Utilization of Millet Seed Flour (Panicum miliaceum L), Chia Seed

Flour (Salvia hispanica), and Sesame Seeds (Sesamum indicum) on

Making High-fibre Flakes

Putri Avidianto Excelinda, Mira Sofyaningsih

a

and Iswahyudi

Nutrition Study Program, Faculty of Health Sciences, University of ňhammadiyah Prof. Dr. HAMKA,

Limau II Street, South Jakarta, Indonesia

Keywords: Chia Seeds, Dietary Fibre, Millet Seeds, Sesame Seeds.

Abstract: Millet seeds have the potential a raw materials food with protein and fibre content. One of the very popular

food is flakes which can be made by combining millet seeds, chia seeds, and sesame seeds. The purpose of

this study was to produce high-fibre flakes that have a good sensory property and to identify the physical and

chemical properties. The design of this study used a completely randomized design of one factor and two

replications. The treatment factors in this study were flakes formulation with ratio of millet and chia seed

flour (4 levels), namely F1 (90%:5%), F2 (85%:10%), F3 (80%:15%), F4 (75%:20%). The results of this

study showed that millet seed flour obtained water content 16.3%, ash content 2.17%, protein 9.74%, fat

0.11%, carbohydrates 71.7%, dietary fibre 12.5%, and 72.2% yield. The results of the organoleptic test

showed that flakes were not significantly different from the hedonic test (p>0.05), while the hedonic quality

of colour and aroma were significantly different (p≤ 0.05). The best formula is F4 with ash content 3.07%,

water content 1.96%, protein content 6.74%, fat content 14.1%, carbohydrate content 74.2%, dietary fibre

content 26.1%, and 450.7 kcal. These flakes are claimed to be high-fibre foods.

1 INTRODUCTION

Proso millet (Panicum miliaceum L) or white millet

is one of the small seed cereals that is usually for bird

feed. The low use of millet seeds in food products is

due to the lack of references and knowledge about the

characteristics and content of millet seeds (Marta,

2016). The result of chemical analysis in research

Prabowo (2010) nutrient content of white millet seed

flour is 9.19% of water, 1.80% of ash, 2.58% of fat,

11.29% of protein, 56.53% of starch, 74.52% of

carbohydrate, and 2.01% of crude fibre. According

Kumar et al., (2018) that proso millet has a higher

content of essential amino acids (leucine, isoleucine,

and methionine) than wheat, and is rich in vitamins

and minerals such as copper and magnesium, vitamin

B6 and folic acid. India, Russia, Nigeria, and China

used Millet seeds as a food source of carbohydrates

(Amadou et al., 2014). The products made include

bread, pasta, porridge, biscuits and drink

fermentation, both of whole millet seeds or combined

a

https://orcid.org/0000-0001-5053-8632

with other grains (Das et al., 2019). Several recent

studies develop millet seeds in the manufacture of

product such as instant baby porridge, dry noodles,

snack bar, and millet sprout flour (Husna et al., 2012;

Atmaja and Sari, 2017; Adi Sarno et al., 2018; Dewi

et al., 2018).

Chia seeds have been approved as a novel food by

the European Parliament and of the Council (E.U

Commission, 2015). Chia seeds are report be a safe as

food because it has no side effects or allergen (EFSA,

2009). Chia seeds are a good source of omega-3 and

omega-6 fatty acids. In addition, chia seeds have a

high protein content (16-26%) and are rich in

essential amino acids, especially leucine, lysine,

isoleucine, and valine, as well as a source of dietary

fibre (23-35%) and antioxidants (Vázquez-Ovando et

al., 2010; Marcinek et al., 2017). Chia seeds have to

used as a staple food by the Aztecs and Mayans

(Muñoz et al., 2013). Recent research has shown that

chia seeds can using to produce foods such as

biscuits, pasta, and bread (Borneo, 2012; Oliveira et

al., 2015; Romankiewicz et al., 2017).

242

Excelinda, P., Sofyaningsih, M. and Iswahyudi, .

Utilization of Millet Seed Flour (Panicum miliaceum L), Chia Seed Flour (Salvia hispanica) and Sesame Seeds (Sesamum indicum) on Making High-fibre Flakes.

DOI: 10.5220/0010758800003235

In Proceedings of the 3rd International Conference on Social Determinants of Health (ICSDH 2021), pages 242-248

ISBN: 978-989-758-542-5

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Sesame seeds are known as the “Queen of

oilseed” due to their high oil content and resistance to

oxidation and rancidity (Myint, 2020). Traditionally,

sesame seeds have to be used as a health food in Asian

countries and is use to enhance taste and aroma of

food, including as a topping for soups, salad, cereals

and yoghurt (Asghar et al., 2014). Sesame seeds

contain large amounts of oil, protein, carbohydrates,

essential mineral, methionine, and tryptophan, as well

as secondary metabolites such as lignans, saponins,

flavonoids, and phenolic compounds. In addition, as

a source of calcium, phosphorus, and iron, and rich in

vitamins B and vitamin E (Hegde, 2012).

