Intelligent Classification of Different Types of Plastics using Deep

Transfer Learning

Anthony Ashwin Peter Chazhoor

1

, Manli Zhu

1

, Edmond S. L. Ho

1

, Bin Gao

2

and Wai Lok Woo

1

1

Department of Computer and Information Sciences, Northumbria University, Newcastle upon Tyne, NE1 8ST, U.K.

2

School of Automation Engineering, University of Electronic Science and Technology of China, Chengdu, China

Keywords: Deep Learning, Transfer Learning, Image Classification, Recycling.

Abstract: Plastic pollution has affected millions globally. Research shows tiny plastics in the food we eat, the water

we drink, and even in the air, we breathe. An average human intakes 74,000 micro-plastic every year, which

significantly affects the health of living beings. This pollution must be administered before it severely impacts

the world. We have substantially compared three state-of-the-art models on the WaDaBa dataset, which

contains different types of plastics. These models are capable of classifying different types of plastic wastes

which can be reused or recycled, thus limiting their wastage.

1

INTRODUCTION

Plastics refer to a wide extend of materials that can

be formed, cast, spun, or coated as a coating at

some point throughout the fabricating process.

Synthetic polymers are ordinarily made by

polymerizing monomers obtained from oil or gas,

and plastics are often manufactured by adding

different chemical additives to them, improving

manufacturing and material performance such as

flexibility, longevity, and aesthetics (Thompson et

al., 2009). Plastic has various uses in day-to-day life

and is used abundantly around the globe as it is

affordable, lightweight and can be used in a wide

range of applications. Based on the application, Some

types of plastics are recyclable while others are

disposed of after single-use (Bonifazi et al., 2018).

Approximately 359 million tonnes of plastics are

produced every year and this number is going to

increase in the coming years due to their excessive

use (Ferdous et al., 2021). Textiles, industrial

machinery, consumer and institutional products,

building and construction, electrical and electronic

industries use plastic on a large scale (Geyer et al.,

2017).

Worldwide, 6.3 billion tonnes of plastic waste

have been generated to date (Mazhandu and

Muzenda, 2019). This has become a global

environmental issue. Moreover, only 19 percent of

this waste is recycled and the rest is dumped into

landfills or incinerated. Plastic biodegradation is a

prolonged process. Almost 40 percent of the plastic

waste generated is from the packaging industry,

which is the highest waste generator in its segment

(Balwada et al., 2021). If one tonne of plastic is

recycled around 5,774 kW-hours of energy is

generated. Approximately 16.3 barrels of oil and

22.9 cubic meters of landfill space can be saved,

together with the environmental impact from its

incineration which releases toxic gases into the

atmosphere (Ferdous et al., 2021). Plastic has

polluted the marine ecosystem and is found in

seafood to the deepest ocean trenches. Most of the

plastic which enters the ocean is sourced through

land (Harris et al., 2021). This massive volume of

plastics can be reused and recycled. The main

challenge is to reduce plastic pollution by

minimizing its use, reusing the existing plastic

materials, and recycling the types of a suitable

plastic. Domestic and industrial plastics can be

segregated and categorized according to their

respective types, which helps minimize its impact by

differentiating recyclables and reusable from dead-

end plastics, which can be done with modern image

classification methods. However, it is challenging

and time- consuming to classify these waste plastics

manually. It leads to the automation of the process

for plastic waste segregation based on its types. With

the advance of computer vision and deep neural

networks, the classification of objects in images and

their localization has become accessible

commercially and is available at a lower price, with

its accuracy increasing every day (Eitel et al., 2015).

This paper aims to benchmark the three widely

implemented architectures on the WaDaBa dataset

190

Chazhoor, A., Zhu, M., Ho, E., Gao, B. and Woo, W.

Intelligent Classification of Different Types of Plastics using Deep Transfer Learning.

DOI: 10.5220/0010716500003061

In Proceedings of the 2nd International Conference on Robotics, Computer Vision and Intelligent Systems (ROBOVIS 2021), pages 190-195

ISBN: 978-989-758-537-1

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Table 1: Types of plastics and examples.

