defined as the model-based CPS of

the different application domains.

4. Logic linking the data to the propositions. It

anticipates the possible steps involved in the data

analysis (e.g., pattern matching). In our case

explanation building and pattern matching were

used as techniques for data analysis. Namely, first

it is explained how the identified industry-relevant

model-based CPS are capturing values and then

the pattern matching technique is used to identify

the value creation patterns of model-based CPS

that are currently relevant in the industry.

5. Criteria for interpreting the findings. A case study

analysis strategy is to identify and address rival

explanations for the findings. Hence, by

addressing rivals the strengths of the findings can

be interpreted. In our case findings about the value

creation of each model-based CPS are

consolidated and compared with the theory. The

data collection for the respective findings is

described in the following sub-section.

2.2 Data Collection

To ensure the quality of the case study investigation,

each case is constructed by considering two data

Value Creation Patterns for Industry-relevant Model-based Cyber-Physical Systems

365

sources: literature review and a workshop with

industry experts. Namely, a systematic literature

review was performed which first considered a

number of relevant keywords (e.g., model-based

approaches for cyber-physical systems, industry-

relevant cyber-physical systems) and then a list of

selection criteria, which is presented in Table 1. In

result, four industry relevant model-based CPS were

identified.

Next, a workshop was conducted to elicit the

value creation of each industry-relevant model-based

CPS. The workshop consisted of four focus groups,

targeting each of the four application domains. The

workshop was set to a duration of 30 minutes. In total

there were 25 participants who are in their final year

of the Master of Science in Business Information

Systems of the University of Applied Sciences and

Arts Switzerland. Participants were (1) employed in

companies across the industry (2) had a mixed

background between engineering and domain

expertise, (3) had an average age of 30 years old and

(4) were free to select the application domain in

which they had expertise. The final findings are

reported in Section 4.

During the workshop, the participants were asked

to provide structured inputs on the value proposition

canvas for the presented model-based CPS. Notes

were taken during the observation of the

brainstorming sessions, to explain the interpretation

how CPS use cases can deliver value. Results from

the workshops were crossed checked with literature

and the final findings are reported in Section 3.

Table 1: Papers Selection Criteria.

Selection Criteria for Papers

Included

Papers which present a description and

visualisation of a conceptual model of

a CPS use case

Excluded

Papers which do not describe a

conceptual model of a CPS use case

Included

Papers which present a CPS use case

for business purpose

Excluded

Papers which present a CPS use case

for non-commercial purpose

Included

Papers which present a CPS use case

with the aim of socio-economic

enhancements

Excluded

Papers which present a CPS use case

for military or other non-socio-

economic purpose

3 CASES FOR

INDUSTRY-RELEVANT

MODEL-BASED CPS

This section describes the four cases that were created

following the case study strategy.