Food sources of fibre are commonly found in

plant foods such as cereals, fruits, vegetables, grains,

and nuts. Based on Riskesdas (2018), it is state that

95.5% of the population aged ≥ 5 years lack fibre

consumption (vegetables and fruits). WHO

recommends dietary fibre intake in the range of 25-

30 g/person/day. Meanwhile, based on the RDA, in

2019 the average dietary fibre recommendation for

Indonesians was 30 g/person/day. Dietary fibre is

able to provide a feeling of fullness for longer,

because foods with high fibre content take longer to

digest so it is good as a food source at breakfast. One

of the popular alternative breakfast products is flakes,

especially for children (Aulia et al., 2017). The

limited time in preparing breakfast made the interest

in flakes increased. This makes flakes as one of the

right choices for the ready to eat product category that

is easy, fast, and practical to serve. Flakes are

generally made from corn (corn flakes) and wheat

(wheat flakes) (Situmorang et al., 2017). Commercial

flakes have nutritional value per 100 g ranging 310-

367 kcal of energy, 1.7 g of fat, 80-83 g

carbohydrates, 3.3-17 g of fibre, and 6.7 -10.3 g of

protein.

In this study, the millet seeds are selected as raw

material for flakes to replace corn flour because the

protein content of millet seed flour is higher (11.29

g/100g) than corn flour (8.78 g/100g), and product

based on millet seed flour have a glycemic index

content (50.2-64.7) which is lower than product from

corn flour (78.5-86.3) (Mcsweeney, 2014). In

addition, millet seed flour is gluten-free so it is safe

for people has disability from celiac disease (gluten-

intolerance) from which they cannot consume gluten-

containing foods such as wheat (Sarita and Singh,

2016). Dietary fibre in millet seeds also has positive

effects on health, such as anti-inflammatory,

antidiabetic, anti-hypercholesterolemia, and

antiradiation (Sulistyaningrum and Aqil, 2017).

In improving the nutritional value of flakes,

required other ingredients besides flour millet seeds

like chia seeds and sesame seeds which is a functional

food ingredient with bioactive components. Chia

seeds flour has a high protein content (26.2%), high

dietary fibre (30.24%), and high levels of alpha-

linolenic acid (68.0%) which are good for health

(Ayza and Coates, 2011). Sesame seeds are high in

protein (19.3 g/100 g), rich in calcium (1125 mg/100

g) and iron (9.5 mg/100 g) in the Indonesian food

composition table (Zulfianto, 2017). The sesame

seeds used in this study were roasted sesame seeds as

a sprinkling on the flakes to produce a nutty aroma

which is expected to increase acceptance of the

product. Product flakes-based millet, chia, and

sesame seeds are expected to be an alternative for

nutritional needs at breakfast. In addition, efforts to

create products with a low glycemic index, rich in

fibre, and gluten-free.

2 MATERIAL AND METHODS

2.1 Material

Millet seeds, chia seeds, sesame seeds, tapioca flour,

milk powder, sugar and salt were purchased

commercially from local market.

2.2 Methods

2.2.1 Millet Seed Flour

Millet seeds were cleaned for extraneous materials,

and then soaked in water for 24 hours. The water

soaking needs to be replaced with clean water every

12 hours. After that, blanching for 2 minutes and

continued drying in an oven at 100℃ for 30 minutes.

After obtaining the dry millet seeds, they were milled

and sieved of 60 mesh with two repetitions in order to

obtain more optimal millet seed flour.

2.2.2 Chia Seed Flour

The chia seeds are roasting for 6 minutes, stirring

frequently. Then roasted chia seeds are milled using

blander and sieved using a sieve of 60 mesh.

2.2.3 Sesame Seed Roasted

The sesame seeds in this study were not made into

flour, but only through a roasting process. The sesame

seeds are roasting for 5 minutes while stirring then

removed.

Utilization of Millet Seed Flour (Panicum miliaceum L), Chia Seed Flour (Salvia hispanica) and Sesame Seeds (Sesamum indicum) on

Making High-fibre Flakes

243

2.2.4 Blend Formulation and Preparation of

Flakes

The flakes formula used consisted of 4 levels of

treatment using a ratio of millet seed flour to chia seed

flour are F1 (90%:5%), F2 (85%:10%), F3

(80%:15%), dan F4 (75%:20%). Roasted sesame

seeds added a fixed amount of 10 grams of each

formulation. The formulation for making these flakes

refers to Khairunissa et al. (2018). The main

ingredients were mixed according to the treatment

and added 5 grams of tapioca flour as a binder for the

dough. Then add 10 grams of powdered milk, 15

grams of sugar, and 1 gram of salt to give the flakes a

taste. The entire dough is mixing with water as much

as 45% of the total dough until completely

homogeneous. Furthermore, the dough is steamed to

help pre-gelatinize the starch for 10 minutes, in this

process there is a change in the starch granules and

the breakdown of hydrogen bonds that function to

maintain the structure so that it cannot return to its

original shape (Muflihani, 2016). Then the dough is

flattened with a noodle maker on a scale of 3 and

printed manually using a knife, then baked using an

oven at 120℃ for 10 minutes.

2.2.5 Physical Properties of Flour

Physical properties that can be seen is the yield of

flour. Yield is the percentage of the main raw material

that can be used as a final product. The purpose of the

yield is to find out how much flour is produced from

the raw materials used. The measurement of flour

yield is calculated based on the ratio of the weight of

flour obtained with the weight of the raw material

expressed in percent (%).

