Smart Access Control System for Industrial Machines and Vehicles

based on RFID Technology

Davide Colaiuda

1a

, Giuseppe Ferri

1b

, Alfiero Leoni

1c

, Andrea Pelliccione

1

, Piero Faraone

2

,

Orlando Quaranta

2

, Valerio Arezzo

2

and Vincenzo Stornelli

1d

1

Department of Industrial and Information Engineering, University of L’Aquila,

Località Campo di Pile, via Gronchi 18, L’Aquila 67100, Italy

2

Faraone Industrie S.p.A., via S. Giovanni 20, Tortoreto 64018, Italy

p.faraone@faraone.com, o.quaranta@faraone.com, v.arezzo@faraone.com, vincenzo.stornelli@univaq.it

Keywords: RFID, Radio-frequency Identification, Smart Card, NFC, Work-related Accidents, Access Control, Industrial

Trucks, Smart Systems, Industry 4.0.

Abstract: In this paper a smart system for Access control of industrial machines and vehicles is presented. The

development of the so-called Industry 4.0, together with the spread of contactless technology such as NFC

Radio Frequency Identification, and the massive industrialization of working process, resulted in a significant

integration of information technologies in smart industrial vehicles and forklifts. These are one of the main

causes of work-related accidents, due to a frequent improper usage of this machines. The presented solution

is a smart system that uses RFID reader and personal smart cards that interrupts machine ignition or

movement, allowing just trained workers use them. Machines usage data are stored in system internal

memory. A dedicated application makes new cards compatible and saves user data in them; a simple user

interface is also implemented to add or remove employees permission or authorised cards and tags.

1 INTRODUCTION

In the last years, a significative part of tracking and

tracing procedures is realized with wireless systems.

Among them, Radio Frequency Identification (RFID)

gained a significative popularity due to its simple

structure, which may involve magnetic coupling or a

proper RF wave transmission, according to the

implemented antenna (Turcu, 2009). This technology

permits a contact-less data transmission using tag or

cards equipped by a built-in memory chip with a

proper data interface and signal modulation circuits

(Kuilin Chen, Dongyan Zhao, Haifeng Zhang, Yubo

Wang & Liang Liu, 2013), based on the operating

frequency. One of the most diffused RFID

technologies is based on data transmission at a 13.56

MHz frequency. In the last years, different standards

have been defined, such as the ISO/IEC 14443, for

which several IC cards interfaces have been

a

https://orcid.org/0000-0002-8488-9606

b

https://orcid.org/0000-0002-8060-9558

c

https://orcid.org/0000-0002-0066-4216

d

https://orcid.org/0000-0001-7082-9429

developed, based on Near Field Communication

(NFC) (Lu Chao & Li Yong-ming, Kuo et al., 2018).

Wireless and contactless data transmission is

widely diffused today, and smart cards are suitable

items to easily store personal data (Bejo, Winata &

Kusumawardani, 2018, Mirza & Alghathbar, 2009).

A “smart card” is a common plastic card that

integrates an IC embedding a non-volatile memory

where data can be stored, a demodulator and an

antenna (Hendry, 1998, Domingo-Ferrer, 2000) that

work passively, getting its energy supply from the

magnetic field generated from a proper reader or

writer interface. Memory blocks are usually protected

by one or more authentication and control keys, that

allows to read or write their content. This guarantees

a certain degree of security, using proper encryption

algorithms for data protection (Feng, Wang, Lu, Jin

& Shu, 2021, He, Lin, Wang & Wang, 2020, Naija,

Y., Beroulle, V., Hely, D., & Machhout, M., 2016).

Colaiuda, D., Ferri, G., Leoni, A., Pelliccione, A., Faraone, P., Quaranta, O., Arezzo, V. and Stornelli, V.

Smart Access Control System for Industrial Machines and Vehicles based on RFID Technology.

