Modelling Advanced Technology Integration for Supply Chains

Anna-Maria Nitsche

1,2 a

and Wibke Kusturica

1,3 b

1

Faculty of Business and Economics, University of Applied Sciences Zwickau, Kornmarkt 1, 08056 Zwickau, Germany

2

Faculty of Economics and Management Science, University of Leipzig, Grimmaische Straße 12, 04109 Leipzig, Germany

3

Faculty of Business and Economics, Technische Universität Dresden, Helmholtzstraße 10, 01069 Dresden, Germany

Keywords: Supply Chain Modelling, Novel Technologies, Design Science Research, Benefit Analysis, Focus Group.

Abstract: The fast-paced evolution of supply chains poses increasing challenges as networks have become more

complex and dynamic. The intense interaction between information technology and business drives the spread

of the physical internet as a supply chain paradigm. While some of the classic supply chain models provide

approaches towards the integration of advanced technologies, few publications focus on a comparison or

further development of these models. We strived to critically discuss existing supply chain models and to

suggest an improved approach for modelling the digital supply chain. We applied the design science research

methodology to systematically analyse and critically evaluate four selected supply chain modelling

approaches. Based on a literature review and benefit analysis, we present an outlook on the potential future

applicability and provide a roadmap for modelling advanced technology integration for supply chains. The

comprehensive analysis highlights if and how selected supply chain models can remain relevant regarding the

digitalisation of supply chains. Thus, this article informs researchers on future research opportunities and

suggests a potential roadmap for practitioners.

1 INTRODUCTION

The fast-paced evolution of global industry and trade

poses increasing challenges to both regional and

global supply chains as supply networks are an

integral part of any business endeavour (Backhaus et

al., 2020; Schröder & Wegner, 2019; Storey,

Emberson, Godsell, & Harrison, 2006). Companies

must compete in challenging and globally integrated

environments and often find their supply chains to be

insufficiently equipped to face global competition,

growing customer expectations, supply chain

disruptions and individualised production

(Christopher, 2000; Golan, Jernegan, & Linkov,

2020; Zanker, 2018). The supply chain management

(SCM) literature provides different approaches

towards the integration of advanced technologies,

such as data analytics (DA), simulation, or artificial

intelligence (AI). For instance, an ecosystem

(Averian, 2017), supply chain capability (Naway &

Rahmat, 2019) or supply chain structure approach

(Bhakoo, Britta Gammelgaard, Singh, & Chia, 2015)

a

https://orcid.org/0000-0003-3164-5066

b

https://orcid.org/0000-0001-6131-2620

are assumed. While the relationship between

information and communication technology and

SCM processes is well-established (e.g. Kumar,

Singh, & Modgil, 2020), few publications focus on a

critical comparison or debate regarding existing

supply chain models.

The purpose of this paper is to (1) critically

discuss existing supply chain models, (2) to

determine whether novel technologies could be used

to adapt classic SCM models, and (3) to provide a

roadmap for modelling advanced technology

integration for supply chain to advance theory and

practice of logistics and SCM. The design science

research methodology (DSRM) for the production

and presentation of Design Science Research (DSR)

in information systems research (Peffers, Tuunanen,

Rothenberger, & Chatterjee, 2007) is adopted. First,

the state-of-the-art section highlights the relevance of

selected technological approaches for logistics and

SCM. Following the presentation of the

methodological approach, the design, development

and evaluation of the roadmap are discussed. Finally,

the results are discussed and a conclusion including a

Nitsche, A. and Kusturica, W.

Modelling Advanced Technology Integration for Supply Chains.

DOI: 10.5220/0010969400003179

In Proceedings of the 24th International Conference on Enterprise Information Systems (ICEIS 2022) - Volume 2, pages 397-407

ISBN: 978-989-758-569-2; ISSN: 2184-4992

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

397

summary of the findings, managerial implications as

well as propositions for future research, is provided.

2 STATE-OF-THE-ART OF

INNOVATIVE

TECHNOLOGICAL

APPROACHES IN SUPPLY

CHAIN MANAGEMENT

2.1 Emerging Technologies Selection

In selecting advanced technologies for this research

project, the authors follow Gartner’s five trends for

supply chain strategy and maturity model (Hippold,

2020; Mauerer, 2018). The following triad of data-

based technologies was selected due to their novelty

regarding application for SCM: DA, AI, and

simulation. The authors acknowledge the relevance of

other emerging technologies such as blockchain,

which have also proven significant in the supply

chain context (Gammelgaard, Welling, & Nielsen,

2019; Subramanian, Chaudhuri, & Kayıkcı, 2020)

and might be included in future studies.

2.2 Application of Data Analytics in

Logistics and Supply Chain

Management

Runkler (2015) describes DA as “an interdisciplinary

field combining aspects of statistics, machine

learning, pattern recognition, systems theory and

artificial intelligence, defined as the application of

computer systems to the analysis of large amounts of

data for decision support”. Numerous literature

reviews on the application of DA in SCM and

logistics highlight the relevance of this research field

and illustrate how the use of DA methods can

significantly increase efficiency (e.g. Mishra,

Gunasekaran, Papadopoulos, & Childe, 2018; Tiwari,

Wee, & Daryanto, 2018). DA enables the

advancement of supply chain 4.0 by improving the

end-to-end process transparency of the supply chain

(Christopher, 2021). Examples of DA application in

logistics and SCM are manifold and include, for

example, big data analytics in cold chain logistics

(Gupta, Chaudhuri, & Tiwari, 2019), arrival time

modelling (van der Spoel, Amrit, & van

Hillegersberg, 2017), and the use of process mining

for supply chain analysis (Górtowski, 2018).

2.3 Application of Simulation in

Logistics and Supply Chain

Management

Supply chains form complex systems due to the large

number of companies involved and their networking

(Kaczmarek, 2002). Gutenschwager and Alicke

(2004, p.178) state that “simulation can help to

examine such complex systems and make them

understandable for the user”, because simulation is

one of the most powerful technologies for decision

support, as complex systems can be realistically

represented (Chandra & Grabis, 2007; Oliveira,

Lima, & Montevechi, 2016). Often, event-discrete

simulation is the only possibility to map complex

supply chains with reasonable effort, as it allows a

cooperation of all actors in a supply chain (Krischke

& Grzesch, 2009; Kuhn & Rabe, 1998). Reasons for

the use of simulation in the SCM environment can be

the investigation of tactical problems, the evaluation

of different production or procurement options, batch

size optimisation, or profitability analysis (Fechteler

& Gutenschwager, 2014).

