Production Capacity as a Factor of Sustainable Development of

Agricultural Enterprises

Inna Viktorovna Kuznetsova

1a

, Elena Gennadievna Zhulina

2b

, Sergey Viktorovich Istomin

3c

and Inna Vasilievna Mukhina

2d

1

Volga region cooperative Institute of Russian University of cooperation, Engels, Russia

2

Yuri Gagarin State technical university of Saratov, Saratov, Russia

3

Volga Interregional Branch of the Federal State Budgetary Institution "VNII Truda" of the Ministry of Labor of Russia,

Saratov, Russia

Keywords: Production capacity, sustainability, agribusiness enterprises, factors, efficiency of use.

Abstract: The article presents the materials of theoretical and empirical studies of the impact of the use of production

capacities of agricultural enterprises on the sustainability of their development. For the modern period of

development of the agro-industrial complex is characterized by such an important landmark as the need to

accelerate the renewal of production on the basis of the development of advanced scientific and technical

achievements. Greenhouse vegetable growing occupies a significant place in solving the problems of food

security of the country. The active attraction of large-scale investments in the greenhouse industry in 2016-

2019 made it possible to launch large-scale industrial greenhouses with tens of thousands of tons of gross

harvest. In 2020, even taking into account the decline in state support and the reduction in the number of new

investment projects, the gross harvest continued to grow, thanks to the full capacity of already built

greenhouse complexes and the reconstruction of old greenhouses. On the example of JSC SOVKHOZ-

VESNA, the use of production capacities in the vegetable growing of protected soil was evaluated and the

impact of the efficiency of their use on the sustainable development of the economic entity was determined.

1 INTRODUCTION

The main role in meeting the needs of the population

for fresh vegetables and herbs in the off-season is

played by greenhouse vegetable growing (Nikitin, A.,

2019). Greenhouse production offers an order of

magnitude greater production of environmentally

friendly products than in the open ground, and allows

you to organize a year-round production cycle

regardless of natural and climatic conditions. The

maximum allowable production of greenhouse

products according to the approved assortment sales

plan based on the full use of the necessary production

equipment and production areas is the production

capacity. At the same time, it is important to take into

account advanced technologies and progressive

organization of work and production.

a

https://orcid.org/0000-0001-6306-4034

b

https://orcid.org/0000-0002-7464-3100

c

https://orcid.org/0000-0002-4735-7723

d

https://orcid.org/0000-0003-2824-355Х

The effective use of production capacity depends

on the implementation of the main task of this stage

of economic transformation – improving the quality

of products, since high competition in the market

contributes to faster sales and high demand for high-

quality products. Retail chains and catering

companies constantly need fresh, high-quality

greenhouse products. Year-round functioning

greenhouse production makes it possible to

constantly receive significant income. Along with

high profitability, good profitability and a quick

return on investment, greenhouse production has

many other advantages. The optimal use of

production capacity in greenhouse production has a

positive impact on the economic indicators of the

functioning of production entities. This ensures an

increase in production volumes and reduces its cost.

60

Kuznetsova, I., Zhulina, E., Istomin, S. and Mukhina, I.

Production Capacity as a Factor of Sustainable Development of Agricultural Enter prises.

DOI: 10.5220/0010682900003169

In Proceedings of the International Scientific-Practical Conference "Ensuring the Stability and Security of Socio-Economic Systems: Overcoming the Threats of the Crisis Space" (SES 2021),

pages 60-69

ISBN: 978-989-758-546-3

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Among other things, the amount of monetary

investments that contribute to the growth of

production volumes is reduced. There is also a saving

of labor, embodied in the main production assets, due

to more intensive use of equipment, etc. Practical

reality confirms that today the production capacity in

the Russian Federation is on average loaded by no

more than 60%. In a significant part of industrial

entities, the load is no more than 30%. Better

utilization of production capacity means, among other

things, faster turnover. And this greatly helps to solve

the problem of reducing the spread in the terms of

physical and moral wear and tear, increasing the rate

of renewal of fixed assets.

2 MATERIALS AND METHODS

Currently, the greenhouse industry in Russia is

developing due to the large-scale introduction of

modern agricultural technologies, equipment,

structures, selection achievements, optimization of

business processes, improvement of pre-sale

preparation of products, expansion of geography and

sales channels. According to Rosstat, over the past

three years, the Russian Federation has seen a small

but steady increase in greenhouse areas, which in

relative terms amounted to 11%. According to the

plans of the Ministry of Agriculture, by 2021 the size

of the production area should be increased by almost

one and a half times, that is, at least 2 thousand

hectares of greenhouses will be built (World, 2018).

Internal competition in the market of domestic

producers is actively developing, while its level

varies greatly depending on the region (Ananiev,

2019). The share of the TOP 10 regions accounts for

49% of the used areas of winter greenhouses, the

Saratov region takes the 8th place in this list.

Currently, the profitability of newly built greenhouse

complexes reaches 40%. The profitability of old

greenhouses, characterized by high energy

consumption and non-year-round harvest time, is 15-

30%. All this helps to significantly increase the

commercial attractiveness of growing vegetables in

greenhouses, not only for specialized, but also for

non-core investors. For this reason, the construction

of more than a hundred large (20 ha) and medium (10-

20 ha) greenhouses has already been announced. In

general, over the past 3 years, many interesting new

products have been introduced in Russia, which has

allowed the industry to constantly develop. In

addition, state support also contributes to the

development of the industry: compensation for the

cost of building greenhouses in the amount of 20%

(for the Far Eastern regions, compensation will be

25%) and soft loans-1-5% per year. From 2020 to

2022, 80 investment projects in the field of closed-

ground vegetable production have been approved in

Russia, including 50 projects that are already being

implemented, and 30 that are planned for

implementation. At the same time, the total annual

capacity was 937.6 thousand tons, the volume of

investments – 247.7 billion rubles (Russian market,

2020).

