Controlled Synthesis of Fibre-reinforced Plastics Images from

Segmentation Maps using Generative Adversarial Neural Networks

Nicolas Schaaf

1 a

, Hans Aoyang Zhou

2 b

, Chrismarie Enslin

2 c

, Florian Brillowski

3 d

and Daniel L

¨

utticke

2 e

1

RWTH Aachen University, Aachen, Germany

2

Information Management in Mechanical Engineering, RWTH Aachen University, Aachen, Germany

3

Institute of Textile Technology, RWTH Aachen University, Aachen, Germany

Keywords:

GAN, Deep Learning, Fibre-reinforced Plastics, Quality Assurance, Defect Detection, Data Augmentation.

Abstract:

The replacement of traditional construction materials with lightweight fibre-reinforced plastics is an accepted

way to reduce emissions. By automating quality assurance, errors in production can be detected earlier, avoid-

ing follow-up costs and hard-to-recycle scrap. Deep learning based defect detection systems have shown

promising results, but their prediction accuracy often suffers from scarce labelled data in production pro-

cesses. Especially in the domain of fibre-reinforced plastics, the task remains challenging because of varying

textile specific errors. In our work, we applied conditional generative adversarial networks combined with

image-to-image translation methods to address data scarcity through generating synthetic images. By train-

ing a generative model on image-segmentation pairs, we produce realistic fibre images matching the given

segmentation maps. Our model enables control over generated output images of arbitrary fibre shapes and

structures, including gaps, ondulations, and folds as error classes. We evaluate our synthetic images based on

GAN metrics, feature distribution and show that they are suitable as a data augmentation method to improve

the error classification performance of deep neural networks. Thereby, we provide a solution for the manufac-

turing domain of fibre-reinforced plastics with scarce data, consequently contributing to an automated defect

detection system that reduces resource-intensive scrap in the future.

1 INTRODUCTION

Climate change, legal emission regulations and in-

creasing environmental awareness in society lead to

a steadily growing demand for lightweight materials

(T

¨

ure and T

¨

ure, 2020). The underlying idea of us-

ing these materials is to minimise the mass of mov-

ing parts, thereby reducing energy consumption, as

well as emissions. Fibre-reinforced plastics (FRP) are

a material class that provides the necessary require-

ments of mechanical strength and at the same time

low weight (Miao and Xin, 2018). However, pro-

ducing FRP is very expensive due to their resource-

intensive manufacturing process. Therefore, FRP

manufacturers need to avoid scrap and have extensive

a

https://orcid.org/0000-0002-7844-3229

b

https://orcid.org/0000-0002-7768-4303

c

https://orcid.org/0000-0002-3047-5846

d

https://orcid.org/0000-0003-4805-9573

e

https://orcid.org/0000-0002-7070-8018

quality control (QC) in order to be profitable and com-

petitive.

Currently, available QC systems can only indi-

rectly detect defects, such as folds (Fuhr, 2017) by

measuring the fibre orientations with for example

Canny-Edge detection. If a deviation in fibre orien-

tation is detected, the specific defect is then deter-

mined by a time-consuming, manual visual inspec-

tion. One possible solution to reduce manual labour

is to use Deep Learning (DL) models for automated

inspection to directly localise and classify defects in

semifinished textile products.

The technical feasibility of DL approaches for QC

in manufacturing of FRP has already been proven for

various approaches, such as using Convolutional Neu-

ral Networks (CNNs) for semantic segmentation in

order to detect defects in fabric image data (Wei et al.,

2019; Jing et al., 2019; Sacco et al., 2018; Sacco et al.,

2019). All approaches have a data-intensive labelling

process in common, in order to achieve high detection

accuracy.

Schaaf, N., Zhou, H., Enslin, C., Brillowski, F. and Lütticke, D.

Controlled Synthesis of Fibre-reinforced Plastics Images from Segmentation Maps using Generative Adversarial Neural Networks.

DOI: 10.5220/0010913700003116

In Proceedings of the 14th International Conference on Agents and Artificial Intelligence (ICAART 2022) - Volume 3, pages 801-809

ISBN: 978-989-758-547-0; ISSN: 2184-433X

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

801

Despite the promising results from the literature,

the usage of DL models as an automated solution for

image-based QC is still not standardised in industrial

environments, particularly not for the manufacturing

industry of FRP. On one hand, many FRP manufac-

turing companies have machine parks consisting of

old devices that lack data-gathering sensors or inter-

faces. On the other hand, due to small production lot

sizes, available data is also limited. As a result, there

is no, or only incomplete data available for the dif-

ferent steps of the production process. The accessible

data is often insufficient for training of detection mod-

els with acceptable detection accuracy. Additionally,

manual annotation of image data is an expensive and

time-consuming process.

An established solution to address insufficient

amounts of data is through data augmentation. Most

commonly, it uses existing images to synthetically

generate similar but realistic images via, e.g. geo-

metric transformations or stochastic noise. One re-

cent learning based approach for generating new data

samples are Generative Adversarial Networks (GAN)

(Goodfellow et al., 2014). By learning the underly-

ing data distribution of the available data, they have

shown remarkable results in generating realistic im-

ages.

Therefore, we investigate in this contribution the

effectiveness of GANs as a data augmentation method

for training DL models in the data scarce environment

of manufacturing FRP. In our work, we do not only

show that GANs are well-suited for generating real-

istic looking images of FRP, but also semantic mean-

ingful images for training a defect classifier without

manual labelling. In our evaluation, we validate nec-

essary use case driven modifications of model archi-

tecture and training process, qualitatively and quanti-

tatively. Through our quantitative results we show,

that the generated images on one hand contribute

positively in error detection accuracy and the other

hand resemble the feature distribution of the available

dataset. Our contribution validates GANs as a data

augmentation method for industrial applications with

scarce labelled data like the manufacturing of FRP.