DOI: 10.5220/0010972900003188

In Proceedings of the 8th International Conference on Information and Communication Technologies for Ageing Well and e-Health (ICT4AWE 2022), pages 163-167

ISBN: 978-989-758-566-1; ISSN: 2184-4984

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

163

Because of this, they are growing in popularity also

in money-involving applications (Jesani, Gupta,

Bhatt, Singh & Saxena, 2020). Every system based on

this technology is very suitable for a lot of different

applications: these usually associate data to tags (or

cards, if using NFC) and elaborates them to find out

sensors data (Turki et al., 2019, Trevisan & Costanzo,

2014), to track items position (Wang, Liu & Wang,

2010, Renuka, Ng Chin Nan & Ismail, 2013) or

localizing them (Al-Saedi & Azim, 2017) and for

other data measures (Chen, Peng & Yan, 2019,

Bevacqua, Bellizzi & Merenda, 2019).

Nowadays there are a lot of available commercial

solutions for NFC RFID communications that uses

smart cards to store data and permissions, managing

other systems with the information stored in them.

Just a few of them, anyway, are aimed to reduce

work-related risk and injuries; a lot of studies focused

their attention on both fatal and non-fatal accidents

involving heavy machinery on working places

(Kazan & Usmen, 2018, Jeong, 1998, Larsson &

Rechnitzer, 1994, Stout-Wiegand, 1987, Pan et al.,

2007). Recent data shows that every year there are

over 3 million of work-related accidents ("Non-fatal

accidents at work by NACE Rev. 2 activity and sex -

Products Datasets - Eurostat", 2022), of which more

than 3000 are fatal ("Fatal Accidents at work by

NACE Rev. 2 activity - Products Datasets - Eurostat",

2022). This kind of injuries are mainly reported by

manufacturing, construction and wholesale industries

that make a great use of forklifts, aerial platforms, and

other industrial trucks. These in fact can be driven

only by trained and qualified operators, due to the

heavy weights, the low stability and the altitudes

involved, and a great part of accidents is due to

operator inaccuracy and lack of training.

In this situation, research is going towards the

“Industry 4.0”, that is in the design of smart machines

with autonomous control systems (Patil, Rajurkar,

Salunke & Pljonkin, 2019, Kasahara & Mori, 2015),

that can automatically abrupt certain operations if

they detect a risk for workers. With this mind, this

paper proposes a built-in access control system for

industrial vehicles, that uses NFC passive smart cards

to manage engine ignition and movement, depending

on the user permissions and specific training.