Further growth in the economic efficiency of

production is possible on the basis of a more complete

use of the production reserves of the agricultural

enterprise. Based on this, the key is to determine the

significant indicator/indicators that most

informatively characterize the production capabilities

of the organization. The main indicator is the

production capacity of the enterprise and the level of

its use. The production capacity of an agribusiness

enterprise is the ability of fixed assets assigned to it

to the maximum allowable volume of a certain type

of product in the most efficient use of existing

equipment and production areas. At the same time,

the applied technologies and the organization of

production should be as perfect as possible. The

production capacity of an agricultural enterprise is an

estimated indicator of the maximum or optimal

volume of production for a certain period (decade,

month, quarter, year). The optimal volume of

production is calculated to determine the moment

when the volume of products produced will meet the

needs of the market, as well as the necessary stock of

finished products in case of changes in the market

situation or unforeseen circumstances. The

determination of the maximum possible volume of

products produced is necessary in order to identify its

reserve in cases where the agro-industrial entity

performs the maximum possible operation. In

practice, an annual production plan (production

program) is developed, which allows you to visualize

the production capacity of an economic unit. The

assessment of production capacities of enterprises is

carried out to analyze the level of technical equipment

of production. This will allow us to determine the

intra-production reserves for increasing the efficiency

of using production capacities. Insufficient use of the

production capacity of agro-industrial enterprises

contributes to an increase in the share of fixed costs,

an increase in the cost price and a decrease in

profitability. In this regard, it is necessary to identify

analytically the changes that have occurred in the

production capacity of an economic entity, the

completeness of its use and the impact of these

characteristics on cost, profit, break-even and other

Production Capacity as a Factor of Sustainable Development of Agricultural Enterprises

61

economic indicators (Moiseenko 2017;

Myasnyankina, 2019; Bashirzade, 2021).

Production capacity is determined both for the

business entity as a whole, and for individual

structural divisions or production sites. To determine

the maximum possible volume of production, the

main production sites are used as a basis, which are

involved in the main technological operations of

manufacturing products and perform the greatest

amount of work in terms of complexity and labor

intensity.

Most often, the effectiveness of the analytical

assessment is influenced by the justification of the

system of indicators that allow you to determine the

intensity of the use of production capacity. This

system is divided into the following groups: the first

includes coefficients that characterize the use of

production and the level of development of the design

capacity of the subject; the second contains indicators

that describe the use of equipment, the third-the cost

characteristics of the output of production. Thanks to

the system of indicators, you can get fairly reliable

information about the level of production capacity

utilization. Based on the information received, a

comprehensive analysis of the use of the existing

production capacities of the organization and its

divisions is carried out in order to determine the

sequence of implementation of reserve measures to

improve the use of production capacities (Zhulina,

2018; Litvinov, 2018).

Taking into account all the above, we will

evaluate the production capacity of the agricultural

enterprise, LLC SOVKHOZ-VESNA, engaged in the

production of greenhouse products, and determine the

impact of the efficiency of their use on the stability of

the functioning of the economic entity.

3 RESULTS AND DISCUSSION

The results of economic activity of JSC SOVKHOZ-

VESNA are significantly influenced by the labor

resources and the efficiency of their use. The

efficiency of using the production capacities of JSC

SOVKHOZ-VESNA depends on the effectiveness of

this resource. Analysis of the dynamics of labor

productivity for 2018-2020 showed that the growth

rate of product sales exceeds the growth rate of the

number of employees, including workers.

Consequently, the growth rate of the average annual

output of both per worker and per worker over the

course of three years tends to increase. The average

annual output of one operating JSC SOVKHOZ-

VESNA increases by 7.24% in 2020 compared to

2018 and remains virtually unchanged in 2020

compared to 2019. The average annual output per

working unit of JSC SOVKHOZ-VESNA increases

by 6.47% in 2020 compared to 2018 and decreases by

0.55 % in 2020 compared to 2019. Similar dynamics

can be traced in the average daily and average hourly

output of 1 working greenhouse production. The

negative fact is that the labor intensity indicator in

2020 compared to 2019 increased by 2.17%, that is,

the cost of physical units of time per 1 ruble of output

increased.