2.2.6 Proximate Analysis of Ingredients and

Flakes Samples

The protein, fat, ash, moisture content of the flour and

flakes with the best formula determined by the SNI

01-2891-1992 proximate analysis. Carbohydrate

content was estimate by difference and caloric value

was calculated by using Atwater factor (4 × protein,

9 × fat, and 4 × carbohydrate). Dietary fibre with

AOAC 1990.9855.29 proximate analysis.

2.2.7 Sensory Evaluation

Sensory evaluation was carried out by 50 consumer

panelists. Sensory analysis of flakes includes hedonic

test and hedonic quality test. The hedonic test was

carried out to determine the most preferred flakes

formula by the panelists. The assessed attributes

include color, texture, taste, aroma, and overall. The

score scale used is a score of 1 (very dislike) to a score

of 7 (very much like). The hedonic quality test is more

specific, not just likes or dislikes. The score scale

used to determine the color quality is a score of 1

(very not strong dark cream color) to a score of 7

(very strong dark cream color), for the aroma used a

score of 1 (very not strong nutty aroma) to 7 (very

strong nutty aroma), for the taste used a score of 1

(not very strong sweet/savory taste) to 7 (very strong

sweet/ savory taste), for the texture used a score of 1

(very not crispy) to 7 (very crispy).

2.2.8 Statistical Analysis

Data were analysed statistically by Analysis of

Variance (ANOVA) when the data were normally

distributed, and if there were significant differences

then conducted a further test using Duncan’s Multiple

Range Test (DMRT). Meanwhile, data that were not

normally distributed were analysed using the Kruskal

Wallis test, and if there were significant differences,

then carried out further using the Mann Whitney test.

3 RESULT AND DISCUSSION

3.1 Physical Properties of Flour

The yield of millet seed flour of 72.2% is not much

different from Mahendra (2019) studies ranged

between 65.27% - 84.60%. This is related to the

processing method carried out such as the soaking

process in this study which reduces water-soluble

components such as potassium, sodium, and tannin in

millet seeds, so the yield of millet seed flour produced

is not much different from previous studies

(Mahendra, 2019). The yield of chia seed flour

produced was 85.0% is no different from

Riernersman (2016) study of 94.0%. The high and

low yields produced are due to the evaporation of

substances contained in chia seeds during the roasting

process, such as evaporation of water and the process

of browning the seed (Purnamayanti et al., 2017).

3.2 Chemical Composition of Millet

Flour

The chemical composition of millet flour is shown in

table 1. Millet flour produced in this study has a

moisture content of 16.3% was higher than millet

flour produced at the research Prabowo (2010) and

Dewi et al (2018) respectively by 9.19% and 8.35%.

The protein content of millet seed flour produced was

ICSDH 2021 - International Conference on Social Determinants of Health

244

9.74% lower than the research conducted by Prabowo

(2010)

at 11.29% but not much different from the

research conducted by Dewi et al (2018) which was

9.77%. This decrease is due to protein denaturation

by high heating. The heating process can damage

amino acids as protein-forming so that the heating

temperature can reduce protein levels (Yuniarti et al.,

2013). The fat content of millet seed flour produced

was 0.11% lower than that of millet seed flour in

Prabowo (2010) study of 2.58% and Dewi et al

(2018) of 7.57%. The decrease in fat content was

caused by the active lipase enzyme during the soaking

process which was secreted by lactic acid bacteria.

Lipase enzymes will hydrolyse fats into simpler

compounds such as fatty acids and glycerol

(Mahendra, 2019). According to Rani et al (2013) fat

content can also decrease due to the soaking process

followed by blanching. The dietary fibre content of

millet seed flour produced was 12.5% higher than the

research conducted by Dewi et al (2018) which was

5.93%. The dominant dietary fibre content in millet

seeds is insoluble dietary fibre (Manish, 2018).