2 RELATED WORK

Closely related to our task of synthesising images of

FRP, is the task of texture synthesis. The first ap-

proach that used a CNN to synthesise textures was

introduced in (Gatys et al., 2015). The main idea was

to describe textures as the correlation between high-

level features acquired through feature maps gener-

ated by different layers of a pretrained CNN. Fur-

ther improvements in generating texture with repet-

itive patterns were addressed by adding spatial trans-

formation (e.g. flipping or translation) on the feature

maps (Berger and Memisevic, 2017) and constraining

the frequency domain acquired with Fourier transfor-

mation of the generated image (Liu et al., 2016), or a

combination of both (S. Schreiber et al., 2016).

The first GAN based texture synthesis was intro-

duced in (Jetchev et al., 2017). In their work, the au-

thors replaced the usual noise vector with a spatial

noise tensor as the input for the generator. This al-

lowed the generation of high-quality images that scale

to bigger synthesised image sizes. Further improve-

ments in controlling the synthesis of images with

GANs were presented in (Xian et al., 2018). The au-

thors developed a conditional GAN that generates im-

ages of objects based on a sketch. Furthermore, dif-

ferent parts of the image can be modified through a

texture patch.

Outside texture synthesis, GANs are used as a

data augmentation method in different domains with

scarce labeled data (Shorten and Khoshgoftaar, 2019).

This is especially crucial for problems with imbal-

anced label distributions (e.g. anomaly detection).

One popular domain where these types of problems

frequently appear is the field of medical imaging (Yi

et al., 2019). Here, training samples are limited due

to their labeling cost or patient privacy, which moti-

vated researchers to investigate GANs as an alterna-

tive for synthesising training samples. Likewise, in

(Zhu et al., 2018) the authors successfully use GANs

to augment training data of underrepresented label

classes for emotion classification. Their results show

that through the data augmentation, the classification

performance increased significantly. In the domain of

textile manufacturing, GANs are investigated to gen-

erate textile design patterns (Fayyaz et al., 2020). In

their work, the authors evaluate different state-of-the-

art GAN-based architectures based on their inception

score and use a style transfer approach to generate

a combination of multiple textile designs. Although

GANs show promising results as a data augmentation

method, our work is the first to apply GANs as data

augmentation method in the context of manufacturing

of fibre-reinforced plastics.

3 METHOD

3.1 Dataset

Our dataset is created from greyscale surface scans

of plain weaves made of carbon fibres. Angle and

distance of the scanner head varies over the different

ICAART 2022 - 14th International Conference on Agents and Artificial Intelligence

802

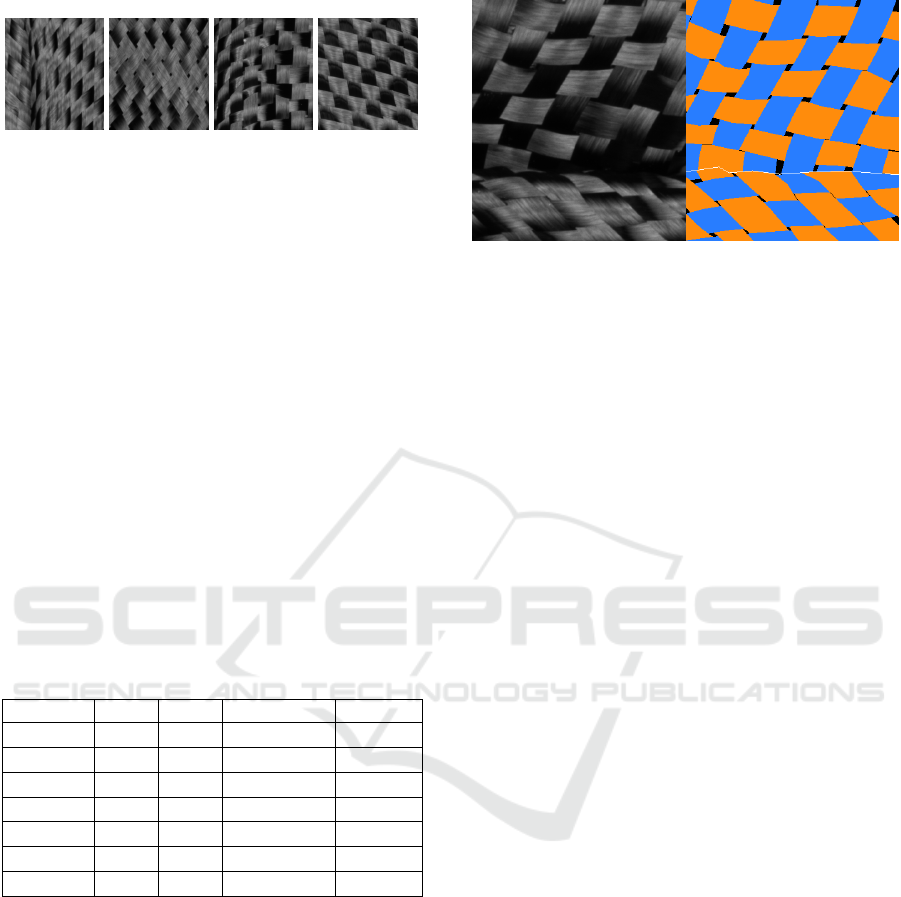

Fold Gap Ondulation Regular

Figure 1: Overview of different error classes of real images.

scans. To form our classification dataset, the surface

scans are cropped into 384 ×341 patches, filtered, and

assigned manually to one of four classes, namely fold,

gap, ondulation and regular (cf. Figure 1). As certain

types of errors often occur together with other errors,

we define the prioritisation with decreasing order as

fold, ondulation, gap, and regular. In the case of mul-

tiple errors we assign the class with the highest pri-

ority. The prioritisation is based on observations that

folds often come along with ondulations and ondula-

tions often come along with gaps. The “regular” class

only contains defect-free images. Our full dataset X

R

full

contains more than 12k instances.