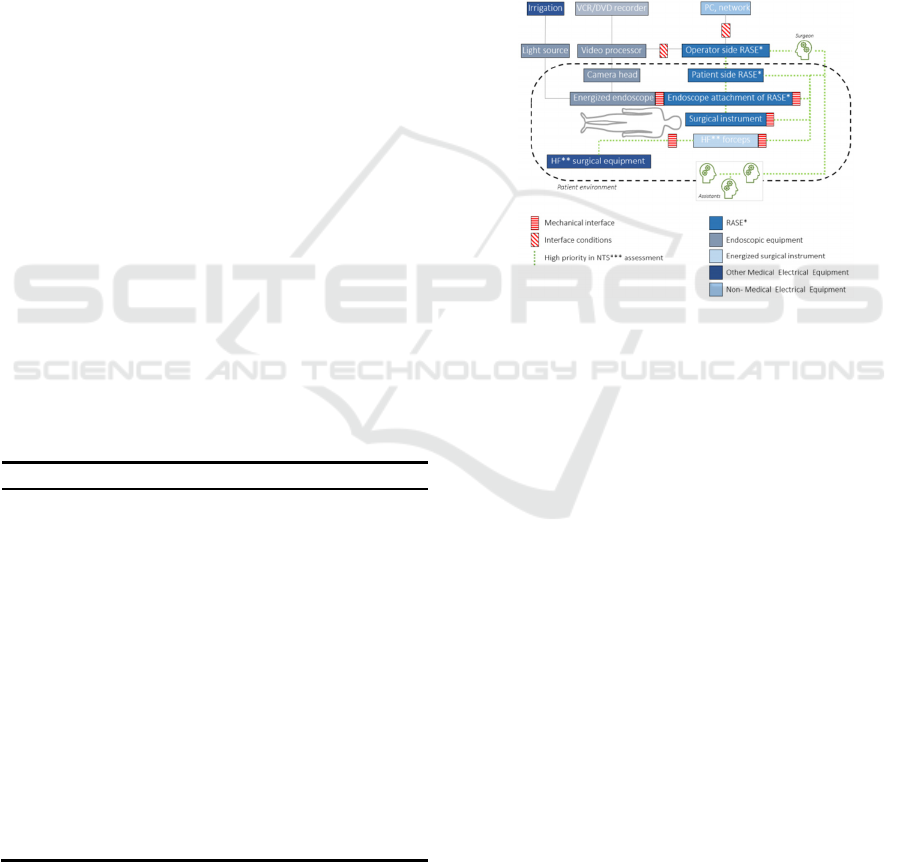

The first case relates to the robotic assisted

surgery, which is presented in Nagyné Elek &

Haidegger (2021). The model includes human

components like surgerons, assistants and a patient.

Furthermore, physical objects are represented in form

of robotic assisted surgial equipment, sensors,

cameras, lights, surgical instruments and computers.

Figure 1: Conceptual Model Robotic Assisted Surgery

(Nagyné Elek & Haidegger, 2021, p. 6).

Upon presentation of prior-described CPS use

case of robotic assisted surgery, the dedicated focus

group was asked to collect inputs through collective

brainstorming and discussions. The goal was to

brainstorm and structure a value proposition for the

customer segment surgeons. Customer jobs were

defined as planning, preparing, executing, and

documenting surgeries. The focus group started by

discussing the pains as administrative work, high

concentration required, zero error tolerance and

complicated procedures. On the other side gains were

described as high-tech materials, highly advanced

medical devices, and precision tools. Next, the focus

group discussed how robotic-assisted surgery can

relieve the prior identified pains. First, it was

mentioned that on the cyber part of the system a

digital twin of the patient could help the surgeon to

plan, model and test certain procedures before

execution. Furthermore, a digital assistance in form

of a smart workflow which is hosted on a digital

platform and represented to the surgeon on monitors,

could help the surgeon to remind if process steps were

missing. On the physical side of the system, the group

MODELSWARD 2022 - 10th International Conference on Model-Driven Engineering and Software Development

366

discussed that a robotic assisted intervention might

achieve a higher level of precision and through that

make complicated procedures easier for the surgeons,

while reducing the patient risk. In summary, robotic-

assisted surgery generates additional value by helping

surgeons to increase their performance while

decreasing risks.

The findings from the workshop go along with the

literature. Lee & Seshia (2017) describe risky

procedures like heart surgeries, which often require

stopping and restarting the heart. In such procedures

robotic assisted surgery might open new

opportunities. CPS might be the solution to avoid the

artificial heart stop during the surgery. This could be

achieved through robotically controlled surgical tools

which synchronize automatically with the motion of

the heart or a stereoscopic video system which

presents the surgeon an illusion of a still heart.

However, it is highlighted that the realization of such

a surgical system requires extensive modelling of the

heart, tools, hardware, and software including a

detailed analysis of the models and decisions to

ensure highest confidence. Thus, safety mechanisms

and fallback behaviors must be programmed to be

able to handle malfunctions (Lee & Seshia, 2017, pp.

2-3).

