Research on Decision Optimization in Enterprise Supply Chain

Management: A Case Study of Tea Industry

Xiang Miao

a

Horton Academy, North York, Canada

Keywords: Supply Chain Management, Decision Optimization, Tea Industry, Value Increment.

Abstract: With the gradual improvement of supply chain system and the continuous strengthening of supply chain

management, increasing enterprises have invested more energy in the supply chain, and sound supply chain

management has a certain value increment potential. From the perspective of enterprise supply chain

management and based on the investigation and analysis of the current situation and problems of supply chain

in China’s tea industry, the decision optimization scheme of supply chain management in the development of

tea industry was proposed in this study from the dimensions of strategic coordination, operation coordination

and response coordination.

1 INTRODUCTION

Supply chain management is to integrate and

optimize suppliers, manufacturers, distributors and

retailers to improve their respective business

efficiency, save costs and optimize operations in the

flow of materials, capital and information, and

achieve a greater degree of supply chain value

increment. China is a big tea producer and consumer.

In 2020, the domestic tea market sales amount has

reached 288.9 billion yuan, and tea consumption

continues to grow. At present, the upstream and

downstream enterprises in the supply chain of the tea

industry generally have problems of asymmetric

information and low level of information, which

leads to the value increment potential of the supply

chain has not been given full play. Therefore, the

decision optimization in supply chain management is

particularly important.

2 OVERVIEW OF SUPPLY

CHAIN MANAGEMENT

2.1 Supply Chain

Supply chain, developed from economic chain, is a

functional network chain mode that links suppliers,

manufacturers, distributors, retailers and end users

into an integral whole, as shown in Figure 1. It can

also be held that supply chain is a logistics network.

Different enterprises constitute different nodes in this

network, and value increment can be realized through

the processing and transportation of materials in the

operation of supply chain, allowing all enterprises to

benefit. In other words, supply chain is also a value-

added chain. (Bogers, 2016)

Figure 1: Diagram of Supply Chain System.

a

https://orcid.org/0000-0003-0140-9839

360

Miao, X.

Research on Decision Optimization in Enterprise Supply Chain Management: A Case Study of Tea Industry.

DOI: 10.5220/0011344900003437

In Proceedings of the 1st International Conference on Public Management and Big Data Analysis (PMBDA 2021), pages 360-366