In this work, we use the superscript R for real and

G for synthetic (generated) datasets and instances.

For the experiments we split up X

R

full

into 3 parts,

X

R

train

, X

R

val

, X

R

test

, for training, validation, and testing

of models, respectively. Table 1 provides a detailed

overview of the number of instances in all datasets

used in our research.

Table 1: Overview of instances per dataset.

Dataset Fold Gap Ondulation Regular

X

R

full

2717 5861 1261 2460

X

R

train,min

42 89 19 35

X

R

train

906 1954 421 820

X

R

val

906 1954 420 820

X

R

test

905 1953 420 820

X

G

U-Net

5000 5000 5000 5000

X

G

StarGAN

5000 5000 5000 5000

3.2 Image-to-Image Approach

Given the goal of using GANs as a data augmentation

method for defect classification, the generation of im-

ages need to be adaptable according to different error

classes. For this purpose, and to capture the geometric

structure of fibre parts, we create segmentation maps,

i.e. pixel-wise class labels, from our image data. To

simplify the manual work, fibre edges are approxi-

mated by quadratic or cubic B

´

ezier curves, or linear

splines.

The occurring patterns between warp and weft are

encoded with two different colours, depicted as or-

ange and blue in Figure 2, each indicating a fibre ori-

Figure 2: Segmentation map annotation of weave.

entation. Note that, since warp and weft cannot be

differentiated in the image patches, the fibre colours

are interchangeable. In addition to the fibre colour,

we add a third colour indicating fold lines, while gaps

are indicated as black sections (cf. Figure 2).

With the derived pairs of segmentation maps and

real images we train a generator, similarly to an

image-to-image approach that translates segmenta-

tion maps to realistic images. This training approach

with corresponding segmentation maps enables the

synthesis of specific weave images and the precise

control of fibre structure and geometry. For the train-

ing of the generator we use a modified implemen-

tation of BicycleGAN (Zhu et al., 2017) to learn a

model that maps segmentation maps to weave images.

BicycleGAN is a multimodal, supervised image-

to-image approach, which works as a hybrid of GANs

and autoencoders. Thus, it trains on input-output

pairs of images and allows, through the modification

of latent variables, to generate images in different

styles. These attributes make it the suitable frame-

work for our use case. In their implementation, Zhu et

al. (2017) use an adaptation of U-Net (Ronneberger

et al., 2015) as generator. U-Net is an architecture

that has been developed and become popular for im-

age segmentation tasks. It consists of an encoder-

decoder “bottleneck” architecture that has been ex-

tended by skip-connections from contracting to ex-

panding layers. A similar, but unsupervised, image-

to-image framework to BicycleGAN is StarGAN v2

(Choi et al., 2020). Like BicycleGAN it is multi-

modal, but, as a major difference, it works also for

unpaired data and can be trained on images from more

than two domains. Unlike Zhu et al. (2017), Choi et

al. (2020) use an encoder-decoder architecture with-

out skip-connections for their generator.

Controlled Synthesis of Fibre-reinforced Plastics Images from Segmentation Maps using Generative Adversarial Neural Networks

803

Input Ground truth Output

Figure 3: Example of the orientation problem, where fibres

of the output image are oriented towards the wrong direc-

tion.

4 IMPLEMENTATION DETAILS

When training BicycleGAN on our dataset in the con-

figuration of Zhu et al. (2017), we were facing several

issues, such as blurry outputs or the “orientation prob-

lem”. The orientation problem appears as fibre parts

oriented in the wrong direction, i.e. rotated 90 degrees

with respect to the direction intended by the segmen-

tation map (cf. Figure 3). We addressed these prob-

lems with a slightly modified architecture and training

setup.

4.1 Architectures

For the generator, we tested two different architec-

tures: An extended version of the U-Net architecture

proposed by Zhu et al. (2017), namely “Extended U-

Net”, and a modified version of the StarGAN v2 gen-

erator architecture proposed by Choi et al. (2020).

4.1.1 Extended U-Net

In our experiments, we found that the U-Net archi-

tecture proposed by Zhu et al. (2017) suffers from

the orientation problem when trained against an un-

conditional discriminator. The problem could not be

solved by additional training or an increased number

of parameters. It appears that an unconditional dis-

criminator is unable to learn the coherence of correct

fibre orientation, as it only gets to see the generator

outputs. The problem can be addressed with a con-

ditional discriminator, i.e. a discriminator which is

fed input-output pairs. Thereby, it is able to learn the

correct coherence from real image pairs and provide a

corrective feedback to the generator. However, we ob-

served that a conditional discriminator in combination

with the U-Net architecture leads to significant lower

image quality and blurry results. Our experiments in-

dicate that this is a general problem of U-Net-like ar-

chitectures.

As an alternative to address the orientation prob-

lem while keeping an unconditional discriminator,

we found it useful to place residual blocks in front

of U-Net. We orient towards the head architecture

of ResNet-34 (K. He et al., 2016) and add a 7 × 7

convolutional layer with 64 filters and a stride of 1,

and three residual blocks in front of U-Net to cre-

ate an “Extended U-Net”. The residual blocks cor-

respond to the ResNet-34 residual block with batch

normalization and ReLU activation replaced by in-

stance normalisation and LeakyReLU, respectively.

We observed that although the orientation problem

still occurred in early phases of training, the modifi-

cation overcomes it with longer training. Unlearning

through overtraining is also possible, therefore an op-

timal stopping point is found.

4.1.2 StarGAN V2

In addition to our proposed “Extended U-Net” archi-

tecture, we also experimented with the StarGAN v2

generator architecture to address the orientation prob-

lem. We found that for this architecture only a condi-

tional discriminator leads to acceptable results, as for

an unconditional discriminator the generator failed to

match the given segmentation maps in its outputs.

