A Digital Twin-based Approach to the Real-time Assembly Line

Balancing Problem

L. Ragazzini

1a

, N. Saporiti

2b

, E. Negri

1c

, T. Rossi

2

, M. Macchi

1d

and G. L. Pirovano

2

1

Department of Management, Economics and Industrial Engineering, Politecnico di Milano, Milano, Italy

2

School of Industrial Engineering, Carlo Cattaneo – LIUC University, Castellanza, Italy

Keywords: Digital Twin, Industry 4.0, Assembly Line Balancing.

Abstract: The emergence of technologies linked to the Industry 4.0 paradigm is increasingly influencing the design and

management of production systems. However, applications related to assembly lines are scarcely explored in

the literature. Hence, in this paper, a Digital Twin-based approach to real-time assembly line balancing

problem (ALBP) in the i-FAB learning factory of Università Carlo Cattaneo – LIUC is presented. The results

show that the implementation of a Digital Twin (DT) can enhance the overall productivity of a manual

assembly line to smooth the effects of disruptions.

1 INTRODUCTION & REVIEW

OF THE STATE OF THE ART

The interest in the topic of Digital Twin (DT) in the

literature presented a steady growth in the last few

years. This strong rise in the study of DT-related

themes can be attributed to the massive use of the

technologies related to Industry 4.0 paradigm

(Havard, Jeanne, Lacomblez, & Baudry, 2019). A DT

can be defined as an integrated simulation

technology, which aims at developing a model of the

environment that has to be fed with real-time data, in

order to provide high fidelity of the overall system

(Saporiti., Cannas, Pirovano, Pozzi, & Rossi, 2020;

Tao, Qi, Wang, & Nee, 2019). The real-time

communication system that characterizes a DT

represents one of the main issues of its

implementation as well. As a matter of fact, in order

to successfully implement and develop a DT, there is

a relevant need for an intense gathering of data from

sensors as well as a robust and fast computing system

(Negri, Fumagalli, & Macchi, 2017).

A few works dealing with the interactions

between DTs and human operators were proposed.

Many of these works focus on the development of

Human-Machine Interfaces to enable collaboration

a

https://orcid.org/0000-0003-2019-751X

b

https://orcid.org/0000-0003-2250-4157

c

https://orcid.org/0000-0002-0006-7497

d

https://orcid.org/0000-0003-3078-6051

with robots (Segura et al., 2020). Other works related

to DTs and manual operations face the problem of

ergonomics by integrating a model of human operator

(Greco, Caterino, Fera, & Gerbino, 2020). Moreover,

a DT was developed to acquire data for monitoring

human activities in manufacturing and to process

them for improving ergonomics as well as to allow

workstation reconfigurations (Nikolakis,

Alexopoulos, Xanthakis, & Chryssolouris, 2019). In

addition, the modeling of human behavior was

considered to perform the optimization of the

manufacturing processes (Bécue, Maia, Feeken,

Borchers, & Praça, 2020). A DT for improving

workers’ ergonomics is discussed also in the work by

Fera, which considers the monitoring of the

balancing of the line as well (Fera et al., 2020).

From a system-oriented perspective, some

methodologies were proposed integrating DT models

of the operators to include them in the production

control decision-making. Graessler and Poehler

developed a self-controlling assembly system that

integrates a real-time control approach based on a DT

capable of replicating the behavior of the operator (I.

Graessler & Poehler, 2018). Another work from the

same authors dealt with matching operators with

assembly tasks using a DT (Iris Graessler & Poehler,

2018)

Ragazzini, L., Saporiti, N., Negri, E., Rossi, T., Macchi, M. and Pirovano, G.

A Digital Twin-based Approach to the Real-time Assembly Line Balancing Problem.

DOI: 10.5220/0010674500003062

In Proceedings of the 2nd International Conference on Innovative Intelligent Industrial Production and Logistics (IN4PL 2021), pages 93-99

ISBN: 978-989-758-535-7

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All r ights reserved

93

Looking at the background of the problem

addressed in this paper, the relevance of the assembly

line balancing problem (ALBP) in the manufacturing

sector is well known and was subject to recent

developments.