ISBN: 978-989-758-589-0

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

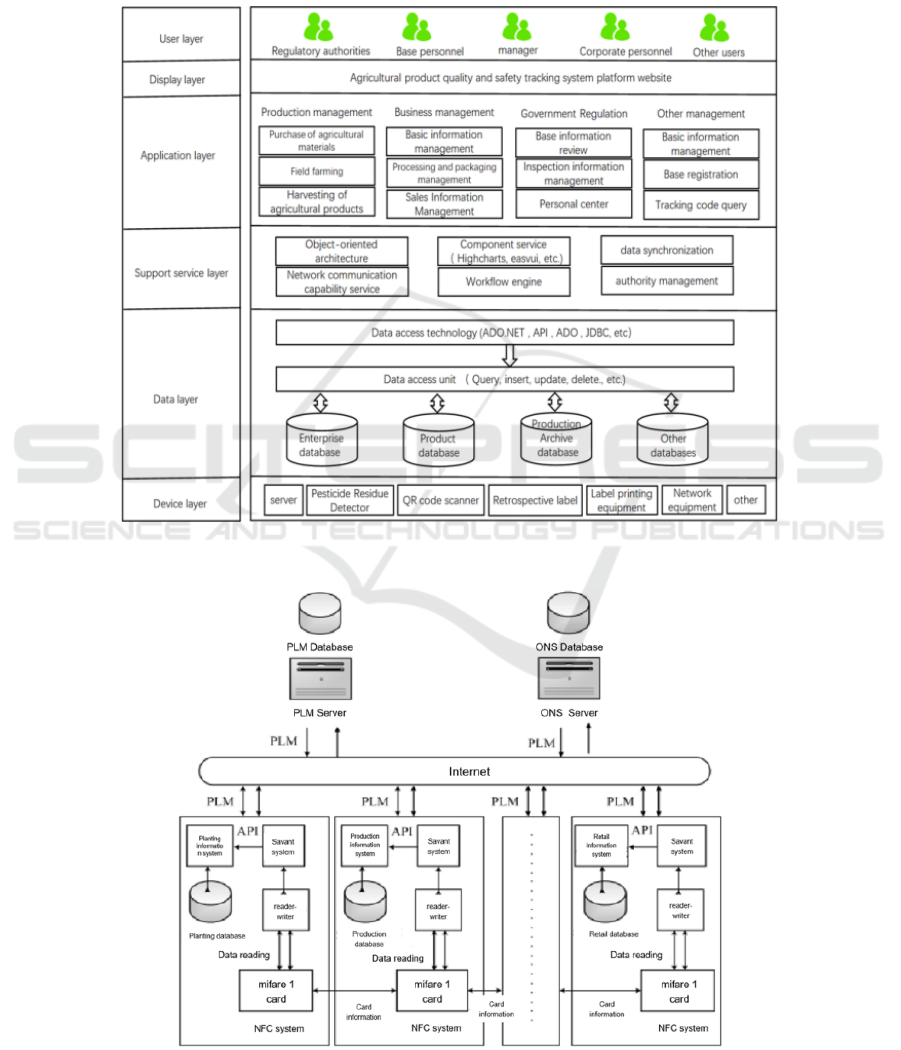

2.2 Architecture Design of Supply

Chain Management System

From the perspective of tea industry supply chain, this

paper analyzes each link of agricultural products

supply chain. Considering that agricultural products

supply chain has the characteristics of many

participants and many uncertain factors, in order to

improve the traceability of the system, the system

adopts sevice-oriented architecture (SOA) design,

which divides the system into user layer, display layer,

application layer, support service layer, data layer and

equipment layer. Its architecture is shown in Figure 2.

Figure 2: Architecture Design of Supply Chain Management System.

Figure 3: Overall framework of information system.

Research on Decision Optimization in Enterprise Supply Chain Management: A Case Study of Tea Industry

361

The overall architecture of the information system

mainly includes four links. Node enterprises use read-

write devices to write data streams into MF1

according to production requirements, and store the

data streams into their own enterprise databases and

upload them to the information system platform

database. Limited by space, this paper only takes tea

planting as an example. In the tea planting process, a

reader with number is equipped to write information

such as tea address, tea environment, growth

situation, fertilizer use, tea varieties, planting time

and so on into MF1 card in the form of data stream.

At the same time, the generated data stream is

associated with the background database of

enterprises and regulatory authorities and compiled

into corresponding information to be stored in the

background database. When the tea leaves are

planted, the planting information recorded in MF1

will be transmitted to downstream enterprises.

Downstream node enterprises can use mobile phones,

personal digital assistant (PADs) or card readers to

obtain the information in the labels, and judge

whether the read information meets the requirements

of product processing.

2.3 Analysis of Value Increment

Potential of Supply Chain

Management

Sound supply chain management has a certain value

increment potential, and the following optimizations

of a supply chain will lay a good foundation for value

increment. First of all, the grasp of information

resources should be strengthened. A supply chain is a

chain, so each node affects the entire chain. The

sharing of commodity information, transportation

information, relevant policy information and

consumption level information should be achieved as

much as possible. Then, the quality of service should

be improved. The supply chain is centered on

customer service. Most consumers expect faster

logistics and better product quality, which requires

smooth connection between each node in the supply

chain to avoid wasting time. Enterprises including

retailers also need to provide customers with better

services. In addition, the supply chain should play the

role of “1+1>2” to unite various enterprises to

complement each other’s advantages. Through

effective management, it can also remove

unnecessary error costs, perfect the whole operation

process of commodities, improve the enterprise’s

inventory backlog, reduce the cost of commodity

storage with smoother transportation, and then

gradually improve customer product satisfaction,

expand market share, and create value increment.

(Simmons, 2017)

Supply chain value increment is achieved through

the needs of the final consumers, which has four

forms generally. First of all, the basic quality of

commodities is the most elementary factor to enhance

value. Customer satisfaction can be improved to

some extent by improving the attributes of

commodities to meet their needs. Secondly, time

control is a very important part of supply chain

management. For the logistics industry, customers

have been yearning for high-speed logistics, so the

full speed operation between each node of the supply

chain can not only save some costs, but also improve

the image in the eyes of customers. Thirdly, the

location selection is also crucial. From suppliers,

manufacturers, distributors to retailers, the location of

each supply chain node is better to supplement with

each other. The transfer of location and the

transportation of commodities also change their

value. Finally, the change of ownership of

commodities will also result in product value

increment. As a result, products, starting from raw

materials, are continuously enhanced in value

through a series of transmission in the supply chain,

and finally accepted by consumers. In this way, the

supply chain value increment is realized. Therefore,

it is necessary to realize the value identification of

consumers through supply chain management, so that

consumers can recognize the value of products,

benefiting both enterprises and the supply chain

itself. Its value increment diagram is shown in Figure

4.