Types of plastic Examples

1.Polyethylene Terephthalate (PET or PETE) Beverage bottles, Food bottles

2.High-Density Polyethylene (HDPE) Milk cartons, detergent bottles

3.Polyvinyl Chloride (PVC or Vinyl) Plumbing pipes, credit cards

4.Low-Density Polyethylene (LDPE) Plastic wrap, sandwich and bread bags

5.Polypropylene (PP) Straws, bottle caps, prescription bottles

6.Polystyrene (PS or Styrofoam) Cups, takeout food containers

7.Other baby bottles, electronics, CD, DVDs

to find out the best model with the support of

trans

fer learning. To ease the recycling process

worldwide, seven different types of plastic have

been categorized based on their chemical

composition and is detailed in Table 1. PET, HDPE

PP and PS dominate the household waste and

segregating them into their respective types will

allow the reuse of certain types and recycling of

other types of plastics (Bobulski and Kubanek,

2021). This paper is the first benchmark paper aimed

towards classifying different types of plastics from

the images using deep learning models, and this can

stimulate the research in this area and serve as a

baseline for future research work.

2 RELATED WORK

Plastics can be sorted manually or by using

sophisticated means of technologies based on the

differences in their chemical, optical, electrical, and

physical property.

In 1994, Inculet et al., patented the separation of

waste plastic materials using electrostatics. In this

method the waste plastic is shredded into small

pieces and then separated electrostatically after

charging by suitable means. The waste materials

were separated based on of different rates of contact

charges picked up by the plastic materials (Inculet et

al., 1994).

Safavi et al. proposed the use of visible

reflectance spectroscopy which was fast and

accurate to separate the polypropylene resins based

on their colour using the “Three-Filter”

identification algorithm, which was limited to only

single type of plastic (Safavi et al., 2010).

In 2012, Masoumi et al., proposed sorting of

different types of plastics using near infrared (NIR)

spectroscopy (Masoumi et al., 2012). Infrared is

used in detecting wide range of materials including

plastics and metals (Gao et al., 2017); (Gao et al.,

2014). Using the NIR spectroscopy with two

specific wave- lengths plastic resins can be correctly

identified but its use is limited to light coloured

plastics only (Feng et al., 2018). The NIR reflects

from the plastic surface and in is received by a

receiver, and based on the intensity of reflection the

plastics is categorized (Masoumi et al., 2012).

The presence and amount of many elements are

identified by a spectroscopic technique called X- ray

fluorescence (XRF). The energy irradiated by the

XRF can classify plastics based on their chemical

composition accurately but at a relatively high cost

and health concerns (Chaqmaqchee et al., 2017);

(Ahmed et al., 2020).

Agarwal et al. achieved an accuracy of 99.7 %

which differentiated 5 types of plastics using

supervised deep learning on the WaDaBa database.

Triplet loss and Siamese network architectures were

used to get the output results (Agarwal et al., 2020).

Having deep architectures and the capacity to

learn more complex models, the deep neural

networks (DNN) have a superior advantage

compared to the traditional approaches for

classification. The robust training techniques make it

possible to learn complex object representations

without having to design features by hand which has

been clearly demonstrated on the challenging

imagenet classification task on a wide range of

classes (Szegedy et al., 2013). These features of the

DNN make it an absolute fit for the classification of

different types of plastic wastes.

This paper benchmarks existing models like

ResNet-50, Alexnet and ResNeXt, which uses

transfer learning and under-sampling and weight

balancing to classify the WaDaBa dataset.

3 METHODOLOGY

3.1 Database

WaDaBa dataset is used for the experiments and can

be requested from its creator, which is available on the

WaDaBa website after signing a consent form. The

dataset consists of 4000 images in which majority are

of PET images (2200) followed by PP images (640),

PE-HD images (600), PS images (520) and other

Intelligent Classification of Different Types of Plastics using Deep Transfer Learning

191

images (40). Each image is made out of a single

object that has been deformed to certain degrees to

mimic the natural settings (Bobulski and Piatkowski,

2017).

3.2 Convolutional Neural Network

With the convolution neural network advancement,

deep learning has become the primary tool for

classification problems. Deep learning is an end-to-

end method based on neural networks (Koh et al.,

2021). CNN has made unprecedented success in the

field of image processing (Ruan et al., 2020) and

because of its superior performance in computer

vision, deep learning has changed a variety of

sectors (Zhao et al., 2021). The Convolutional

Neural Network (CNN) is a popular Deep Learning

model for image classification (Fadli and

Herlistiono, 2020). A convolutional layer, a pooling

layer, and a fully connected layer are used in a CNN

to extract features and recognize tar- gets (Luo et al.,

2019). The convolutional layer and pooling layer are

the foundation of a CNN. The net- work

accomplishes its training by a back-propagation

algorithm (Yang et al., 2021).

