Discussion on the Measures to Promote the Development

of High-quality Inland Ships

Fangfang Jiao

Institute of Water Transport Science of the Ministry of Transport, Beijing, China

Keywords: Inland ship, Technical level, Policy

Abstract: In the 21st century, the inland ships in China have been greatly developed. The large-scale and professional

development trends of ships are obvious, and the overall technical level of ships has been greatly improved.

However, the quality of ships constructed is still evidently poorer than that of inland ships in Europe, the

overall existing ships are not green enough, and the fleet capacity cannot be updated promptly. For the high-

quality development of inland ships, this paper recommends the combination of the upgrading of inland

ships with adjustment, transformation, and updating of ship industry structure, promoting the high-quality

development of inland shipbuilding industry on the supply side, presenting and promoting optimal ship

types, and implementing economic policies to encourage the adjustment of the technical-level structures of

inland ships.

1 INTRODUCTION

Compared to highway and railway transportation,

inland river transportation has the advantages of

large capacity, small land area occupied, low energy

consumption, environmentally friendliness, and low

marginal cost. China has abundant inland river

transportation resources. Since the reform and

opening up, especially since the 21st century, the

inland shipping has developed remarkably, and

played an important role in supporting the economic

and social development of the river basin. In the

future, the high-level inland channels of China will

be doubled to 2.5 km. Instructed by the plan of

forming an inland channel network connecting rivers

to the sea, it is a strategic opportunity to improve the

overall quality and technical level of inland ships, to

make full use of the channel infrastructure capacity,

and to improve the overall benefit of inland river

transportation system.

2 OVERVIEW OF CHINA

INLAND VESSELS

At the end of 2019, China has 119.5 thousand inland

vessels, with a total load of 121 million tons. The

inland rivers are widely distributed. The types of

ships are various, and the sizes are relatively small

in general. 70% of them are small vessels with a

capacity of less than 1000 tons. The economy of

ship transportation has an obvious relationship with

its capacity. The low-cost advantage of inland river

transportation is obvious when the capacity reaches

about 1000 tons. Therefore, ships with a capacity of

1000 tons should be the dominant tools of inland

river transportation. In China, the sum of capacities

of vessels with a capacity of ≥ 1000 tons accounts

for about 75% of the total capacity. Therefore, the

following sections focus on the analysis of the

situations of the inland vessels with a capacity of ≥

1000 tons in China.

In the year of 2020, 34.3 thousand inland ships

with a capacity of ≥ 1000 tons were located in

China. The total and average loading capacities were

94.05 million and 2738 tons, and the mean ship age

was 9.88 years. The owners of these ships, more

than 4800 enterprises and more than 10000

individuals, are relatively scattered.

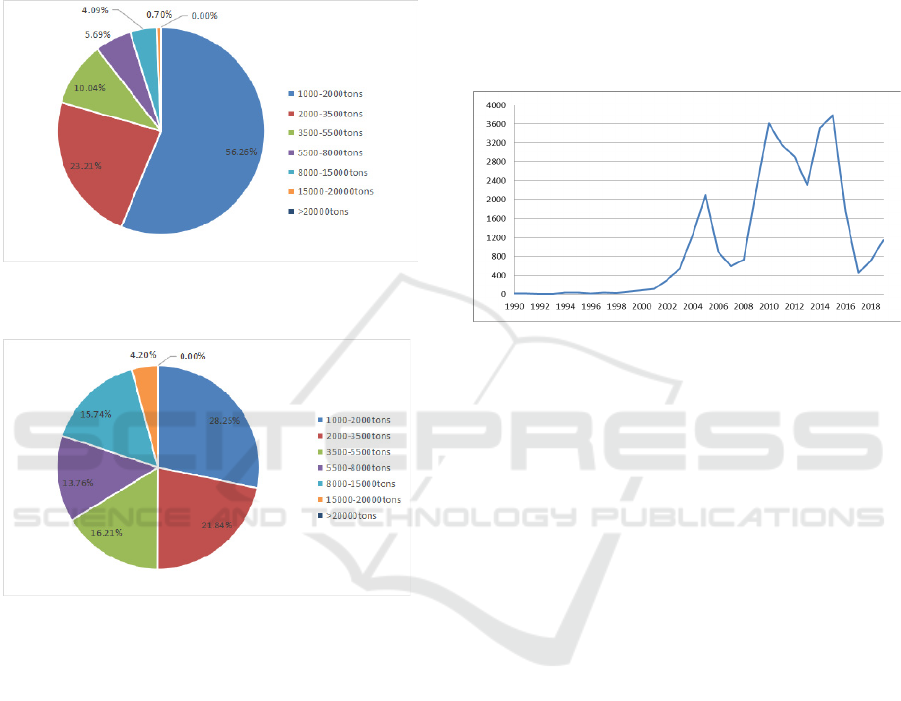

In terms of the number of ships with a specific

capacity, the number of ships with a capacity of <

5500 tons accounts for a large proportion of almost

89%, and the number of ships with a capacity of

1000 to 2000 tons accounts for 56%, that of ships

with a capacity of 2000 to 3500 tons accounts for

23%, and that of ships with a capacity of 3500 to

5500 tons accounts for 10%, as shown in the Figure

Jiao, F.