2.4 Application of Artificial

Intelligence in Logistics and Supply

Chain Management

Following several so-called AI springs and winters

(Duan, Edwards, & Dwivedi, 2019), the current

revitalisation of AI research is fuelled by the

advancement of BDA. AI “can be defined as human

intelligence exhibited by machines; systems that

approximate, mimic, replicate, automate, and

eventually improve on human thinking” (Gesing,

Peterson, & Michelsen, 2018, p.3) and includes a

great variety of techniques such as machine learning

algorithms and agent-based modelling. Recent

comprehensive literature reviews and special issues

(e.g. Fosso Wamba, Queiroz, Guthrie, & Braganza,

2021; Toorajipour, Sohrabpour, Nazarpour, Oghazi,

& Fischl, 2021) illustrate that the areas of interest for

AI application are widespread. AI is used in contexts

such as scheduling and routing (El-Yaakoubi, El-

Fallahi, Cherkaoui, & Hamzaoui, 2017), cloud

computing for supply chain integration (Manuel

Maqueira, Moyano-Fuentes, & Bruque, 2019), and

interorganisational integration and coordination

(Sergeyev & Lychkina, 2019).

ICEIS 2022 - 24th International Conference on Enterprise Information Systems

398

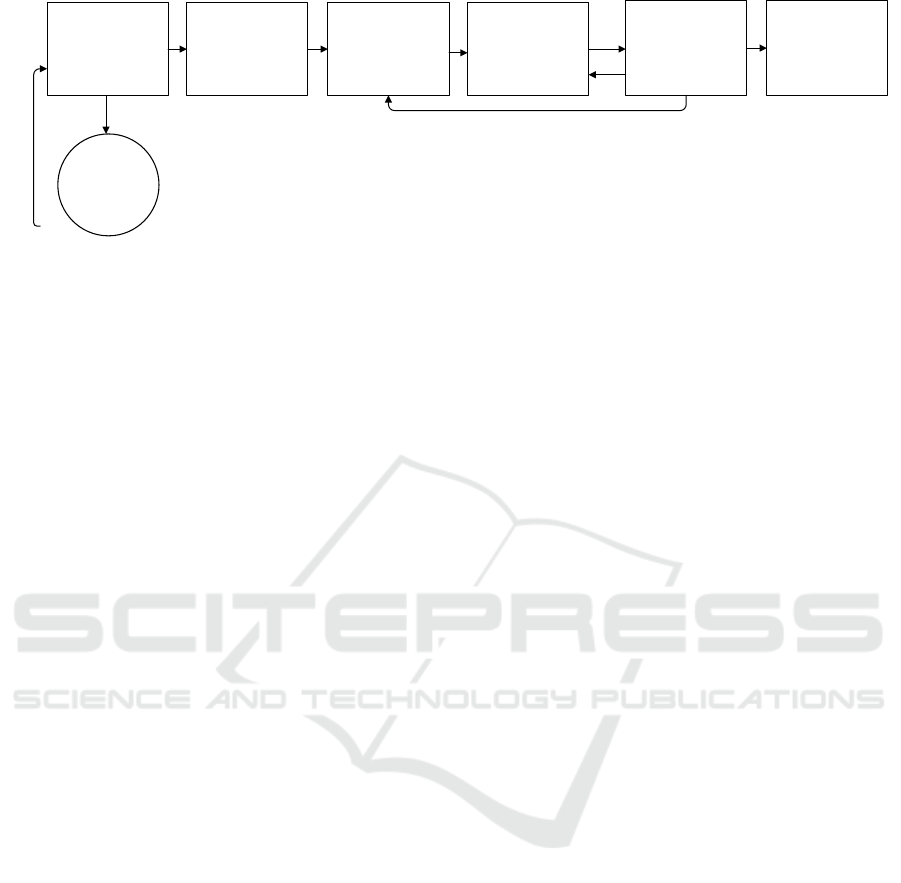

Figure 1: Adapted design science research methodology (DSRM) (based on Peffers et al., 2007, p.54).

2.5 Research Gaps and Focus

The conceptualisation of the problem space and the

addressed solution space follow the

recommendations of Maedche, Gregor, Morana, and

Feine (2019) and comprise the following four

dimensions: needs, goals, requirements, stakeholder.

As the classic supply chain models designed in the

1990s mostly do not relate to new technologies,

supply chain managers and lecturers lack models that

actively incorporate advanced technologies. The

review of the state-of-the-art shows that the

application of technological approaches such as DA,

simulation, and AI in logistics and SCM drives the

increasingly fast-paced digitalisation of supply

chains.

This paper aims to investigate whether the

technologies described above can be used to map

classic SCM models to exploit the potential of

advanced technologies. This paper thus strives to (1)

critically discuss existing supply chain models, (2) to

determine whether novel technologies could be used

to adapt classic SCM models, and (3) to provide a

roadmap for modelling advanced technology

integration for supply chain to advance theory and

practice of logistics and SCM by addressing the

following question: Which supply chain modelling

approaches are potentially suitable for the integration

of advanced technological concepts?

3 METHODOLOGICAL

APPROACH

This paper is based on the DSRM for the production

and presentation of DSR in information systems

research, as proposed and developed by Peffers et al.

(2007) (see Figure 1). It intends to evaluate classic

supply chain modelling approaches regarding their

applicability for the implementation and illustration

of innovative technological approaches. The findings

are subsequently distilled into a roadmap for future

supply chain modelling as a DSR construct (Peffers,

Rothenberger, Tuunanen, & Vaezi, 2012).

The research entry point for this paper is thus a

problem-centred initiation. The first two activities are

conducted as a review of the state-of-the-art,

including an assessment of the application of

innovative technological approaches in SCM

followed by the research question. A benefit analysis

in activity three is chosen for the comparison and

critical evaluation of the predominant supply chain

modelling approaches. This paper adopts the process

for the implementation of a benefit analysis as

described by Kühnapfel (2014). Subsequently, the

artifact demonstration and evaluation in activities

four and five is done using focus group research to

gather expert opinions (O'Gorman & MacIntosh,

2015). The final activity consists of the

communication of the research results to the relevant

interest groups.

4 ARTEFACT DESIGN AND

DEVELOPMENT

The artefact is developed iteratively following eight

steps of benefit analysis:

1) Organisation of the Working Environment

To allow for a systematic and transparent research

process, group discussion using a focus group is

chosen as the research method for the evaluation step

of the benefit analysis. First, the purpose of the focus

group is defined, and the focus group conversation

guide is developed based on the comparison of the

decision alternatives derived from the literature. As

suggested by O'Gorman and MacIntosh (2015) the

authors choose a purposive non-probability sampling

strategy in the second phase. The selected four

participants from the authors’ research network are

Analysis Phase

Review of the

State-of-the-art

Analysis Phase

Research

Question

Design and

Development

Benefit Analysis

Demonstration

Artefact

Evaluation

Focus Group

Communication

Publication of

Findings

Problem-

Centered

Initiation

Modelling Advanced Technology Integration for Supply Chains

399

experts in the fields relevant for this paper (DA,

simulation, AI) and experienced academics with a

computer science or informatics background and

knowledge of logistic and SCM processes. As. The

main section of the focus group is organised relatively

loosely in three parts, the first dealing with the

participants’ impressions on the suitability of the

SCM models for the technological concepts, the

second with improvements and adjustments for the

technological concepts and the third with an

individual ranking of the SCM models for the

technological concepts.