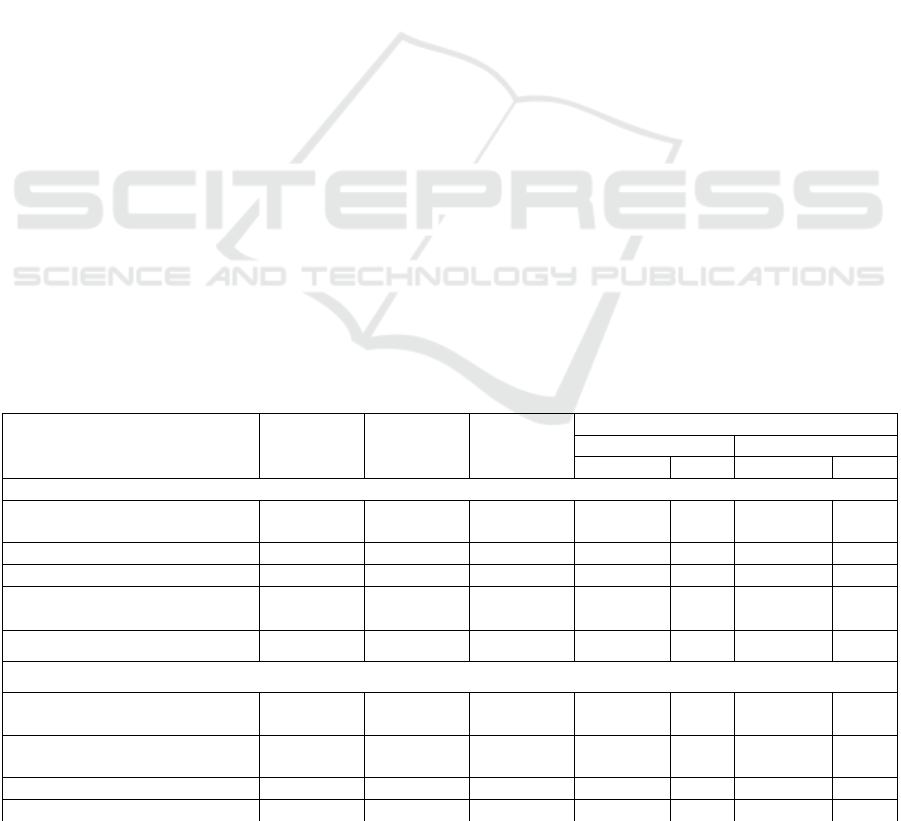

Table 1: Indicators of the use of working time and the production of the labor unit of JSC SOVKHOZ-VESNA for 2018-

2020.

Economic indicator 2018 2019 2020

2020 deviation from

2018 2019

(+,-) % (+,-) %

Source data

Volume of sales of products

(services), thousand rubles.

812,840.00 856,104.00 845,205.00 32,365.00 3.98

-

10,899.00

-1.27

Number of employees, people 626 612 607 -19.00 -3.04 -5.00 -0.82

including workers 557 548 544 -13.00 -2.33 -4.00 -0.73

Worked by one worker during

the year, days

206 205 210 4.00 1.94 5.00 2.44

Average working day duration, h

7.90 8.00 8.00 0.10 1.27 0.00 0

Calculated data

Share of workers in the total

number of employees, %

88.98 89.54 89.62 0.64 - 0.08 -

Total amount of time worked per

year:

b

y all workers, person-hou

r

128,956.00 125,460.00 127,470.00 -1,486 -1.15 2,010.00 1.6

one worker, person-hou

r

1,627.4 1,640.00 1,680.00 52.6 3.23 40.00 2.44

SES 2021 - INTERNATIONAL SCIENTIFIC-PRACTICAL CONFERENCE "ENSURING THE STABILITY AND SECURITY OF

SOCIO - ECONOMIC SYSTEMS: OVERCOMING THE THREATS OF THE CRISIS SPACE"

62

Table 1: Indicators of the use of working time and the production of the labor unit of JSC SOVKHOZ-VESNA for 2018-

2020 (cont.).

Average annual output:

1 worker, thousand rubles. 1,459.32 1,562.23 1,553.69 94.37 6.47 -8.54 -0.55

1 em

p

lo

y

ee, thousand rubles. 1,298.47 1,398.86 1,392.43 93.96 7.24 -6.43 -0.46

Average daily output

1 worker, rub.

11,312.56 12,398.65 12,138.2 825.64 7.3 -260.45 -2.1

Average output per hour

1 worker, rub.

1,431.97 1,549.83 1,517.28 85.31 5.96 -32.55 -2.1

Labor intensity, person-hour/

rub.

0.698 0.645 0.659 -0.039 -5.59 0.014 2.17

The increase in the average annual output of one

worker and worker of JSC SOVKHOZ-VESNA

predetermined the impact of the following changes:

the average output per hour; the number of days

worked by one labor unit and the length of the

working day. The absolute impact of factors on the

change in the level of average output per year of

working units was determined by the method of

absolute differences (Table 2).