3.3 Deep Transfer Learning

CNNs are great at image recognition. CNNs require

a large amount of training data and take ample time

to complete a set of training. However, by using

transfer learning, we can overcome these limitations.

Transfer learning helps to train new data with the

help of previously trained data. A pre-trained model

is generally utilized for fine-tuning in transfer

learning.

The pre-trained model is a deep learning model

trained on a large benchmark dataset such as the

ImageNet and typically excels in extracting the

image features. Transfer learning also helps to avoid

the over- fitting of data effectively. Thus, pre-trained

models might have better performance while

training (Zeng et al., 2021).

3.4 Classification Models

3.4.1 ResNet-50

ResNet-50 is a convolution neural network with 50

layers. Resnet employs residual blocks, mainly

consisting of skip connections, which provide a

quicker gradient flow. Even if the network is too

deep, it reduces the complications like vanishing

gradient (He et al., 2016).

3.4.2 AlexNet

AlexNet is a neural network with three

convolutional layers and two fully connected layers

and was introduced by Alex Krizhevesky in 2012.

By expanding network depth and employing multi-

parameter optimization techniques, AlexNet

improves learning capacity. After AlexNet’s

outstanding performance on the ImageNet dataset in

2012, CNN-based applications became popular

(Krizhevsky, 2014).

3.4.3 ResNeXt

Facebook proposed the ResNeXt model, which

ranked second in the ILSVRC 2016 classification

competition and improved COCO detection

performance. ResNeXt model introduced a new

dimension called cardinality along with width and

depth as an essential parameter. When it came to

expanding model capacity, cardinality is seen to be

more effective than going deeper or broader,

especially when going deeper and broader resulted

in decreased returns (Hitawala, 2018).

3.5 Experimental Settings

The WaDaBa dataset was requested from its creator

by signing a consent form. The data set has been

described in the section 3.1.

3.5.1 Imbalance in the Data

The classes in the dataset have an unequal number of

images. The first class (PET) has 2200 images, and

the last class (Others) has only 40 images. It is pretty

challenging to get datasets for certain types of

plastic due to their size and cost. Due to the

imbalance in the classes, the under-sampling

approach was adopted along with the balanced

weight distribution of the WaDaBa dataset. Five

hundred images were selected from the first four

classes and were split at 80 percent for the training

and the remaining 20 percent for the testing. From

the last class, 32 images were taken for training and

the remaining 8 for testing.

3.5.2 Model Parameters

The training images were passed through ResNet50,

AlexNet, and ResNeXt architectures and has been

normalized. The dataset was run through each of

these models for 20 epochs. Before passing on the

training, the data has been normalized. The data then

goes through a series of augmentation techniques

such as random horizontal flip and center crop. The

ROBOVIS 2021 - 2nd International Conference on Robotics, Computer Vision and Intelligent Systems

192

optimizer used was Stochastic Gradient Descent

(SGD) with a learning rate of 0.001 and momentum

of 0.9. The loss used for the experiments was cross-

entropy loss.