2) Identification of the Decision Problem

The benefit analysis aims to evaluate the selected

supply chain models, hereafter referred to as decision

alternatives, concerning their applicability to

advanced technological approaches. The focus group

participants evaluate the suitability of the decision

alternatives and prioritize them in relation to their

respective areas of expertise.

3) Selection of Decision Alternatives

Classic supply chain models encompass declarative,

simulation, and optimisation models. Due to the need

for comparability of the modelling concepts and

approaches, this paper focuses on declarative SCM

models. The supply chain models to be included in

the benefit analysis are defined following a review of

the literature:

the Supply Chain Operations Reference (SCOR)

model, (APICS, 2017b)

the supply chain model based on Metz, (Metz,

1998)

the supply chain modelling approach by

Bowersox (Bowersox & Closs, 1996)

the model developed by Cooper, Lambert and

Pagh (CLP) (Cooper, Lambert, & Pagh, 1997)

These decision alternatives are derived from the

literature and represent some of the most used models

in the field of logistics and SCM. While there are

numerous other models available, the SCOR, Metz,

Bowersox and CLP models are chosen due to several

reasons. First, all four decision alternatives were

developed in the 1990s during the early phases of

SCM research. Second, literature searches using the

Scopus database and Google Scholar underline their

academic and practical relevance. Third, previous

research as well as domain knowledge of the authors

facilitated the choice.

4) Collection of Decision Criteria

Following the definition of the decision alternatives

(i.e. supply chain modelling methods), the decision

criteria need to be selected. The criteria should be

complete, assessable, relevant and reproducible

(Kühnapfel, 2014) and their selection is highly

relevant for the benefit analysis as it has a significant

impact on the study results (Sonntag, 2015). A review

of the literature is used to compose an initial list of

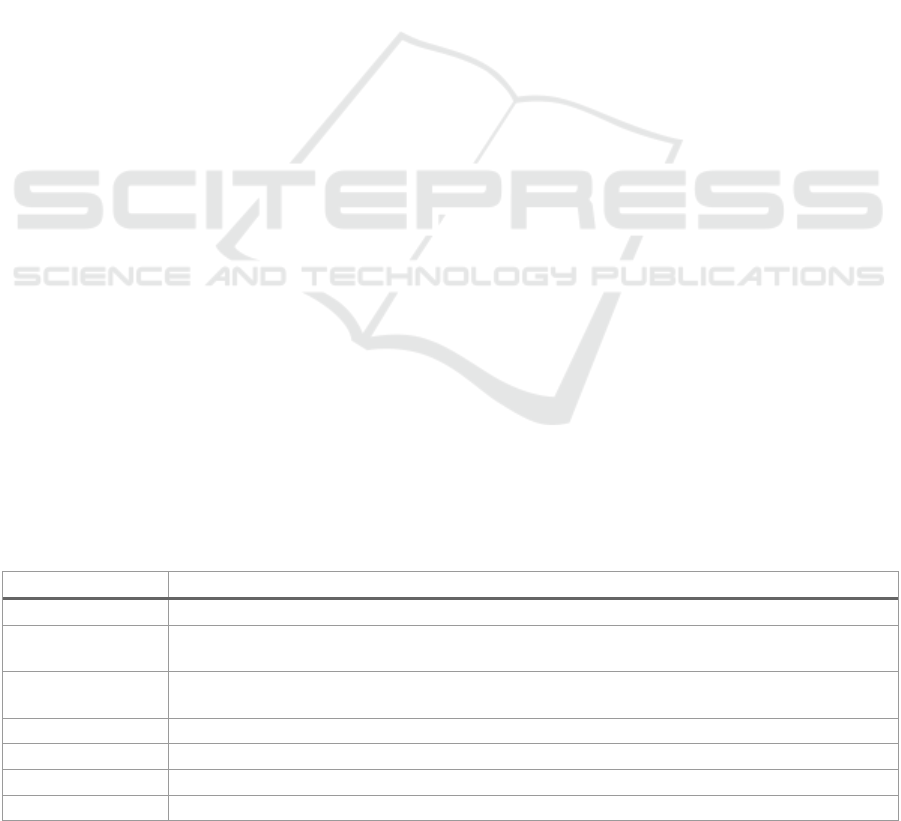

potential criteria (see Table 1).

5) Weighting of Decision Criteria

The seven decision criteria are weighted to result in a

total of 100 %. Comprehensiveness, abstraction

levels, adaptability and usability are estimated to be

the most relevant. The authors judge endorsement,

development over time and application rate to be the

least important criteria in the context of this study. As

a next step, those ranked on the same level were given

the same weight. Further discussion and iterations

yielded the final weight distribution of the selected

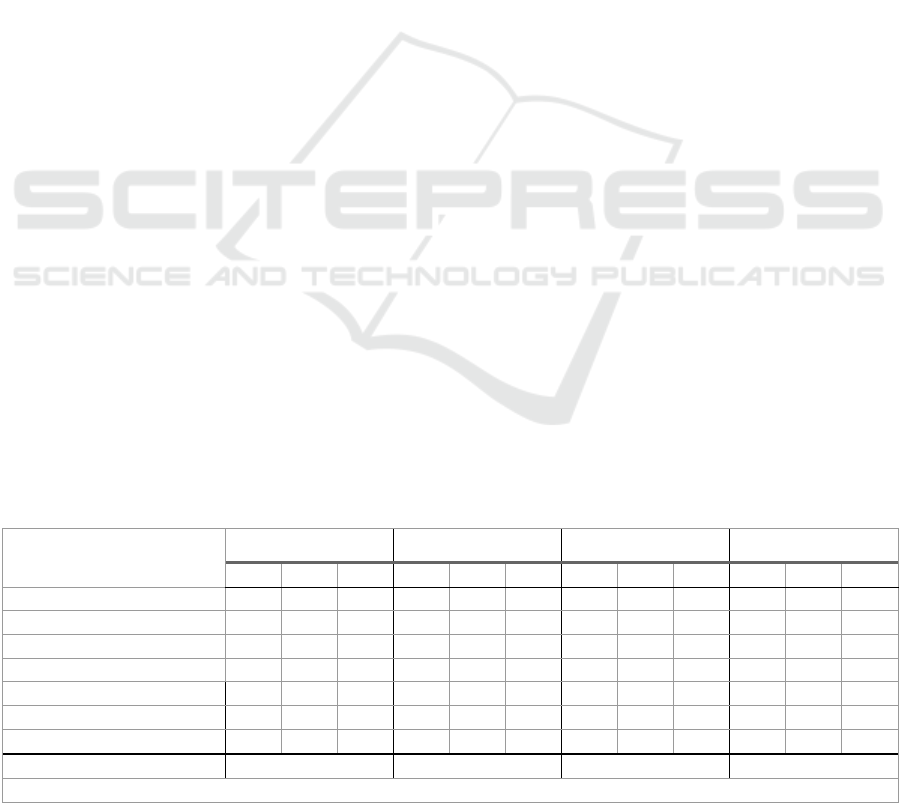

decision criteria illustrated in Table 2.