For our implementation, we slightly modified the

architecture by adding a downsampling and upsam-

pling block, respectively, to shrink the bottleneck to

a size of 8 × 8 × 512. Additionally, we removed the

adaptive wing based heatmaps from the skip connec-

tions, as our dataset does not require an alignment of

faces, and do not use a latent mapping network, as we

only have a single target domain.

4.2 Training

To show that our approach works for small dataset

sizes, we train our generator on a small dataset

X

R

train,min

consisting of 185 images from X

R

train

and their

corresponding segmentation maps. The models are

trained on 256 × 256 patches randomly cropped from

the training images. Before cropping, we scale im-

ages larger by a factor of 1.1 to 1.33, since it leads to

improved image quality. During the test phase, we

scale segmentation maps larger by a factor of 1.3,

feed them into the generator, and scale the output

back to the original size. Training samples are aug-

mented through rotating, flipping, and commuting the

fibre channels of the segmentation maps. We repre-

sent the colours in our segmentation maps in terms

of one-hot-encoding instead of RGB values in order

to prevent erroneously implied proximity by numeri-

cally close colour values. Due to the increased num-

ber of parameters of our generator architectures, we

train the Extended U-Net generator for 1200 epochs

ICAART 2022 - 14th International Conference on Agents and Artificial Intelligence

804

and the StarGAN v2 generator for 1600 epochs dur-

ing the normal training phase and fine-tuning phase,

respectively. Unlike Zhu et al. (2017), we use the

same discriminator for the two training cycles, since

the usage of two independent discriminators does not

yield any benefits in our experiments.

5 EVALUATION

For the evaluation of our synthesised images we build

on four different methods: a manual, qualitative in-

spection by eye, an evaluation based on GAN scores,

an evaluation of the feature distribution, and a use

case based evaluation using synthetic images as aug-

mentation in a defect classification task. To create

our synthetic images, we generate 5000 synthetic seg-

mentation maps by modelling fibre courses with lines

or quadratic B

´

ezier curves and adding class-specific

characteristics, i.e. gaps, ondulations, or folds, in var-

ious shapes. We translate the same 5000 segmentation

maps once with the Extended U-Net and the StarGAN

v2 generator to create X

G

U-Net

and X

G

StarGAN

, respec-

tively. For our evaluation we assume that the class

intended to imitate in the segmentation map is equiv-

alent to the real class of the corresponding generator

output.

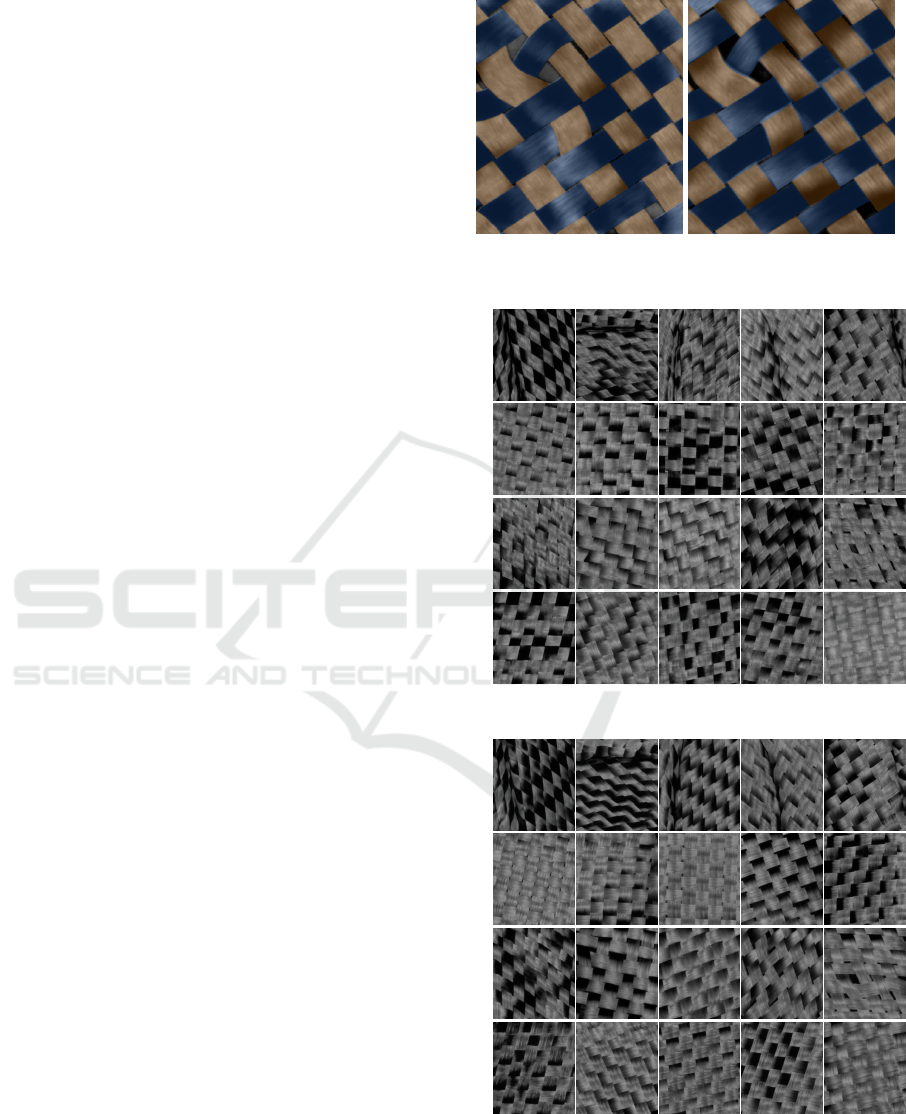

5.1 Manual Evaluation

To evaluate qualitative criteria and gain a first impres-

sion of the generated image quality, we assess our

synthetic images by eye. We found that both gener-

ator architectures produce sharp and realistic results,

without any evidence of the previously introduced ori-

entation problem. Blending of segmentation maps

and output images (cf. Figure 4) reveals that both

architectures produce matching results, while the Ex-

tended U-Net architecture produces perfectly aligned

images and the results of StarGAN v2 deviate up to 4

pixels from segmentation inputs in some cases.