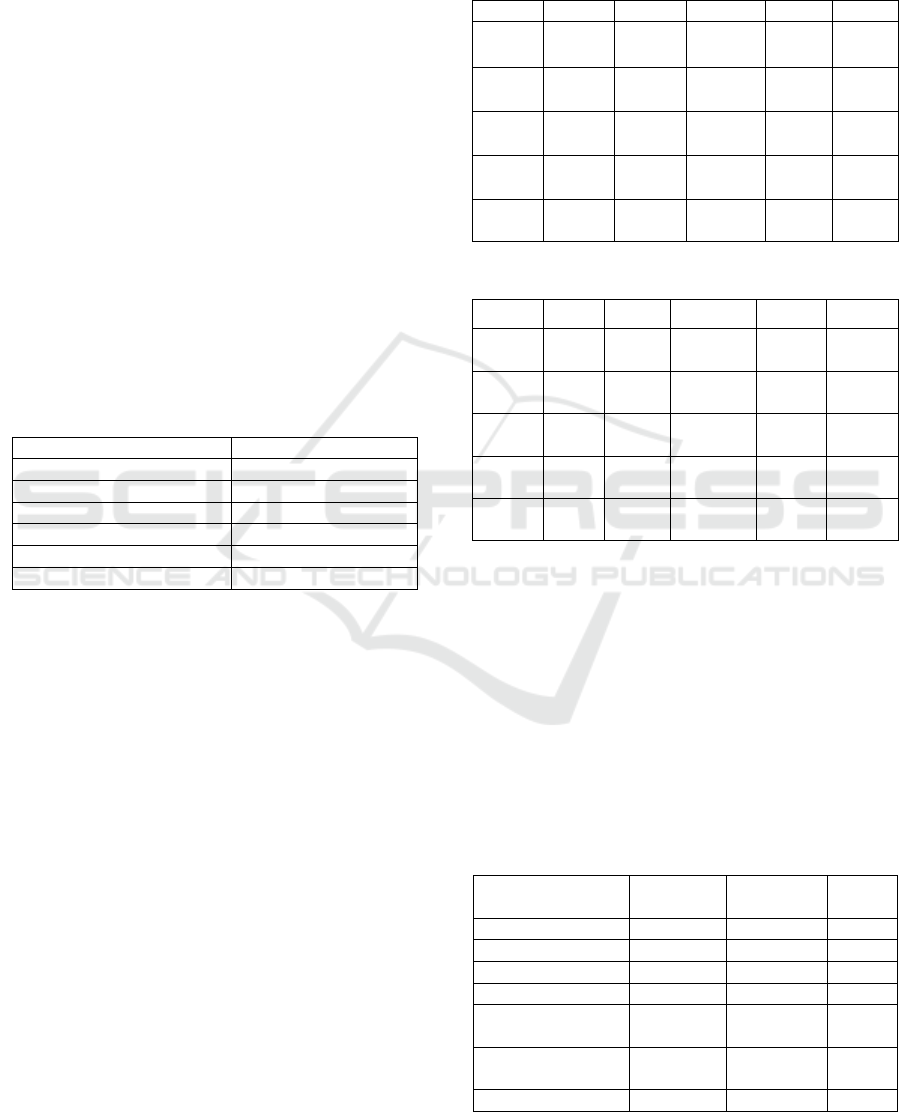

Table 1: Chemical composition of millet flour.

Components Millet Flou

r

Moisture (g/ 100 g) 16.3

Ash

(g

/ 100

g)

2.17

Protein

(g

/ 100

g)

9.74

Fat

(g

/ 100

g)

0.11

Carbohydrate (g/ 100 g) 71.7

Dietary fibre (g / 100 g) 12.5

3.3 Sensory Evaluation of Flakes

The hedonic characteristics of flakes made from millet

seed flour, chia seed flour, and sesame seeds such as

color, aroma, taste, texture and overall acceptability

are shown in table 2. There were no significant

differences in all sensory properties of flakes. The

hedonic quality there are differences in color and

aroma attributes, shown in table 3. The color in each

formulation is influenced by the percentage of chia

seed flour added to the flakes product. The higher the

percentage of chia seed flour then the resulting color

will be darker. This is also supported by the statement

of Pizarro et al (2013) that the use of 0% to 30% chia

seed flour will reduce the brightness value of pound

cake. The aroma of flakes is obtained from millet seed

flour which has a nutty aroma and a distinctive aroma

of chia seed flour (Casper et al., 2014)

. Supported by

research by Shivakumar et al (2014) the addition of

millet seed flour to cheese making gives a nutty

aroma. Coorey et al (2012)

the addition of 5% chia

seed flour can affect the aroma of the chips. According

to Hatamian et al (2020) the aroma of chia seed flour

is obtained from the process of roasting the seeds

before they become flour.

Table 2: Hedonic score of flakes.

Colo

r

Aroma Taste Texture Overall

F1

4.40±

1.29

a

4.62±

1.22

a

4.73±

1.31

a

5.17±

1.31

a

4.99±

1.22

a

F2

4.52±

1.11

a

4.28±

1.21

a

4.67±

1.21

a

4.90±

1.09

a

4.86±

1.18

a

F3

4.41±

1.27

a

4.45±

1.26

a

4.41±

1.33

a

4.57±

1.25

a

4.74±

1.36

a

F4

4.48±

1.46

a

4.40±

1.29

a

4.97±

1.14

a

4.97±

1.17

a

5.08±

1.11

a

LSD

5%

0.98 0.61 0.17 0.09 0.54

Table 3: Hedonic quality score of flakes.