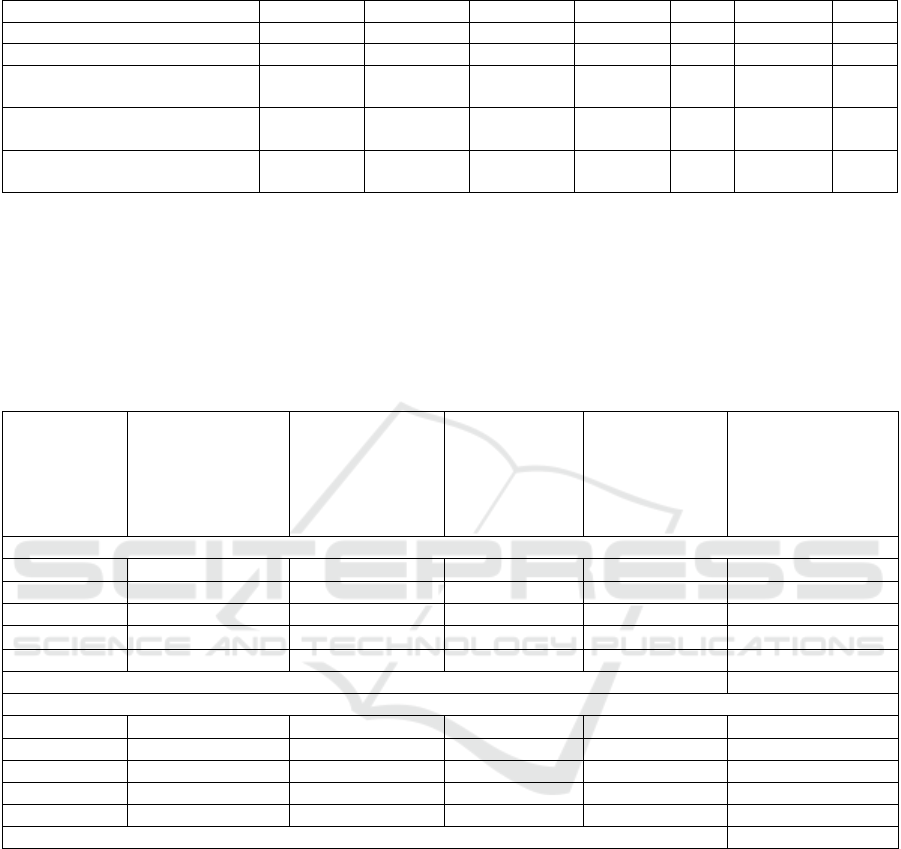

Table 2: Results of the influence of factors of working time use on the change in the average annual output of one working

unit by the method of chain substitutions in JSC SOVKHOZ-VESNA for 2019 and 2020.

Specific

weight of

working

units, %

The number of

working days of

one working unit

per year, people-

days

Working day

duration, hour

Production of

one working

unit on average

per hour,

rubles.

Production

of one working

unit on average

per year,

thousand rubles.

Changes in the

average annual

output of one

working unit,

thousand rubles, (+/-

)

2019

(

base

p

eriod

)

2018 - 88,98 2018 - 129 2018 - 7,9 2018 - 1,431,97 1,298.47 -

2019 - 89,54 2018 - 129 2018 - 7,9 2018 - 1,431,97 1,306.71 8.24

2019 - 89,54 2019 - 126 2018 - 7,9 2018 - 1,431,97 1,276.32 -30.39

2019 - 89,54 2019 - 126 2019 - 8 2018 - 1,431,97 1,292.48 16.16

2019 - 89,54 2019 - 126 2019 - 8 2019 - 1,549,83 1,398.86 106.38

The result of all factors 100.39

2020 (reporting period)

2019 - 89,54 2019 - 126 2019 - 8 2019 - 1,549,83 1,398.86 -

2020 - 89,62 2019 - 126 2019 - 8 2019 - 1,549,83 1,400.09 1.23

2020 - 89,62 2020 - 128 2019 - 8 2019 - 1,549,83 1,422.31 22.22

2020 - 89,62 2020 - 128 2020 - 8 2019 - 1,549,83 1,422.31 0.00

2020 - 89,62 2020 - 128 2020 - 8 2020 - 1,517,28 1,392.44 -29.87

The result of all factors -6.42

This increase was due to the following changes:

the share of workers increased by 0.56

percentage points (from 88.98 to 89.54%). This

led to an increase in the result by 8.24 thousand

rubles;

the number of days worked per one labor unit

per year decreased by 3 people/days (from 129

to 126 people/days). This fact affected the

decrease in the effective indicator by 30.39

thousand rubles;

the working day length increased by 0.1 hours

(from 7.9 to 8 hours), which led to an increase

in the average output for the year by 16.16

thousand rubles;

the average output per hour of one working unit

increased by 117.86 thousand rubles (from

1,431.97 to 1,549.83 thousand rubles). This

resulted in an increase in the effective indicator

by 106.38 thousand rubles;

The reporting period is characterized by a

negative final result – a decrease in the average

annual output compared to the base period by 6.42

thousand rubles. This negative trend is explained by:

a slight increase in the share of workers by

0.08% (from 89.54 to 89.62%). This led to an

increase in the effective indicator by 1.23

thousand rubles;

Production Capacity as a Factor of Sustainable Development of Agricultural Enterprises

63

increase in the number of working days per

working unit per year by 2 people/day (from

126 to 128 people/day). This fact affected the

increase in the effective indicator by 22,22

thousand rubles;

a decrease in the average hourly output of one

labor unit by 32.55 thousand rubles (from

1,549.83 to 1,517.28 thousand rubles). This

resulted in a decrease in the effective

indicator by 29.87 thousand rubles.