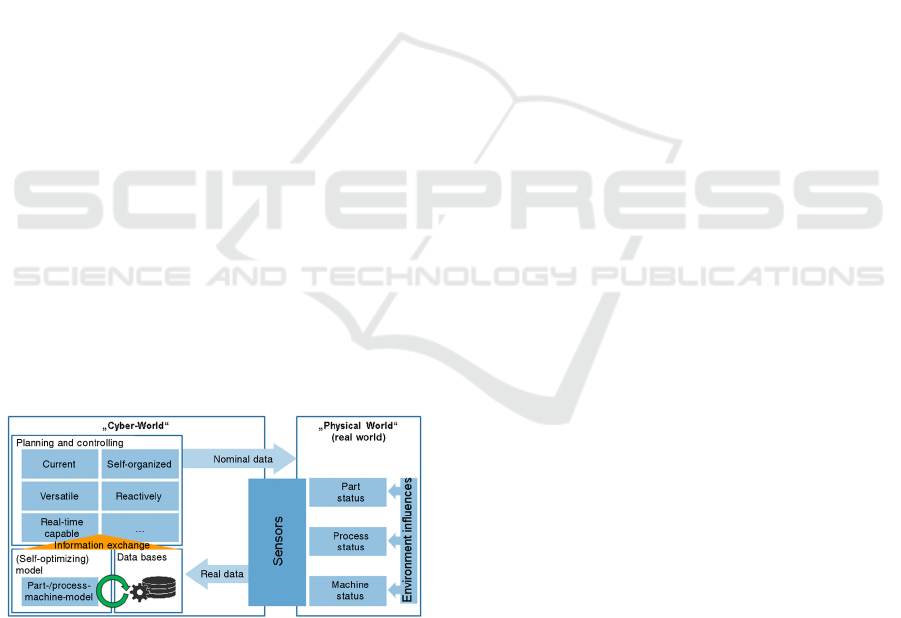

The second case relates to the model-based CPS

described by Inkamp et al. (2016). The physical part

of the system is represented by the parts, which can

be spare parts or raw materials, and the process,

which involves human operators, factory, and

assembly line workers, and machines, which are

integral part of the manufacturing infrastructure. The

cyber side of the system is represented by data bases,

machine models, planning and controlling systems.

Figure 2: Conceptual Model Cyber-Physical Production

System (Inkamp, et al., 2016, p. 326).

A brainstorming with the dedicated focus group

on the use case Cyber-Physical Production Systems

has been conducted. As such, the customer segment

was defined as manufacturing plant managers. The

plant managers are confronted with tasks such as

overseeing of production, planning and resource

allocation as well as taking management decisions.

The focus group discussed major pain points around

backorders, defects, inventory management as well as

complex decisions to be taken. On the other side, the

group mentioned that concepts like lean

manufacturing, six sigma or just-in-time production

represent a gain for plant managers. Furthermore, it

was discussed that CPPS can relieve pain points from

plant managers in the form of advanced monitoring

and regulating systems and ultimately generate

additional value by self-optimizing and operating

system capabilities. In summary, CPPS generates

additional value by helping plant managers to

increase productivity and through that managers

reach a higher performance while reducing the costs.

The findings from the focus group workshop

point into a direction of highly advanced and

automated production systems. Literature goes

beyond automation and describes Cyber-Physical

Production Systems as a combination of highly

advanced computer science, information, and

communication technologies with manufacturing

science (Inkamp, et al., 2016). A practical example of

a CPPS is described by Lee & Seshia (2017) as a

high-speed printing press for a print-on-demand

service. As such, the control motors driving the press

which is governed by laws and strategies

compensating for paper stretch, temperature, and

humidity, whereas the network structure allows rapid

shutdowns in case of paper jams to prevent damage

of equipment (Lee & Seshia, 2017, pp. 2-3). Thus,

artifacts of CPPS are adopted across the

manufacturing sector and ideally are also embedded

within supply chain systems from other domains,

such as transportation and logistics.