Additionally, we evaluate the influence of the la-

tent vectors by generating several results from each

segmentation map with different latent vectors. We

found that both generators are able to cover the full

spectrum of appearances in real images, i.e. variations

in lighting and shadows (cf. Figure 5) and Figure 6.

5.2 Evaluation on GAN Scores

A manual evaluation is not feasible to capture the en-

tire variance of generator outputs, as that would mean

inspection of thousands of images. Moreover, the va-

riety in possible outputs makes it difficult to assess

Extended U-Net StarGAN v2

Figure 4: Blending of segmentation maps with output im-

ages.

Fold

Gap

Ondulation

Regular

Figure 5: Results of Extended U-Net generator architecture.

Fold

Gap

Ondulation

Regular

Figure 6: Results of StarGAN v2 generator architecture.

which dataset is of higher quality. To address these

problems, we use GAN scores, more specifically: In-

ception Score (IS)(Salimans et al., 2016), Fr

´

echet

Controlled Synthesis of Fibre-reinforced Plastics Images from Segmentation Maps using Generative Adversarial Neural Networks

805

Inception Distance (FID)(Heusel et al., 2017), and

their conditional extensions Between-class (BCIS)

and Within-class (WCIS) IS, and Between-class (BC-

FID) and Within-class (WCFID) FID (Benny et al.,

2021). The conditional extensions provide additional

meaning for our specific approach, as our combi-

nation of segmentation map synthesis and image-

to-image generator can be interpreted as a class-

conditional image generator modelling p(x|c), with

the segmentation map synthesis modelling the distri-

bution p(s|c) of segmentation maps s conditioned on

conditional classes c and the image-to-image genera-

tor modelling p(x|s). Since our real dataset is imbal-

anced, we slightly modify scores by weighting sam-

ples depending on the number of instances per class

in order to ensure that each class contributes the same

amount to the final score. This ensures that every er-

ror class is equally important for the given use case.

5.2.1 Inception Score

To capture if our synthetic images match distinct

classes, we use the Inception Score (IS) (Salimans

et al., 2016). In their work, the authors defined the

score as the expectation of the Kullback-Leibler di-

vergence between the true class posterior p(t|x) and

the true class prior p(t) over the distribution p(x) of

images x defined by the generator or real dataset:

IS = exp

E

x∼p(x)

D

KL

(p(t|x) k p(t))

(1)

Usually, the expectation is estimated as an average

over all instances x

(i)

. To ensure that each class has

the same influence on the score result, we replace the

average by the following weighted average scheme:

IS ≈ exp

1

C

C

∑

c=1

1

N

c

N

c

∑

i

c

=1

D

KL

(p(t|x

(i

c

)

k ˆp(t))

!

ˆp(t) =

1

C

C

∑

c=1

1

N

c

N

c

∑

i

c

=1

p(t|x

(i

c

)

).

(2)

Hence, we first calculate an average over the N

c

instances within each class c then an average over the

C class averages. Thereby, we avoid domination of

the score result by classes with many instances. We

calculate the IS on 10 Inception v3 models (Szegedy

et al., 2016) trained on X

R

train

and average the IS re-

sults, since the IS is reported to show high variances

between different training runs(Barratt and Sharma,

2018). The training procedure is identical to the pro-

cedure used in 5.4. In the same manner of the IS,

we modify the BCIS and WCIS by assuming that the

class priors are equally distributed, i.e. p(c) =

1

C

.

Table 2: Inception scores and FID scores (compared to X

R

val

)

for different datasets.

Dataset IS BCIS WCIS FID BCFID WCFID

X

R

test

3.30 2.81 1.28 0.14 0.06 0.42

X

G

U-Net

2.22 1.64 1.35 41.38 37.93 51.76

X

G

StarGAN

2.20 1.48 1.49 61.00 60.11 74.30

X

R

test

achieves significant higher scores than both

synthetic datasets, while scores of X

G

U-Net

and X

G

StarGAN

only differ on a minor level (cf. Table 2). Note that

since we modified the final Inception v3 layer to pre-

dict 4 classes, the IS has an upper bound of 4 instead

of 1000 (Barratt and Sharma, 2018).

5.2.2 Fr

´

echet Inception Distance

To compare real and synthetic images on a feature dis-

tribution level, we use the Fr

´

echet Inception distance

(FID)(Heusel et al., 2017). The FID is defined as the

Fr

´

echet distance between the (assumed) normal dis-

tribution of Inception v3 feature vectors with mean

vectors µ

R

, µ

G

and covariance matrices Σ

R

, Σ

G

from

real and generated data, respectively:

FID = kµ

R

− µ

G

k

2

2

+ Tr

Σ

R

+ Σ

G

− 2(Σ

R

Σ

G

)

1

2

(3)

Analogous to our modification of the IS, we adapt the

estimate of the mean vector ˆµ and the covariance ma-

trix

ˆ

Σ to

ˆµ =

1

C

C

∑

c=1

1

N

c

N

c

∑

i

c

=1

f (x

(i

c

)

), (4)

and

ˆ

Σ

m,n

=

N

(N − 1)C

C

∑

c=1

1

N

c

N

c

∑

i

c

=1

( f (x

(i

c

)

)

m

− ˆµ

m

)( f (x

(i

c

)

)

n

− ˆµ

n

),

(5)

with f (x) denoting the extracted feature vector of an

instance x and N the total number of instances in the

dataset. In the same manner, we modify the BC-

FID and WCFID by assuming that the class priors are

equally distributed, i.e. p(c) =

1

C

. To obtain feature

vectors relevant for the use case, we extract them from

an Inception v3 models trained on X

R

train

instead of the

original model trained on ImageNet(Szegedy et al.,

2016; Deng et al., 2009) and average the score results

from 10 different training runs. As a reference dataset

representing the real data we use X

R

val

. The FID scores

(cf. Table 2) indicate that both synthetic datasets dif-

fer significantly from the real dataset in terms of fea-

tures, while the feature distribution of X

G

U-Net

is more

similar than the one of X

G

StarGAN

.