6) Evaluation of Decision Criteria

Before the determination and evaluation of the

respective criterion values, an appropriate scale needs

to be defined. For this paper, a rating scale of 1 to 3

was chosen as the criteria do not differ enormously in

importance. Table 2 shows the criteria and the

respective meaning of the scale.

Table 1: List of decision criteria.

Criterion

Description

Application rate

Number of publications on the supply chain model within the last 5 years (Google Scholar, Scopus)

Development over

time

Growth in publications referring to model (first decade after publication compared to second

decade, Google Scholar), Model updates (if applicable)

Endorsement

Which organisations promote or use the model Predominantly used in research or practical

application

Usability

Standardisation of elements, Simplicity of the model

Comprehensiveness

Depiction of flows relevant in logistics and SCM

Abstraction levels

Availability of different abstraction levels

Adaptability

Model adaptability to changing market requirements

ICEIS 2022 - 24th International Conference on Enterprise Information Systems

400

Table 2: List of decision criteria including respective scales and weighting.

Criterion Scale and Meaning

Criterion

Weight

Application rate

1=low, 2=medium, 3=high

0.1

Development over

time

1=decline, 2=stagnation, 3=growth 0.1

Endorsement

1=not applied in practice, 2=somewhat applied in practice, 3= widely applied in practice

0.1

Usability 1=extensive training required and low standardisation, 2=somewhat standardised with

some training required to use, 3= standardised and easy to use

0.1

Comprehensiveness 1=some of the relevant flows can be depicted, 2=the majority of relevant flows can be

depicted, 3= all relevant flows can be depicted

0.2

Abstraction levels

1=only 1 level, 2=2 levels, 3= more than 2 levels

0.2

Adaptability

1=low, 2=medium, 3= high

0.2

7) Utility Calculation

For this paper, the authors encouraged the focus

group participants to discuss the defined decision

criteria in relation to the decision alternatives.

Subsequently, the focus group transcript was

thoroughly analysed to identify the suitable ranking.

In addition to the focus group discussion, the rating

values are based on findings from the literature. Each

rating value is then multiplied by the corresponding

criterion weight. Adding up all the resulting criterion

values enables the researchers to obtain the specific

utility value for each decision alternative.

8) Result Documentation

This section presents a summary of the results of the

benefit analysis for each decision alternative based on

the seven decision criteria. An overview of the

individual rating values and overall utility values is

shown in Table 3.

First, the decision criterion application rate will

be analysed. A Google Scholar search for the

publication period from 2017 to 2020 on 24th March

2020 using the search phrase “SCOR supply chain

model” yielded 5,130 results, compared to 6,060 for

“Metz supply chain model”, 2,760 for “Bowersox

supply chain model” and 1,370 for “Cooper Lambert

Pagh supply chain model”. Additionally, a Scopus

search using the same search terms with no time

restriction was executed on 2nd April 2020 and

resulted in 503 matches for the SCOR model, three

for Bowersox and three for CLP.

Second, the researchers considered the

development over time. Again, Google Scholar was

used to gain an overview of the development in

references by comparing the first decade following

the first publication of the respective models and the

second decade thereafter. The search phrase “SCOR

supply chain model” resulted in 11,200 matches for

the first decade from 2006 to 2015 and 2,750 for the

second period from 1996 to 2005 (02.04.2020). This

shows a continuity in research publications while the

number of references in the second decade is four

times higher than during the first. The focus group

participants support this observation and state that the

SCOR model development is driven by the industry.

This observation is also strengthened by the

continuous updates of the model versions since 1996.

The Metz supply chain model exhibits a similar

development over time as the number of references

tripled in the second decade (15,500 results in 2008-

2017, 5,400 results in 1998-2007). Although the

Google Scholar search results for the Bowersox and

CLP model indicate usage in more recent times

(7,890 results in 2007-2016 and 2,480 results in 1997-

2006 for Bowersox, 3,840 results in 2007-2016 and

987 results in 1997-2006 for CLP), the application

appears to decline.

Concerning the model endorsement, SCOR is

generally viewed as the most commonly used

approach, as the APICS consortium, which comprises

over 45,000 members and approximately 300 channel

partners (APICS, 2017a), develops and promotes it.

The other three modelling approaches appear to be

mainly used in research.

The fourth decision criterion is usability. SCOR

is an approach to describe the actual and the target

state of the supply chain, consists of standardised

levels and comprises a set of tools and KPI to make it

user friendly. Metz similarly depicts the targeted

process with increasing integration over four

integration levels. Furthermore, in the focus group

discussion, it was noted that the Bowersox model,

similar to the CLP model, is more of a reference

framework that appears to be of limited usefulness

because there is no operational focus.

For the criterion comprehensiveness, SCOR is

observed to include material, information and

financial flows (Corsten & Gössinger, 2008). The

participants argued that descriptions for resources,

state transitions as well as for events triggering state

Modelling Advanced Technology Integration for Supply Chains

401

transitions are not included. As a descriptive

modelling approach, SCOR is not intended for the

depiction of resources but for the description of

connections, like process description languages, and

might thus potentially not be useful for simulation.

Metz's modelling approach includes different levels

of integration for mapping internal material and

information flows. The focus group participants

further criticised that the model does not correspond

to the definition of SCM as it only focuses on one

organisation. Also, an additional level depicting

individual activities or process steps is missing. On

the other hand, the Metz model can map the types of

information that cannot be mapped in the SCOR

model and it can also show the entities corresponding

to the activities. Concerning the Bowersox modelling

approach, material, financial and information flows

are included. The technology context presents a

potential to describe how the supply chain technology

works, but it would need to be extended (e.g.

centralised or decentralised structure, starting points

for technology integration) to be comprehensive. In

general, the focus group discussed its shortcomings

due to it being a reference framework. From today’s

perspective it is not complete as it only shows the

relevant main components. The CLP comprises

value-adding processes along the supply chain and

business-wide processes, it also depicts material flow,

relationships, and information flow. It is however

criticised by the participating experts due to its

simplicity. A technological aspect is completely

missing, and it consequently cannot be used for the

integration of novel technological approaches at the

moment.

