IoT Natural Gas Pipeline Monitoring System

Will Cook, Haley Felberg, Natalie Palos and James Yeh

Department of Engineering and Computer Science, Azusa Pacific University, 901 E Alosta Ave., Azusa, CA 91702, U.S.A.

Keywords: Long Range Radio (LoRa), Internet of Things (IoT), Daisy-Chain Topology, Natural Gas Storage,

Natural Gas Safety, Methane, Ethane, Greenhouse Gas.

Abstract: In this paper, we discuss our construction of a natural gas monitoring system that utilizes a network of nodes

that communicate with each other using LoRa modulation techniques. After the devastating gas leak in 2015

at the Aliso Canyon Natural Gas Storage Facility in Los Angeles county, in which a total of 104,400 tonnes

of methane and ethane gas was released into the atmosphere, it became apparent that gas storage facilities and

pipelines are in need of more efficient gas leak observation and monitoring methods. Our solution involves

constructing nodes from a LoRa32 microcontroller, MQ-4 gas sensor, solar panel, and a 3.7V lithium battery.

The nodes will be configured in a daisy-chain topology that can be positioned along any pipeline or gas storage

facility. The daisy-chain topology will allow data to be sent along the chain to a data collection node and

subsequently stored in the cloud hosted Firebase database. It is also anticipated that this monitoring system

will be surveyed using an intuitive mobile application for iOS and Android devices.

1 INTRODUCTION

The monetary, environmental, and health

implications of a gas leak are as immense as they are

detrimental. Gas leaks can go undetected for weeks,

and it can take months to identify the source of the

leak. Thus, it is imperative that gas storage facilities

and pipelines are closely monitored in order to

minimize the damage done by gas leakage. According

to Debra Wunch et al. in their article “Quantifying the

loss of processed natural gas within California's

South Coast Air Basin using long-term measurements

of ethane and methane,” the South Coast Air Basin,

with a population of about 18 million people, emits

approximately 413,000 tonnes of methane and 23,000

tonnes of ethane annually (Wunch et al., 2016). These

numbers are severely exacerbated by gas leaks, which

is the issue that this project seeks to address.

One should consider the case of the Aliso Canyon

Natural Gas Storage Facility. First discovered in

October 2015, the Aliso Canyon gas leak was a

prominent and dangerous natural gas leak in the Santa

Susana Mountains of Southern California. The Aliso

Canyon gas leak is credited as the worst gas leak in

U.S. history (Conley et al., 2016). It released 97,100

tonnes of methane and 7,300 tonnes of ethane into the

atmosphere (Conley et al., 2016). The severity of this

gas leak was enabled by the fact that the gas leak was

undetected for weeks, and it took several attempts by

SoCalGas to finally stop the gas leak on February 12,

2016 (SoCalGas, 2016).

The Aliso Canyon gas leak negatively affected

both the people living in the area and the Southern

California Gas Company, the primary utility

company providing natural gas to Southern

California. The occupants of Aliso Canyon

experienced several health complications, and nearly

3,000 households, 11,000 people, and two schools

were displaced, causing more than 6,500 families to

file for help (Gazzar, 2015). Methane and ethane are

unsafe for humans to inhale in large amounts, and the

residents of Aliso Canyon reported symptoms

including mood changes, slurred speech, vision

problems, memory loss, nausea, vomiting, facial

flushing, and headaches because of gas inhalation

from the leak (Abram, 2015).

Steve Conley, an atmospheric scientist at the

University of California Davis, measured the massive

gas leak’s emissions and cited that “[w]e do not have

anything in place to measure giant leaks like this, or

to watch them to solve issues” (Ortiz, 2016). There

were eight infrared methane monitors installed at

Aliso Canyon that were intended to measure the ppm

of the methane in the air by sending an infrared beam

between a sender and a receiver. However, it is

possible that some weather conditions interrupted the

168

Cook, W., Felberg, H., Palos, N. and Yeh, J.

IoT Natural Gas Pipeline Monitoring System.