ICAART 2022 - 14th International Conference on Agents and Artificial Intelligence

806

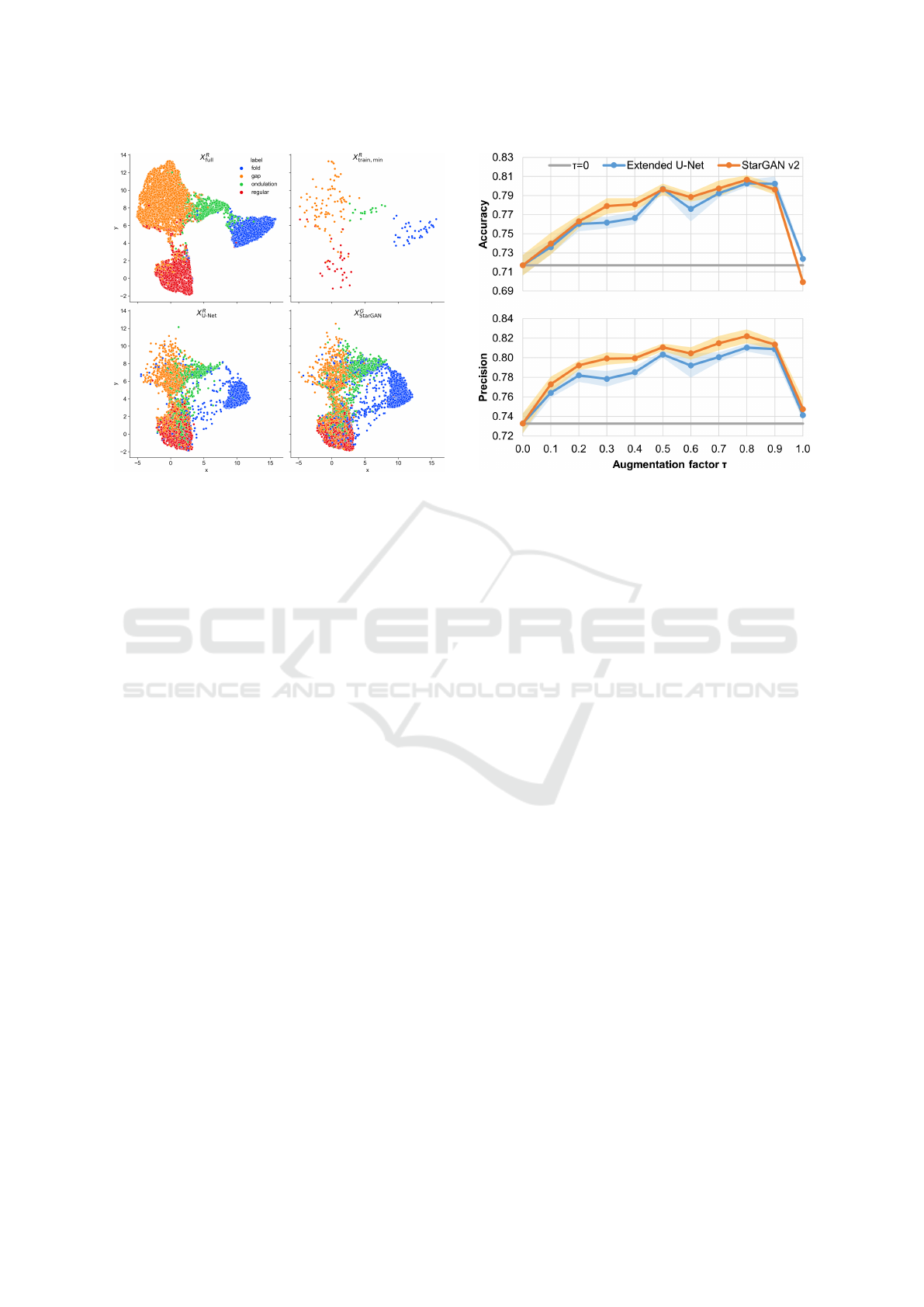

Figure 7: Feature distribution mapped in 2D using UMAP.

5.3 Evaluation of Distribution

The FID only compares datasets in terms of an esti-

mated normal distribution over the extracted feature

vectors. However, the assumption of a normal dis-

tribution is not always justified. To further investi-

gate the feature distributions of our real and synthetic

datasets, we extract for all datasets the feature vec-

tors from an Inception v3 model trained on X

R

train

and

map them into two-dimensional space using UMAP

(McInnes et al., 2020). The UMAP embedding is

learned on the features of X

R

full

. Instances are plot-

ted in random order to prevent a biased representation

due to a specific class-order within the instances.

The scatter plot of the reduced features (cf. Fig-

ure 7) reveals that, although there are notably differ-

ences between the cluster boundaries, there is a strong

correlation between the feature distributions of real

and synthetic data. Our synthetic images do not cover

the full real data distribution, which can be partly ex-

plained by three main factors: the scarce training data,

which do not cover all parts of the distribution ade-

quately, the generator model, which possibly is not

able to learn certain features from the training data,

and our segmentation map generation method, which

only allows to generate simple segmentation maps.

The latter might also be an explanation for the un-

sharp cluster boundaries, as we deliberately created

segmentation maps close to the class boundaries in

order to generate hard samples and increase the aug-

mentation effect of the synthetic data.

We also tried to create the same scatter plots with

feature vectors extracted from the original Inception

v3 model trained on a ImageNet, but UMAP failed to

Figure 8: Accuracy and precision for different values of τ.

produce a cluster structure. This can be interpreted

as a lack of information in the extracted features and

corroborates our decision not to use this model for the

FID.