The next criterion is the level of abstraction. The

SCOR model provides the highest variability of

abstraction levels, which was also highlighted in the

focus group discussion. The second modelling

approach proposed by Metz considers information

and material flows in a company as a low integration

level and those with other companies as a higher

integration level and thus also supports for different

abstraction levels. Bowersox and CLP are different as

they are reference frameworks offering an abstract

four-dimensional perspective and the viewpoint of an

individual company within the supply chain,

respectively.

Lastly, the adaptability of the modelling

approaches for the integration of novel technologies

is considered. The focus group found that the

adaptability of the SCOR-Model might be restricted

due to missing descriptions, for example of resources.

An extension of the model is judged to be possible as

it is already quite comprehensive but would perhaps

also remain on a descriptive level. The Metz model

includes an information processing function, an

integrative SCM perspective and ICT development as

enablers for complexity handling as well as a specific

consideration of ICT developments. The model by

Bowersox focuses on internal and external supply

chain integration which could possibly be a suitable

starting point for technology integration across

company borders. Finally, the CLP model has an

information flow facility structure as a management

component. Table 3 illustrates the resulting total

utility values for the decision alternatives. To assess

the potential of each modelling approach in terms of

its future applicability and suitability, participants

were asked to provide an overall judgment. Across all

experts, the SCOR model was rated as the most

promising option, followed by Metz. Due to its

continuous updating and widespread use in practice,

the SCOR model is chosen as the basis for the

targeted roadmap construct for modelling advanced

technology integration for supply chains.

Table 3: Resulting overall utility values for the decision alternatives.

Criterion/ Modelling

Approach

SCOR Metz Bowersox Cooper/Lambert/Pagh

RV W CV RV W CV RV W CV RV W CV

Application rate 3 0.1 0.3 2 0.1 0.2 2 0.1 0.2 2 0.1 0.2

Development over time 3 0.1 0.3 3 0.1 0.3 1 0.1 0.1 1 0.1 0.1

Endorsement 3 0.1 0.3 1 0.1 0.1 1 0.1 0.1 1 0.1 0.1

Usability 2 0.1 0.2 2 0.1 0.2 1 0.1 0.1 1 0.1 0.1

Comprehensiveness 3 0.2 0.6 2 0.2 0.4 1 0.2 0.2 1 0.2 0.2

Abstraction levels 3 0.2 0.6 2 0.2 0.4 1 0.2 0.2 1 0.2 0.2

Adaptability 3 0.2 0.6 2 0.2 0.4 2 0.2 0.4 1 0.2 0.2

Overall Utility Value 2.9 2.0 1.3 1.1

RV = Rating Value, W = Weight, CV = Criterion Value

ICEIS 2022 - 24th International Conference on Enterprise Information Systems

402

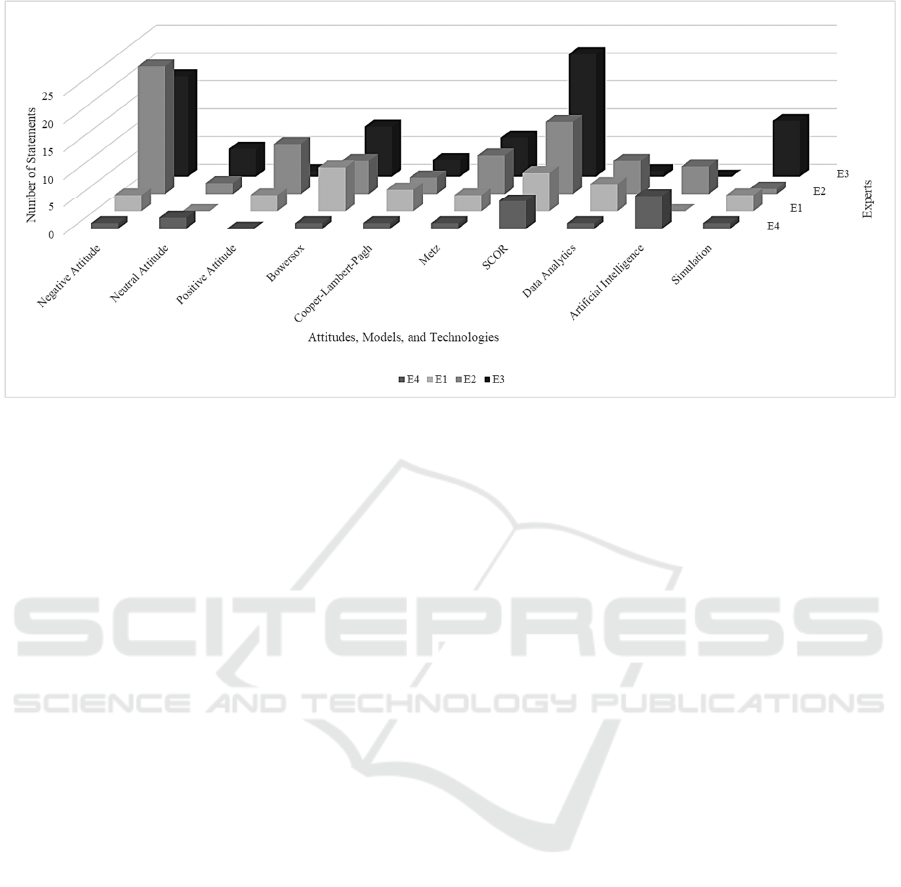

Figure 2: Number of statements per expert regarding attitude, modelling approach and technological approach.

The Bowersox and CLP models, on the other

hand, are not considered useful in this context. This is

also reflected in the experts' statements, as shown in

Figure 2 As shown by Figure 2, the attitudes

expressed by the experts vary substantially. Due to

their familiarity with the SCOR model, the experts

were able to quantitatively make the most statements

about this modelling approach (19 statements, thereof

11 negative statements). At level 4, the SCOR model

serves only as a purely descriptive model to describe

a fact, but does not reveal any reference to the

application of the technologies under consideration

(E1, E2, E3, E4). The experts also appear to be

relatively familiar with the Metz model (nine

statements), which is also not fundamentally different

from the SCOR model. The experts expressed

negative thoughts regarding the high abstraction of

the model and the lack of integration into the

companies involved in the supply chain (seven

statements). Relatively speaking, more positive and

neutral statements are made about the SCOR model

than about the Metz model, which leads the experts to

prefer the SCOR model for any future adaption. The

CLP model and the Bowersox-based approach will be

considered unsuitable for integrating advanced

technology.