2 SYSTEM OPERATION

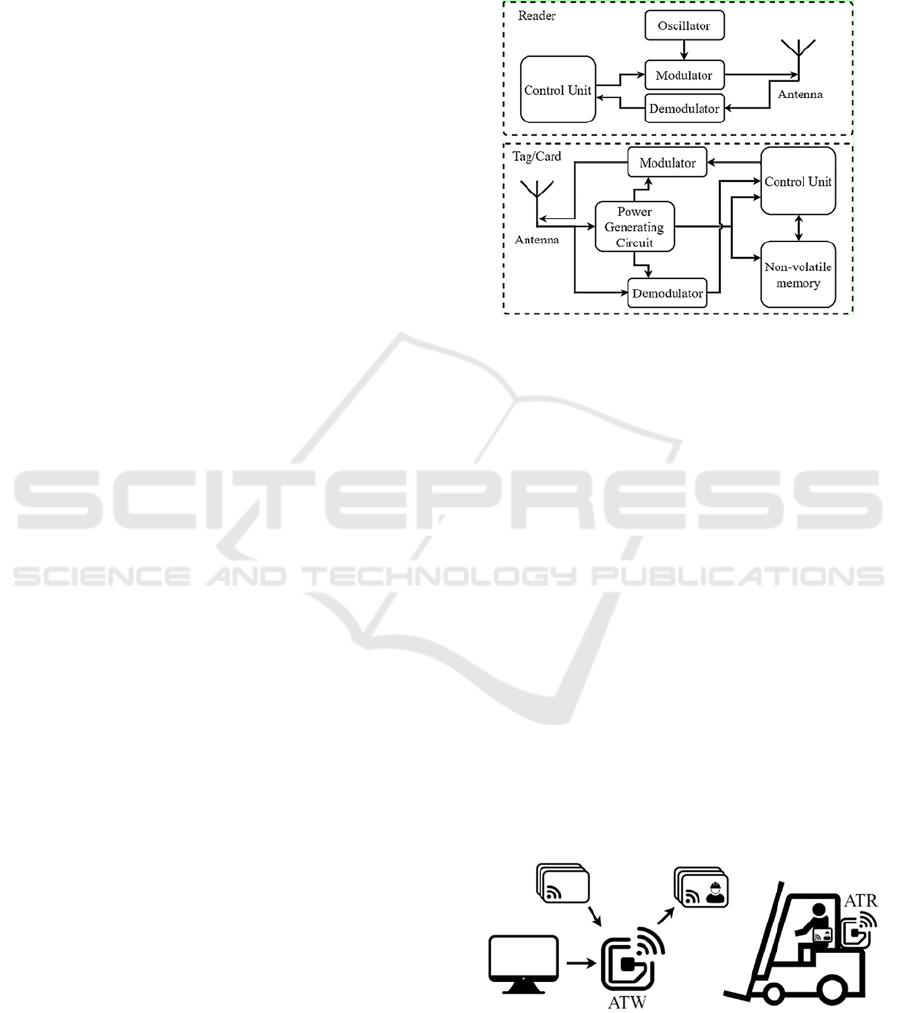

A block diagram of RFID card (or tag) and reader is

shown system in Fig.1. The proposed system (Fig.2)

consists of two devices: one or more Access Tag

Writer (ATW) with a dedicated software application

and several Access Tag Readers (ATR), one for each

machine to control. The system is completed with a

number of MIFARE Classic 1K (NXP, 2022) smart

cards depending on the number of possible operators

and workers in which are stored operator data.

Figure 1: Block diagram of a RFID-based reader and a

RFID passive smart card.

The data structure of 1K MIFARE Classic cards is

that following: the whole memory storage is divided

into 16 sectors, with 4 blocks of 16 bytes each. For

every sector, the first three blocks are general purpose

usable bytes, that can be written with user information

and data; the last block of a sector (called “sector

trailer”) contains the protection bytes and access bits

for the whole sector’s block. The first and last six

bytes contains two protection keys (key A and key B,

respectively) that needs to be used (one or both,

depending on Access bits) to read or write on the

relative sector. The left 3 bytes are Access bytes

(whose combination controls permissions to read,

write or doing other operations) and a general

purposes byte. Once correctly authenticated, the card

content can be read or written by a compatible RFID

reader. In the proposed system each worker has a

personal smart card containing information and

guidance permissions for heavy trucks and machines

utilisation.

Figure 2: Proposed system operation.

The ATW writes users data on their personal

smart card, making them compatible with the ATR.

ICT4AWE 2022 - 8th International Conference on Information and Communication Technologies for Ageing Well and e-Health