Discussion on the Measures to Promote the Development of High-quality Inland Ships.

In Proceedings of the 7th International Conference on Water Resource and Environment (WRE 2021), pages 435-439

ISBN: 978-989-758-560-9; ISSN: 1755-1315

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

435

1. In terms of the total loading capacity, the total

capacity of ships with a capacity of < 5500 tons

accounts for about 66%. Among them, the total

capacities of ships with a capacity of 1000 to 2000,

2000 to 3500, and 3500 to 5500 tons account for

28%, 22%, and 16%, respectively, as shown in the

Figure 2.

Figure 1: Proportions of numbers of inland ships with a

capacity of ≥ 1000 tons.

Figure 2: Proportions of total capacities of inland ships

with specific capacities of ≥ 1000 tons.

In terms of the ship age, among the inland

vessels with a capacity of ≥ 1000 tons, 16.6

thousand ships, with a total capacity of 4127 million

tons, were built before September 1, 2011, as shown

in the Figure 3. The number and capacity account

for 53.04% and 47.76% of the total values. 715 old

ships with an age of ≥ 18 years, with a total capacity

of 1.31 million tons, account for 2% and 1.5% of the

total values, respectively. 78 special-overhaul ships

have an age of over 29 years, with a total capacity of

150 thousand tons. Most of the inland ships were

built in 2009-2015, accounting for 70% in number.

This is closely related to the strong demand for

inland river transportation and implementation of the

standardization policy of inland ship type. During

the implementation of the policy of inland ship-type

standardization, from October 1, 2009 to December

31, 2017, 21.5 thousand small and old ships, with a

total capacity of 5874.4 thousand tons, were

disassembled. 22.5 thousand ships, with a total

capacity of 36941.2 thousand tons, were constructed

during 2009-2015. The total capacity of ships

constructed is 6.29 times that of the ships

disassembled. Therefore, the ship-type

standardization policy had certain promoting and

driving effects, but more new ships were constructed

due to the demand of capacity expansion and

updating driven by the market.

Figure 3: Distribution of the ages of inland ships.

3 PROBLEMS IN THE

DEVELOPMENT OF INLAND

SHIPS

3.1 Poor Overall Quality of Inland

Ships Constructed

The report of the 19th National Congress of the

Communist Party of China declares that the

structural reform on the supply side should be

deepened, and the improvement of quality of the

supply system should be the main task in the

building of modern economic system (Jia, 2015).

Since 2003, a series of inland ship-type

standardization policies have been implemented. By

encouraging the dying out of small ships, which are

adverse to the efficiency of ship lock and violate

market demand, as well as the old, unsafe, energy-

consuming, and environmentally hazardous ships,

the economic, technological and green development

levels of the inland ships in China have been

comprehensively improved. In the end of 2019, the

average net load of inland ships in China was 1095

tons, 10.6 times that in 2000. The adjustment of

transport capacity structure has achieved remarkable

results, the efficiency of inland river transport has

been effectively improved, and the quality of inland

WRE 2021 - The International Conference on Water Resource and Environment

436

ships on the supply side has been greatly improved,

which has greatly promoted the development of the

shipbuilding industry. After the development of

inland ships in the past 20 years, a strong inland

transport fleet adapting to the rapid economic and

social growth has already formed. However, the

overall quality of inland ships is still far poorer than

that of European inland ships and coastal ships of

China, and the poor quality is the bottle neck of

shipping on the supply side.

Due to the long service life of European inland

ships, the requirements for materials, equipment, and

technologies during the construction are relatively

high, and more attention is paid to maintenance in

operation. 40-year-old ships still have good ship

conditions, capacities, and appearance, forming an

inland river landscape. In contrast, during the

construction of inland ships in China, the cost is

more important, and the requirements for materials

and technologies are less important. In addition,

maintenance is lacked during the operation.

Although the ships are young, their conditions,

capacities, and appearance are not as good as those

of the old ships in Europe, and are not in harmony

with the development levels of cities along the rivers

(CCNR, 2013).

The service life of coastal fleet of China is also

shorter than that of Europe, but the overall

conditions, capacities, and appearance of coastal

ships are qualified, showing no obvious difference

compared to Europe. The differences between the

coastal and inland fleets of China are closely related

to the attributes of their individual markets and

development of shipbuilding industry of China

(UNECE, 2011).