DOI: 10.5220/0010713600003062

In Proceedings of the 2nd International Conference on Innovative Intelligent Industrial Production and Logistics (IN4PL 2021), pages 168-173

ISBN: 978-989-758-535-7

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

infrared beams, which may have resulted in

inaccurate methane readings (“Aliso Canyon Infrared

Fence-Line Methane-Monitoring System:

SoCalGas”, n.d). Since there was no reliable system

in place to pinpoint the location of the leak, the leak

was undetected for multiple weeks, and SoCalGas

was found to be at fault for the massive gas leak. They

were sued for $119.5 million for the damages and

other effects of the gas leak (Domonoske, 2018). This

is just one case of a gas leak in the industrial sector

going firstly unnoticed and secondly unfixed due to a

lack of the technology in place to do so. Other major

gas leaks that have occurred around the world include

the following (“List of Pipeline Accidents,” 2021):

● November 30, 2000: pipeline caught fire near

the fishing village of Ebute near Lagos, Nigeria,

killing at least 60 people

● July 30, 2004: Ghislenghien, Belgium killing

24 people and leaving 122 wounded, some

critically

● 2011 Nairobi Kenya pipeline fire kills

approximately 100 people and hospitalized 120

● November 22, 2013: Sinopec Corp oil pipeline

exploded in Huangdao, Qingdao, Shandong

Province, China, 55 people were killed

● June 27, 2014: a pipeline blast in Southern

Indian state of Andhra Pradesh killed 22 people

and injured 37

Thus, it is crucial that a more effective gas

monitoring system is put in place in order to prevent

the consequences of another massive gas leak.

To allow real-time monitoring of natural gas

leaks, our team developed a low-cost Internet of

Things (IoT) Natural Gas Pipeline Monitoring

System. Our flammable and toxic gas monitoring

system is low-cost, can be deployed over a wide area,

has robust communication, and can be provisioned

quickly and easily. Essentially, the installer could

simply place and secure a self-contained portable

monitoring unit in any appropriate location, push a

button on their smartphone/tablet, and the new node

would configure itself to be part of the monitoring

system.

2 SYSTEM DESCRIPTION

Our IoT gas monitoring system consists of a network

of sensor nodes placed around natural gas containers,

transport facilities, pipelines, or openings that might

leak. The first phase of the system involves sensor

node modules, a communications network for the

nodes, and a central interface. The nodes are built

with the relevant gas sensor(s) (MQ-4 for methane

and ethane, etc.), solar panels and batteries for power,

and inexpensive communication modules. The

system provides connectivity for each node’s data

using a variety of communication standards such as

Bluetooth, WiFi, or LoRa, depending on the distance

between the nodes. Each node’s data is relayed

toward the central node and aggregated to the cloud

database. The user interface is built to work on a

multitude of platforms (Android, iOS, Windows,

macOS), providing widespread access to the cloud

database and thus the current gas level readings of

each node.

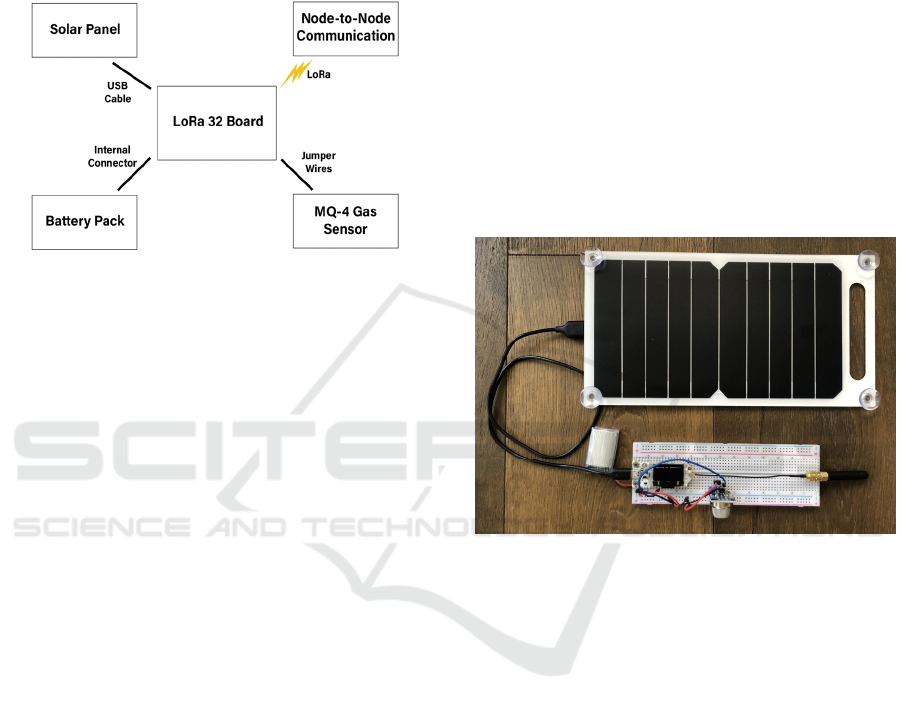

2.1 LoRa Sender Modules

The primary element of our natural gas monitoring

system is a network of LoRa-based gas sensor

modules. Figure 1 shows the block diagram of a LoRa

sender module. Each of these modules consists of a

LoRa32 microcontroller board, a low-cost (MQ-4)

gas sensor, a solar panel, and a 3.7 Volt lithium

battery. The LoRa32 is an ESP32-based

microcontroller which acts as the bridge between the

MQ-4 gas sensor module and the cloud database.