Color Aroma Sweetness Savory Texture

F1

3.82±

1.21

a

3.56±

1.19

a

4.07±

0.98

a

3.93±

1.27

a

5.27±

1.27

a

F2

4.56

±

0.97

b

4.22±

1.33

bc

3.94±

1.06

a

4.20±

1.12

a

5.11±

1.14

a

F3

4.73

±

1.12

b

4.15±

1.29

b

3.78±

0.95

a

4.14±

1.01

a

5.13±

1.19

a

F4

5.06

±

1.21

b

4.71±

1.14

cd

4.31±

1.03

a

4.36±

1.23

a

5.28±

1.20

a

LSD

5%

0.00 0.00 0.65 0.40 0.83

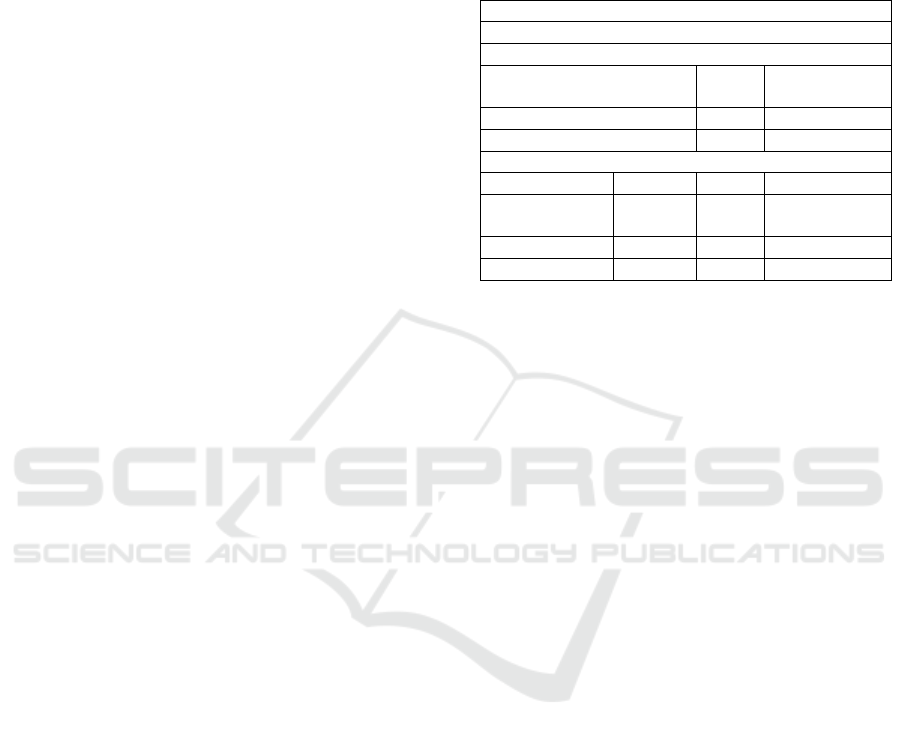

3.4 Chemical Composition of Flakes

The result of the hedonic and hedonic quality test

obtained the selected formulations is F4 be obtained

with the use of 75% millet seed flour and 20% chia

seed flour. The nutritional content of selected flakes

is shown in the table 4. The selected flakes will be

compared with commercial flakes and the cereal

quality requirements according to SNI No. 01-4270-

1996 to determine the suitability of the nutritional

quality of the selected formula.

Table 4: Analysis of selected flakes composition.

Components

Selected

Flakes

Commercial SNI

Moisture

(g

/ 100

g)

1.96 - Max.3

Ash

(g

/ 100

g)

3.07 - Max.4

Protein (g/ 100 g) 6.74 6.7 Max.5

Fat (g/ 100 g) 14.1 1.7 Max.7

Carbohydrate

(g/ 100 g)

74.2 80 Min.60

Dietary fibre

(g

/ 100

g)

26.1 3.3 -

Ener

gy

(

k

cal

)

450.7 366.7 -

Utilization of Millet Seed Flour (Panicum miliaceum L), Chia Seed Flour (Salvia hispanica) and Sesame Seeds (Sesamum indicum) on

Making High-fibre Flakes

245

Based on the results of the proximate analysis and

dietary fibre, it showed that the fat content and dietary

fibre content of the selected flakes were significantly

higher than those of commercial flakes made from

corn flour. This is due to the use of chia seed flour as

much as 20% in selected flakes which is a source of

fibre. Based on all the nutritional parameters of the

selected flakes product, it has complied with SNI 01-

4270-1996 for cereal quality. The fat content of the

selected flakes is much higher. This can happen

because of the oil content in chia seeds and sesame

seeds. The fat content of chia seed flour is 32.59%

(Arumsari dan Sofyaningsih, 2020).

Research

conducted by Rendón-Villalobos et al (2012) stated

that the manufacture of corn tortillas with the addition

of 20% chia seed flour resulted in a much higher fat

content (10.95%) than the control (4.08%) which

could be attributed to concentration of chia seed oil..

According to Mohd Ali et al., 2012 chia seeds contain

25-40% fat, which is in the form of polyunsaturated

fatty acids such as omega-3 (alpha linolenic acid /

ALA) and omega-6 (linoleic acid). The dominant

fatty acid content in sesame seeds in the form of oleic

and linoleic acids ranges from 80-85% of the total

amount (Mahmood Biglar, 2012). These fatty acids

are included in the essential fatty acids needed by

health.

These selected flakes have fulfilled nutritional

claims as high-fibre foods because they contain more

than 6 g per 100 g solid weight. The high content of

dietary fibre in the selected flakes was caused by

several ingredients such as chia seed flour and millet

seed flour which contain high dietary fibre. In this

study, the dietary fibre content of millet seed flour

reached 12.5 g per 100 g. While the content of dietary

fibre in chia seed flour is 30.24 g per 100 g

(Arumsari

dan Sofyaningsih, 2020).

Increased dietary fibre can also

result from the development of resistant starch during

the heating and cooling process

(Takhellambam et al.,

2016)

. The dietary fibre content of millet seeds and

chia seeds is included in the insoluble dietary fibre

(Rana, 2019). Insoluble fibre includes lignin, cellulose,

and hemicellulose. The main component found in

insoluble fibre is lignin, which plays an important role

in the protection of unsaturated fats and is responsible

for the hypercholesterolemic activity associated with

fibre intake

(Tolba et al., 2011). Chia seed flour has a

much higher fibre content, so it will determine the

percentage of fibre content of the flakes.