164

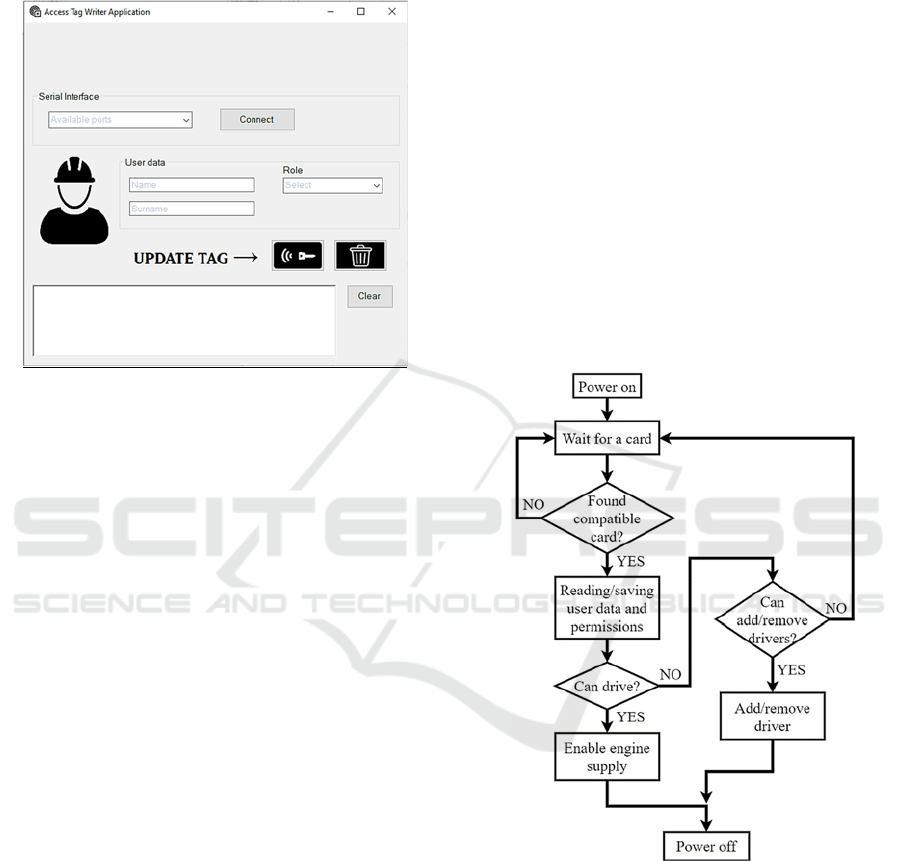

This process is realized through the dedicated

application (see Fig. 3) where information is entered,

and cards (or tags) are written or deleted. The ATR is

installed on a machine and divides truck engines

Figure 3: Access Tag Writer (ATW) application interface.

with their power supply, using normally opened

relays. Since permissions can be temporary, a specific

role for adding and remove permissions has been

implemented. In this way, a department head can use

his own smart card to give driving permission to a

specific user without the need of using the ATW, but

just passing his card close to the ATR and right before

passing the worker one, so to authorise to drive the

vehicle (the same principle is used to remove that

permission). This device is the effective machines

access control and is designed to work only with

specific cards written by the ATW. Also, to keep trace

of vehicle usage, user data are stored in a local

memory every time the machine is enabled by an

operator.

3 INTERNAL ARCHITECTURE

The presented ATW consists of a microcontroller that

communicates with a commercial RFID reader IC,

reading data from a serial port (transmitted by the

application in the correct format) and writing the

detected tag immediately after. To associate a card

with his owner, the designed ATW is used: this is a

device with an RFID tag reader and writer

(compatible with Standard ISO/IEC 14443 smart IC

cards), that works on empty cards. Through the

dedicated application, user data are entered in the app

and transmitted to the ATW through a serial port;

these data concern in identity and role (that includes

permissions). Once entered, an empty smart card

must be approached to the ATW in order to write

them and protect the used sectors with secret keys:

this is both for security and with the aim to make new

cards compatible with the ATR.

The ATR also consists of a microcontroller and

the same RFID reader, but it also embeds relays for

engines, a non-volatile memory chip, an RTC and

some status led. When the machine is powered on, the

RFID reader of the ATR starts scanning for MIFARE

cards in his close field and tries to authenticate them

with the same keys written by the ATW. When it

detects a valid smart card, the role written in the

relative blocks is checked. At this point, machine

engines will be powered on only if the user have the

permission to drive it, and time and data of the user

activity will be registered on an internal memory to

keep trace of machine usage. In Fig. 4 is shown a

simplified algorithm run by the ATR installed on

machines. When powered up, the device starts

Figure 4: Simplified algorithm executed by the Access Tag

Reader.

scanning his field close looking for a card; if a

compatible one is detected, the system saves user data

and check its authorization to drive or to change other

users permissions. In this way, the Access Tag Writer

is required only to make cards compatible as first

instance or to newly hired employees; the truck

driving permission can be managed just on the truck

themselves. In this way, the proposed system

guarantees a safe usage of industrial trucks letting

Smart Access Control System for Industrial Machines and Vehicles based on RFID Technology

165

only trained people drive them, then identity

information is collected to avoid card disposal among

workers.