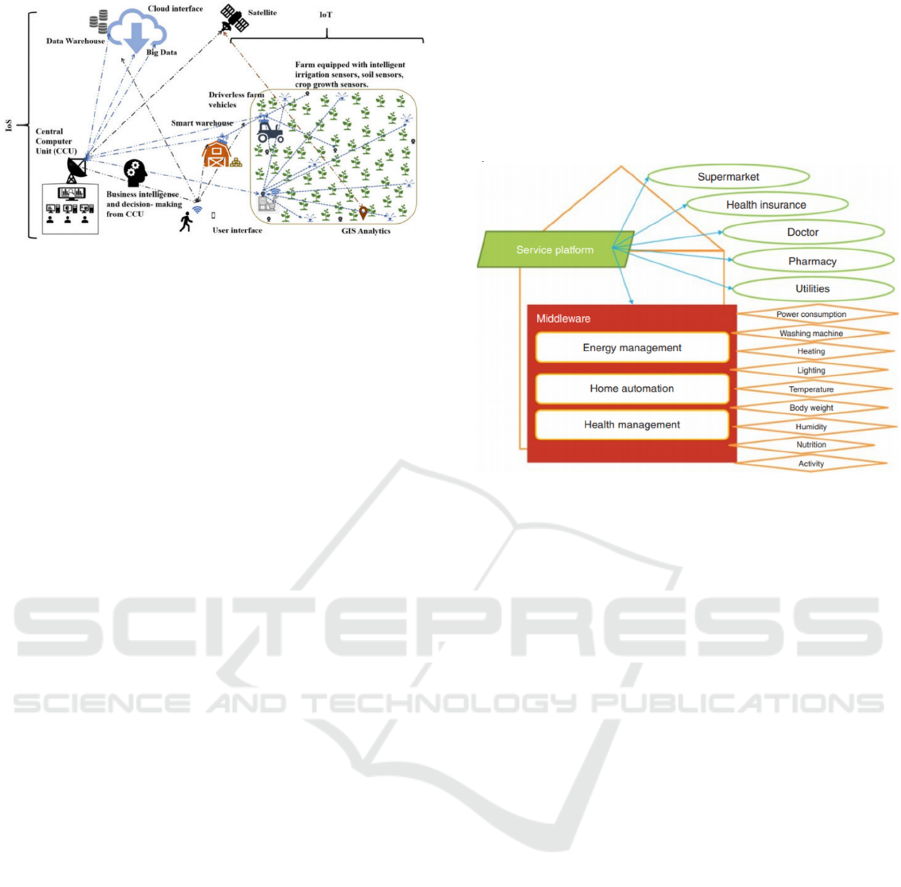

The third case focuses on Agricultural Cyber-

Physical System, ACPS, which is described by

Sharma et al. (2021). The physical part of the system

is conceptualized by the warehouse, machines, field,

plants and a satelite. The cyber part of the system is

conceptualized by the data warehouse, business

intelligence applications and a virtual network of

interconnected systems.

A brainstorming with a dedicated focus group on

the use case ACPS has been conducted. The customer

segment has been defined as farmers. Tasks of

farmers can be very diverse, however for the purpose

of the workshop were defined as managing the farm,

planning, cultivating, and monitoring fields. In the

Value Creation Patterns for Industry-relevant Model-based Cyber-Physical Systems

367

Figure 3: Conceptual Model of ACPS (Sharma, Parhi, &

Sishodia, 2021, p. 809).

discussion of the focus group first pain points were

described as bad weather conditions or soil erosion,

which are difficult for farmers to manage, especially

as farmers are facing an ongoing productivity

pressure while they must make sure to comply with

increasing regulations. On the other hand, if farmers

follow the regulations subsidies are provided, which

represents a gain. As per discussion of the focus

group, ACPS can relieve pains via automation of

heavy work in connection with the use of modern

technology tools and machines. Furthermore, a gain

can be created through the implementation of self-

regulating smart systems which adjust according to

changing weather conditions to optimize the output.

In summary, the hereby presented use case of an

ACPS generates value to farmers in form of increased

productivity as the performance of existing

agricultural processes is enhanced. Also, value is

generated in form of customization, as farmers can

customize the agricultural production through the

modification of the ACPS.

The value proposition described by the focus

group points out the importance of data in the

agricultural field. This goes along with literature,

which describes the concept of precision agriculture.