3.5 Nutrition Facts of Flakes

Determination of the serving size of flakes is adjusted

to the suggestion of serving commercial products

from corn flakes is 30 g and served with milk. The

energy and nutritional contributions of flakes based

on millet seed flour, chia seed flour and sesame seeds

are shown in table 5.

Table 5: Nutrition facts of flakes.

Nutrition Facts

serving size 1 cup (30g)

Servings Per Container About 1

Amount Per Serving Flakes Flakes with

200ml Mil

k

Calories 135 257

Calorie from Fat 36 99

% Dail

y

Value

Total Fat 4

g

6% 17%

Total

Carbohydrate

22 g 7% 10%

Dietar

y

Fibre 8

g

27% 27%

Protein 2

g

3% 14%

4 CONCLUSIONS

The results showed that the best formulation of flakes

from millet seed flour, chia seed flour, and sesame

seeds based on the organoleptic test is F4 (75% millet

seed flour: 20% chia seed flour). The results of the

sensory test analysis in the study of the comparison of

millet seed flour and chia seed flour with hedonic

parameters of color, aroma, taste, texture and overall

showed that there was no significant difference.

Meanwhile, the hedonic quality was significantly

different to the color and aroma quality of the flakes.

Analysis of the nutritional content of the best flakes

formula that is ash content of 3.07%, water content of

1.96%, protein content of 6.74%, fat content of

14.1%, carbohydrate content of 74.2%, dietary fibre

content of 26.1%, and calories produced 450.7 kcal

per 100 grams. The resulting flakes can be claimed as

flakes with high dietary fibre.

REFERENCES

Adi Sarno, I. P., Wulandari, Y. W., & Suhartatik, N. (2018).

Karakteristik Snack Bars dengan Variasi Suhu

Pemanggangan dan Perbandingan Tepung Milet

Kuning (Panicum sp) dengan Tepung Pisang Raja

Bandung (Musa paradisiaca L). Jurnal Teknologi

Pangan, 12(2), 47–53.

Https://Doi.Org/10.33005/Jtp.V12i2.1288

Amadou, I., Gounga, M. E., Shi, Y. H., & Le, G. W. (2014).

Fermentation and Heat-Moisture Treatment Induced

Changes on The Physicochemical Properties of Foxtail

Millet (Setaria italica) Flour. Food and Bioproducts

ICSDH 2021 - International Conference on Social Determinants of Health

246

Processing, 92(1), 38–45.

Https://Doi.Org/10.1016/J.Fbp.2013.07.009

Arumsari, I., & Sofyaningsih, M. (2020). Evaluasi Zat Gizi

Tepung Chia (Salvia hispanica L.) dan Tepung Wijen (

Sesamum indicum L ) sebagai Alternatif Tepung Tinggi

Serat dan Protein. 5(1), 27–33.

Https://Doi.Org/10.22236/Argipa.V5i1.4950

Asghar, A., Majeed, M. N., & Akhtar, M. N. (2014). A

Review on The Utilization of Sesame as Functional

Food. Am. J. Food. Nutr., 4(1), 21–34.

Https://Doi.Org/10.5251/Ajfn.2014.4.1.21.34

Atmaja, R. P., & Sari, R. Y. (2017). Pembuatan Tepung

Millet Terfermentasi dan Pemanfaatannya dalam

Produk Mie Kering Fermentation. Journal of Chemical

Information And Modeling, 53(9), 1689–1699.

Https://Doi.Org/10.1017/Cbo9781107415324.004

Aulia, T., Suhaidi, I., & Rusmarilin, H. (2017). Tepung

Pisang dan Persentase Kuning Telur terhadap Mutu

Flakes Talas. Ilmu dan Teknologi Pangan, 5(2), 333–

342.

Borneo, R. (2012). Chia (Salvia hispanica) Can be Used to

Manufacture Sugar-Snap Cookies with an Improved

Nutritional Value. International Journal of Food

Studies, 1(2), 135–143.

Https://Doi.Org/10.7455/Ijfs/1.2.2012.A4

Casper, J. L., Cargill, I., Plymouth, M., Atwell, W. A., &

Champlin, M. (2014). Gluten-Free Ingredients. In

Gluten-Free Baked Products (Pp. 23–47).

Https://Doi.Org/10.1016/B978-1-891127-80-9.50003-0

Coorey, R., Grant, A., & Jayasena, V. (2012). Effects of

Chia Flour Incorporation on The Nutritive Quality and

Consumer Acceptance of Chips. Journal of Food

Research, 1(4), 85.

Https://Doi.Org/10.5539/Jfr.V1n4p85

Das, S., Khound, R., Santra, M., & Santra, D. K. (2019).

Beyond Bird Feed: Proso Millet For Human Health and

Environment. Agriculture (Switzerland), 9(3).

Https://Doi.Org/10.3390/Agriculture9030064

Dewi, I. S., Ekawati, I., & Pratiwi, I. (2018). Pengaruh

Lama Perkecambahan Millet (Panicum milliaceum)

Terhadap Karakteristik Flakes. Jurnal Ilmu Dan

Teknologi Pangan, 7(4), 175–183.