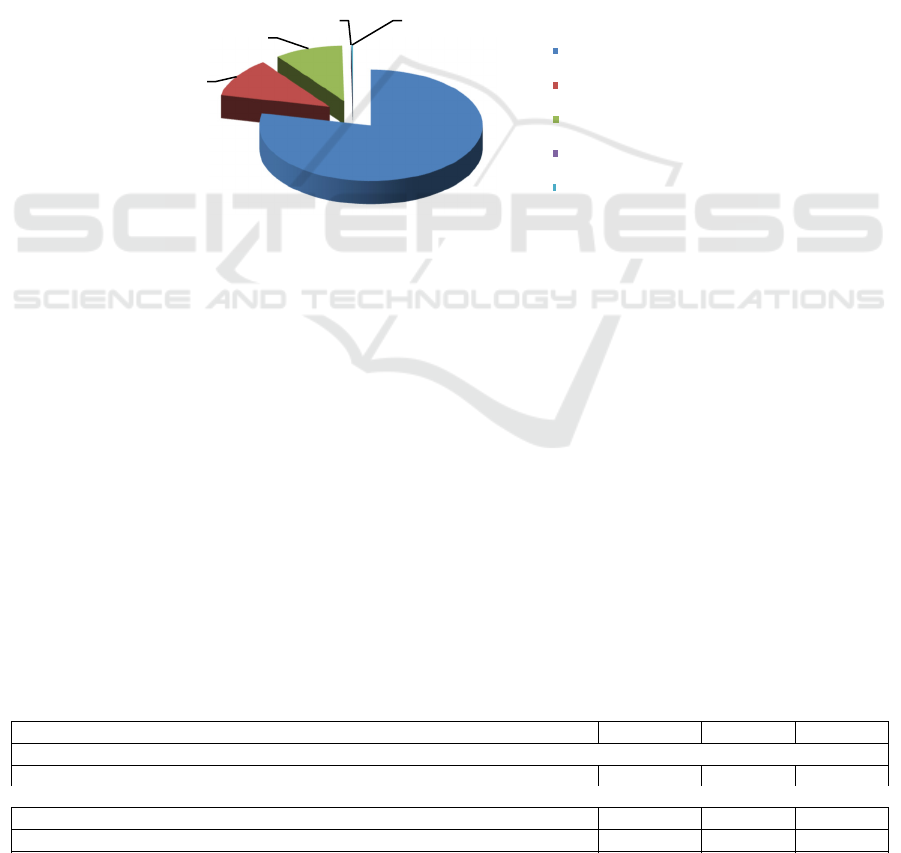

Next, we will consider the provision of JSC

SOVKHOZ-VESNA with the main production funds.

The largest share in the structure of fixed assets is

occupied by buildings, structures and transmission

devices: in 2020, this figure was 78.43%. The

smallest share is accounted for by production and

household inventory, which is only 0.01% of the total

amount of all fixed assets (Fig. 1). Decrease in the

cost of fixed assets in 2020 (1,207,819 thousand

rubles) compared to 2018 (15,300.92 thousand

rubles) by 322,273 thousand rubles. or 21.06% is

associated with the disposal of items of fixed assets

that are morally and physically worn out and monthly

depreciation. The share of machinery and equipment

in the enterprise in 2020 is 11.37% of the total fixed

assets.

The following equipment is installed in JSC

SOVKHOZ-VESNA: ventilation system; air

recirculation complex; drip irrigation system; CO2

plant feeding system; artificial seedling lighting

system; heating system. Each of these elements

increases the possibilities of greenhouses for the

output of finished products.

Figure 1: Structure of fixed assets of JSC SOVKHOZ-VESNA in 2020.

When analyzing the condition of the equipment,

special attention is paid to its physical and moral wear

and tear (the equipment may completely fail due to

wear and tear) (Table 2). The following results are

obtained. The coefficient of renewal of machinery

and equipment in 2018 was 24.3%, in 2019 its value

increased to 26.2% due to an increase in fixed assets

(purchase of a truck, updating of irrigation systems,

heating, etc.). In 2020, the renewal rate decreased to

1.2%. The disposal rate was 1.4%, 26.1% and 3.0%,

respectively. A fairly significant disposal was

observed in 2019 when replacing a completely worn-

out irrigation system. The equipment wear rate in

2020 is 39.1% (the critical acceptable value of the

wear rate is 50%), and the shelf life rate is 60.9%,

respectively. Consequently, the company does not

have sufficient quantity and quality of fixed assets for

the implementation of production and economic

activities, since at present the machines and

equipment are almost half worn out. The

consequences of wear and tear are manifested in

various aspects of the activities of JSC SOVKHOZ-

VESNA: in a decrease in product quality; a drop in

the production capacity of equipment and its technical

productivity; an increase in the cost of maintaining

and operating equipment; an increase in unplanned

downtime associated with equipment malfunction; a

change in the duration of the repair cycle; an increase

in maintenance and repair costs, etc.

Thus, it is inefficient to operate morally and

physically outdated equipment, so it must be replaced

before the state of physical wear and tear occurs.

Table 3: Characteristics of the state and movement of the equipment of JSC SOVKHOZ-VESNA in 2018-2020.

Economic indicato

r

2018 2019 2020

Source data

Fixed

p

roduction assets, thousand rubles 1,530,092 1,539,953 1,207,819

Table 2: Continue

d

Active

p

art of

p

roduction assets, thousand rubles 1,149,099 1,190,384 869,629

Functionin

g

e

q

ui

p

ment, thousand rubles. 139,872 139,931 137,351

78,43

11,37

9,92

0,01

0,27

Здания, сооружения и

передаточные устройства

Машины и оборудование

Транспортные средства

Производственный и

хозяйственный инвентарь

Другие виды основных

средств

Buildings, structures and transfer devices

Machinery and equipment

Transport vehicles

Production and household inventory

Other types of fixed assets

SES 2021 - INTERNATIONAL SCIENTIFIC-PRACTICAL CONFERENCE "ENSURING THE STABILITY AND SECURITY OF

SOCIO - ECONOMIC SYSTEMS: OVERCOMING THE THREATS OF THE CRISIS SPACE"

64

Table 3: Characteristics of the state and movement of the equipment of JSC SOVKHOZ-VESNA in 2018-2020 (cont.).