Precision agriculture is described as an approach

in which data is gathered, processed, and analysed

and combined with other information to support

management decisions to optimize efficiency,

productivity, quality, profitability, and sustainability

of agricultural production. As such, sophisticated

technologies such as robots, drones, temperature and

moisture sensors, aerial images and GPS are used.

These advanced devices enable precision agriculture

that help farms to be more profitable, efficient, safe,

and environmentally friendly (Stafford, 2019).

In the fourth case focuses on smart homes and is

described by Bakakeu et al. (2017). The physical part

of the system is conceptualized by the house. The

cyber part of the system is conceptualized by a service

platform, which interfaces to a number of external

services, such as utilities, pharmacies, doctors, health

insurances or supermakets. Aspects like energy

management, home automation and health

management are self-regulated by the smart house

system.

Figure 4: Conceptual Model Smart Home (Bakakeu et al.,

2017, p. 629).

A value proposition brainstorming with a

dedicated focus group on the use case smart homes

has been conducted. The customer segment has been

defined as homeowners. Tasks of homeowners

include but are not limited to housekeeping,

maintenance, or gardening. In the discussion of the

focus group first pain points were described as

security and privacy. Homeowners invest financial

resources and efforts to securing their own home to

protect it from burglary. Next, the focus group

discussed other pain points, such as housekeeping,

maintenance, and high utility costs. Thus, often the

described pain points are involved with human efforts

or costly services. On the other side, it was discussed

that new developments have brought up innovative

concepts like cleaning robots or smart kitchen tools,

which tend to relieve the pain of housekeeping and

maintenance. Also, it was mentioned that owning a

house which is located with access to public services

like transport, healthcare, education, grocery is

described as a big gain. Embedded self-regulating

efficiency management systems were described as

pain relievers, especially in the context of optimizing

the utilities consumption. In summary, the presented

use case of a smart home generates value for

homeowners in form of convenience, cost reduction

and sustainability aspect.

The focus groups value proposition of smart

homes goes along with literature, which argues that

technology is already part of our social community

MODELSWARD 2022 - 10th International Conference on Model-Driven Engineering and Software Development

368

and will be an integral part of our future homes and

buildings supporting an adaptive, intelligent

communication in decision making processes. Hence,

smart homes or buildings are described as dynamic

complex of living beings and intelligent technical

devices, which requires a complex interrelationship

(Bakakeu, Schäfer, Bauer, Michl, & Franke, 2017).

The findings of this section clearly go along with

efforts of existing smart home providers, which

address comfort, security, and efficiency of utilities

as a value proposition (BKW, 2020).

4 VALUE CREATION

ELEMENTS PATTERNS

As described by Yin (2003), case study analysis

pattern matching logic is one of the most desirable

techniques. As this is an explorative case study the

patterns relate to how the presented model-based CPS

use cases generate value.

Osterwalder & Pigneur (2010) describe value

creation as the distinct mix of elements catering a

customer segment’s needs. Elements listed by

Osterwalder & Pigneur include newness,

performance, customization, design, price, cost,

accessibility, risk reduction, convenience, and

usability (Osterwalder & Pigneur, 2010, pp. 22-25).

Thus, the following analysis was inspired by the value

proposition elements by Osterwalder & Pigneur

(2010). However, the challenge of this paper was to

analyse the elements of value propositions on the

level of use cases rather than products. Elements like

design, price, accessibility, and usability are hard to

assess as they are strongly product dependent and

may vary from case to case. Therefore, on the one

hand, these elements were excluded from the

analysis. On the other hand, this paper follows an

explorative approach and elements which emerged

during the data collection, e.g, productivity or

sustainability, were included in the analysis.