5 DEVELOPMENT OF THE

ROADMAP FOR MODELLING

ADVANCED TECHNOLOGY

INTEGRATION

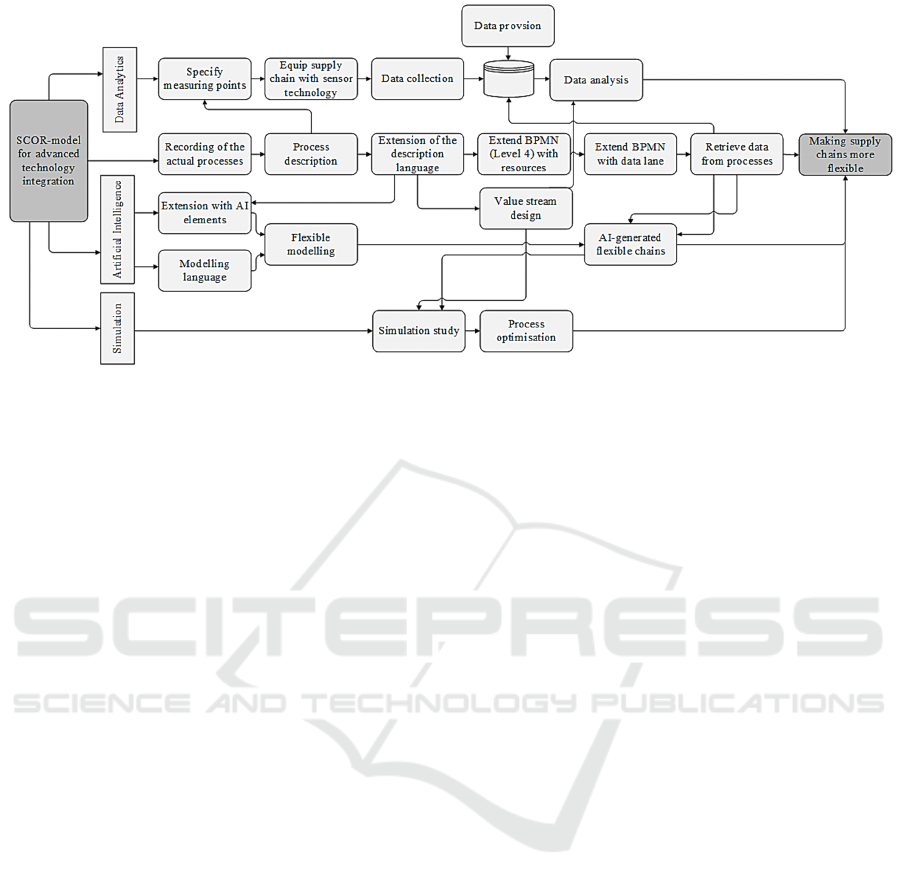

A roadmap construct for modelling advanced

technology integration for supply chains is developed

as a DSR artefact (see Figure 3) based on iterative

reading, deductive analysis, and coding of the experts'

statements. Using a non-scaled timeline, the roadmap

represents an approach towards the integration of

advanced technologies, which can potentially lead to

a more flexible design of the supply chain. The

individual steps of the roadmap are divided along four

main identified streams of DA, SCOR, AI,

simulation.

Currently, it is judged to be difficult to adapt or

extend models such as SCOR and Metz to integrate

novel technological aspects (E4). The experts assess

the potential of the individual technological

approaches quite differently, but the potential

increase in supply chain flexibility through the

opportunities enabled by DA and AI are generally

acknowledged. Level 4, the most precise description

of the SCOR model, goes down to the process

element level to which resources can be added in the

Information and Communication Lane. For instance,

E1 states that “(SCOR) level four would not be

sufficient for a data analysis, because I still need to

describe somewhere where I get which data at which

process step and, therefore, before I could do any

further processing” and summarises that “if I

suddenly wanted to start simulating or analysing

something, then (…) I wouldn’t get any further

because I need other methods”. An extension of level

four is thus necessary for both DA and AI. The

current supply chain process needs to be recorded in

more detail and a process description is required. This

is supported by the experts who state that “to be able

to do that I would have to have a state model of the

system, plus a description of the event” (E2) and

Modelling Advanced Technology Integration for Supply Chains

403

Figure 3: Roadmap construct for modelling advanced technology integration for supply chains.

that “the point is to first describe these

interrelationships (…) which is represented in more

detail in other description languages” (E3).

As a next step, the description language needs to

be extended. For this purpose, the process description

on level four in the Business Process Model and

Notation could be developed to include resources and

elements of data analysis. To do this, detailed data

about the process must be available. To achieve this

level of detail, specific measuring points must first be

defined for data acquisition and these must be

equipped with sensors as suggested by the experts. E2

states that “when it comes to data, I have to be able to

specify some kind of measuring point. (…) the whole

logistic supply chain process must be, so to say,

equipped with sensors, among other things, to simply

have an overview of the processes”, a sentiment

which is mirrored by E1 who says that “the actual data

generation, or data transfer, or something like that,

would have to be included in some way”. Retro-

lifting the existing models is proposed as a possible

approach (E4). In addition to the recorded data,

process information is included in the analysis. A

need to examine the current model to define to what

extent it allows a flexible approach is expressed by

E4. Instead of designing a rigid supply chain, AI or

machine learning tools can be applied to determine a

suitable supply chain for a particular task. E4 argues

that “we need the learning ability of the individual

components, the ability to communicate between the

individual components in the SCOR model. (…) To

achieve this, we need data”. It is further stated that

“when AI complements classic SC modelling, it

builds new models that create far more flexibility”

(E4).

6 DISCUSSION

The benefit analysis and focus group discussion

revealed that the modelling approaches currently

available to supply chain managers all have

shortcomings. In addition to the decision criteria

included in the benefit analysis, the participants also

discussed aspects of model validity. So, to evaluate

the validity of the supply chain models, but also of the

developed artefact in the form of the roadmap

construct, use cases, scenarios or a specific purpose

need to be applied. The researchers thus decided to

evaluate and develop the artefact following a later

quantitative empirical survey.

The focus group also yielded interesting ideas

concerning the relation between the modelling and

the technological approaches as well as regarding the

potential for further development. In general, the

experts consider the application of the modelling

approaches for the integration of advanced

technological approaches to be of little use, except

perhaps the application of SCOR for simulation, if

reasonably possible, as the available supply chain

modelling approaches could be applied and

subsequently transferred into a simulation model.

However, in their current versions, none of the

models are judged to be sufficiently advanced for the

integration of advanced technological approaches

such as DA, simulation or AI. These models primarily

describe the current state of affairs and facilitate

communication about the supply chain, but they are

only conditionally suitable for strategic decisions and

likely only useful in technology implementation

projects up to a certain stage such as the problem

ICEIS 2022 - 24th International Conference on Enterprise Information Systems

404

definition. In addition, SCOR and Metz should also

be considered separately from Bowersox and CLP as

the have a different purpose.