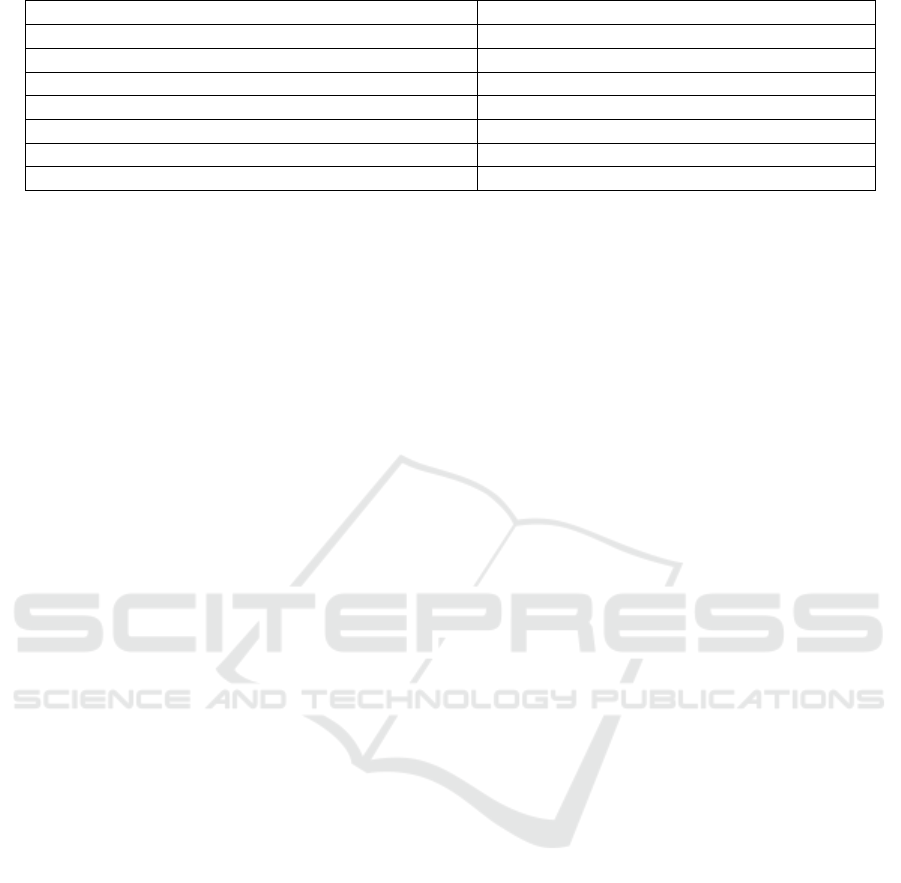

Figure 1: Accuracy and loss curves of training and testing for ResNet50.

Figure 2: Accuracy and loss curves of training and testing for AlexNet.

Figure 3: Accuracy and loss curves of training and testing for ResNext.

Intelligent Classification of Different Types of Plastics using Deep Transfer Learning