The problem of optimally dividing (i.e. balancing)

the assembly tasks among the available stations in

order to minimize or maximize one or more objective

functions is known as ALBP (Scholl & Becker,

2006). In particular, Cakir developed a Simulated

Annealing (SA) algorithm to deal with assembly line

balancing considering a certain degree of

stochasticity in the task times (Cakir, Altiparmak, &

Dengiz, 2011).

Altekin and Akkan defined line rebalancing as the

way to change the tasks and assignment of tasks to

stations and proposed a model to cope with failures

and recover performance losses (Altekin & Akkan,

2012). Yang stated that assembly line rebalancing has

to consider not just performance improvements, but

also the adjustment costs (Yang, Gao, & Sun, 2013).

Often, assembly line rebalancing is performed due to

variations of some parameters such as task times,

cycle time, or even product features (Gamberini,

Grassi, & Rimini, 2006).

Huo studied a fuzzy control logic for real-time

assembly line balancing (Huo, Zhang, & Chan, 2020).

The authors focused on machine health states to

define triggers for rebalancing the line.

Despite the growing interest in DTs, and the

relevance of the ALBP in the manufacturing

engineering sector, to the best of our knowledge, no

application to solve the ALBP based on the use of

DTs is available in the literature.

This paper proposes the implementation of a

working DT in i-FAB, the learning factory of

Università Carlo Cattaneo – LIUC is presented

(Figure 1). In i-FAB, a series of production activities

aimed at enhancing the knowledge of university

students, as well as company employees and

managers, about the themes of Lean Manufacturing

and Industry 4.0 paradigm, are carried out. As a

matter of fact, in i-FAB the operators perform

complex assembly tasks, representing, therefore, an

assembly line that could be considered as fully

manual.

Figure 1: i-FAB: learning factory of LIUC.

The learning factory developed by LIUC presents

a series of workstations that allows to fully perform

an assembly of different kinds of complex products

and to deliver the final product to the quality check

department. The number of workstations is variable,

the layout is flexible, and the main goal is to enable a

production that respects the takt time set in advance.

For the purposes of this work, the number of

workstations was set to five and they were arranged

in a line. The layout of the assembly line is sketched

in Figure 2.

Figure 2: i-FAB layout.

A DT model has been built in order to enhance the

overall productivity of the manufacturing system,

thanks to a real-time balancing of the assembly line.

In this context, this work aims at answering the

following research questions:

• What is the impact of a DT in an ALBP?

• What are the advantages of a DT in a human-

intensive assembly line?

This paper is structured as follows. Firstly, the

research design is presented, and therefore, gaps and

objectives of the research are discussed (section II).

Secondly, the research approach is described by

presenting the adopted modeling methodology (section

III). Thirdly, the main findings of this work are

presented (section IV). Finally, a discussion on the

results as well as on limitations and future research

directions of the paper is carried out (section V).

2 RESEARCH DESIGN

2.1 Gaps

From an analysis of the literature, some gaps emerged

which are to be tackled by this work. Indeed, these

gaps are relevant to drive the development of the

work.

• Only a few papers face the issue of real-time

line balancing problem, although this could

be of great potential to maintain high system

performances in case of disruptive events.

• No author has studied the interrelationships

between line balancing problems and DTs,

IN4PL 2021 - 2nd International Conference on Innovative Intelligent Industrial Production and Logistics

94

even though these appear relevant issues, in

light of the importance of the ALBP in the

manufacturing engineering, on one hand,

and of the potential due to the

synchronization with field operations

favored by the use of DTs, on the other hand.

• DTs considering operators under a system

perspective are scarcely found in the

literature. Nevertheless, it is interesting to

study the effects of local variability induced

by the operators on the performances at a

system level, i.e., the line. This is not a

novelty per se, its innovativeness lies in the

context of a DT-based approach and real-

time assembly line balancing.

2.2 Objectives

The main objective of this work is to develop a DT of

a human-intensive assembly line to improve overall

system performances. In order to achieve this, a new

methodology for real-time ALB based on DT will be

defined. Moreover, this will assist in the exploration

of the potential of DTs in fully manual assembly

systems.