Overall, the modelling and the technological

approaches are regarded as separate entities that are

orthogonal to one another. On the one hand there are

the modelling approaches as descriptive languages

that can be used to enable shared understanding and

on the other hand there are technology-based methods

of analysis. If and to what extent they can be

combined could be discussed and should be weighed

against the potential cost and usefulness as well the

intended purpose.

While the findings suggest that the integration of

modelling and technological approaches needs to be

carefully examined, the literature suggests that

innovative supply chain design, and thus supply chain

modelling, can have positive effects. For instance,

Arlbjørn, de Haas, and Munksgaard (2011) found that

the integration of innovative supply chain designs,

innovative supply chain management practices and

enabling technology could make initiatives such as

the introduction of new products and services more

likely to be successful. Similarly, a mediating effect

of technology integration on the relationship between

supply chain capability and supply chain operational

performance was observed by Naway and Rahmat

(2019).

7 CONCLUSION AND

LIMITATIONS

The proposed roadmap construct for modelling

advanced technology integration for supply chains is

developed as a DSR artefact during the research

process. It describes a possible approach towards the

integration of advanced technologies along the four

main roadmap streams of DA, SCOR, AI and

simulation. Moreover, the evaluation of supply chain

modelling tools regarding the integration of advanced

technological approaches will be useful for both

research and practical application as it provides a

basis for scientific discussion and the modernisation

of supply chain models.

First, as a practical contribution, the critical

discussion of the established supply chain modelling

approaches enables supply chain managers and

decision makers to choose the appropriate tool more

easily and to perhaps also consider a model that was

previously unknown. The proposed roadmap

construct can serve as a driver for digitalisation

within the supply chain and for the integration of

novel technological concepts in SCM. The

contributions to research include the applied

systematic methodological approach based on a

benefit analysis and qualitative research tools,

incentives for the advancement and development of

advanced supply chain modelling as well as a critical

discussion about the timeliness and future

applicability of established supply chain modelling

approaches. The paper consequently proposes various

avenues for future research regarding the

combination of supply chain modelling approaches

and novel technological concepts as well as strategic

SCM.

Despite the systematic structure of the

methodological approach, several research

limitations need to be acknowledged. The choice of

the supply chain modelling approaches and the

technological concepts is subjectively based on the

personal experience of the researchers. Disregarded

technologies, such as blockchain, and other supply

chain modelling approaches can be included in future

research. Concerning the research approach, benefit

analysis has been criticised for its relatively time-

consuming process as well as the subjectivity

regarding the determination and weighting of the

criteria and the evaluation and interpretation. The

focus group method also has its limitations such as

information overload, subjectivity of both the

participants’ opinions and the researcher’s

interpretation as well as the influence of group

dynamics.

ACKNOWLEDGEMENTS

The authors would like to express their gratitude

towards the expert focus group participants for their

time and insights.

This work was supported by the tax revenues on

the basis of the budget adopted by the Saxon State

Parliament under Grant SAB/100379142 and by

WHZ/402222.

REFERENCES

APICS. (2017a). New SCOR 12.0 Model Launched at

APICS 2017, Advancing the Global Standard for

Supply Chain Excellence. Retrieved from http://www.

apics.org/about/overview/apics-news-detail/2017/10/

16/new-scor-12.0-model-launched-at-apics-2017-adva

ncing-the-global-standard-for-supply-chain-excellence

Modelling Advanced Technology Integration for Supply Chains

405

APICS. (2017b). SCOR Supply Chain Operations

Reference Model Version 12.0. Retrieved from

Arlbjørn, J. S., de Haas, H., & Munksgaard, K. B.

(2011). Exploring supply chain innovation. Logistics

Research, 3(1), 3-18.

Averian, A. (2017). Supply chain modelling as digital

ecosystem. Paper presented at the International

Scientific Conferenc on IT, Tourism, Economics,

Management and Agriculture ITEMA, Budapest,

Hungary.

Backhaus, A., Grotemeier, C., Jacobi, C., Kille, C.,

Lehmacher, W., Meißner, M., Stiehm, S. (2020).

Logistik 2020: Struktur- und Wertewandel als

Herausforderung. Retrieved from Hamburg:

Bhakoo, V., Britta Gammelgaard, P. G. D., Singh, P. J., &

Chia, A. (2015). Supply chain structures shaping

portfolio of technologies. International Journal of

Physical Distribution & Logistics Management, 45(4),

376-399. doi:10.1108/ijpdlm-12-2014-0298

Bowersox, D. J., & Closs, D. J. (1996). Logistical

management. The integrated Supply Chain Process.

New York: McGraw-Hill.

Chandra, C., & Grabis, J. (2007). Supply chain

configuration. New York: Springer.

Christopher, M. (2000). The Agile Supply Chain

Competing in Volatile Markets. Industrial Marketing

Management, 29(1), 37-44.

Christopher, M. (2021). Supply Chain 4.0 - Enabling

market-driven strategies. In E. Aktas, M. Bourlakis, I.

Minis, & V. Zeimpekis (Eds.), Supply Chain 4.0:

Improving Supply Chains with Analytics and Industry

4.0 Technologies (pp. 1-15).

Cooper, M. C., Lambert, D. M., & Pagh, J. D. (1997).

Supply Chain Management: More Than a New Name

for Logistics. The International Journal of Logistics

Management, 8(1), 1-14. doi:10.1108/095740997108

05556

Corsten, H., & Gössinger, R. (2008). Einführung in das

Supply Chain Management (2nd ed.). München:

Oldenbourg Verlag.

Duan, Y., Edwards, J. S., & Dwivedi, Y. K. (2019).

Artificial intelligence for decision making in the era of

Big Data–evolution, challenges and research agenda.

International Journal of Information Management, 48,

63-71. doi:10.1016/j.ijinfomgt.2019.01.021

El-Yaakoubi, A., El-Fallahi, A., Cherkaoui, M., &

Hamzaoui, M. R. (2017). Tabu search and memetic

algorithms for a real scheduling and routing problem.

Logistics Research, 10(7), 1-18.

Fechteler, T., & Gutenschwager, K. (2014). Die Landkarte

zeigt, wie gut es funktioniert. IT&Production, 9, 64-65.

Fosso Wamba, S., Queiroz, M. M., Guthrie, C., &

Braganza, A. (2021). Industry experiences of artificial

intelligence (AI): benefits and challenges in operations

and supply chain management. Production Planning &

Control, 1-13. doi:10.1080/09537287.2021.1882695

Gammelgaard, B., Welling, H. S., & Nielsen, P. B. M.

(2019). Blockchain Technology for Supply Chains: A

Guidebook: Copenhagen Business School, CBS.

Gesing, B., Peterson, S. J., & Michelsen, D. (2018).