193

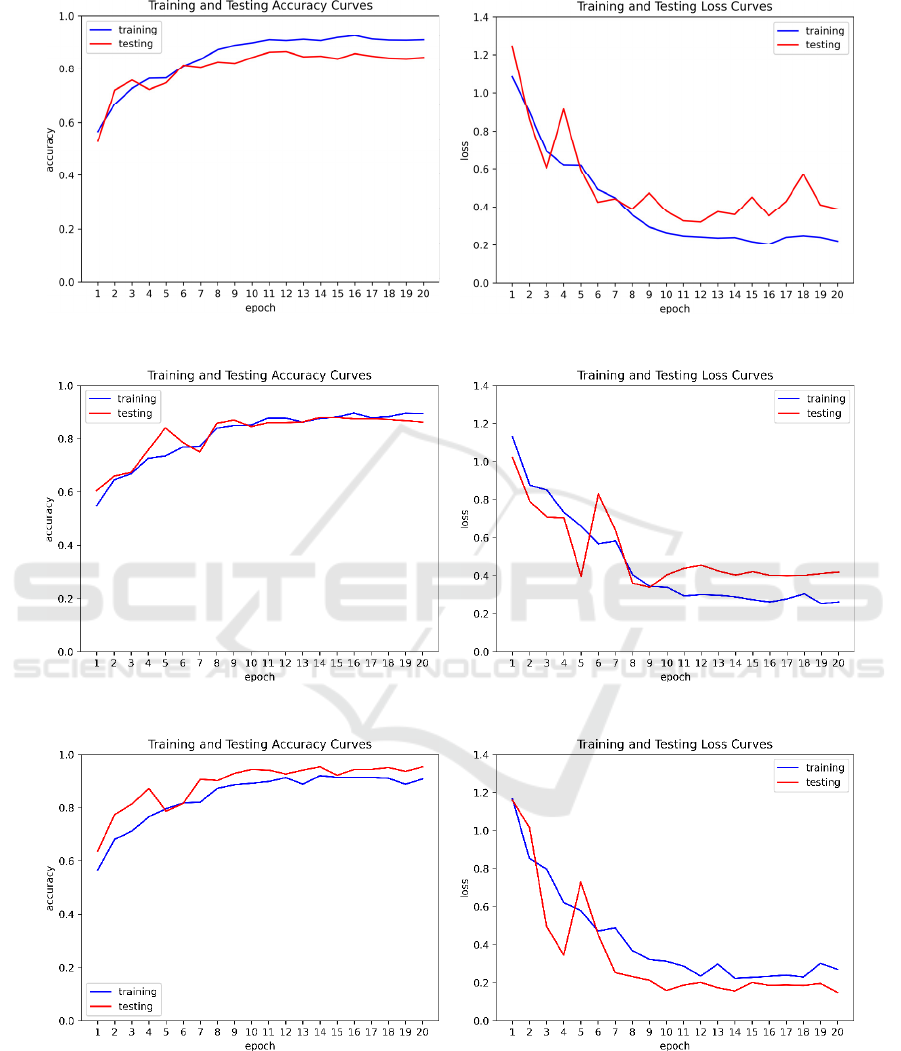

Figure 4: ROC and AUC comparison between different

models.

Once the training was completed the testing

accuracy was computed and has been given in Table

2.

4 EXPERIMENTAL RESULTS

4.1 Accuracy Results

The ResNeXt architecture shows the highest testing

accuracy with 91 percent followed by ResNet-50

with an accuracy of 89 percent and Alexnet with an

accuracy of 88 percent. The accuracy curves and the

loss curves with respect to epochs for ResNet50,

AlexNet and ResNeXt architectures are given in the

Fig. 1, 2 and 3 respectively. From the graphs, we can

see the training and the testing rates increases with

the number of epochs and once it reaches a certain

threshold, it maintains its accuracy. Similarly, the

loss decreases with the increase in epochs. We can

also infer that there is no over-fitting of data after

viewing the accuracy versus epoch curves.

From the ROC curves and AUC in Fig. 4, we can

see that all three models have very high AUC.

ResNeXt achieves the best performance, ResNet-50

has a very similar AUC to ResNet50, followed by

AlexNet. The reason is that both ResNet50 and

ResNext50 have a deeper model than AlexNet.