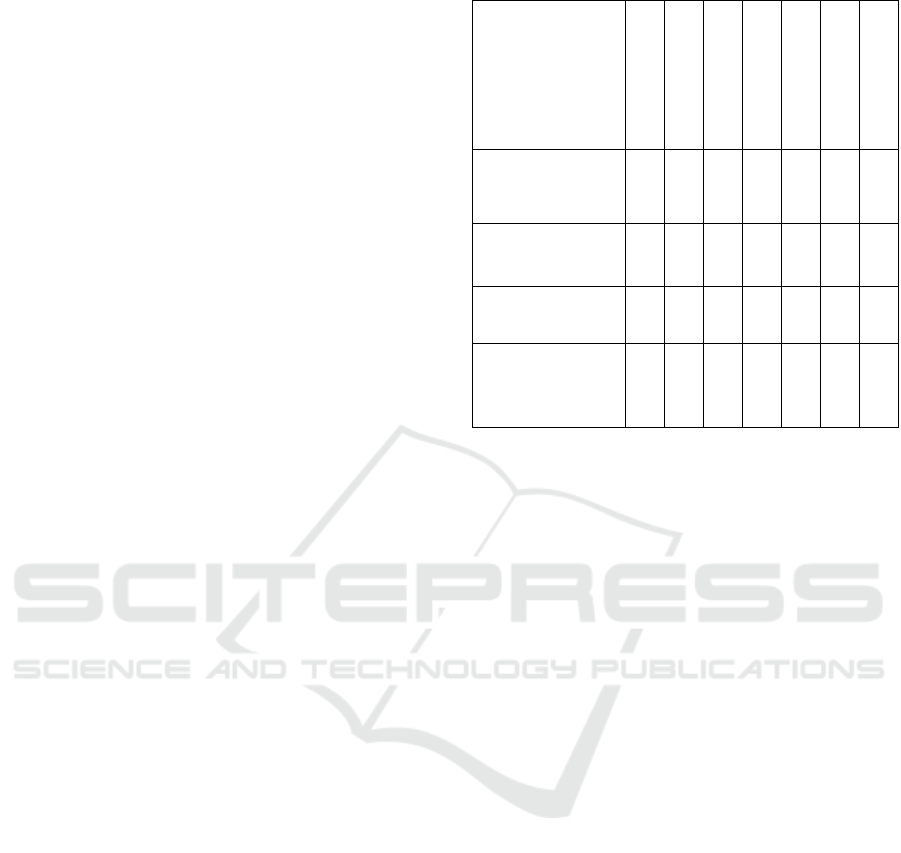

Table 2 outlines a value creation pattern that is

based on the qualitative inputs presented earlier. It

can be interpreted that industries with high pressure

on productivity, like manufacturing or agriculture can

profit from CPS in form of increased productivity.

Furthermore, it was found that industries which have

a low error tolerance, like healthcare can profit in

form of risk reduction. Additionally, CPS also offer

opportunities for industries which struggle with high

societal pressure towards more sustainability.

Table 2: Value Creation Patterns.

Industry-relevant

and model-based

CPS cases

Productivity

Performance

Customization

Cost Reduction

Risk Reduction

Convenience

Sustainability

Robotic Assisted

Surgery

X X

Cyber-Physical

Production

Systems

X X X

Smart Homes X X X

Agricultural

Cyber-Physical

Systems

X X X

5 CONCLUSION AND OUTLOOK

This paper explored value proposition of model-

based approaches of industrial Cyber-Physical

Systems. Upon literature review, application domains

of CPS were defined as healthcare, manufacturing,

energy, facility management and agriculture. For

each application domain one model-based use case

was assessed. Dedicated focus groups discussed how

value propositions of the presented model-based

approaches of CPS use cases can emerge. The

findings suggest that CPSs generate value in form of

enhanced productivity, performance, customization,

cost reduction, risk reduction, convenience, and

sustainability.

Before deducting any practical value of the

presented findings, it is important to consider rival

explanations as per Yin (2003). First, it must be

reflected if the observation of the result is a chance of

circumstances only. The circumstances presented in

this paper are largely dependent on the data collection

from a workshop with dedicated focus groups.

However, it is argued that based on the logical

reasoning of the findings, a replication of a larger

empirical study would show similar results. Next, the

treats of the validity, such as maturity, instability, or

selection must be assessed. The findings presented in

this paper are based on a rigorous case study design

and the selection criteria has been clearly described.

