Application of Project Management Tools in the Enterprise

Jiongjie Liu

1,a,*,†

, He Sun

2,b,*,†

and Shizhuo Sun

3,c,*,†

1

School of Electrical and Electronic Engineering, Huazhong University of Science and Technology,

Wuhan, Hubei, 430070, China

2

School of Economic and Management, Tiangong University, Tianjin, 300000, China

3

School of Mechanical Engineering, Nanjing Institute of Technology, Nanjing, Jiangsu, 213000, China

†

These authors contributed equally

Keywords: Project Management, Project Progress Management Method, Critical Path Method, Plan Evaluation and

Review Technology, Time-cost Trade-off.

Abstract: To ensure the successful implementation of the project and the orderly progress of the project progress for

more economic benefits, companies need to invest in resources, time, and other costs and join the scientific

and technical guidance of the project progress management system theory. This paper focuses on the basic

knowledge and related project management theories, with the critical path method, PERT and Time-cost trade

as the tools. It systematically discusses how to forecast and control the project duration through project

schedule management methods and supports achieving refined project management. Also, the tools in this

thesis apply to the project management practices of enterprises in various fields.

1 INTRODUCTION

1.1 Project Management Research

Background

With the development of the knowledge economy,

the world's economy is changing from high growth to

high-quality development, which requires enterprises

to further develop and implement a more professional

project management process. Scholars generally

believe that a project refers to using limited resources

and time to achieve specific goals for specific users

according to a specific life cycle. Project

management is the overall monitoring and

management of activities related to realising a series

of objectives (Liu 2020). Project management uses

expertise, skills, tools and methods to plan, organize,

implement and control project activities. The main

challenge is the need to accomplish all project

objectives within the established constraints. These

constraints include project scope, completion time,

quality, and budget (Tan 2019). Project progress

management is the process of using the relevant

theoretical knowledge of the project risk

management, formulating the corresponding plans

for the different stages and combining with the

enterprise resources, and determining the

corresponding objectives to monitor the progress

project's objectives can be summarized into three

aspects: progress, cost and quality, which jointly

drive the project management process. Among them,

the management of progress objectives is usually

regarded as the priority objective in the process of

project implementation, and the management of cost

and quality objectives is often carried out based on

the progress management system, such as earned

value management and the determination of quality

control points (Tan 2019).

At present, China's economy is in a critical period

of transformation from high growth to high-quality

development. Therefore, it is more necessary for

enterprises to further explore and practice a more

professional project management process.

To conclude, project management can be seen as

a way to deal with the strategy of the organization, a

means of survival and development in the changing

and relentless market competition, and it should be

more widely used. The realization of project

management and the development of project

management cannot be separated from the

modernization of management ideas, management

organizations, management methods and means,

which is the inevitable trend of project management

development. Facing the rapidly changing market

Liu, J., Sun, H. and Sun, S.

Application of Project Management Tools in the Enterprise.

DOI: 10.5220/0011301900003437

In Proceedings of the 1st International Conference on Public Management and Big Data Analysis (PMBDA 2021), pages 101-112

ISBN: 978-989-758-589-0

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

101

and the fierce competition among enterprises, our

only choice is to innovate and grasp the pulse of

management.

1.2 Current Status of Project

Management Research

There are many methods for risk analysis of

engineering project progress. Still, the PERT (Plan

Evaluation and Review Technology) based on

CPM(Critical Path Method) Network technology is

the most common use with the fastest development.

From the original classic PERT network program to

various improvements to the PERT approach today,

the researchers remain unenthusiastic and applied to

various engineering fields (Wu 2016). Network

Planning Technology was introduced in the early

1960s by the famous mathematician Professor Hua

Luogeng. In his book "Coordinating Method

Translation and Supplement" (Hua 1965), PERT

technology is introduced and dedicated to promoting

PERT technology.

In 1981, Project Management Institute(PMI)

launched the "Project Management Standardization"

study, named PMBOK(Project Management Body

of Knowledge), and registered and published 15

years later. The Chinese Project Management Body

of Knowledge (CPMBOK) is based on PMBOK (Ma

2013) and consists of 38 processes. However, the

current situation of many project management

knowledge systems also shows that project

management is still a young discipline and is still

developing and improving (Yin 2003).

Munns A K & Bjeirmi B F identify the overlap

between the project and project management

definition and discuss how the confusion between the

two may affect their relationship. It identifies the

different individuals involved in the project and

project management and their objectives,

expectations, and influences. It demonstrates how a

better appreciation of the distinction between the two

will increase project success (Munns, Bjeirmi 1996).

In "A Study on Project Cost Management System

Based on Project Management Theory", Bi Xing

pointed out that project management is different from

general business management, with its unique

characteristics: activity-oriented, non-repetitive,

complex implementation and life-cycle risks, thus

making project management more challenging. In

addition, the definition and meaning of project cost

management are explained (Bi 2007).

Zhou Yongjun, in "Research on the Current

Situation and Development of Project Management",

studies the development history of project

management in China, points out the characteristics

of engineering project management in China and

makes suggestions for its scientific development

(Zhou 2006).

In "Discussion on the use of modern project

management theory in engineering management",

Yang Guang proposes improvement methods for

modern project management in the project

management process to reduce costs (Yang 2021).