The construction specifications of coastal and

oceangoing ships are consistent, and the marketing

operation of coastal ships is closely correlated with

international ocean transportation. The circulation

between coastal and oceangoing ships is extensive,

and the construction of coastal ships is in line with

the world, so the overall construction quality level of

ships is synchronized with that in the world. On the

other hand, the shipbuilding industry of China is one

of the three largest shipbuilding bases in the world.

In 2019, the capacity output of global shipbuilding

in the world reached 98.82 million tons, while that

of China reached 36.72 million tons, accounting for

37.2%. The shipbuilding business is mainly export-

oriented, and is one of the most internationalized

industries in China. The market is highly

concentrated in China Shipbuilding Group Co., Ltd,

with the market share of as high as 90%. From

techniques and operation rules to various regulations

and on-site managements, all the construction

procedures are implemented in accordance with the

requirements of international norms.

In contrast, the construction of inland ships is

different. First, the inland ship construction

specifications and standards of China are formed

after learning from the relevant experience of the

former Soviet Union and European inland ships.

However, different from the oceangoing ships

circulating in a worldwide market, the inland ship

market is relatively independent, lack of room for

continuous improvement through global

competition.

Secondly, the distribution of inland ship yards is

scattered and disorderly, and most of them are

private enterprises. The shipbuilding and office

places are mostly rented river beach land and

wasteland. The facilities are simple and crude, the

production mode is extensive, and the techniques,

operation specifications, and on-site managements

are distinct. Additionally, the inland shipping

enterprises, which are mainly individual or small-

and medium-sized enterprises, are very sensitive to

the shipbuilding cost, leading to the big gap between

overall quality of inland ships and that of

oceangoing ships.

Thirdly, the inland ships are inexpensive and

low-valued compared to coastal ships, lack of long-

term attention. Under most circumstances, an inland

ship is exclusively designed and built by a private

small- and medium-sized shipyard. The ship design

and ship-type R & D abilities are far weaker than

those of the coastal ones, and both the ship design &

manufacturing and shipping enterprises lack

innovations and abilities.

Inland shipping enterprises are usually confused

when they build new ships. Generally, no shipyard

actively designs, develops, and promotes new ship

types, and only the existing ship types are selected

for construction and modification according to the

owner's experience, leading to slow promotion of

new ship types and new techniques.Innovations that

are the result of extensive dedicated research

projects are rarer and even hydrodynamic analysis or

hullform optimization through Computational Fluid

Dynamics (CFD) or model tests are often not

executed during the design stage of inland vessels.

In contrast, for seagoing ships, this is common

practice. The reasons behind this are not only the

gaps in the owner’s expertise and lack of financial

leeway, but also include the low building cost and

fuel consumption of inland vessels compared to

seagoing ships. This implies that the potential gain

from innovations is often not large enough to justify

Discussion on the Measures to Promote the Development of High-quality Inland Ships

437

large investments in research. Notable exceptions

include the crashworthy Y-shaped side structure

(Ludolphy, 2001), air lubrication of the hull to

reduce resistance (Foeth, 2008) and bio-inspired

propulsion (Berg, 1996; O-foil, 2015). These

innovations are all preceded by extensive research.

3.2 Great Environmental Protection

Pressure of The Existing Inland

Ships

The inland river transportation will have an

environmental impact on both banks, and this is

different from the main impact of marine

transportation, which is only caused by the entry and

exit of ships in the port and terminal operation.

However, the release of relevant environmental

protection standards of inland ships in China missed

the development stage of fleet scale fast expansion

and elimination and renewal of a large number of

old ships, directly affecting the overall

environmental protection level of inland ships.

Taking the emission of NOx as an example, the

inland-ship regulations phase I and phase II were

implemented in 2011 and 2015, respectively. About

50% of the existing inland ships were built before

the implementation of regulation phase I, and the

engine maintenance was insufficient in the actual

operation of inland ships, resulting in the

environmental protection pressures of ships such as

air pollution.

3.3 Difficult Renewal of the Inland

Shipping Enterprises

The recent survey of development of inland shipping

reports that most of the shipping enterprises tend to

upgrade the inland ships. The reasons are the

following. First, with the innovative technologies

such as new engine energy-saving technologies, the

economy of new ships will be greatly improved;

Secondly, the maintenance cost of most of the inland

ships will increase if their ages are longer than 10

years, and the economy is far lower than that of new

ships; Thirdly, the supply and demand of

transportation capacity in the inland shipping market

of China are more and more stable, and the focus of

business is changing from rapid expansion of

transportation capacity to occupy the market to the

improvement of operation efficiency of current

market.