LoRa stands for “long range”, and provides low bit

rate communications over distances up to 10 km. The

LoRa32 module adds LoRa capabilities to the low-

cost ESP32 IoT platform. The MQ-4 gas sensor is an

extremely low-cost, widely available sensor that

detects the presence of methane gas in the air.

Methane (CH₄) is the principal constituent of natural

gas, so leaks from natural gas processing facilities can

be detected by measuring higher concentrations of

methane gas in the atmosphere. Therefore, methane is

an ideal gas for us to target, as it can be measured

easily and affordably.

The solar panel and lithium battery provide local

electrical power to the sender modules. They allow

the modules to be placed anywhere outdoors without

the need to connect to power supplies, which means

that they can be deployed easily along gas pipelines

and gas wells.

2.2 LoRa Receiver Module

The data collection node will not need a battery nor a

solar panel as it will be installed at a gas distribution

company’s station where it will have access to power

and network infrastructure such as WiFi. It will

receive packets from the sender modules over LoRa

and will store the data in the local and/or cloud-based

database such as Google Firebase. Therefore, the data

IoT Natural Gas Pipeline Monitoring System

169

collection node will use both LoRa and WiFi

communication.

2.3 Network

Our network of nodes is configured in a daisy-chain

topology. Data packets will be passed to each other

Figure 1: Block diagram of our LoRa sender module.

towards the data collection node. Each field node acts

as both a sender and a receiver in the sense that it both

receives packets from other nodes and sends those

received data packets and its own data packets to the

next node in the network.

The measured range of the LoRa32 modules is up

to 10 km; thus, nodes can be placed along a gas

pipeline or gas storage system at up to 5 km from each

other. This is so that a given node is in range of at

least two other nodes in the network. This provides

redundancy in the event of a node failure. If a node

were to become disconnected from the network, the

other nodes in the network would still be online.

2.4 Cloud Database

The cloud database will be where all of the data from

the various sender modules will be stored. Our

receiver module will connect to the cloud database

and upload the measured methane levels from each

sender node to the database. Once the data is in the

cloud database, our website and mobile application

will connect to the cloud database and display the data

contained within it.

2.5 Mobile Application and Website

Our mobile application will run on iOS and Android

devices and allow our users to monitor the pipelines

our sensors are deployed on remotely. The website

will provide the same feature set to our users, but will

be accessible from any desktop device on any

platform (Windows, macOS, and Linux).

3 CURRENT STATUS

Development of a prototype for this natural gas

monitoring system has been completed. The prototype

consists of two LoRa32 microcontrollers (one sender

and one receiver) with the corresponding gas sensor,

solar panel, and battery mentioned previously.

3.1 System Prototype

We have built working prototypes of our LoRa sender

node and our LoRa receiver node. Both nodes use the

same hardware, with the exception of the receiver

node, which has no gas sensor due to its role being the

accumulation and handling of data, and potentially no

battery nor solar panel due to its easy accessibility to

power.

Figure 2: The prototype of the LoRa sender module.

Importantly, the total material cost of the

prototype in very small quantities, including a solar

panel, lithium battery, LoRa32, 9 different types of

MQ-series gas sensors, but excluding a case, is under

USD86 (~EUR73). Buying in larger quantities will

significantly reduce the cost. With this sensor

configuration, we expect that the total material cost

including a weather-resistant case will be under

USD100 (~EUR85).

The MQ-4 is a low-cost (~USD5, ~EUR4)

chemical sensor with an SnO2 sensing layer, which

has a detection sensitivity of 200ppm, and is

applicable for the detection of gas leaks in the

proximity of gas pipelines and wells. If higher

sensitivity is required, such as for the detection of

natural gas concentrations in the surrounding areas,

sensors with sensitivities of 30ppm such as the SGX

IR13BD IR Hydrocarbon Sensor are commercially

available for USD200 (~EUR170). The use of higher

sensitivity sensors is still extremely cost efficient for

larger scale deployment.