1.3 Thesis Organization

In this paper, we analyze a new product design and

market launch project for a domestic company that

plans to design and develop a new model of product

and needs to move forward with the project as soon

as possible to capture the current market share, win

in the market and make a profit.

Based on the initial data, this thesis plans to

analyze the project duration and optimize it using the

CPM (Critical Path Method), PERT (Plan Evaluation

and Review Technology) and TT (Time-cost Trade-

off) methods. In the first part of the thesis, project

management research's background and current

status are synthesized, the second part analyses each

of the three methods used in project management, and

the third part discusses the results. The fourth part

concludes and explores the general applicability of

the findings.

2 METHOD

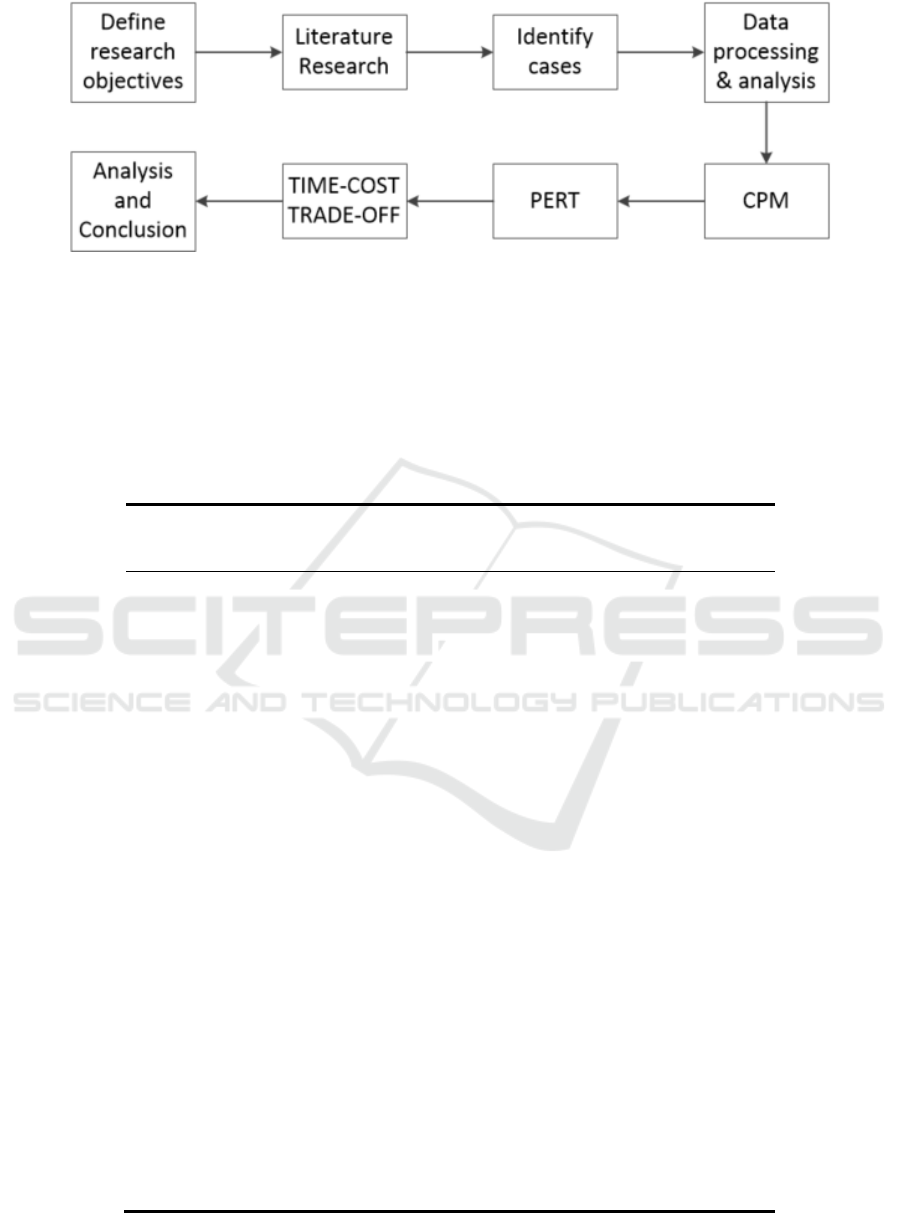

The thesis intends to use a research method

combining theoretical deduction, case induction

method and quantitative analysis method to analyze

theoretical analysis through literature collection and

collation, to analyze the current situation of domestic

and foreign research, to collect domestic and foreign

research results on project duration risk evaluation

and dynamic control, and to explore the theoretical

application of engineering project duration risk

management, especially engineering project duration

risk evaluation and dynamic control. Identify the

influencing factors of project duration risk, and then

complete the research on project duration risk

evaluation and dynamic control by combining with

actual engineering projects. The specific technical

route is as follows.

PMBDA 2021 - International Conference on Public Management and Big Data Analysis

102

Figure 1: Method Roadmap.

2.1 Data

The case data of this thesis is provided by the project

department of a domestic manufacturing company,

and the private information of the company involved

has been blurred to protect the company data. At

present, the company plans to launch a new product.

The project manager gives a description of the

project, the activities and their time give estimates as

shown in table 1, from which a network diagram can

be drawn to find the critical path.