Hatamian, M., Noshad, M., Abdanan-Mehdizadeh, S., &

Barzegar, H. (2020). Effect of Roasting Treatment on

Functional and Antioxidant Properties of Chia Seed

Flours. Nfs Journal, 21(March), 1–8.

Https://Doi.Org/10.1016/J.Nfs.2020.07.004

Hegde, D. M. (2012). Sesame. Handbook Of Herbs and

Spices: Second Edition, 2, 449–486.

Https://Doi.Org/10.1533/9780857095688.449

Husna, E. A., Affandi, D. R., & Anandito, R. B. K. (2012).

Karakterisasi Bubur Bayi Instan Berbahan Dasar

Tepung Millet (Panicum sp) dan Tepung Kacang Hijau

(Phaseolus radiatus) Dengan Flavor Alami Pisang

Ambon (Musa paradisiaca Var. Sapientum L.). 1(1).

Khairunissa, Harun, N., & Rahmayuni. (2018).

Pemanfaatan Tepung Talas dan Tepung Kacang Hijau

dalam Pembuatan Flakes [Utilization Of Taro Flour and

Mung Bean Flour in Making Flakes]. Jurnal Sagu

Universitas Riau, 17(1), 2018.

Kumar, A., Tomer, V., Kaur, A., Kumar, V., & Gupta, K.

(2018). Millets: A Solution to Agrarian and Nutritional

Challenges. Agriculture and Food Security, 7(1), 1–15.

Https://Doi.Org/10.1186/S40066-018-0183-3

Pizarro, P. L., Almeida, E. L., Sammán, N. C., & Chang, Y.

K. (2013). Evaluation of Whole Chia (Salvia hispanica

L.) Flour and Hydrogenated Vegetable Fat In Pound

Cake. Lwt - Food Science and Technology, 54(1), 73–

79. Https://Doi.Org/10.1016/J.Lwt.2013.04.017

Mahendra, P. E. D., Yusasrini, N. L. A., & Pratiwi, I. D. P.

K. (2019). Pengaruh Metode Pengolahan Terhadap

Kandungan Tanin dan Sifat Fungsional Tepung Proso

Millet (Panicum miliaceum). Jurnal Ilmu dan Teknologi

Pangan (Itepa), 8(4), 354.

Https://Doi.Org/10.24843/Itepa.2019.V08.I04.P02

Mahmood Biglar. (2012). Profiling of Major Fatty Acids In

Different Raw and Roasted Sesame Seeds Cultivars.

African Journal Of Biotechnology, 11(24), 6619–6623.

Https://Doi.Org/10.5897/Ajb11.1966

Manish, C. El. (2018). Nutritional and Nutraceutical

Properties of Millets : Clinical Journal of Nutrition And

Dietetics, 1(1), 1–10.

Marcinek, K., & Krejpcio, Z. (2017). Chia Seeds (Salvia

hispanica): Health Promoting Properties and

Therapeutic Applications – A Review. Roczniki

Panstwowego Zakladu Higieny, 68(2), 123–129.

Marta, H. (2016). Sifat Fungsional dan Amilografi Pati

Millet Putih (Pennisetum glaucum) Termodifikasi

Secara Heat Moisture Treatment dan Annealing. Jurnal

Aplikasi Teknologi Pangan, 5(3), 76–84.

Https://Doi.Org/10.17728/Jatp.175

Mcsweeney, M. (2014). Proso Millet As An Ingredient In

Foods Common To North Americans. (October).

Mohd Ali, N., Yeap, S. K., Ho, W. Y., Beh, B. K., Tan, S.

W., & Tan, S. G. (2012). The Promising Future of Chia,

Salvia Hispanica L. Journal of Biomedicine And

Biotechnology, 2012.

Https://Doi.Org/10.1155/2012/171956

Muflihani, Y. (2016). Uji Organoleptik Formula Flakes

Dari Pasta Ubi Jalar Dengan Penambahan Tepung

Jalejo. Prosiding Seminar Hasil Penelitian Tanaman

Aneka Kacang dan Umbi., (Widowati 2011), 603–610.

Muñoz, L. A., Cobos, A., Diaz, O., & Aguilera, J. M.

(2013). Chia Seed (Salvia Hispanica): An Ancient Grain

and A New Functional Food. Food Reviews

International, 29(4), 394–408.

Https://Doi.Org/10.1080/87559129.2013.818014

Myint, D., Gilani, S. A., Kawase, M., & Watanabe, K. N.

(2020). Sustainable Sesame (Sesamum indicum L.)

Production Through Improved Technology: An

Overview Of Production, Challenges, and

Opportunities In Myanmar. Sustainability

(Switzerland), 12(9), 1–21.

Https://Doi.Org/10.3390/Su12093515

Oliveira, M. R., Novack, M. E., Santos, C. P., Kubota, E.,

& Da Rosa, C. S. (2015). Evaluation of Replacing

Wheat Flour with Chia Flour (Salvia hispanica L.) In

Pasta. Semina:Ciencias Agrarias, 36(4), 2545–2553.