Number of units of functionin

g

e

q

ui

p

ment, units 22 27 25

E

q

ui

p

ment at the be

g

innin

g

of the time

p

eriod, thousand rubles. 107,351 139,872 139,931

Received e

q

ui

p

ment, thousand rubles. 33,979.1 36,661.2 1,648.2

Retired equipment, thousand rubles. 1,458.1 36,602.2 4,228.2

Equipment at the end of the time period, thousand rubles 139,872 139,931 137,351

Calculated data

Functionin

g

e

q

ui

p

ment in the cost of the active

p

art of

p

roduction assets, % 12.2 9.1 11.4

Active

p

art of fixed assets, % 75.1 77.3 72.0

Relative in

p

ut rate, % 24.3 26.2 1.2

Relative disposal rate, % 1.4 26.1 3.0

Relative growth rate, % 30.3 0.04 -1.84

Relative wear rate, % 35.5 32.8 39.1

Relative shelf life, % 64.5 67.2 60.9

To develop measures to improve the use of

equipment, it is necessary to monitor the age

composition of various types of equipment,

determining their suitability. The age composition is

characterized by the grouping of equipment by service

life. There is a positive trend of a small increase in the

share of "young" equipment (age groups up to 5 years

and 5-10 years). In this case, we can conclude that the

company commissioned new equipment in 2018 and

2019, and as a result, the share of "young" equipment

increased to 27.20% in 2019, compared to 27% of the

level of 2018. Most of the equipment for the

production of greenhouse vegetables has a sufficient

service life. The average age of the machines is: (5,7 ∙

5 + 21,5 ∙ 10 + 67,7 ∙ 20 + 5,1 ∙ 30) / 100 = 17,5 years.

The standard life of the equipment is 30 years. The

equipment of JSC SOVKHOZ-VESNA was used for

58,3% (17,5 / 30 ∙ 100%).

If the service life of the equipment is long enough

and exceeds the standard values, then the technical

and economic characteristics of the equipment

deteriorate. This applies to the accuracy of product

processing, the productivity of equipment, and the

growth rate of production volumes. In addition, the

quality of the products themselves deteriorates, and

production errors increase. At the same time, the cost

of repairing and operating the equipment increases

significantly.

The analysis of the efficiency of the use of the

main production capacities (Table 4) based on the

factor analysis of the return on funds showed that JSC

SOVKHOZ-VESNA received products in the amount

of 0.53 rubles from each ruble invested in the main

production assets in 2018, and 0.69 rubles in 2020.

The increase in capital productivity in 2020 compared

to 2019 by 0.14 points and the decrease in capital

intensity by 0.34 points is a positive change. The

increase in the return on capital ratio allows you to

save¬ current operating costs. This occurs as a result

of a decrease in the amount of depreciation¬ charges

per unit of income. In this case, a corresponding profit

increase is generated. As a result, it expands its

opportunities for ¬material incentives for workers,

industrial and social ¬development.

Over the past three years, the labor capital ratio

has decreased by 526,446 thousand rubles or by

20.9%, which is a negative trend. The specified

decrease in the labor capital ratio per 1 employee was

due to a decrease in the cost of fixed assets by 21.6%

or 322,134 thousand rubles and the number of

employees by 5 people. In 2019, for every 100 rubles

of spent fixed assets, 8.69 rubles of profit was

received, in 2020-11.55 rubles, which increases the

efficiency of operations.

Table 4: Factor analysis of the capital return of fixed assets of JSC SOVKHOZ-VESNA in 2019-2020.

Economic indicator

2019

(base

period)

2020

(reportin

g period)

Deviation of the

reporting period

from the reference

p

eriod,

(

+, -

)

Growth rate,

%

Source data

Volume of crop production, thousand rubles 822,801 814,326 -8,475 98.9

Fixed production assets, thousand rubles

1,539,95

3

1,207,81

9

-332,134 78.4

Functioning equipment, thousand rubles. 139,931 137,351 -2,580 98.2

Number of units of functioning equipment, units 25 27 +2 108.0

Production Capacity as a Factor of Sustainable Development of Agricultural Enterprises

65

Table 4: Factor analysis of the capital return of fixed assets of JSC SOVKHOZ-VESNA in 2019-2020 (cont.).

The average cost of a unit of functioning equipment,

thousand rubles

7,200 7,963 +763 110.5

Number of working days (Tdn) 215 216 1 100.5

Number of machine shifts worked

(

Tsm

)

5,805 6,882 +1,077 118.6

Duration of one shift tcm, h 8 8 - 100

Useful o

p

eratin

g

time of the e

q

ui

p

ment

(

T

p)

, h 1,271 1,423 152 111.9

Calculated data

Relative load indicator of the equipment during the shift

(

Kz

)

0.684 0.698 +0.014 102.0

Relative shift rate

(

Ksm

)

1.08 1.18 0.1 109

Average hourly output per unit of equipment, thousand

rubles

25.895 21.195 -4.7 81.8

Ca

p

ital return of functionin

g

e

q

ui

p

ment, rub./rub. 5.88 5.93 0.05 100.9

Fund return of OF, rub./rub. 0.53 0.67 0.14 126.4

Fund capacity of the OF, rub./rub. 1.79 1.45 -0.34 81.0

Labor capital ratio, thousand rubles/person

2,516.26

3

1,989.81

7

-526.446 79.1

Return on fixed assets, % 8.69 11.55 2.86 -

The impact of various factors on the change in the

effective indicator-the return on funds of JSC

SOVKHOZ-VESNA-is determined by the method of

chain substitution (Table 5).