Table 1: Project Schedule Worksheet.

ACTIVITY

Required

Time/Weeks

Immediate

Predecessors

Slack Time

/Weeks

A Research and Manufacturing

A1 Project Launch Phase 2 None 1

A2 R&D Design 5 A1, B1 0

A3 Material Information Integration 5 A2 3

A4 Equipment Purchase 6 A3, B6 0

A5 Layout of equipment 4 A4 0

A6 Order external parts 1 B10 0

A7 Assembly and production 5 A6 0

A8 Produce products 7 A7 0

B Marketing

B1 Market Positioning 3 None 0

B2 Product introduction information 10 B1 3

B3 Product property protection 10 B2 3

B4 Identify promotional vendors 3 B1 2

B5 Trial Promotion 4 A2,B4 0

B6 Review & Decision Making 4 B5 0

B7 Price Analysis 7 None 15

B8 Define market strategy 4 B7,C3,C4 3

B9 Run test market 8 A5,B3.B8 0

Application of Project Management Tools in the Enterprise

103

Table 1: Project Schedule Worksheet (cont.).

ACTIVITY

Required

Time/Weeks

Immediate

Predecessors

Slack Time

/Weeks

B10 Evaluate sales data and revise 5 B9 0

B11 Promote strategy 8 B10 5

C Advertising and Promotion

C1 Determine the communication program 4 B1 8

C2 Evaluation& Decision Stage 2 C1 8

C3 Cooperate with promotional agencies 5 B2,C2 4

C4 Purchase promotion materials 6 B2 3

Considering the uncertainty of the project, the

company also used a more accurate estimation

method for each activity of the project - PERT. The

corresponding Pessimistic, Most Likely, Optimistic

time for each activity is given in Table 2 below,

allowing for a more accurate project estimation.

Table 2: PERT Original Data.

ACTIVITY Predecessor

TIME REQUIRED (WEEKS)

Pessimistic Most Likely Optimistic

A1 None 3 2 1

A2 A1, B1 7 5 4

A3 A2 6 5 4

A4 A3, B6 8 6 4

A5 A4 5 4 3

A6 B10 3 1 0.5

A7 A6 7 5 4

A8 A7 9 7 4

B1 None 5 3 1

B2 B1 12 10 6

B3 B2 13 10 6

B4 B1 6 3 1

B5 A2,B4 6 4 1

B6 B5 6 4 2

B7 None 9 7 4

B8 B7,C3,C4 8 4 3

B9 A5,B3.B8 10 8 5

B10 B9 6 5 3

B11 B10 9 8 5

C1 B1 6 4 3

C2 C1 4 2 0.5

C3 B2,C2 7 5 3

C4 B2 8 6 3

PMBDA 2021 - International Conference on Public Management and Big Data Analysis

104

In addition to the project duration estimation, it is

necessary to use cost-effective methods to reduce the

project duration to minimize project expenditures,

considering that the earlier the project is completed.

Below (Table 3) is the list of activities that potentially

could be completed faster, together with the original

and “crashed” time for each activity and the cost for

crashing. Time and cost values between those shown

may be estimated using linear interpolation. For

example, the duration of A3 can be reduced by 1

week at the cost of $1050.

Table 3: TIME-COST TRADE-OFF Original Data.

Activity ID

Original

Time(weeks)

Crashed

Time (weeks)

additional

cost

Slope

Maximum

Crash Time

A3 5 3 2100 1050 2

A4 6 3 3900 1300 3

A7 6 4 7000 3500 2

B2 10 8 3200 1600 2

B5 4 3 1700 1700 1

B6 4 3 3400 3400 1

2.2 CPM

As a network planning technique, the critical path

method cannot be ignored in practical project

management. The critical path is the logical path in a

design with the longest delay from input to output.

Optimizing the critical path is an effective way to

improve the speed of design work. Generally, the

delay from input to output depends on the path with

the largest delay through which the signal travels,

independent of other paths with small delays. The

critical path method can be used repeatedly in the

optimization design process until it is impossible to

reduce the critical path delay (Pan 2010). The critical

path method is mainly a kind of network diagram

based on single-point time estimation with strict

order. It has emerged as an important aid for projects,

especially for providing a graphical display of the

project and its major activities. This quantitative

information provides an extremely important basis

for identifying potential project delay risks (Du

2007). Li-Li-Ping, Zhao-Xue in "Implementation of

Critical Path Method" explained in detail how to get

the earliest start time(ES), earliest finish time(EF),

latest start time(LS), and latest finish time(LF) by

using Forward Pass and Backward Pass (Li 2005),

which will not be repeated in this paper. Tan Zetao

explained the application of the critical path method

in schedule management in detail in "Research on

project schedule management based on critical path

method" (Tan 2019).