3 MODELLING

METHODOLOGY

3.1 Hypotheses & Mathematical Model

Hereafter, the mathematical model of the problem

addressed by this work is presented. Task durations

are expressed in seconds [s].

i,h=1:n tasks index

G=

i,h

directed acyclic graph

k=1:m station

𝜉 scenario, it includes the various errors states that

could happen to the assembly line (error states are

adopted to represent the disruptions, deeply described

in section 3.2)

t

i

average task duration [s]

t

i

ξ

average task duration under a scenario ξ [s]

x

ik

1,

0,

if task i is assigned to station k

otherwise

∀i=1,…,n; ∀k=1,…,m

We define the workload on a certain station as:

w

k

ξ

= t

i

ξ

x

ik

n

i=1

s

(1

)

Cycle time is assumed as the maximum value

among stations workloads:

C

ξ

max w

k

ξ

s

(2)

In addition, we define the Smoothing Index (SI)

as:

SI

ξ

=

C

ξ

-w

k

ξ

2

m

k=1

(3)

SI is a relative index commonly used for

measuring the balancing of an assembly line,

accounting for the differences in the workload of the

stations. Hence, it allows the comparison between

different system configurations.

The objective of the optimization problem is to

minimize the SI:

min SI

ξ

=

C

ξ

-w

k

ξ

2

m

k=1

(4)

The constraints of the problem must ensure that

any task is assigned to one and only one station:

x

ik

= 1

m

k=1

, ∀i=1,…,n

(5)

Besides, precedence constraints must be

respected:

kx

hk

≤ kx

ik

m

k

=

1

m

k

=

1

∀

h,i

(6)

3.2 Solution Method

The proposed solution method for the ALBP is

depicted in Figure 3 and relies on a DT-based

methodology including a SA algorithm.

Figure 3: Solution method for ALBP.

The physical assembly system in the lower part of

the block diagram is provided with local computers

connected to the Manufacturing Execution System

(MES). This allows communication between each

A Digital Twin-based Approach to the Real-time Assembly Line Balancing Problem

95

workstation and the centralized information system.

The MES is the connection point between the

physical and the virtual domain: here the DT and the

real-time line balancing module (designated as

workload controller in the figure) lie. The former

consists of a Discrete Event Simulation (DES) model

which is connected to the MES to gather information

related to the current situation of the shop floor. The

latter collects just the data related to eventual error

states to be addressed in order to improve the

workload balance. Furthermore, workstation state

may represent either proper functioning state or any

error state.

In fact, the whole system remains silent until it is

triggered by the MES, which is responsible for

detecting errors states related to three main causes:

• Lack of materials, which does not allow the

execution of a certain assembly task for

which a specific material is required;

• Lack of equipment, which does not allow the

execution of any assembly task for which a

given tool is necessary;

• Lack of operators, which does not allow the

execution of the tasks strictly requiring two

operators. Moreover, this increases the

completion time of all the other tasks by

50% on average, due to the lack of

parallelization of part of the work.

The recovery from a given error state is

considered as a trigger itself.