Artificial intelligence in logistics: A collaborative

report by DHL and IBM on implications and use cases

for the logistics industry. Retrieved from

Golan, M. S., Jernegan, L. H., & Linkov, I. (2020). Trends

and applications of resilience analytics in supply chain

modeling: systematic literature review in the context of

the COVID-19 pandemic. Environment Systems &

Decisions, 1.

Górtowski, S. (2018). Supply Chain Modelling Using Data

Science. Paper presented at the International

Conference on Business Information Systems.

Gupta, V. K., Chaudhuri, A., & Tiwari, M. K. (2019).

Modeling for deployment of digital technologies in the

cold chain. IFAC-PapersOnLine, 52(13), 1192-1197.

doi:10.1016/j.ifacol.2019.11.360

Gutenschwager, K., & Alicke, K. (2004). Supply Chain

Simulation mit ICON-SimChain. In T. Spengler, S.

Voß, & H. Kopfer (Eds.), Logistik Management -

Prozesse, Systeme, Ausbildung (pp. 161-178).

Heidelberg: Physica.

Hippold, S. (2020, 30.09.2020). 5 Trends aus dem Hype

Cycle von Gartner für Lieferkettenstrategie, 2020.

Kaczmarek, M. (2002). Definition von Anforderungen an

die Modellierung und Analyse der Supply Chain.

Retrieved from

Krischke, A., & Grzesch, S. (2009). Supply Chain

Simulation als geeignetes Werkzeug auch für kleine

und mittlere Unternehmen? . IPL-Magazin. Retrieved

from https://ipl-mag.de/ipl-magazin-rubriken/scm-

daten/110-scm-daten-08

Kuhn, A., & Rabe, M. (1998). Simulation in Produktion

und Logistik. Berlin: Springer-Verlag.

Kühnapfel, J. B. (2014). Das Vorgehen bei der

Nutzwertanalyse. In J. B. Kühnapfel (Ed.),

Nutzwertanalysen in Marketing und Vertrieb (pp. 5-

20). Wiesbaden: Springer Fachmedien Wiesbaden.

Kumar, A., Singh, R. K., & Modgil, S. (2020). Exploring

the relationship between ICT, SCM practices and

organizational performance in agri-food supply chain.

Benchmarking: An International Journal.

Maedche, A., Gregor, S., Morana, S., & Feine, J. (2019).

Conceptualization of the Problem Space in Design

Science Research. Paper presented at the International

Conference on Design Science Research in Information

Systems and Technology (DESRIST), Cham,

Switzerland.

Manuel Maqueira, J., Moyano-Fuentes, J., & Bruque, S.

(2019). Drivers and consequences of an innovative

technology assimilation in the supply chain: cloud

computing and supply chain integration. International

Journal of Production Research, 57(7), 2083-2103.

Mauerer, J. (2018, 31.01.2018). Big-Data-Trends im

Überblick - Was ist was bei Predictive Analytics?

Retrieved from https://www.cio.de/a/was-ist-was-bei-

predictive-analytics,3098583,4

Metz, P. J. (1998). Demystifying supply chain

management. Supply Chain Management Review, 1(4),

46-55.

ICEIS 2022 - 24th International Conference on Enterprise Information Systems

406

Mishra, D., Gunasekaran, A., Papadopoulos, T., & Childe,

S. J. (2018). Big Data and supply chain management: a

review and bibliometric analysis. Annals of Operations

Research, 270(1), 313-336. doi:10.1007/s10479-016-

2236-y

Naway, F., & Rahmat, A. (2019). The mediating role of

technology and logistic integration in the relationship

between supply chain capability and supply chain

operational performance. Uncertain Supply Chain

Management, 7(3), 553-566.

O'Gorman, K. D., & MacIntosh, R. (2015). Mapping

Research Methods. In Research Methods for Business

and Management.

Oliveira, J. B., Lima, R. S., & Montevechi, J. A. B. (2016).

Perspectives and relationships in Supply Chain

Simulation: A systematic literature review. Simulation

Modelling Practice and Theory, 62, 166-191.

Peffers, K., Rothenberger, M., Tuunanen, T., & Vaezi, R.

(2012). Design Science Research Evaluation. Paper

presented at the International Conference on Design

Science Research in Information Systems (DESRIST),

Las Vegas, US.

Peffers, K., Tuunanen, T., Rothenberger, M. A., &

Chatterjee, S. (2007). A Design Science Research

Methodology for Information Systems Research.

Journal of Management Information Systems, 24(3),

45-77. doi:10.2753/MIS0742-1222240302

Runkler, T. A. (2015). Data Mining – Modelle und

Algorithmen intelligenter Datenanalyse (2nd ed.).

Wiesbaden: Springer Viehweg.

Schröder, M., & Wegner, K. (Eds.). (2019). Logistik im

Wandel der Zeit – Von der Produktionssteuerung zu

vernetzten Supply Chains. Wiesbaden: Springer Gabler.

Sergeyev, V. I., & Lychkina, N. N. (2019). Agent-Based

Modelling and Simulation of Inter-Organizational

Integration and Coordination of Supply Chain

Participants. Paper presented at the Conference on

Business Informatics (CBI), Moscow, Russia.

Sonntag, A. (2015). Instrument Nutzwertanalyse. Retrieved

from https://www.inf.uni-hamburg.de/de/inst/ab/itmc/

research/completed/promidis/instrumente/nutzwertanal

yse

Storey, J., Emberson, C., Godsell, J., & Harrison, A. (2006).

Supply chain management: theory, practice and future

challenges. International Journal of Operations &

Production Management, 26(7), 754-774. doi:10.

1108/01443570610672220

Subramanian, N., Chaudhuri, A., & Kayıkcı, Y. (2020).

Blockchain and Supply Chain Logistics: Evolutionary

Case Studies: Springer Nature.

Tiwari, S., Wee, H.-M., & Daryanto, Y. (2018). Big data

analytics in supply chain management between 2010

and 2016: Insights to industries. Computers &

Industrial Engineering, 115, 319-330.

Toorajipour, R., Sohrabpour, V., Nazarpour, A., Oghazi, P.,

& Fischl, M. (2021). Artificial intelligence in supply

chain management: A systematic literature review.

Journal of Business Research, 122, 502-517.

doi:10.1016/j.jbusres.2020.09.009

van der Spoel, S., Amrit, C., & van Hillegersberg, J. (2017).

Predictive analytics for truck arrival time estimation: a

field study at a European distribution centre.

International Journal of Production Research, 55(17),

5062-5078.

Zanker, C. (2018). Branchenanalyse Logistik: Der

Logistiksektor zwischen Globalisierung, Industrie 4.0

und Online-Handel. Retrieved from https://www

.boeckler.de/de/faust-detail.htm?sync_id=HBS-

006916

Modelling Advanced Technology Integration for Supply Chains

407