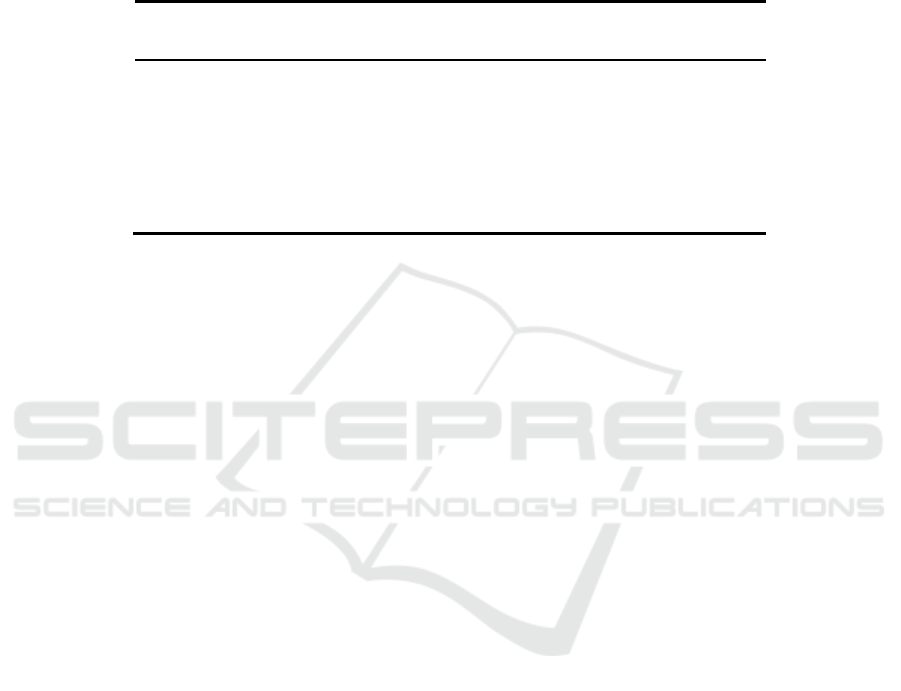

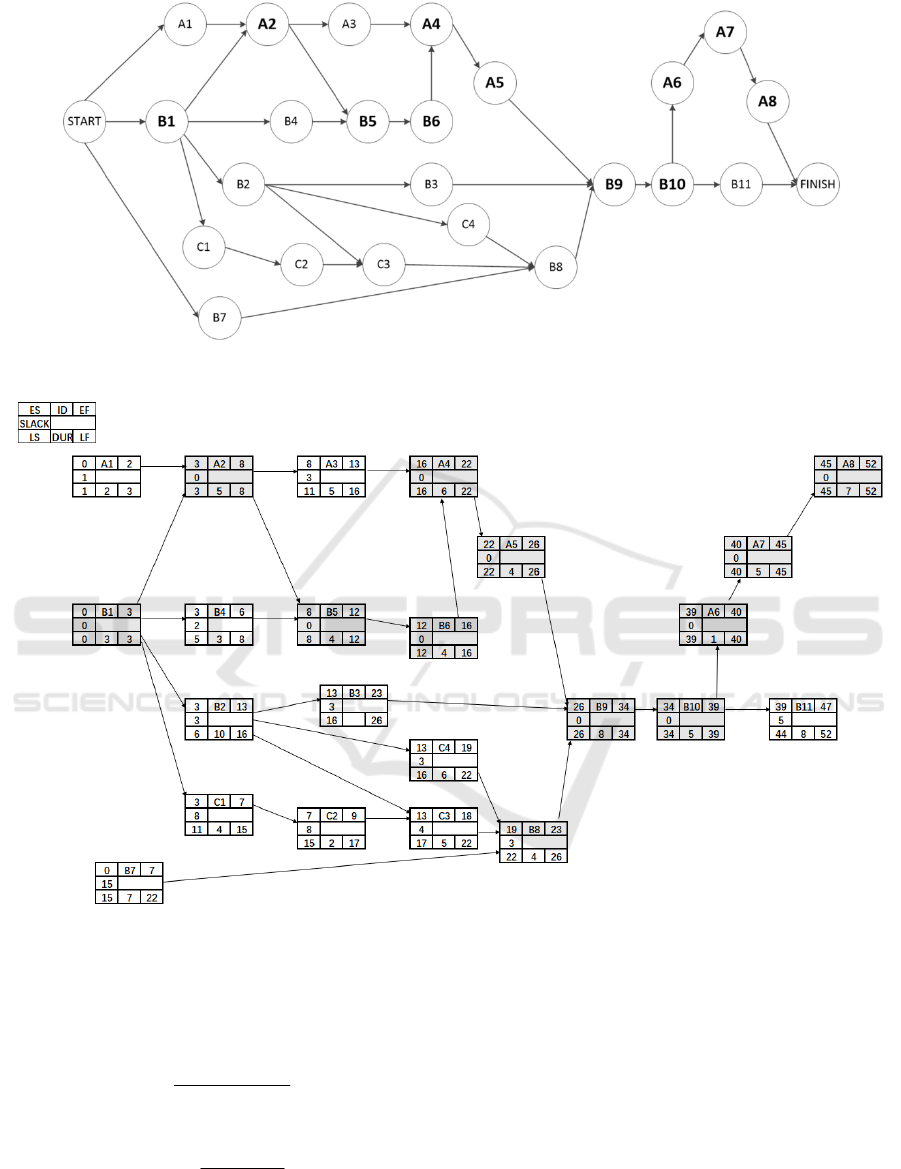

In this thesis, under the condition that the initial

data of the case is known, the critical path method is

used to draw the network flow diagram and get ES、

EF 、 LS 、 LF according to the principle that the

SLACK of activity on the critical path equals 0. The

project duration can be obtained for the subsequent

optimization.