To better evaluate system functionality, a

prototype version of the full system has been

implemented to ensure its functionality. It has been

mounted on the machine Elevah

5 ("Elevah E5 -

Aerial platform", 2022), that is an aerial lift designed

Figure 5: Elevah

5 aerial platform by Faraone Industrie

S.p.A.

by Faraone Industrie S.p.A. (see Fig. 5): this has two

engines that control movement and elevation,

respectively. The ATR interrupted their power

supply, enabling them just if an allowed smart card

was detected, confirming the overall functionality.

4 CONCLUSIONS

This work proposed a RFID-based system, composed

of an Access Tag Writer to write user data in their

personal smart card, and a device (the Access Tag

Reader, specific for each machine) that manages

engines power supply according to the operator

permission, to avoid accidents and physical damage

due to improper use of vehicles from unqualified

users. Data read from cards are stored every time

engines are enabled from an operator with their card,

which contains identity and licenses of the owner.

Though cards data can be written only with the

relative application, permission managing is easily

implemented with proper tags, that when read from

the ATR make the following-read card allowed or

not-allowed to drive the truck. As a future

development, different sensors, such as distance

sensors or accelerometer, can be embedded to the

system, so to control differently machine movements,

enabling just the ones for which the operator is

trained. Also, a proper remote interface can be

implemented embedding a WiFi or GSM module,

reading usage data from a remote software

application for data consultation.

REFERENCES

Turcu, C. (2009). Development and implementation of

RFID technology. IN-TECH.

Kuilin Chen, Dongyan Zhao, Haifeng Zhang, Yubo Wang,

& Liang Liu. (2013). 13.56 MHz passive electron tag

for smart card application with high-security. 2013

IEEE International Conference On RFID-Technologies

And Applications (RFID-TA).

Lu Chao, & Li Yong-ming. The RF interface circuits design

of contactless IC cards. ASICON 2001. 2001 4Th

International Conference On ASIC Proceedings.

Kuo, Y., Grosso, A., Galimberti, F., Tantera, J., Mallo, J.,

& Verrastro, S. (2018). Analog front-end design of

contactless RFID smart card ISO/IEC14443A standard

— Compliant. 2018 IEEE 9Th Latin American

Symposium On Circuits & Systems (LASCAS).

Bejo, A., Winata, R., & Kusumawardani, S. (2018).

Prototyping of Class-Attendance System Using Mifare

1K Smart Card and Raspberry Pi 3. 2018 International

Symposium On Electronics And Smart Devices

(ISESD).

Mirza, A., & Alghathbar, K. (2009). Acceptance and

Applications of Smart Cards Technology in University

Settings. 2009 Eighth IEEE International Conference

On Dependable, Autonomic And Secure Computing.

Hendry, M. (1998). Smart Card Security and Applications.

EDPACS, 25(11), 18-18.

Domingo-Ferrer, J. (2000). Smart card research and

advanced applications. Boston: KLUWER

ACADEMIC PUBLISHERS.

Feng, Y., Wang, H., Lu, H., Jin, W., & Shu, N. (2021).

Security Analysis and Optimization Methods of LSFR

Generating Function for MIFARE Classic CARD. 2021

IEEE 4Th International Conference On Computer And

Communication Engineering Technology (CCET).

He, H., Lin, H., Wang, R., & Wang, H. (2020). Research on

RFID technology security. 2020 IEEE 3Rd

International Conference On Automation, Electronics

And Electrical Engineering (AUTEEE).

Naija, Y., Beroulle, V., Hely, D., & Machhout, M. (2016).

Implementation of a secured digital ultralight 14443-

type A RFID tag with an FPGA platform. 2016

International Conference On Design And Technology

Of Integrated Systems In Nanoscale Era (DTIS).

Jesani, N., Gupta, N., Bhatt, S., Singh, P., & Saxena, A.

(2020). Smart Card For Various Application In

Institution. 2020 IEEE International Students'

Conference On Electrical,Electronics And Computer

Science (SCEECS).