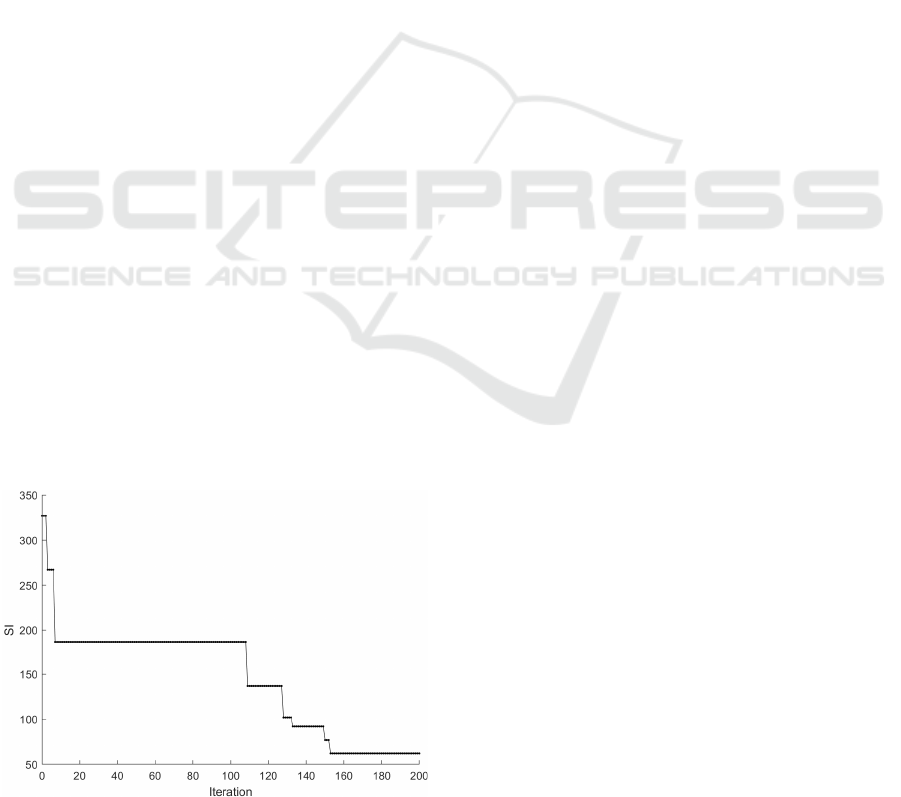

The workload controller solves the ALBP thanks

to the SA algorithm (Figure 4) and tests the solution

on the DT of the line. The behavior of the system

considering the new assignment of the tasks is

compared to the present one: only in case a significant

performance improvement is detected, the new

solution is implemented. The decision is then

feedbacked to the MES, which is responsible for

actuating eventual changes in the task assigned to

each workstation.

Figure 4: Simulated Annealing algorithm.

The nervousness of the system is mitigated by the

introduction of an ad-hoc heuristic in the workload

balancing module. This function allows preventing

changes in the assignment of the tasks in case the

improvement does not reach a certain threshold.

Indeed, the DT predicts the system behavior in the

following 15 minutes simulating both the current and

the proposed solutions to the ALBP, which consist of

the allocation of tasks to workstations.

To accept the new assignment, for each task

moved from a station to another one there must be a

significant improvement in the lead time of an

assembled product (i.e., a job) completed in the DT

prediction window. The lead time of a job is

computed as the difference between its enter and exit

times.

It has to be remarked that, for the development

and testing phases of the proposed methodology, a

physical twin of the assembly line was realized,

according to the definition by Ait-Alla (Ait-Alla,

Kreutz, Rippel, Lütjen, & Freitag, 2020). The

physical twin consists of a DES model which

replicates the behavior of the physical system.

3.3 Software/Tools/Languages

In order to develop the DT model, two main software

tools has been exploited, i.e., MATLAB® and

R/RStudio.

The former has been used as a computing system.

As a matter of fact, Simulink has been used to develop

the simulation model of i-FAB. In this sense, the

model has been built as a simulation meta-model,

based on the number of active assembly workstations

on the shopfloor.

The latter has been exploited in order to integrate

the MES system of i-FAB with the newly developed

DT. Hence, the MES itself of i-FAB has been

developed in RStudio, and in particular as a

ShinyApp. However, several code changes in the

main body of the MES were needed. These were

aimed at performing two main tasks. Firstly, RStudio

has been used as an interface to the real physical part

of the factory in order to gather data and to rearrange

them in the best form. RStudio monitors mainly two

kinds of information. Firstly, there is a constant check

of the overall condition of the factory, as every piece

and every activity are tracked from the very start to

the delivery of the finished product. Secondly,

R/RStudio and therefore the MES itself monitor a

series of events that are reported by the operators as

errors. The gathered and reworked data constitute the

input of the simulation performed on Simulink.

Secondly, after that the simulations have been

performed, R/RStudio gathers the results and

transmits the data to the MES of i-FAB.

Subsequently, the MES pushes the information about

IN4PL 2021 - 2nd International Conference on Innovative Intelligent Industrial Production and Logistics