2.3 PERT

Planning review technology is another network

planning technology that is basically consistent with

the principles of the key path method. They all

arrange their project plans as a network map. The

main difference is the time estimation for each

operation. In the critical path method, the estimated

time of each operation is determined. Still, it is

difficult to accurately estimate the duration of each

operation in a project, such as some unheard of

projects or during the project, uncertain due to other

external factors, which will complicate the whole

project. Planning review technology provides a good

solution for this situation (Wu 2016).

In the classical PERT, the duration of each project

operation is a random variable and cannot give its

accurate time value, but its three time estimates can

be given, namely optimistic estimated time 𝑎, most

likely estimated time 𝑚 and pessimistic estimated

time 𝑏. The following assumptions are made: each

operation is independent of each others with no

correlation; the duration of the operation follows the

slice distribution.

The classical PERT approach assumes that all

operations are independent with no correlation.

Therefore, it does not consider critical operations on

Application of Project Management Tools in the Enterprise

105

Figure 2. Activity-on-node Network.

Figure 3: Activity-on-node Network with ES, EF, LS, LF.

non-critical operations and the expected mean 𝐷

ij

for the duration of each operation. And the variance

𝜎

is calculated by the following formula.

ij

(4 )

6

amb

D

++

=

(1)

2

2

()

36

ij

ba

σ

−

=

(2)

The expected mean D

ij

And the variance 𝜎

were

calculated for each operation., The proposed method

transforms the problem of uncertain construction

period into a definite problem that can be solved by

the CPM method. For a given line, the expected

duration 𝐸(𝑇

) and variance 𝜎

are calculated.

()

nij

ET D=

(3)

22

nij

σσ

=

(4)

PMBDA 2021 - International Conference on Public Management and Big Data Analysis

106

The completion probability 𝑃(𝑡 ≤ 𝑇

) under the

planned construction period 𝑇

is calculated with the

following formula.

2

2

1

()

2

0

1

()

2

S

S

n

tT

T

S

n

Pt T e dt

σ

σπ

−

−

≤=

(5)

Based on the initial data, PERT is calculated as

follows.

Table 4: PERT Calculation Results.

ACTIVITY

Predessor

TIME REQUIRED (WEEKS)

Pessimistic Most

Likely

Optimistic Te Var ES EF LS LF SLACK

A1 None 3 2 1 2 0.111 0 2 1 3 1

A2 A1, B1 7 5 4 5.16 0.25 3 8.166 3 8.166 0

A3 A2 6 5 4 5 0.111 8.166 13.16 11 16 2.833

A4 A3, B6 8 6 4 6 0.444 16 22 16 22 0

A5 A4 5 4 3 4 0.111 22 26 22 26 0

A6 B10 3 1 0.5 1.25 0.173 38.66 39.91 38.66 39.91 0

A7 A6 7 5 4 5.16 0.25 39.91 45.08 39.91 45.08 0

A8 A7 9 7 4 6.83 0.694 45.08 51.91 45.08 51.91 0

B1 None 5 3 1 3 0.444 0 3 0 3 0

B2 B1 12 10 6 9.66 1 3 12.66 6 15.66 3

B3 B2 13 10 6 9.83 1.361 12.66 22.5 16.16 26 3.5

B4 B1 6 3 1 3.16 0.694 3 6.166 5 8.166 2

B5 A2,B4 6 4 1 3.83 0.694 8.166 12 8.166 12 0

B6 B5 6 4 2 4 0.444 12 16 12 16 0

B7 None 9 7 4 6.83 0.694 0 6.833 14.66 21.5 14.66

B8 B7,C3,C4 8 4 3 4.5 0.694 18.5 23 21.5 26 3

B9 A5,B3.B8 10 8 5 7.83 0.694 26 33.83 26 33.83 0

B10 B9 6 5 3 4.83 0.25 33.83 38.66 33.83 38.66 0

B11 B10 9 8 5 7.66 0.444 38.66 46.33 44.25 51.91 5.583

C1 B1 6 4 3 4.16 0.25 3 7.166 10.25 14.41 7.25

C2 C1 4 2 0.5 2.08 0.340 7.166 9.25 14.41 16.5 7.25

C3 B2,C2 7 5 3 5 0.444 12.66 17.66 16.5 21.5 3.833

C4 B2 8 6 3 5.83 0.694 12.66 18.5 15.66 21.5 3

END A8,B11 0 0 0 0 0 51.91 51.91 51.91 51.91 0

PERT has the same fundamentals from CPM in

that CPM gives the determined duration of the

operation, which determines the start and end time of

each job, and determines the maneuver time on each

line through the earliest start time and the earliest and

latest end time, thus determining the key line and the

key operation. However, PERT is based on some

uncertainties in the project. Each job gives H time

estimates, respectively optimistic time estimate 0, the

most likely time estimate m, pessimistic time

estimate A, and then calculates the expected value of

the construction period according to the PERT

calculation method, thus transforming into the CPM

algorithm.

The advantages of PERT plan review technology

are mainly reflected in the following aspects:

(1) PERT is an effective method of prior control;

(2) Head at all levels can, through the project time

network analysis, not only can understand the whole

project construction process, understand the task

responsible for the status in the construction process,

enhance the overall view, also can make them more

clear their work focus, the mind on the key points that

Application of Project Management Tools in the Enterprise

107

need to take corrective measures, make the control

work has better results;

(3) PERT is a planning optimization method (Xie

2015).