5.4 Evaluation on Classification Use

Case

We consider a test with the use case as the most im-

portant evaluation method, as the most realistic im-

ages might be worthless if they do not serve the use

case and even the least realistic images might have

benefits for specific applications.

With regard to our quality assurance use case, we

set up a classification task based on the error classes

of our training dataset. To keep it consistent with the

GAN scores, we use the Inception v3 model and train

it on X

R

train,min

to create a baseline. To improve the

baseline and demonstrate that our synthetic images

exceed the usage of vanilla image augmentations, we

apply flipping, rotations, and colour augmentations

during training. The training procedure, i.e. learn-

ing rate adaptation and fine-tuning, is completely au-

tomatised and kept constant through all experiments

to minimise human bias on the results. The real train-

ing data is augmented by sampling a fixed fraction τ

of training instances from the augmenting synthetic

dataset (X

G

U-Net

or X

G

StarGAN

). From each training run,

the model with the highest accuracy on X

R

val

is used.

We measure accuracy and precision of the trained

model on X

R

test

and average the results over 10 train-

ing runs, as they slightly vary depending on parameter

initialisation and training sample selection. Figure 8

summarises our results for different values of τ. Note

Controlled Synthesis of Fibre-reinforced Plastics Images from Segmentation Maps using Generative Adversarial Neural Networks

807

Figure 9: Confusion matrices of X

train,min

from left to right:

no augmentation (τ = 0), augmented with X

G

U-Net

(τ = 0.8),

augmented with X

G

StarGAN

(τ = 0.8).

that we calculate accuracy and precision from a con-

fusion matrix, that is normalised over rows, to avoid

bias by many instances in certain classes.

Our results confirm that our synthetic images can

significantly improve the performance of a classifier

when being used as data augmentation. The actual

performance improvements depend less on the gen-

erator architecture as on τ. We found that for both

datasets the peak performance is achieved at τ = 0.8.

Moreover, the (normalised) confusion matrices

show that the recall improved for every class when

synthetic data augmentation was applied during train-

ing, while augmentations with X

G

U-Net

and X

G

StarGAN

lead to comparable results despite of their different

scores in 5.2 (cf. Figure 9). We find that the con-

fusion matrix is the better alternative to the inception

scores in order to evaluate class-conditional GANs, as

it takes into account the correct/conditional class of

an image and breaks down the scores of results within

the different classes.

6 CONCLUSION

In this work we showed that GANs can effectively be

used to generate synthetic FRP images for the purpose

of data augmentation in a data scarce environment.

In our implementation we adapted BicycleGAN and

tested two generator architectures, namely Extended

U-Net and StarGAN v2. We were able to achieve the

goal of generating realistic textile images with both

architectures.

The generated images in this work are thoroughly

validated in four different ways. Firstly, a qualitative

visual inspection was performed to judge the realism

of the generated images. Secondly, two scores were

implemented, namely IS and FID with their respective

class-conditional versions, to add an objective quanti-

tative inspection. Thirdly, the distribution of original

and synthetic images were compared in terms of their

feature clustering structure using UMAP. It was found

that the synthesised images share a high overlap with

the real images, but do not cover the distribution of

the real images and are therefore less varied. Lastly, a

classifier was trained to predict the type of error found

in the images, where using a mix of real and synthe-

sised data significantly improved the performance of

the classification model.

In future work, we plan to extend our approach

to three-dimensional weaves. This would emphasise

the effects of certain defects, such as ondulations and

folds, which would require either 3D segmentation

maps, or a combination of 2D segmentation from dif-

ferent angles. The output of such model could be 3D

textile objects. Furthermore, we want to explore dis-

entanglement learning methods for generative models

to remove the necessity of segmentation maps for a

controlled synthesis of FRP images.

With our contribution we show that generative ad-

versarial networks are usable in an industrial use case

of manufacturing FRP. They are capable to learn high-

level feature representations of the observation from

which they synthesise new realistic and useful im-

ages. In order to further investigate the learned repre-

sentations in the future, we believe that feature disen-

tanglement methods may unravel meaningful knowl-

edge about the underlying manufacturing process.

ACKNOWLEDGEMENTS

Funded by the Deutsche Forschungsgemeinschaft

(DFG, German Research Foundation) under Ger-

many’s Excellence Strategy - EXC-2023 Internet of

Production - 390621612. Simulations were per-

formed with computing resources granted by RWTH

Aachen University under project thes0947.

REFERENCES

Barratt, S. and Sharma, R. (2018). A Note on the Inception

Score.

Benny, Y., Galanti, T., Benaim, S., and Wolf, L. (2021).

Evaluation metrics for conditional image genera-

tion. International Journal of Computer Vision,

129(5):1712–1731.

Berger, G. and Memisevic, R. (2017). Incorporating long-

range consistency in cnn-based texture generation.

ArXiv, abs/1606.01286.

Choi, Y., Uh, Y., Yoo, J., and Ha, J. W. (2020). Stargan

v2: Diverse image synthesis for multiple domains. In

2020 IEEE/CVF Conference on Computer Vision and

Pattern Recognition (CVPR), pages 8185–8194.

Deng, J., Dong, W., Socher, R., Li, L.-J., Li, K., and Fei-

Fei, L. (2009). ImageNet: A large-scale hierarchical

image database. In 2009 IEEE Conference on Com-

puter Vision and Pattern Recognition, pages 248–255,

Piscataway, NJ. IEEE.

ICAART 2022 - 14th International Conference on Agents and Artificial Intelligence

808

Fayyaz, R. A., Maqbool, M., and Hanif, M. (2020). Textile

design generation using gans. In 2020 IEEE Canadian

Conference on Electrical and Computer Engineering

(CCECE), pages 1–5.

Fuhr, J.-P. (2017). Schichtbasierte Modellierung von Ferti-

gungseffekten in der Struktursimulation von Faserver-

bundwerkstoffen. Verlag Dr. Hut.