Figure 4: Diagram of Supply Chain Value Increment (Christopher M,2011).

PMBDA 2021 - International Conference on Public Management and Big Data Analysis

362

3 ANALYSIS OF THE

DEVELOPMENT STATUS AND

PROBLEMS OF TEA

INDUSTRY IN THE SUPPLY

CHAIN ENVIRONMENT

3.1 Data on the Development Status of

China’s Tea Industry

According to the data of China Tea Marketing

Association, since 2011, the total amount of tea

consumption in China and the total per capita

consumption have been on the rise, and the domestic

tea market sales amount have reached 288.9 billion

yuan in 2020. With the upgrading of consumption and

the improvement of health concept, China’s tea

consumption continues to grow, and its proportion of

consumption in the global market sales is increasing

year by year. It is gradually developing into a key

market of global tea consumption. By the end of

2020, tea producing areas in China covered nearly

1,000 counties (cities and districts) in 18 provinces

(municipalities and autonomous regions), with a total

area of 47.4769 million mu, a national tea output of

2.9860 million tons, a total output value of 262.658

billion yuan, a domestic sales volume of 2.2016

million tons, an annual per capita consumption of 1.2

kg, with nearly 500 million tea consumers, an export

volume of 348,800 tons, and a total export of $2.038

billion. (Data source: China Tea Marketing

Association)

Table 1: Total Domestic Sales Volume of Chinese Tea from 2011 to 2020 (Unit: ten thousand tons).

Year 2020 2019 2018 2017 2016 2015 2014 2013 2012 2011

Domestic

sales

220.16 202.56 191.05 181.70 171.06 167.91 150.25 133.83 124.01 109.61

Data source: China Tea Marketing Association

Table 2: Total Domestic Sales Amount of Chinese Tea from 2011 to 2020 (Unit: 100 million yuan).

Yea

r

2020 2019 2018 2017 2016 2015 2014 2013 2012 .

Domestic

sales

2889 2740 2661 2405 2148 1869 1669 1385 1176 971

Data source: China Tea Marketing Association

Table 3: Average Domestic Price of Chinese Tea from 2011 to 2020 (Unit: Yuan/kg).

Yea

r

2020 2019 2018 2017 2016 2015 2014 2013 2012 2011

Domestic

sales

131.2 135.2 139.3 132.4 125.5 111.3 111.1 103.5 94.9 88.5

Data source: China Tea Marketing Association

Data source: China Tea Marketing Association

Figure 5: Area of Tea Gardens in Major Tea-producing Provinces of China in 2020 (10,000 Mu).

Research on Decision Optimization in Enterprise Supply Chain Management: A Case Study of Tea Industry

363

3.2 Main Problems Existing in the Tea

Industry Supply Chain

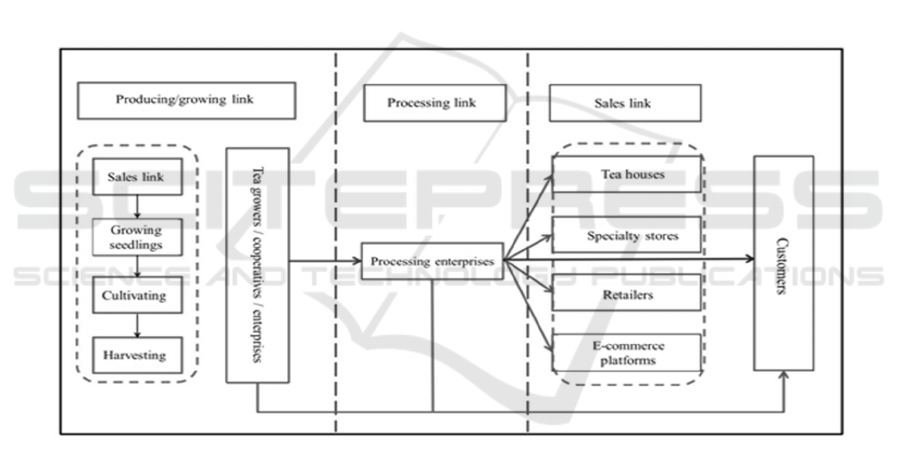

Supply chain refers to the network chain involving the

process of supply, production, acquisition, processing,

storage, and sale of means of production until finally

reaching consumers. The process from tea cultivation

to market, including pre-harvest selection of superior

varieties, field management, post-harvest processing

and storage, pre-market commercial treatment,

transportation, and marketing, is a complete supply

chain, as shown in the figure below.