2.4 TIME-COST TRADE-OFF

First, the time cost is the cost of not reaching a

specific agreement, and it is also the loss of market

opportunity during the waiting time. If a project does

not have a good time-cost trade-off, it is very likely

that the project will not achieve the company's

expected results, which makes time cost trade-offs

particularly important.

Next, we discuss the time cost trade-off method,

combining the critical activity in CPM with the

crashed time and additional cost of the trade-off

activity, following the following pattern"1" prioritize

the critical activity with the lowest single-day

addition cost

"2" Prioritize the critical activity with the longest

trade-off time. "3" prioritize the critical activity that

has the least impact on the critical path of the entire

project process.

These three priority principles are used to analyze

and trade-off the entire project process and carefully

select the critical activities that are needed and worth

trade-offs to ensure the optimal solution for the trade-

off costs.

As we all know, the process and schedule of a

project is never static. Perhaps there is no process in

our project that can satisfy the priority principle "3"

so that in our time-cost trade-off process, the number

of critical paths will most likely increase as the time

of some critical processes changes, which means that

in our step-by-step analysis process, we need to

simultaneously This means that the number of

processes that need to be traded off will also increase

as we move through the analysis. This means that the

number of processes that need to be traded off at the

same time increases as we move through the analysis.

Therefore, when there are too many processes in a

project, and the processes are too closely linked, we

can create an Excel spreadsheet to trade off the

project day by day, process by process.

We list all the paths and the time required for the

paths in the table, bold the font size of the critical

paths, and record the extra cost and the duration of

the tradeoff according to the priority principle

mentioned earlier. And observe whether new critical

paths appear.

For this tradeoff, we chose the A3 process that

followed all three priorities and reduced its time by 3

wks.

Table 5: TIME-COST TRADE-OFF Step 1-3.

Paths Length

A1-A2-A3-A4-A5-B9-B10-A6-A7-A8 48

A1-A2-A3-A4-A5-B9-B10-B11 43

A1-A2-B5-B6-A4-A5-B9-B10-B11 46

A1-A2-B5-B6-A4-A5-B9-B10-A6-A7-A8 51

B1-A2-A3-A4-A6-A7-A8 32

B1-A2-A3-A4-A5-B9-B10-A6-A7-A8 49

B1-A2-A3-A4-A5-B9-B10-B11 44

B1-A2-B5-A4-A6-A7-A8 35

B1-A2-B5-B6-A4-A5-B9-B10-A6-A7-A8 52

B1-A2-B5-B6-A4-A5-B9-B10-B11 47

B1-B4-B5-B6-A4-A6-A7-A8 33

B1-B4-B5-B6-A4-A5-B9-B10-A6-A7-A8 50

B1-B4-B5-B6-A4-A5-B9-B10-B11 45

B1-B2-B3-B9-B10-A6-A7-A8 49

B1-B2-B3-B9-B10-B11 44

B1-B2-C3-B8-B9-B10-A6-A7-A8 48

Table 5: TIME-COST TRADE-OFF Step 1-3 (cont.).

PMBDA 2021 - International Conference on Public Management and Big Data Analysis

108

Paths Length

B1-B2-C3-B8-B9-B10-B11 43

B1-B2-C4-B8-B9-B10-A6-A7-A8 49

B1-B2-C4-B8-B9-B10-B11 44

B1-C1-C2-C3-B8-B9-B10-A6-A7-A8 44

B1-C1-C2-C3-B8-B9-B10-B11 39

B7-B8-B9-B10-A6-A7-A8 37

B7-B8-B9-B10-B11 32

Steps Alternatives Decision Extra

Cost

New Duration

1) A4,A7,B5,B6 Crash

A4

1300 51

1300;3500;1700;3400

2) A4,A7,B5,B6 Crash

A4

1300 50

1300;3500;1700;3400

3) A4,A7,B5,B6 Crash

A4

1300 49

1300;3500;1700;3400

Note: In a project, the benefit of weighing one

process alone may be less than weighing multiple

processes at the same time, so we can achieve time-

cost trade-offs by weighing different processes in

different critical paths.

In this figure, we can see that if we want to shorten

the project duration, we can choose to trade-off A7 or

both B2 and B5. In the comparison table between the

trade-off process and its additive cost

We can find that the extra cost needed to weigh B2

and B5 at the same time is smaller than the extra cost

needed to weigh A7. To follow the first priority

principle, we choose to weigh B2 and B5 at the same

time and record the duration of the weighed items and

the extra cost needed for this tradeoff at the bottom

of the table.

Let's skip to the last tradeoff.

Table 6: TIME-COST TRADE-OFF Step 6.

Paths Length

A1-A2-A3-A4-A5-B9-B10-A6-A7-A8 48 47 46 45 44

A1-A2-A3-A4-A5-B9-B10-B11 43 42 41 40

A1-A2-B5-B6-A4-A5-B9-B10-B11 46 45 44 43 42

A1-A2-B5-B6-A4-A5-B9-B10-A6-A7-A8 51 50 49 48 47 46

B1-A2-A3-A4-A6-A7-A8 32 31 30 29 28

B1-A2-A3-A4-A5-B9-B10-A6-A7-A8 49 48 47 46 45

B1-A2-A3-A4-A5-B9-B10-B11 44 43 42 41

B1-A2-B5-A4-A6-A7-A8 35 34 33 32 31 30

B1-A2-B5-B6-A4-A5-B9-B10-A6-A7-A8 52 51 50 49 48 47

Application of Project Management Tools in the Enterprise

109

Table 6: TIME-COST TRADE-OFF Step 6 (cont.).