96

the balancing of the assembly line directly to the

shopfloor, thanks to the monitor that is embedded in

every workstation in the factory. Therefore, the

operators are constantly updated about the next

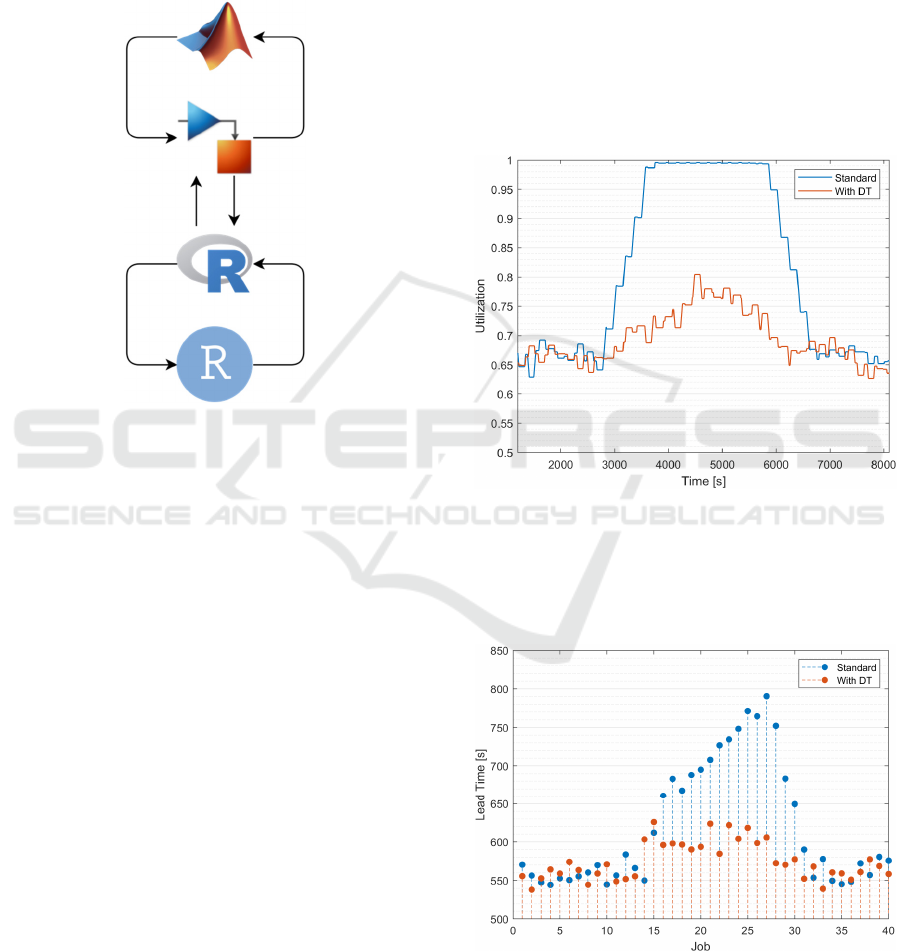

activities to be performed. As depicted in Figure 5,

the joint use of R/RStudio and MATLAB allowed

closing a double data loop that connects the real world

to the virtual one.

Figure 5: Software architecture data loop.

Hence, data first flow from the physical shopfloor

to R/RStudio and then to the MES. Afterward, data

are elaborated and simulations are performed by

Simulink. Finally, results flow back to the physical

world thanks to the use of monitors to communicate

with the operators on the workstations.

4 FINDINGS

The proposed methodology allows the exploitation of

the DT paradigm on a system constituted of a manual

assembly line. As a matter of fact, it is possible to

control the line by assigning tasks to the workstations

in real-time after (re)-balancing the workload.

The architecture developed permits to effectively

use a DT to solve the real-time ALBP. The

workstations have been modelled considering

nondeterministic assembly times due to the

performance of the operators, allowing to provide

more robust solutions.

From a system performance viewpoint, the

proposed work is able to grant some improvements.

An experiment was performed considering the

following conditions. An error state induced by the

lack of an operator in a workstation was in action for

45 minutes (i.e., 2700 seconds). The error occurred

after 45 minutes from the beginning of the

experiment.

The results of the performed test are two-fold as

they entail both workstations utilization and lead time

of the assembled products.

The utilization of the workstation where the error

occurs increases drastically with respect to its normal

operating condition. In fact, as depicted in Figure 6,

its value approaches the upper limit of utilization, i.e.,

one. On the other hand, when the DT is active, in the

same situation it is possible to remarkably mitigate

the effects of the error on the utilization level. As a

matter of fact, the increment of this value is limited to

approximately 0.15, thus reaching a maximum value

of nearly 0.8.

Figure 6: Comparison Utilization DT/Standard.

Furthermore, in Figure 7 the comparison between

the lead time of the jobs in the standard situation

(without the use of the DT) versus the one using the

DT is provided.

Figure 7: Comparison Lead Time DT/Standard.