Table 5: Assessment of the impact of factors on the return on capital of functioning equipment

Factor

The size of the impact

on the return on

capital of functioning

equipment

Share of

influence,

%

The size of

the impact on

the return on

funds

Share of

influence,

%

The first level of influence

S

p

ecific

g

ravit

y

of the active

p

art - - -0.028 -20.0

S

p

ecific wei

g

ht of functionin

g

e

q

ui

p

ment - - 0.0974 69.57

Ca

p

ital return on functionin

g

e

q

ui

p

ment - - 0.0706 50.43

Total - - 0.14 100.0

Second level of influence

Equipment changeabilit

y

0.423 5.62 0.0039 2.79

Loadin

g

e

q

ui

p

ment 0.102 1.35 0.00095 0.68

Performance of a unit of e

q

ui

p

ment -0.924 -12.27 -0.00866 -6.19

Average price per unit of equipmen 7.927 105.3 0.0743 53.07

Total 7.528 100.0 0.07049 50.35

In the reporting period, compared to the reference

period, there is an increase in the relative indicators

of shift and equipment load. This indicates a

reduction in downtime losses during the day and

within the shift. This fact has a positive effect on the

change in the return on capital of the equipment. The

decrease in the share of the active part of fixed assets

had a negative impact on the first level of influence.

The ratio between the value of the influence of

each factor and the value of the deviation of the return

on capital from fixed assets is calculated. As a result,

the influence of each factor on the variation of the

aggregated indicator was established.

The decrease in the productivity of a unit of

equipment had the strongest negative impact on the

return on assets.

The influence of the third-level factors on the

return on funds was determined by analyzing the

relative indicators of the use of the time balance.

These include the relative shift indicator and the

relative load indicator. The possibility of assessing

the impact of downtime on the relative load of

equipment arises if this characteristic is considered as

the ratio between the useful and nominal time. In turn,

the effective time depends on a number of factors.

These include: the planned time of preventive

maintenance, the time of equipment modernization,

and other technological reasons.

SES 2021 - INTERNATIONAL SCIENTIFIC-PRACTICAL CONFERENCE "ENSURING THE STABILITY AND SECURITY OF

SOCIO - ECONOMIC SYSTEMS: OVERCOMING THE THREATS OF THE CRISIS SPACE"

66

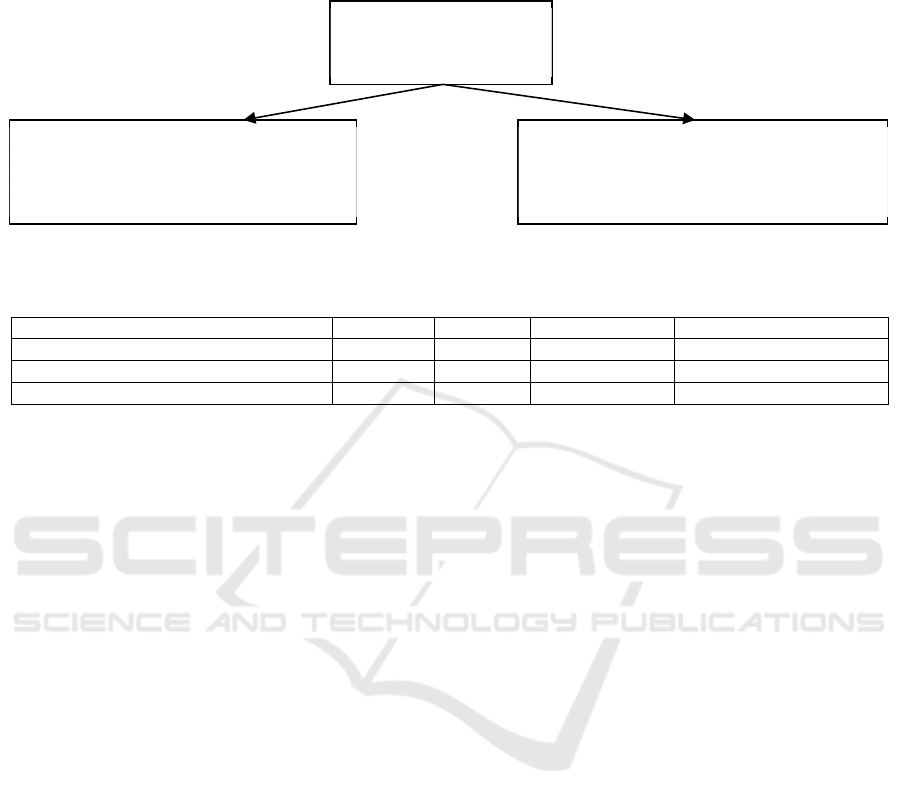

Thus, the impact of in-shift downtime on the

aggregate indicator-return on funds-is defined as the

influence of third-level factors. All factors taken into

account for changes in capital productivity and

growth in output can be divided into two groups

(Figure 2, Table 6).

Figure 2: Factors of change in return on funds and growth in output.

Table 6: Calculation of the integral indicator of the production use of equipment.