As a future work, the identified model-based

CPS-aware industry use cases can be implemented in

OMiLAB infrastructure. Such implementation would

Value Creation Patterns for Industry-relevant Model-based Cyber-Physical Systems

369

serve as a basis to learn more about the employment

of a model-based approach for CPSs. Moreover, to

assign priority for implementation one possibility

would be investigate about to technology readiness

level (TRL) of the presented CPSs. Those with the

least level could be chosen as first as they would gain

more value from the OMiLAB experiment. Finally,

the presented value propositions can serve as a basis

to continue research about how to embed the

presented value propositions into innovative CPS

based business models.

REFERENCES

Acatech. (2011). Cyber-Physical Systems - Driving force

for innovations in mobility, health, energy and

production. Berlin: Springer.

An, W., Wu, D., Luo, H., Adamchuk, V., & Xu, Z. (2017).

Agriculture Cyber-Physical Systems. London: Elsevier.

Bakakeu, J., Schäfer, F., Bauer, J., Michl, M., & Franke, J.

(2017). Building Cyber-Physical Systems - A Smart

Bulding Use Case. Smart Cities, 605-639.

Benyon, D., Green, T., & Bental, D. (2012). Conceptual

modeling for user interface development. Berlin:

Springer Science & Business Media

BKW. (2020). Das «Smart Living»-Haus im Verkehrshaus

der Schweiz ist eröffnet. Retrieved from https://www.

bkw.ch/de/ueber-uns/aktuell/medien/medienmitteilun

gen/das-smart-living-haus-im-verkehrshaus-der-

schweiz-ist-eroeffnet

Giachetti, R. E. (2011). Design of enterprise systems:

Theory, architecture, and methods. Boca Raton: CRC

Press.

Hinkelmann, K., Gerber, A., Karagiannis, D., Thoenssen,

B., van der Merwe, A., & Woitsch, R. (2016). A new

paradigm for the continuous alignment of business and

IT: Combining enterprise architecture modelling and

enterprise ontology. Computers in Industry (79), 77-86

Inkamp, D., Berhold, J., Heizmann, M., Michael, K., Kniel,

M., Peterek, M., Sommer, K. (2016). Challenges and

trends in manufacturing measurement technology - The

"industrie 4.0" concept. Journal of Sensors and Sensor

Systems(5), 325-335.

Kravets, A. G., Salnikova, N., Dmitrenko, K., & Lempert,

M. (2020). Industrial Cyber-Physical Systems: Risks

Assessment and Attacks Modeling. Cham: Springer.

Lee, E. A., & Seshia, S. A. (2017). Introduction to

Embedded Systems: A Cyber-Physical Systems

Approach. Cambdridge: MIT Press.

Nagyné Elek, R., & Haidegger, T. (2021). Non-Technical

Skill Assessment and Mental Load Evaluation in

Robot-Assisted Minimally Invasive Surgery.

Sensors(21), 1-23.

OMiLAB. (n.d). A Digital Innovation Environment.

Retrieved from https://www.omilab.org/brochure/

Osterwalder, A., & Pigneur, Y. (2010). Business model

generation: A handbook for visionaries, game changers

and challengers. New Jersey: Wiley.

Saunders, M. N., Lewis, P., & Thornhill, A. (2019).

Research Methods for Business Students. New York:

Pearson Education.

Sharma, R., Parhi, S., & Sishodia, A. (2021). Industry 4.0

applications in agriculture: cyber-physical agricultural

systems CPASs. Advances in Mechanical Engineering,

807-813.

Stafford, J. (2019). Precision Agriculture for Sustainability.

Camrbidge: Burleigh Dodds Science Publishing

Limited.

Tao, F., Qi, Q., Wang, L., & Nee, A. (2019). Digital Twins

and Cyber-Physical Systems toward Smart

Manufacturing and Industry 4.0. Engineering(5), 653-

661.

Vyshnevskyi, O. S. (2020). Impact of digitalization on

industry: problems of definition in EU countries.

Economy of industry(89 (1)), 31-44.

Yin, R. K. (2003). Case Study Research: Design and

Methods. Thousand Oaks: Sage.

MODELSWARD 2022 - 10th International Conference on Model-Driven Engineering and Software Development

370