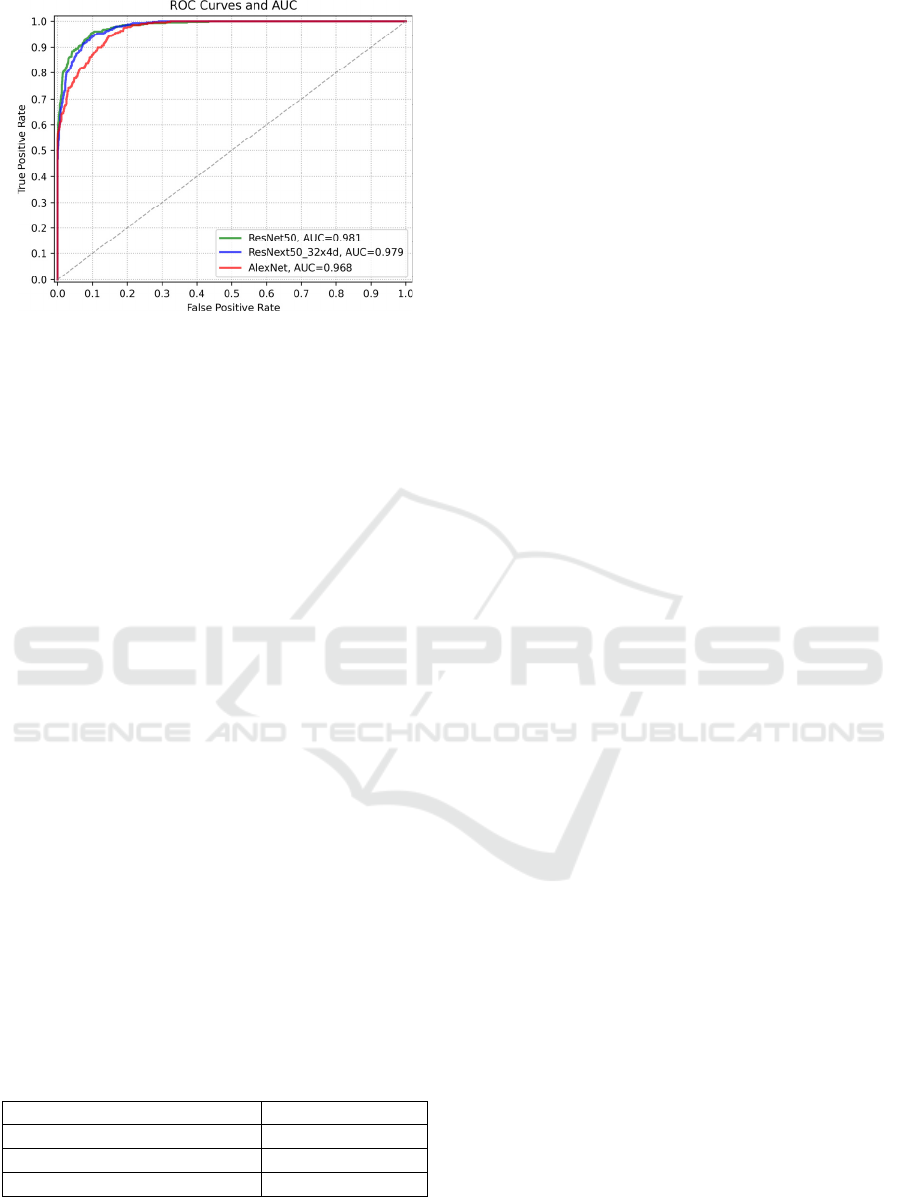

Table 2: Accuracy comparison between different models.

Pre-trained Network Accuracy

ResNeXt 91 %

ResNet-50 89 %

AlexNet 88 %

5 CONCLUSIONS

In this paper, we have benchmarked the accuracy of

three different models on the WaDaBa dataset,

which helps in automatically classifying different

types of plastic wastes that need to be reused and

recycled. This will help increase the overall

recycling of plastic products and thus reduce plastic

wastes. It can be used in the recycling industry to

classify different plastic wastes and for further

research to segregate them from others with different

classes. From the results, we can see that ResNeXt

model achieved the highest accuracy.

Once the plastic is correctly classified, it can be

segregated with the help of an air nozzle or a robotic

arm. Future work includes localization and detection

of plastic objects.

REFERENCES

Agarwal, S., Gudi, R., and Saxena, P. (2020). One-shot

learning based classification for segregation of plastic

waste. In 2020 Digital Image Computing: Techniques

and Applications (DICTA), pages 1–3.

Ahmed, J., Gao, B., Woo, W. L., and Zhu, Y. (2020). En-

semble joint sparse low-rank matrix decomposition for

thermography diagnosis system. IEEE Transac- tions

on Industrial Electronics, 68(3):2648–2658.

Balwada, J., Samaiya, S., and Mishra, R. P. (2021). Packag-

ing plastic waste management for a circular economy

and identifying a better waste collection system using

analytical hierarchy process (ahp). Procedia CIRP,

98:270–275.

Bobulski, J. and Kubanek, M. (2021). Deep learning for

plastic waste classification system. Applied Computa-

tional Intelligence and Soft Computing, 2021.

Bobulski, J. and Piatkowski, J. (2017). Pet waste classi-

fication method and plastic waste database-wadaba. In

International Conference on Image Processing and

Communications, pages 57–64. Springer.

Bonifazi, G., Capobianco, G., and Serranti, S. (2018).

A hierarchical classification approach for recognition

of low-density (ldpe) and high-density polyethylene

(hdpe) in mixed plastic waste based on short-wave

infrared (swir) hyperspectral imaging. Spectrochim-

ica Acta Part A: Molecular and Biomolecular Spec-

troscopy, 198:115–122.

Chaqmaqchee, F. A. I., Baker, A. G., and Salih, N. F.

(2017). Comparison of various plastics wastes using x-

ray fluorescence. American Journal of Materials

Synthesis and Processing, 5(2):24–27.

Eitel, A., Springenberg, J. T., Spinello, L., Riedmiller, M.,

and Burgard, W. (2015). Multimodal deep learning for

robust rgb-d object recognition. In 2015 IEEE/RSJ In-

ternational Conference on Intelligent Robots and Sys-

tems (IROS), pages 681–687.

ROBOVIS 2021 - 2nd International Conference on Robotics, Computer Vision and Intelligent Systems

194

Fadli, V. F. and Herlistiono, I. O. (2020). Steel surface de-

fect detection using deep learning. Int. J. Innov. Sci.

Res. Technol, 5:244–250.