Paths Length

A1-A2-A3-A4-A5-B9-B10-A6-A7-A8 48 47 46 45 44

A1-A2-A3-A4-A5-B9-B10-B11 43 42 41 40

A1-A2-B5-B6-A4-A5-B9-B10-B11 46 45 44 43 42

A1-A2-B5-B6-A4-A5-B9-B10-A6-A7-A8 51 50 49 48 47 46

B1-A2-A3-A4-A6-A7-A8 32 31 30 29 28

B1-A2-A3-A4-A5-B9-B10-A6-A7-A8 49 48 47 46 45

B1-A2-A3-A4-A5-B9-B10-B11 44 43 42 41

B1-A2-B5-A4-A6-A7-A8 35 34 33 32 31 30

B1-A2-B5-B6-A4-A5-B9-B10-A6-A7-A8 52 51 50 49 48 47

3 RESULTS AND DISCUSSION

3.1 CPM

Analyzing the network diagram, we can find out the

critical path according to SLACK=0 and get the

project cycle time of 52 days. The activities on the

critical path will affect the completion time of the

whole project, so we can optimize the activities on

the critical path to advance the project completion

time.

3.2 PERT

Various risk factors in the construction of the project

are identified and given sufficient analysis. We can

better prevent and control the construction period

delay.

For this project, the subsequent analysis for

probability of completion of construction period

before node

D

and deviation value of normal

distribution

Z

are calculated using the formula of

normal distribution.

2

()D

Z

μ

σ

−

=

(6)

2

DZ

μ

σ

=+ (7)

It can be calculated that the time required to

complete 90% of the project cycle is 121.973074; the

proportion of projects that can be completed within

130 days is 0.999878867.

3.3 TIME-COST TRADE-OFF

When we find that there are no more processes to be

weighed after a tradeoff, or that the processes to be

weighed are no longer critical activities, the tradeoff

ends. The sum of the extra costs under each table is

calculated, which is the total extra cost needed for

this time cost tradeoff. The item at the bottom of the

penultimate table duration is the total duration of the

project after the time cost tradeoff.

In the case of this project, we can find that it is not

common to find a critical path that can satisfy all

three priority principles at the same time, so we

ranked the three priority principles following their

importance in the time cost tradeoff at the same time,

priority principle 1 is more important than priority

principle 2, and priority principle 2 is more important

than priority principle 3.

Table 7: TIME-COST TRADE-OFF Results.

Number of weeks by which the project can be

shortened

Decision PROJECT DURATION

/Weeks

EXTRA COST

52

1 A4 51 1300

2 A4 50 2600

3 A4 49 3900

4 B2&B5 48 7200

5 A7 47 10700

6 A7 46 14200

PMBDA 2021 - International Conference on Public Management and Big Data Analysis

110

3.4 Discussion of Improvement Points

In view of the above research results, we can find that

the company still has room for optimization and

improvement in the process of project

implementation, and first put forward the following

suggestions:

3.4.1 Equipment Purchase Cycle Is Long

In the project start stage, after the project team is

established, and the project objectives, scope and

basic data are concluded, the project procurement

leader can be invited to intervene, fully understand

the specific needs of the project, and arrange

experienced professional suppliers to intervene in

advance from the existing qualified supplier database

according to the situation. If the resources are

insufficient in the existing supplier information

database, the procurement leader shall conduct high-

quality supplier sourcing and evaluation selection.

According to the project needs, the procurement

leader develops potential suppliers through various

ways to form the Supplier Situation Survey Form.

The procurement leader shall organize demand

department/project responsible department, quality

control department and other relevant departments to

conduct a joint review of potential suppliers, focus on

their basic situation, enterprise matching degree,

quality management, technical ability, delivery

ability, cost control, sustainability, etc., conduct

objective and comprehensive evaluation, form a

complete New Supplier Review Report and signed by

the joint review team, and be listed as potential

qualified suppliers.

The project leader shall formulate a project plan,

confirm key nodes, responsibilities, track and

monitor the supplier performance under agreed terms

and standards, implement positive and negative

incentives to motivate suppliers to cooperate actively

to improve performance level to avoid penalty; the

project team shall obtain management approval to

avoid supplier loss or form negative reputation of

illegal operation.

3.4.2 Equipment Assembly Time Is Lengthy

After project acceptance and delivery, the

procurement leader shall timely organize the relevant

core team and departments to conduct a performance

evaluation of suppliers, including quality

management, cost control, technical ability,

sustainable development, delivery ability, etc., make

comprehensive, specific and objective performance

evaluation scores for suppliers, and form supplier

performance feedback, communicate with the senior

level of suppliers and make targeted project summary

and improvement. As an important part of the

supplier information database, 2, supplier

performance evaluation should form closed-loop

management, continuous dynamic update, and form

a qualified and preferred supplier database. At the

same time, develop and develop supplementary

quality suppliers according to the situation, with a

virtuous cycle.