IN4PL 2021 - 2nd International Conference on Innovative Intelligent Industrial Production and Logistics

170

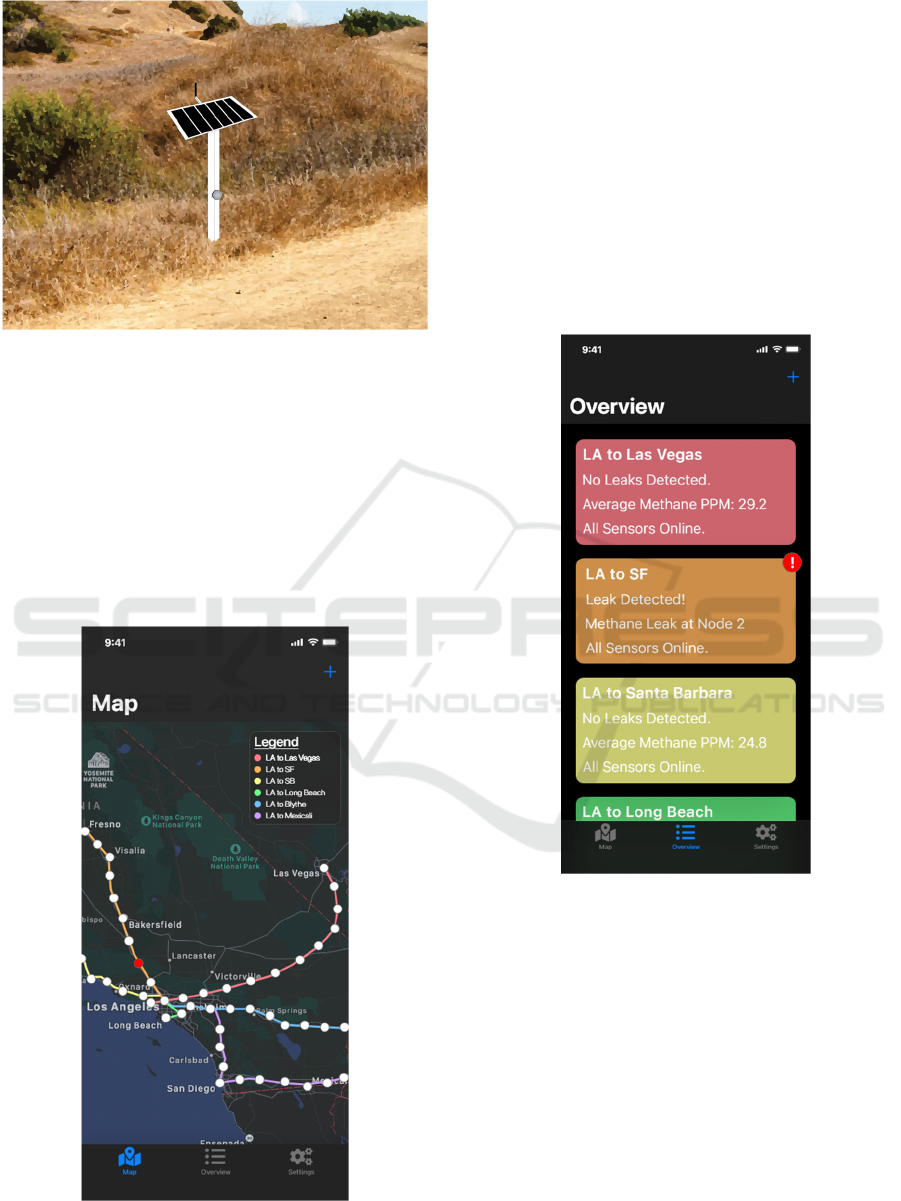

Figure 3: Concept installation drawing of the LoRa sender

module.

3.2 Mobile Application

The mobile application is being developed for

iOS/Android devices and will allow the user to easily

monitor each node to access the amount of methane

present. This will allow the user to effortlessly

pinpoint the location of a gas leak along a pipeline

and prevent any hazardous effects that may ensue

from an otherwise unnoticeable gas leak.

Figure 4: Screenshot of the map tab of the proposed mobile

application.

Figures 4, 5, and 6 show screenshots of various

tabs of the proposed mobile application: map,

overview, and detail.

The map tab will display an entire map of the

user’s designated location that consists of each

pipeline under surveillance. Each pipeline will be

distinguishable by a unique color that can be

identified by the given legend. The nodes of each

pipeline will be represented by white circles that will

change to red if a leak has been detected. Both the

overview tab and the map tab will allow the user to

observe every pipeline, but the map tab allows the

user to visually identify the location of the leak on a

map.

Figure 5: Screenshot of the overview tab of the proposed

mobile application.

The overview tab will display a brief rundown of

each pipeline that will indicate whether any of the

nodes have detected a leak, if any of the sensors have

disconnected from the network, and the average

methane ppm of the pipeline. By selecting any of the

pipelines from the overview tab, the user will be

presented with a new screen which contains the

details for each individual node along that specific

pipeline. This information will include whether the

node has detected a leak, if the node has been

disconnected from the network, how many data

packets have been sent by the node, and the average

methane ppm at that node.