The connection and information communication

of each link in the tea supply chain is not smooth. Tea

producing areas are mainly highland and mountainous

areas with remote geographical location. Most of the

growers in the upper reaches of the tea supply chain

are ordinary farmers and are not sensitive enough to

information technology. Most of the registered

processing enterprises in the middle reaches of the

supply chain are small-scale enterprises, as well as

processing points and cooperatives, who have not

established enterprise information management

system; there are many points of sale in the lower

reaches of the supply chain, and ordering activities are

launched to the middle and upper reaches mainly

relying on mobile communication, and the dynamic

information of market demand cannot be timely and

effectively transmitted to the middle and upper

reaches of the supply chain. The information

transmitted in each link of the tea supply chain is

prone to variation, amplification, and hockey stick

effect, leading to the information island of horizontal

and vertical integration of the supply chain, and

enabling the members of the supply chain to maximize

their own profits, which damages the overall benefit

of the supply chain and produces double marginal

effect, not conducive to tea production, processing,

and sales related enterprises to make correct decisions.

Figure 6: Diagram of Tea Supply Chain Structure.

4 DECISION OPTIMIZATION IN

SUPPLY CHAIN

MANAGEMENT OF TEA

PRODUCTS: SUPPLY CHAIN

COLLABORATION CAPACITY

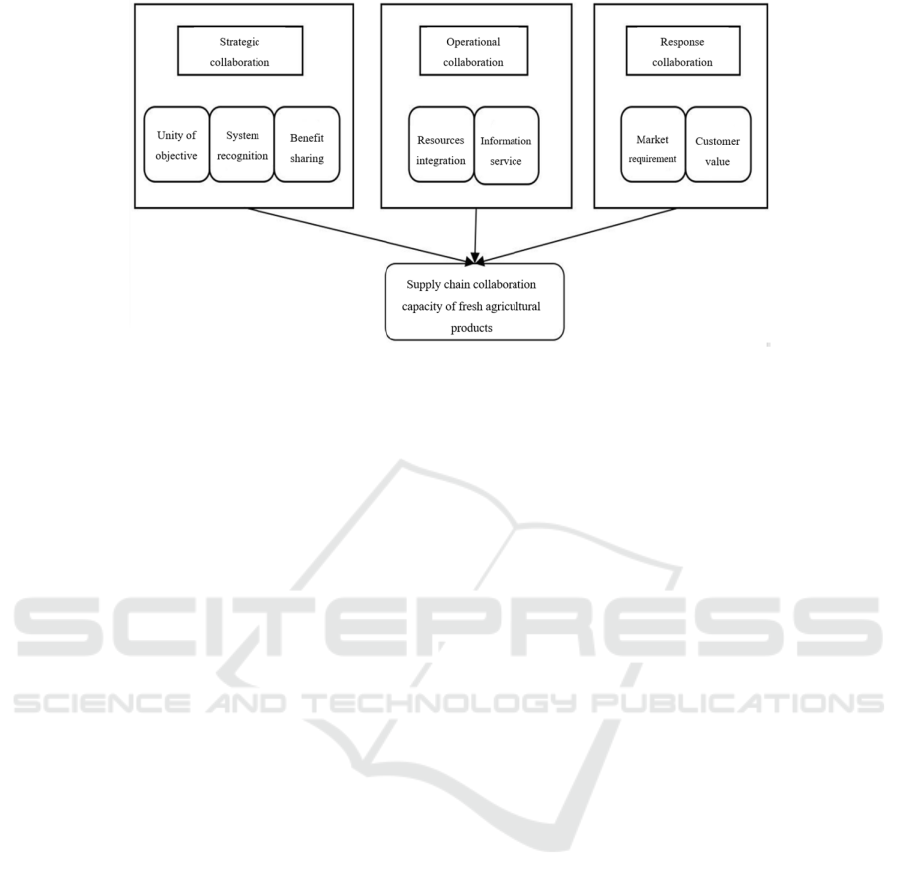

The supply chain of tea products is a complex system

composed of multiple subsystems, which mainly

consists of production and supply subsystems,

logistics subsystems, sales subsystems, consumption

subsystems and other auxiliary subsystems. A system

composed of many subsystems is in a state of self-

organization when the subsystems collaborate with

each other to produce synergistic and cooperative

effects. The core concept of tea product supply chain

lies in realizing the maximization of customer value.

The core subject of the supply chain leads the other

subjects to form an organic united whole by signing

collaborative contracts, so as to transform the tea

product supply chain from the original loose state to

the self-organization state in pursuit of common core

interests. In the continuous evolution of the

collaborative system, the supply chain system is

transformed from disordered collaboration to orderly

collaboration. (Huang, 2000)

PMBDA 2021 - International Conference on Public Management and Big Data Analysis

364

Figure 7: Supply Chain Collaboration Capacity.