Indicato

r

2019 2020 Deviation Rate of change, %

Relative index of extensive loading 3.63 4.39 0.76 120.94

Relative index of intensive loadin

g

0.2589 0.2119 -0.047 81.85

Inte

g

ral load indicato

r

0.9398 0.93024 -0.00956 98.98

The integral indicator of the production use of

equipment has increased as a result of an increase in

the extensive load of equipment. At the same time,

there is a decrease in intensive loading. This fact

indicates that there are untapped opportunities to

increase production volumes without attracting

additional capacity and new capital investments. This

indicator can be increased by eliminating production

bottlenecks. It is possible to achieve the desired result

by optimizing the organizational and technical level

of production.

In general, it is advisable to divide the main

directions of improving the use of production

capacities of enterprises of the agro-industrial

complex into extensive and intensive ones (Figure 3).

Factors of changes in

capital productivity and

growth in output

Group I - intensive factors:

performance of a unit of equipment

for 1 hour of useful time use

Group II - extensive factors:

factors of working time use;

number of pieces of equipment

Production Capacity as a Factor of Sustainable Development of Agricultural Enterprises

67

Figure 3: Directions for improving the use of production capacities of agricultural enterprises

4 CONCLUSIONS

To improve the use of production capacities of JSC

SOVKHOZ-VESNA, a whole range of measures is

needed. It is required to reduce equipment downtime

or replace it with a new, more modern one. It is

important to increase the number of basic production

labor units that can produce more products. It is

possible to increase the productivity of workers by

setting a shift schedule or increasing output. At the

same time, it is necessary to attract bonus systems for

the implementation of an increased production plan.

It is important to improve the skills of a key part of

the industrial and production personnel – production

workers, namely: to train existing specialists or hire

new highly qualified specialists. Improved capacity

utilization can also be achieved by reducing the labor

intensity of manufacturing a unit of production.

An important prerequisite for the development of

a set of measures to improve the use of production

capacities and fixed assets of companies is the

forecast of growth in the production of goods and

services. This can be achieved mainly through the full

and efficient use of on-farm reserves. Rational

operation of machinery and equipment, increasing the

relative shift rate, reducing or eliminating downtime

will also improve the efficiency of production

capacity utilization. In addition, it is important to pay

attention to reducing the development periods of

newly commissioned capacities. Thus, it can be

concluded that the fixed assets and production

capacities of the enterprise are one of the main factors

for the sustainable development of the agro-industrial

complex.

REFERENCES

Ananiev, М.А., Burlankov, S.P., Sedova, N.V., Ananieva

О.М., 2019 Regional agri-food policy of the Russian

Federation in the framework of the national food

security system. In International Journal of

Engineering and Advanced Technology.

Bashirzadeh, R.R., 2021. Development of effective

communications in the field of science, technology and

innovation. Collective monograph. Engels. Limited

Directions for improving the use

of production capacities of agricultural

enterprises

Extensive measures-increasing

the working time of the equipment

due to:

reduction of downtime for

various organizational and

technical reasons;

improvements in logistics

services;

reduce the amount of

unnecessary equipment;

involvement in the

production of unidentified

equipment;

improvement of repair

services as a result of

reducing the duration and

improving the quality of

repair work;

implementation of the system

of planned preventive

maintenance, etc.

I

ntensive activities –more efficient use of equipment

performance:

acceleration of the movement of working bodies;

intensification of technological processes;

limiting the consumption of catalysts to a certain limit

without compromising the quality of the processed raw

materials;

reduction of defects, product losses;

use of waste-free technologies;

technical development of production, including

mechanization and automation of production processes,

modernization of existing equipment and its

replacement with more modern;

maintaining appropriate proportionality between

individual sites, workshops and departments;

elimination of bottlenecks;

strengthening of labor discipline;

timely installation and commissioning of new

equipment;

creation of an optimal production structure of fixed

assets and commissioning of new equipment, etc.

SES 2021 - INTERNATIONAL SCIENTIFIC-PRACTICAL CONFERENCE "ENSURING THE STABILITY AND SECURITY OF

SOCIO - ECONOMIC SYSTEMS: OVERCOMING THE THREATS OF THE CRISIS SPACE"

68

Liability Company "Institute of Scientific Research and

Development of Professional Competencies".

Zhulina, E.G., 2018. Enterprise resource support:

organization, management and efficiency of use.

Saratov. Limited Liability Company "Institute for

Research and Development of Professional

Competencies".

Litvinov, S.A., Kuznetsova, I.V., 2018. Methods of

assessing the production potential of an enterprise.

Saratov: Limited Liability Company "Institute for

Research and Development of Professional

Competencies".

World and Russian prospects of greenhouse vegetable

growing. 2018. https://www.agroxxi.ru/

Moiseenko, D.D., 2017. Economy of enterprises

(organizations). Simferopol. University of Economics

and Management.

Myasnyankina, O.V., Pakhomova Yu.V., 2019. Economy

and organization of production. Voronezh. Voronezh

State Technical University, EBS ASV.

Nikitin, A., Kuzicheva, N., Karamnova, N., 2019.

Establishing efficient conditions for agriculture

development. In International Journal of Recent

Technology and Engineering.

The Russian market of vegetables of the closed ground: the

state and prospects. https://specagro.ru/

Production Capacity as a Factor of Sustainable Development of Agricultural Enterprises

69