As it can be noticed, the DT grants a remarkable

improvement in the lead times when the error state

A Digital Twin-based Approach to the Real-time Assembly Line Balancing Problem

97

arises. In the standard situation, the occurrence of an

error implies a relevant increase in the lead time of

the jobs, whereas, in the case of the use of DT, this

increase in time is far lower. On average, the lead time

of the jobs affected by the error state is 113 seconds

lower with respect to the case without the DT. Indeed,

we can notice an improvement of 16.0% in the overall

system performance under the error condition.

Hence, the DT can represent a valid instrument in

order to enhance the solutions of an ALBP.

As a matter of fact, the reactivity of the system is

strongly enhanced as assembly tasks are re-assigned

by the DT as soon as some error state is identified on

the MES.

The centralized control of the system leads to an

overall increased autonomy of the manual assembly

line. In this sense, the DT permits the system to self-

optimize its behavior, according to the analysis of the

current state of the line and to the predictions

provided.

Finally, the proposed methodology is also capable

to cope with the discussed errors through line

rebalancing but avoiding any nervousness of the

system.

5 CONCLUSIONS

This research presents an introductory model of a DT

aimed at approaching a real-time balancing problem

in the learning factory of Università Carlo Cattaneo –

LIUC, i.e., i-FAB. The results show that the use of a

DT can be highly beneficial for the entire

manufacturing system, even in the case of a manual

assembly line. Indeed, the DT can be exploited in

order to dynamically enhance the line balancing on

the workstations with respect to the different error

states that could possibly happen on the shopfloor.

Hence, the use of a DT can lead to a remarkable

reduction of the increase in the lead time of the jobs

and in the utilization of the station in which the error

occurs.

However, several limitations can be found in this

study. Firstly, the number of experiments performed

in i-FAB on the DT could be greatly increased. As a

matter of fact, inthis work, only a few experiments

were performed, mainly aimed at validating the

features of the DT as well as the right flow of data and

information from and to the field.

Secondly, in this model, the operators are

permanently assigned to their initial workstation.

Indeed, operators are not allowed to move from a

station to another one no matter the event/error states

that occur, even if this could lead to improvements to

the overall performance. However, this limitation is

quite representative of the real behavior of the

operators in i-FAB. Hence, in the learning factory

operators generally are not allowed to move to

another workstation unless in very particular

situations.

Additionally, some future research directions can

be derived from this research that could be addressed

in upcoming works.

First of all, in future work, a larger experimental

campaign should be held with a twofold purpose.

Firstly, deeper data gathering could be exploited in

order to fine-tune the main parameters of the model.

This could lead to higher reliability of the overall DT.

Secondly, a larger experimental campaign could be a

valid tool to enhance the validity of this research.

Furthermore, in future works, it could be of high

interest to perform tests on different manufacturing

systems. It could be interesting to consider the

interaction with co-bots, AGVs as well as the

application of the DT model to semi-automatic lines.

This could represent major future applications to

research on; this would give a context where tasks

assignment may be considered with various levels of

flexibility due to the available resources, being

concerned also of different levels of skills and roles

for the operators. Closely related, another future

research direction could lay on the possibility to

include the mobility of the operators among the

workstations on the shopfloor. Indeed, this feature

could represent a relevant enhancement of the validity

of the model, as well as a resolution for a limitation

of this research.

REFERENCES

Ait-Alla, A., Kreutz, M., Rippel, D., Lütjen, M., & Freitag,

M. (2020). Simulated-based methodology for the

interface configuration of cyber-physical production

systems. International Journal of Production Research.

https://doi.org/10.1080/00207543.2020.1778209

Altekin, F. T., & Akkan, C. (2012). Task-failure-driven

rebalancing of disassembly lines. International Journal

of Production Research, 50(18), 4955–4976.

https://doi.org/10.1080/00207543.2011.616915

Bécue, A., Maia, E., Feeken, L., Borchers, P., & Praça, I.

(2020). A new concept of digital twin supporting

optimization and resilience of factories of the future.

Applied Sciences (Switzerland), 10(13).

https://doi.org/10.3390/app10134482

Cakir, B., Altiparmak, F., & Dengiz, B. (2011). Multi-

objective optimization of a stochastic assembly line

balancing: A hybrid simulated annealing algorithm.