Https://Doi.Org/10.5433/1679-0359.2015v36n4p2545

Utilization of Millet Seed Flour (Panicum miliaceum L), Chia Seed Flour (Salvia hispanica) and Sesame Seeds (Sesamum indicum) on

Making High-fibre Flakes

247

Prabowo, B. (2010). Kajian Sifat Fisikokimia Tepung

Millet Kuning Dan Tepung Millet Merah. Skripsi, 1–39.

Purnamayanti, N. P. A., Gunadnya, I. B. P., & Arda, G.

(2017). Pengaruh Suhu dan Lama Penyangraian

Terhadap Karakteristik Fisik dan Mutu Sensori Kopi

Arabika (Coffea Arabica L). Jurnal Beta (Biosistem

Dan Teknik Pertanian, 5(2), 39–48.

Rana. (2019). Characterization Of Chia Seed Flour and

Wellbeing Endorsing Possessions. International Journal

Of Food Science, Nutrition And Dietetics, 8(5), 419–

426. Https://Doi.Org/10.19070/2326-3350-1900075

Rani, H., Zulfahmi, & Widodo, Y. R. (2013). Optimasi

Proses Pembuatan Bubuk (Tepung) Kedelai

Optimization Process Soybean Flouring. Jurnal

Penelitian Pertanian Terapan, 13(3), 188–196.

Rendón-Villalobos, R., Ortíz-Sánchez, A., Solorza-Feria,

J., & Trujillo-Hernández, C. A. (2012). Formulation,

Physicochemical, Nutritional and Sensorial Evaluation

of Corn Tortillas Supplemented with Chía Seed (Salvia

hispanica L.). Czech Journal Of Food Sciences, 30(2),

118–125. Https://Doi.Org/10.17221/393/2010-Cjfs

Riernersman, C. N., & María, R. A. (2016). Whole Chia

Flour As Yield Enhancer, Potential Antioxidant and

Input Of N-3 Fatty Acid In A Meat Product. Food And

Nutrition Sciences, 07(10), 855–865.

Https://Doi.Org/10.4236/Fns.2016.710085

Romankiewicz, D., Hassoon, W. H., Cacak-Pietrzak, G.,

Sobczyk, M. B., Wirkowska-Wojdyba, M., Ceglinska,

A., & Dziki, D. (2017). The Effect of Chia Seeds (Salvia

hispanica L.) Addition on Quality and Nutritional Value

of Wheat Bread. Journal Of Food Quality, 2017.

Https://Doi.Org/10.1155/2017/7352631

Sarita, & Singh, E. (2016). The Pharma Innovation Journal

2016; 5(8): 42-46 Millet’s Anti-Nutrients and Their

Therapeutic Effects. 5(8), 42–46. Retrieved From

Http://Ww.Slideshare.Net/Poshadri/Cereals-Millet-

Processing,

Shivakumar, Arunkumar.H, & Venkatesh.M.V. (2014).

Process Optimization For The Production of Paneer

(Soft Cheese) Kheer Blended with Foxtail Millet and

Finger Millet Flour. Quest Journals Journal Of Research

In Agriculture And Animal Science, 2(6), 2321–9459.

Retrieved From Www.Questjournals.Org

Situmorang, C., Swamilaksita, D. P., Anugrah, N., Gizi, P.

I., Kesehatan, F. I., & Unggul, U. E. (2017). Substitusi

Tepung Kacang Hijau dan Tepung Kacang Kedelai pada

Pembuatan Bean Flakes Tinggi Serat dan Tinggi Protein

Sebagai Sarapan Sehat.

Sulistyaningrum, A., & Aqil, M. (2017). Karakteristik

Tepung Jewawut (Foxtail Millet) Varietas Lokal

Majane dengan Perlakuan Perendaman. 11–21.

Zulfianto. N. A. (2017). Tabel Komposisi Pangan

Indonesia. Jakarta: Kementerian Kesehatan RI.

Takhellambam, R. D., Chimmad, B. V., & Prkasam, J. N.

(2016). Ready-To-Cook Millet Flakes Based on Minor

Millets For Modern Consumer. Journal of Food Science

and Technology, 53(2), 1312–1318.

Https://Doi.Org/10.1007/S13197-015-2072-0

Tolba, R., Wu, G., & Chen, A. (2011). Adsorption Of

Dietary Oils Onto Lignin for Promising Pharmaceutical

and Nutritional Applications. Bioresources, 6(2), 1322–

1335. Https://Doi.Org/10.15376/Biores.6.2.1322-1335

Vázquez-Ovando, J. A., Rosado-Rubio, J. G., Chel-

Guerrero, L. A., & Betancur-Ancona, D. A. (2010). Dry

Processing of Chia (Salvia hispanica L.) Flour:

Chemical Characterization of Fibre and Protein Article.

Cyta - Journal Of Food, 8(2), 117–127.

Https://Doi.Org/10.1080/19476330903223580

Yuniarti, D. W., Sulistiyati, T. D., & Suprayitno, E. (2013).

Pengaruh Suhu Pengeringan Vakum terhadap Kualitas

Serbuk Albumin Ikan Gabus (Ophiocephalus striatus).

Thpi Student Journal, 1.

ICSDH 2021 - International Conference on Social Determinants of Health

248