Gatys, L., Ecker, A. S., and Bethge, M. (2015). Texture syn-

thesis using convolutional neural networks. Advances

in Neural Information Processing Systems, 28.

Goodfellow, I. J., Pouget-Abadie, J., Mirza, M., Xu, B.,

Warde-Farley, D., Ozair, S., Courville, A., and Ben-

gio, Y. (2014). Generative adversarial networks.

Heusel, M., Ramsauer, H., Unterthiner, T., Nessler, B., and

Hochreiter, S. (2017). GANs Trained by a Two Time-

Scale Update Rule Converge to a Local Nash Equi-

librium. In I. Guyon, U. V. Luxburg, S. Bengio, H.

Wallach, R. Fergus, S. Vishwanathan, and R. Garnett,

editors, Advances in Neural Information Processing

Systems, volume 30, pages 6626–6637. Curran Asso-

ciates, Inc.

Jetchev, N., Bergmann, U., and Vollgraf, R. (2017). Texture

synthesis with spatial generative adversarial networks.

Jing, J.-F., Ma, H., and Zhang, H.-H. (2019). Automatic

fabric defect detection using a deep convolutional neu-

ral network. Coloration Technology, 135(3):213–223.

K. He, X. Zhang, S. Ren, and J. Sun (2016). Deep Residual

Learning for Image Recognition. In 2016 IEEE Con-

ference on Computer Vision and Pattern Recognition

(CVPR), pages 770–778.

Liu, G., Gousseau, Y., and Xia, G.-S. (2016). Texture

synthesis through convolutional neural networks and

spectrum constraints. In 2016 23rd International Con-

ference on Pattern Recognition (ICPR), pages 3234–

3239.

McInnes, L., Healy, J., and Melville, J. (2020). Umap: Uni-

form manifold approximation and projection for di-

mension reduction.

Miao, M. and Xin, J. H. (2018). Engineering of high-

performance textiles. The Textile Institute Book Se-

ries. Woodhead Publishing.

Ronneberger, O., Fischer, P., and Brox, T. (2015). U-Net:

Convolutional Networks for Biomedical Image Seg-

mentation. In Navab, N., Hornegger, J., Wells, W. M.,

and Frangi, A. F., editors, Medical image computing

and computer-assisted intervention - MICCAI 2015,

Lecture notes in computer science, pages 234–241,

Cham and Heidelberg and New York and Dordrecht

and London. Springer.

S. Schreiber, J. Geldenhuys, and H. de Villiers (2016).

Texture synthesis using convolutional neural networks

with long-range consistency and spectral constraints.

In 2016 Pattern Recognition Association of South

Africa and Robotics and Mechatronics International

Conference (PRASA-RobMech), pages 1–6.

Sacco, C., Radwan, A. B., Beatty, T., and Harik, R. (2019).

Machine learning based afp inspection: A tool for

characterization and integration. In SAMPE 2019

Conference & Exhibition. Charlotte, NC: SAMPE.

doi, volume 10, pages 19–1594.

Sacco, C., Radwan, A. B., Harik, R., and Van Tooren, M.

(2018). Automated fiber placement defects: Auto-

mated inspection and characterization. In Proceedings

of the SAMPE 2018 Conference and Exhibition, Long

Beach, CA, USA, pages 21–24.

Salimans, T., Goodfellow, I., Zaremba, W., Cheung, V.,

Radford, A., and Chen, X. (2016). Improved Tech-

niques for Training GANs. In D. Lee, M. Sugiyama,

U. Luxburg, I. Guyon, and R. Garnett, editors, Ad-

vances in Neural Information Processing Systems,

volume 29, pages 2234–2242. Curran Associates, Inc.

Shorten, C. and Khoshgoftaar, T. M. (2019). A survey on

image data augmentation for deep learning. Journal

of Big Data, 6(1):1–48.

Szegedy, C., Vanhoucke, V., Ioffe, S., Shlens, J., and Wojna,

Z. (2016). Rethinking the Inception Architecture for

Computer Vision. In 2016 IEEE Conference on Com-

puter Vision and Pattern Recognition (CVPR), pages

2818–2826.

T

¨

ure, Y. and T

¨

ure, C. (2020). An assessment of using

aluminum and magnesium on co2 emission in euro-

pean passenger cars. Journal of Cleaner Production,

247:119120.

Wei, B., Hao, K., Tang, X.-s., and Ding, Y. (2019). A

new method using the convolutional neural network

with compressive sensing for fabric defect classifica-

tion based on small sample sizes. Textile Research

Journal, 89(17):3539–3555.

Xian, W., Sangkloy, P., Agrawal, V., Raj, A., Lu, J., Fang,

C., Yu, F., and Hays, J. (2018). Texturegan: Control-

ling deep image synthesis with texture patches. pages

8456–8465.

Yi, X., Walia, E., and Babyn, P. (2019). Generative adver-

sarial network in medical imaging: A review. Medical

Image Analysis, 58:101552.

Zhu, J.-Y., Zhang, R., Pathak, D., Darrell, T., Efros, A. A.,

Wang, O., and Shechtman, E. (2017). Toward multi-

modal image-to-image translation. In I. Guyon, U. V.

Luxburg, S. Bengio, H. Wallach, R. Fergus, S. Vish-

wanathan, and R. Garnett, editors, Advances in Neural

Information Processing Systems 30, pages 465–476.

Curran Associates, Inc.

Zhu, X., Liu, Y., Li, J., Wan, T., and Qin, Z. (2018). Emo-

tion classification with data augmentation using gen-

erative adversarial networks. In Phung, D., Tseng,

V. S., Webb, G. I., Ho, B., Ganji, M., and Rashidi, L.,

editors, Advances in Knowledge Discovery and Data

Mining, Lecture notes in computer science, pages

349–360, Cham. Springer International Publishing.

Controlled Synthesis of Fibre-reinforced Plastics Images from Segmentation Maps using Generative Adversarial Neural Networks

809