Computers and Industrial Engineering, 60(3), 376–384.

https://doi.org/10.1016/j.cie.2010.08.013

Fera, M., Greco, A., Caterino, M., Gerbino, S., Caputo, F.,

Macchiaroli, R., & D’amato, E. (2020). Towards digital

twin implementation for assessing production line

IN4PL 2021 - 2nd International Conference on Innovative Intelligent Industrial Production and Logistics

98

performance and balancing. Sensors (Switzerland),

20(1). https://doi.org/10.3390/s20010097

Gamberini, R., Grassi, A., & Rimini, B. (2006). A new

multi-objective heuristic algorithm for solving the

stochastic assembly line re-balancing problem.

International Journal of Production Economics, 102(2),

226–243. https://doi.org/10.1016/j.ijpe.2005.02.013

Graessler, I., & Poehler, A. (2018). Integration of a digital

twin as human representation in a scheduling procedure

of a cyber-physical production system. IEEE

International Conference on Industrial Engineering and

Engineering Management, 2017-Decem, 289–293.

https://doi.org/10.1109/IEEM.2017.8289898

Graessler, Iris, & Poehler, A. (2018). Intelligent control of

an assembly station by integration of a digital twin for

employees into the decentralized control system.

Procedia Manufacturing, 24, 185–189.

https://doi.org/10.1016/j.promfg.2018.06.041

Greco, A., Caterino, M., Fera, M., & Gerbino, S. (2020).

Digital twin for monitoring ergonomics during

manufacturing production. Applied Sciences

(Switzerland), 10(21), 1–20.

https://doi.org/10.3390/app10217758

Havard, V., Jeanne, B., Lacomblez, M., & Baudry, D.

(2019). Digital twin and virtual reality: a co-simulation

environment for design and assessment of industrial

workstations. Production and Manufacturing Research,

7(1), 472–489. https://doi.org/10.1080/

21693277.2019.1660283

Huo, J., Zhang, J., & Chan, F. T. S. (2020). A fuzzy control

system for assembly line balancing with a three-state

degradation process in the era of Industry 4.0.

International Journal of Production Research, 1–18.

https://doi.org/10.1080/00207543.2020.1786186

Negri, E., Fumagalli, L., & Macchi, M. (2017). A Review

of the Roles of Digital Twin in CPS-based Production

Systems. Procedia Manufacturing, 11(June), 939–948.

https://doi.org/10.1016/j.promfg.2017.07.198

Nikolakis, N., Alexopoulos, K., Xanthakis, E., &

Chryssolouris, G. (2019). The digital twin

implementation for linking the virtual representation of

human-based production tasks to their physical

counterpart in the factory-floor. International Journal of

Computer Integrated Manufacturing, 32(1), 1–12.

https://doi.org/10.1080/0951192X.2018.1529430

Saporiti., N., Cannas, V. G., Pirovano, G. L., Pozzi, R., &

Rossi, T. (2020). Barriers and enablers to the

implementation of Digital Twins in manufacturing

companies: a literature review. Proceedings of the

Summer School Francesco Turco.

Scholl, A., & Becker, C. (2006). State-of-the-art exact and

heuristic solution procedures for simple assembly line

balancing. European Journal of

Operational Research, 168(3), 666–693.

https://doi.org/10.1016/j.ejor.2004.07.022

Segura, Á., Diez, H. V., Barandiaran, I., Arbelaiz, A.,

Álvarez, H., Simões, B., … Ugarte, R. (2020). Visual

computing technologies to support the Operator 4.0.

Computers and Industrial Engineering, 139(November

2018), 105550. https://doi.org/10.1016/j.cie.2018.11.060

Tao, F., Qi, Q., Wang, L., & Nee, A. Y. C. (2019). Digital

Twins and Cyber–Physical Systems toward Smart

Manufacturing and Industry 4.0: Correlation and

Comparison. Engineering, 5(4), 653–661.

https://doi.org/10.1016/j.eng.2019.01.014

Yang, C., Gao, J., & Sun, L. (2013). A multi-objective

genetic algorithm for mixed-model assembly line

rebalancing. Computers and Industrial Engineering,

65(1), 109–116. https://doi.org/10.1016/j.cie.

2011.11.033.

A Digital Twin-based Approach to the Real-time Assembly Line Balancing Problem

99