The inland shipping enterprises surveyed reflect

that the disassembling of 10-year-old ships costs a

lot, and the ideal dealing mode is to sell it as a

second-hand ship. Some second-hand ships can be

sold to Southeast Asia. However, the inland river

freight volume of China is the largest in the world.

Especially, since 2000, the transportation capacity of

inland ships was expanded rapidly. The demand for

inland ships in Southeast Asia and other regions is

negligible.

4 SUGGESTIONS FOR

PROMOTING THE

DEVELOPMENT OF

HIGH-QUALITY INLAND

SHIPS

Currently, the shipbuilding industry is in the new

situation of market downturn and increasing

pressure of transformation, and the problem of

overcapacity is obvious. Most of the inland

shipyards are built near rivers. The environmental

protection pressure and safety risk along the Yangtze

River are relatively high, the adjustment,

transformation, and upgrading of industrial structure

are urgent. It is also urgent to integrate and optimize

the existing assets, by centralizing technologies,

intelligence, facilities, and other resources, and to

promote the integration and regrouping of inland

shipbuilding enterprises for the purpose of scale

benefit. The overall strategy to promote the high-

quality development of inland ships is to combine

the upgrading of inland ships with the structural

adjustment and transformation-upgrading of the

shipbuilding industry, to encourage the

disassembling and building activities of shipping

enterprises with financial subsidies, to reduce the

financing and insurance costs of shipping enterprises

by introducing financing and insurance institutions,

to reduce the increase of shipbuilding costs caused

by the improvement of quality, and to encourage the

daily maintenance activities of inland ships.

1. Promoting the high-quality development of

inland ship building industry on the supply side.

Promote the merging, regrouping, and cooperation

of large state-owned shipbuilding groups with

advanced technologies and strong shipbuilding

abilities with inland ship building enterprises with

strong comprehensive abilities, and improve the

design, construction technology, and equipment of

shipyards to improve the construction quality of

inland ships. The mode of "government-funded

support" should be adopted to guide the cooperation

between shipbuilding enterprises. The large-scale

ship enterprises provide technical assistance, and

WRE 2021 - The International Conference on Water Resource and Environment

438

small- and medium-sized shipbuilding and

supporting enterprises participate in the R & D,

production and manufacturing, R & D and

production of supporting modules and various parts,

to improve the overall technical level of inland ship

building industrial chain. Promote the

transformation of some shipbuilding enterprises into

ship maintenance and repair enterprises, develop the

entire-life-cycle service industry for inland ship

repair and maintenance, and improve the daily

maintenance level of inland ships.

2. Releasing and promoting preferable ship

types. The ship type optimized should be selected as

the parent ship for further modification and redesign

of the cabin layout and appearance. By optimizing

the materials and equipment operation and

improving the construction technologies,

characteristic inland ships which adapt to the level

of economic and social development in China can be

built, and the ship types should be released to the

society to encourage the development and

application of these types in primary inland river

shipyards. In addition, the technical schemes of

inland ships with advanced technologies such as new

energy, clean energy, and intelligence should be

released as demonstrations to lead the green and

intelligent development of inland ships.

3. Implementation of economic encouragement

policies to adjust the technical-level structure of

inland ships. Compensate the shipping enterprises

with a certain amount of subsidy for their

disassembling of inland ships with ages of ≥ 10

years, and provided subsidy for those enterprises

building ships with types encouraged after the

disassembling. On the other hand, introduce large-

scale financing and insurance institutions to provide

financing convenience for the shipping enterprises

that perform entire-life-cycle management and

maintenance of new inland ships, to reduce the

financing and insurance costs.

ACKNOWLEDGMENT

This research is supported by the research project on

the safe operation guidelines and technical standards

of the shore power supply of international sailing

ships, the special self-help project for the innovation

of green and intelligent inland ships and the special

project of green ecological and environmental

protection ship engineering.

REFERENCES

Berg, W. van den. (1996). The Whale Tail Wheel. ITTC

1996 Workshop on Unconventional Propulsion.

Central Commission for the Navigation of the Rhine.

(2013). Inland Navigation in Europe Market

Observation 2013, Panteia.

Foeth, E. J. (2008). Decreasing frictional resistance by air

lubrication. Amsterdam: 20th International Hiswa

Symposium on Yacht Design and Yacht Construction.

Jia D. S. (2015). Inland River Advantage Strategy.

Beijing: People's Communications Press Co., Ltd.

Ludolphy, H. (2001). The unsinkable ship: development of

the Y-shape support web. Copenhagen: 2nd

International Conference on Collision and Grounding

of Ships.

O-foil. (2015, July). www.ofoil.nl

United Nations Economic Commission for Europe.

(2011). White paper on Efficient and Sustainable

Inland Water Transport in Europe. New York and

Geneva.

Discussion on the Measures to Promote the Development of High-quality Inland Ships

439