4.1 Strategic Collaboration

By unifying the development plan of tea product

supply chain, on the basis of determining the

consistent collaboration goal, stipulating the

collaboration scope and degree and formulating a

reasonable collaboration system and benefit sharing

mechanism are the foundation of the tea product

supply chain system collaboration. For example,

most enterprises regard supply chain collaboration as

a part of their development strategy, formulate

unified strategic planning and operational objectives,

and make all collaborative subjects of the supply

chain abandon pursuing the maximization of their

own interests. In the meanwhile, through

collaboration, the core competitive advantages of

each subject can be brought into play to cultivate

consumers’ trust and purchasing habits, so as to

promote enterprises to establish a firm collaborative

relationship from the strategic level, and promote

collaboration in operation and response of tea product

supply chain. Therefore, this paper argues that

strategic collaboration has a significant positive

impact on operational collaboration and response

collaboration.

4.2 Operational Collaboration

Operational collaboration is the further refinement of

collaboration objectives under the guidance of

strategic collaboration. For the tea product supply

chain, the strategic decision content developed by

strategic decision-makers is detailed through the

operational collaboration of supply chain resource

integration and information service support, which is

the operation basis of strategic collaboration. For

example, West Lake Longjing tea is very sensitive to

changes in temperature and humidity. Once the

temperature is raised, aging metamorphism occurs

easily. The suitable transportation environment for

the tea is very strict, requiring precise temperature

and humidity. Generally 10 degrees Celsius is

appropriate, 0 to 5 degrees Celsius is the best, and

humidity is less than 70%. Short distance

transportation also requires to avoid carriage

moisture, maintain temperature control, and keep

ventilation. The tea is best stored in vacuum, and the

transportation equipment is ideal to be clean, dry,

odor-free and low-temperature refrigerated cabinet,

so as to avoid oxidative deterioration, thus affecting

the taste and aroma. Compared with the general

logistics system, the construction cost of specific

logistics system of tea products is high, and the daily

operation and maintenance cost of their facilities and

equipment is also expensive.

Also, it is difficult for a

single subject in the supply chain to build a dedicated

logistics system to meet market demand by its own

strength. In view of this, special logistics centers for

tea products can be built through the coordination of

logistics resources to share cold chain logistics

facilities and equipment, thus relieving financial

pressure and improving the utilization rate of cold

chain facilities and equipment.

4.3 Response Collaboration

Customers’ demand for high-quality shopping

experience of tea products forces the supply chain to

constantly reduce operating costs and improve

response speed. For example, once the market

demand for tea products changes, the business

process of the supply chain should be recombined

through collaboration to improve its response speed.

Research on Decision Optimization in Enterprise Supply Chain Management: A Case Study of Tea Industry

365

Each cooperative subject should clarify its own

positioning and responsibilities in the supply chain,

and remove the barriers to collaboration among

various subjects, which drives the change of the

original operation mode of the supply chain, so as to

carry out business and assign tasks at any time, thus

reducing the collaborative operation cost of the

supply chain and obtaining the advantage of rapid

response to the needs of end customers. (Rosenzweig,

2009)

REFERENCES

Bogers, M, Hadar, R, Bilberg, A. (2016). Additive

manufacturing for consumer-centric business models:

Implications for supply chains in consumer goods

manufacturing. Technological Forecasting & Social

Change, 102: 225-239.

Christopher, M, Holweg, M. (2011). “Supply Chain 2. 0”:

Managing supply chains in the era of turbulence.

International Journal of Physical Distribution &

Logistics Management, 41(01):63-82

Eve, D. Rosenzweig. (2009). A contingent view of e

collaboration and performance in manufacturing.

Journal of Operations Management, 27(6):426-478

Simmons, R, Brennan, C. (2017). User voice and

complaints as drivers of innovation in public

services[J]. Public Management Review, 19 (8): 1085‐

1104.

Yuan-Ko Huang, Eldon Li, Ja-Shen Chen. (2000).

Information synergy as the catalyst between

information technology capability and innovativeness:

empirical evidence from the financial service sector[J].

Information Research, 14(1): 1-23.

Yanhua Sun, (2019). User-driven Innovation, Dynamic

Capabilities and the Evolution of Supply Chain

Business Models: Based on the Research of Tea Supply

Chains in Hunan Province. Journal of Management

Case Studies, (12):652-667

PMBDA 2021 - International Conference on Public Management and Big Data Analysis

366