Feng, Q., Gao, B., Lu, P., Woo, W. L., Yang, Y., Fan, Y.,

Qiu, X., and Gu, L. (2018). Automatic seeded re- gion

growing for thermography debonding detection of

cfrp. NDT & E International, 99:36–49.

Ferdous, W., Manalo, A., Siddique, R., Mendis, P., Zhuge,

Y., Wong, H. S., Lokuge, W., Aravinthan, T., and

Schubel, P. (2021). Recycling of landfill wastes (tyres,

plastics and glass) in construction–a review on global

waste generation, performance, application and future

opportunities. Resources, Conservation and Recy-

cling, 173:105745.

Gao, B., Bai, L., Woo, W. L., and Tian, G. (2014). Ther-

mography pattern analysis and separation. Applied

Physics Letters, 104(25):251902.

Gao, B., Li, X., Woo, W. L., and yun Tian, G. (2017).

Physics-based image segmentation using first order

statistical properties and genetic algorithm for induc-

tive thermography imaging. IEEE Transactions on Im-

age Processing, 27(5):2160–2175.

Geyer, R., Jambeck, J. R., and Law, K. L. (2017). Produc-

tion, use, and fate of all plastics ever made. Science

advances, 3(7):e1700782.

Harris, P., Westerveld, L., Nyberg, B., Maes, T., Macmillan-

Lawler, M., and Appelquist, L. (2021). Exposure of

coastal environments to river-sourced plastic pollu-

tion. Science of The Total Environment, 769:145222.

He, K., Zhang, X., Ren, S., and Sun, J. (2016). Deep resid-

ual learning for image recognition. In Proceedings of

the IEEE conference on computer vision and pattern

recognition, pages 770–778.

Hitawala, S. (2018). Evaluating resnext model archi-

tecture for image classification. arXiv preprint

arXiv:1805.08700.

Inculet, I. I., Castle, G., and Brown, J. D. (1994). Elec-

trostatic separation of mixed plastic waste. US Patent

5,289,922.

Koh, B. H. D., Lim, C. L. P., Rahimi, H., Woo, W. L., and

Gao, B. (2021). Deep temporal convolution network

for time series classification. Sensors, 21(2):603.

Krizhevsky, A. (2014). One weird trick for paralleliz-

ing convolutional neural networks. arXiv preprint

arXiv:1404.5997.

Luo, Q., Gao, B., Woo, W. L., and Yang, Y. (2019). Tem-

poral and spatial deep learning network for infrared

thermal defect detection. NDT & E International,

108:102164.

Masoumi, H., Safavi, S. M., and Khani, Z. (2012). Identi-

fication and classification of plastic resins using near

infrared reflectance. Int. J. Mech. Ind. Eng, 6:213–20.

Mazhandu, Z. S. and Muzenda, E. (2019). Global plastic

waste pollution challenges and management. In 2019

7th International Renewable and Sustainable Energy

Conference (IRSEC), pages 1–8. IEEE.

Ruan, L., Gao, B., Wu, S., and Woo, W. L. (2020). Deftect-

net: Joint loss structured deep adversarial network for

thermography defect detecting system. Neurocomput-

ing, 417:441–457.

Safavi, S., Masoumi, H., Mirian, S., and Tabrizchi, M.

(2010). Sorting of polypropylene resins by color in

msw using visible reflectance spectroscopy. Waste

management, 30(11):2216–2222.

Szegedy, C., Toshev, A., and Erhan, D. (2013). Deep neural

networks for object detection.

Thompson, R. C., Swan, S. H., Moore, C. J., and Vom Saal,

F. S. (2009). Our plastic age.

Yang, X., Zhang, Y., Lv, W., and Wang, D. (2021). Im-

age recognition of wind turbine blade damage based

on a deep learning model with transfer learning and an

ensemble learning classifier. Renewable Energy,

163:386–397.

Zeng, F., Li, X., Deng, X., Yao, L., and Lian, G. (2021). An

image classification model based on transfer learning

for ulcerative proctitis. Multimedia Systems, pages 1–

10.

Zhao, W., Chen, F., Huang, H., Li, D., and Cheng, W.

(2021). A new steel defect detection algorithm based

on deep learning. Computational Intelligence and

Neuroscience, 2021.

Intelligent Classification of Different Types of Plastics using Deep Transfer Learning

195