Turki, B., Ali Ziai, M., Hillier, A., Belsey, K., Parry, A., &

Yeates, S. et al. (2019). Chemical Vapor Detecting

Passive RFID Tag. 2019 IEEE International

ICT4AWE 2022 - 8th International Conference on Information and Communication Technologies for Ageing Well and e-Health

166

Conference On RFID Technology And Applications

(RFID-TA).

Trevisan, R., & Costanzo, A. (2014). Exploitation of

passive RFID technology for wireless read-out of

temperature sensors. 2014 IEEE RFID Technology And

Applications Conference (RFID-TA).

Wang, W., Liu, Y., & Wang, S. (2010). A RFID-enabled

Tracking System in Wire Bond Station of an IC

packaging assemble line. 2010 IEEE International

Conference On RFID-Technology And Applications.

Renuka, N., Ng Chin Nan, & Ismail, W. (2013). Embedded

RFID tracking system for hospital application using

WSN platform. 2013 IEEE International Conference

On RFID-Technologies And Applications (RFID-TA).

Al-Saedi, S., & Azim, M. (2017). Radio Frequency Near

Communication (RFNC) Technology: An Integrated

RFID-NFC System for Objects' Localization. 2017 9Th

IEEE-GCC Conference And Exhibition (GCCCE).

Chen, I., Peng, C., & Yan, Z. (2019). A simple NFC

parameters measurement method based on ISO/IEC

14443 standard. 2019 IEEE International Conference

On RFID Technology And Applications (RFID-TA).

Bevacqua, M., Bellizzi, G., & Merenda, M. (2019). Field

Focusing for Energy Harvesting Applications in Smart

RFID Tag. 2019 IEEE International Conference On

RFID Technology And Applications (RFID-TA).

Kazan, E., & Usmen, M. (2018). Worker safety and injury

severity analysis of earthmoving equipment accidents.

Journal Of Safety Research, 65, 73-81.

Jeong, B. (1998). Occupational deaths and injuries in the

construction industry. Applied Ergonomics, 29(5), 355-

360.

Larsson, T., & Rechnitzer, G. (1994). Forklift trucks—

analysis of severe and fatal occupational injuries,

critical incidents and priorities for prevention. Safety

Science, 17(4), 275-289.

Stout-Wiegand, N. (1987). Characteristics of work-related

injuries involving forklift trucks. Journal Of Safety

Research, 18(4), 179-190.

Pan, C., Hoskin, A., McCann, M., Lin, M., Fearn, K., &

Keane, P. (2007). Aerial lift fall injuries: A surveillance

and evaluation approach for targeting prevention

activities. Journal Of Safety Research, 38(6), 617-625.

Non-fatal accidents at work by NACE Rev. 2 activity and

sex - Products Datasets - Eurostat. (2022). Retrieved 4

March 2022, from https://ec.europa.eu/eurostat/

web/products-datasets/-/hsw_n2_01

Fatal Accidents at work by NACE Rev. 2 activity - Products

Datasets - Eurostat. (2022). Retrieved 4 March 2022,

from https://ec.europa.eu/eurostat/web/products-

datasets/-/hsw_n2_02

Patil, P., Rajurkar, V., Salunke, A., & Pljonkin, A. (2019).

Smart Forklift to Reduce Accidents. 2019 2Nd

International Conference On Intelligent

Communication And Computational Techniques

(ICCT).

Kasahara, M., & Mori, Y. (2015). The proposal of the

forklift fall accidents prevention method using sliding

mode control. 2015 54Th Annual Conference Of The

Society Of Instrument And Control Engineers Of Japan

(SICE).

NXP (2022). Retrieved 4 March 2022, from

https://www.nxp.com/docs/en/data-

sheet/MF1S50YYX_V1.pdf

Elevah E5 - Aerial platform. (2022). Retrieved 4 March

2022, from https://www.elevah.com/en/products/

elevah-5.

Smart Access Control System for Industrial Machines and Vehicles based on RFID Technology

167