The value of procurement lies in building an

efficient supply chain, ensuring timely delivery of

purchased raw materials/production equipment by

quality, ensuring smooth production, realising price

reduction of the product life cycle, and succeeding by

making other departments succeed. Supplier

management covers many aspects of supply source

search, contract management and supplier

relationship management. It is the main task of

procurement involving supplier base rationalizations,

supplier selection, coordination, performance

evaluation, potential development and long-term

collaboration where appropriate.

3.4.3 Project Input into the Preliminary

Market Work Needs to Be Optimized

Specific optimization directions are given as follows.

(1) Opportunity Studies. Seek investment

opportunities and identify the investment direction

(2) Preliminary feasibility study. Determine

whether the project has vitality, macro necessity,

construction conditions, profit, etc. Project proposal:

implementation necessity and basis of the project;

product plan, proposed scale and construction site;

preliminary analysis of resources, construction

conditions, cooperative process and equipment;

investment estimate and financing plan; schedule;

preliminary estimate of economic effects and social

benefits

(3) Detailed feasibility study. Detailed technical

and economical demonstration, select the optimal

scheme based on multiple comparisons. The project

feasibility study is based on the project proposal and

the approval documents: whether technical

feasibility; whether significant economic and social

benefits; whether financial profit, human, material

and natural resources; how long the construction is

required; how much investment is required; whether

to raise funds, etc.

(4) Economic evaluation and decision-making.

Reduce and avoid investment risks, give full play to

investment benefits, and improve investment

decisions' scientific level. Financial evaluation is an

Application of Project Management Tools in the Enterprise

111

important basis for investment decisions, loans and

approval for national economic evaluation. Based on

the current financial system, current prices and

relevant regulations, predict the investment project,

solvency, and foreign exchange balance financial

status and determine the project's financial

feasibility.

3.4.4 Promotion Test Has a Large Room for

Improvement

The application of emerging social software and the

new product launch attempts held on the field can be

used as a new direction of promotion to reduce the

unnecessary time and capital cost brought by

traditional promotion methods.

In the preparation stage, I divide the material into

several directions; prepare 3-5 materials and art for

each direction. Select 3 materials from each direction,

three materials in each direction; prepare a landing

page for each direction or a general landing page.

During the test stage, each direction should ensure a

univariate test; more than three accounts in the same

channel. In the re-test stage, the test results in a good

direction, optimize the corresponding landing page,

expand more materials, try different copywriting,

other colleagues with good test results. Finally,

through the review, the reasonable and promotion of

publicity.

4 CONCLUSION

This thesis utilizes three tools, CPM, PERT, and TT,

which are used in the project management process to

predict and manage the cycle time of a case project.

It can be found that these three tools can contribute to

a great extent to the development and advancement

of projects.

In addition, the project management methods

discussed in this thesis are universally applicable.

Whether it is the launch of a new product in the food

industry, the development of a new product in the

industrial manufacturing industry, or the

implementation of a construction project, the

methods and tools discussed in this thesis can be used

for effective project management in all industries.

REFERENCES

Bi Xing. Research on cost management system of

engineering projects based on project management

theory[D]. Tianjin University, 2007.

Du Wenqiang. Application of critical path method in

project management [J]. Civil Construction Academic

Library,2007,8(00):342-343.

Hua Luogeng. Plain talk on integrated methods and

supplements [M]. Beijing: China Industrial Press,

1965.

Li Liping, Zhao Xueying. Implementation of critical path

method[J]. Journal of Hebei Software Vocational

Technology College, 2005, 7(4):61-64.

Liu, Jing. Research on project schedule management

method - critical path method [J]. Marketing World,

2020(16):158-160.

Ma Zunwu. Comparative analysis of Chinese and

American project management knowledge systems

based on process sequencing [J]. Project Management

Technology,2013,11(03):42-45.

Munns A K , Bjeirmi B F . The role of project management

in achieving project success [J]. International Journal

of Project Management, 1996, 14(2):81-87.

Pan Song. EDA Technology and Verilog HDL: Tsinghua

University Press, 2010

Tan Zetao. Research on project schedule management

based on critical path method[J]. Construction

Economics, 2019(9).

Tan Zetao. Research on project schedule management

based on critical path method [J]. Construction

economics, 2019(9).

Tan Zetao. Research on project schedule management

based on the critical path method [J]. Construction

Economics, 2019(9).

Wu Fei Fei. Research on project schedule risk evaluation

and dynamic control based on PERT [D]. Tianjin

University of Technology.

Wu Fei Fei. Research on project schedule risk evaluation

and dynamic control based on PERT [D]. Tianjin

University of Technology, 2016.

Xie WJ. Software development project schedule

management based on PERT and CCPM methods[D].

Zhejiang University of Technology,2015.

Yang Guang. Discussion on the application of modern

project management theory in engineering

management [J]. Engineering Construction and

Design,2021(06):223-224+227.

Yin Yilin, Zhu Junwen. Research on the development of

project management knowledge system[J]. China Soft

Science,2003(08):103-105+95.

Zhou Yongjun. Research on the status and development of

project management [D]. Northeast Normal University,

2006.

PMBDA 2021 - International Conference on Public Management and Big Data Analysis

112