IoT Natural Gas Pipeline Monitoring System

171

Figure 6: Screenshot of the pipeline details tab of the

proposed mobile application.

Lastly, the mobile application will also consist of

a settings tab. From this tab the user will be able to

alter some of the general characteristics of the

application such as the language of the text. The

settings tab will also provide the user with an

opportunity to temporarily remove pipelines from

surveillance as well as an option to add removed

pipelines back into the app. An official prototype of

the application may reveal the need for more tools

that would be included under this tab.

4 SUMMARY

The Aliso Canyon gas leak was the worst gas leak in

United States history (McGrath, 2016). As a direct

solution to this event and events like it, we are

designing a low-cost, deployable-anywhere gas

monitoring system that can be installed densely

around gas pipelines. For gas storage facilities, our

system can work in tandem with existing gas

monitoring systems to provide localized high

concentration measurements around potential

leakages, while the existing systems provide high

sensitivity measurements around the entire storage

facility. Our Natural Gas Pipeline Monitoring System

seeks to streamline the process of finding and fixing

gas leaks, thereby preventing the negative effects of

major gas leaks.

ACKNOWLEDGEMENTS

This project/publication was made possible through

the support of a grant from the W. M. Keck

Foundation.

Design resources courtesy of Apple Inc., Adobe,

and FontAwesome. All rights to their respective

owners.

REFERENCES

Abram, Susan. (2017, August 28). Two months in, Porter

Ranch gas leak compared to BP Gulf oil spill. Daily

News. https://www.dailynews.com/2015/12/19/two-

months-in-porter-ranch-gas-leak-compared-to-bp-gulf-

oil-spill/

Conley, S., Franco, G., Faloona, I., Blake, D. R., Peischl, J.,

& Ryerson, T. B. (2016). Methane emissions from the

2015 Aliso Canyon blowout in Los Angeles, CA.

Science, 351(6279), 1317-1320. doi:10.1126/science.

aaf2348

Domonoske, Camila (2018, August 8). California

Company Reaches $119.5 Million Settlement Over

Massive Gas Leak. NPR. https://www.npr.org/2018/08/

08/636779692/california-company-reaches-119-5-

million-settlement-over-massive-gas-leak

FontAwesome. https://fontawesome.com/license

Gazzar, B. (2015, December 25). Porter Ranch gas leak

dampens Christmas spirit for those struggling to

relocate. Daily News. https://www.dailynews.com/

2015/12/25/porter-ranch-gas-leak-dampens-christmas-

spirit-for-those-struggling-to-relocate/

Green America. (n.d.). Volatile: Natural Gas Pipeline

Explosions. Green America. https://www.green

america.org/natural-gas-pipeline-and-infrastructure-

explosions-nationwide

McGrath, M. (2016, February 26). California methane leak

'largest in US history'. BBC. https://www.bbc.com/

news/science-environment-35659947

SoCalGas. (n.d.) Methane Emissions. SoCal Gas.

https://www.socalgas.com/stay-safe/methane-

emissions

Ortiz, Edward. (2016, January 9). UC Davis scientist key to

measuring massive methane leak at Aliso Canyon.

Sacramento Bee. https://www.sacbee.com/news/local/

environment/article53629265.html

SoCalGas. (2016, February 11). SoCalGas Temporarily

Controls Flow of Gas at Leaking Aliso Canyon Well;

Initiates Process of Permanently Stopping the Leak

[Press release]. Sempra. https://www.sempra.com/es/

node/3165

SoCalGas. (n.d.) Aliso Canyon Infrared Fence-Line

Methane-Monitoring System. SoCal Gas.

IN4PL 2021 - 2nd International Conference on Innovative Intelligent Industrial Production and Logistics

172

https://www.socalgas.com/stay-safe/pipeline-and-

storage-safety/aliso-canyon-methane-monitoring

Wikimedia Foundation. (2021, July 11). List of pipeline

accidents. Wikipedia. https://en.wikipedia.org/wiki/

List_of_pipeline_accidents

Wunch, D., Toon, G. C., Hedelius, J. K., Vizenor, N.,

Roehl, C. M., Saad, K. M., Blavier, J.-F. L., Blake, D.

R., and Wennberg, (2016). Quantifying the loss of

processed natural gas within California's South Coast

Air Basin using long-term measurements of ethane and

methane. Atmospheric Chemistry and Physics, 16(22),

14091-14105. doi:10.5194/acp-16-14091-2016

IoT Natural Gas Pipeline Monitoring System

173