Empirical Analysis of the Impact of Additional Padding on the

Collaborative Robot Velocity Behavior in Transient Contact Cases

Christopher Schneider

1a

, Maximilian M. Seizmeir

1b

, Thomas Suchanek

1c

,

Martina Hutter-Mironovová

1d

, Mohamad Bdiwi

2e

and Matthias Putz

2

1

Department of Product Management and Safety, Yaskawa Europe GmbH, Allershausen, Germany

2

Fraunhofer IWU Machine Tools and Forming Technology, Chemnitz, Germany

{mohamad.bdiwi, matthias.putz}@iwu.fraunhofer.de

Keywords: Biomechanical Thresholds, Collaborative Robots, Force and Pressure Measurements, Machine Tending,

Transient Contact.

Abstract: In this paper, a suitable measurement setup is presented and applied to conduct force and pressure

measurements for transient contact cases with the shoulder at the example of lathe machine tending. Empirical

measurements were executed on a selected collaborative robot’s behavior regarding allowable operating

speeds under consideration of sensor sensitivity, robot collision geometry, and damping materials.

Comparisons between the theoretic calculations proposed in ISO/TS 15066 and the practical measurement

results present a basis for future research. With the created database, preliminary risk assessment and

economic assessment procedures of collaborative machine tending cells can be facilitated.

1 INTRODUCTION

Within the last years, collaborative robot (cobot)

machine tending installations increased rapidly with

growing potential to become one of the main cobot

applications (BIS Research 2016). Due to their high

usability and fenceless operation, systems can be

adapted to new requirements conveniently. Small-

and medium-sized companies (SME’s) with high-

mix-low-volume production programs increasingly

benefit from the flexibility enhancements of robotic

machine loading and unloading. However, end-users

are confronted with an extensive risk assessment

when it comes to safety and CE marking, especially

regarding the force and pressure measurements

defined in ISO/TS 15066:2016 (Fraunhofer Institute

for Industrial Engineering IAO 2016). To prevent

injuries, the application must comply with body-

region-specific biomechanical threshold values that

determine the allowed velocity the robot can operate

at and, therefore, the achieved cycle time (DGUV

a

https://orcid.org/0000-0003-2903-8347

b

https://orcid.org/0000-0002-5755-4405

c

https://orcid.org/0000-0002-8366-3066

d

https://orcid.org/0000-0001-5823-8159

e

https://orcid.org/0000-0001-7070-9988

2017). Since these tests must be executed on-site, a

prototypical cell is required, usually available at a

well-advanced planning stage of an automation

project. Economic considerations, on the other side,

are required already at the project’s beginning to

determine a return on investment (ROI) upfront. On

this basis, the investment can be justified regarding

other automation options, such as linear axis or

fenceless industrial robots. Since the achieved

collaborative operating speeds are determined at the

end of the project, investment reliability and trust in

the automation solution are inhibited.

Currently, the dominant guideline is the ISO/TS

15066, which provides equations to calculate the

allowed collaborative speeds for a collision in free

space (transient contact). As an option, the compliant

velocities can also be determined by practical tests.

Despite the progress made in human-robot

collaboration during the last years, influencing factors

on the velocity results, system parameter modeling,

and demonstrated risk assessment procedures are

216

Schneider, C., Seizmeir, M., Suchanek, T., Hutter-Mironovová, M., Bdiwi, M. and Putz, M.

Empirical Analysis of the Impact of Additional Padding on the Collaborative Robot Velocity Behavior in Transient Contact Cases.

DOI: 10.5220/0010604202160223

In Proceedings of the 18th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2021), pages 216-223

ISBN: 978-989-758-522-7

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

lacking, leading to mismatching with the needs of

end-users.

This paper aims to reveal insights on the

maximum allowed collaborative speed (MACS) for a

selected robot model. Other cobot models are

welcomed to replicate the proposed test setup to

provide comparison values and contribute to a mutual

empirical database. In the future, such databases can

help to facilitate the risk and economic assessment

procedure. In the presented empirical study, different

typical transient contact cases in lathe machine

tending have been analyzed regarding the influence

of sensor sensitivity settings and additional padding

on the force and pressure development. Comparisons

to the equations provided by the technical

specification show potential future research fields.

This paper contributes to fundamental research

regarding robot behavior modeling in transient

contact cases, emphasizing biomechanical threshold

values.

2 THEORY

A general overview of different aspects of safety is

given by Chemweno et al. (2020), Lasota et al.

(2014), Marvel and Bostelman (2014), Robla-Gómez

et al. (2017), and Villani et al. (2018). As defined in

ISO/TS 15066:2016, two contact situations in

human-robot collaboration have been distinguished.

Quasi-static or clamping contacts occur when

continuously increasing weight is partially

compensated by elastic deformation. Transient cases

or collisions in free space, on the other side, force the

collision object to move in the resultant impact

direction. Human subject research empirically

derived biomechanical threshold values for forces

and pressures to avoid operator injuries, depending on

the respective body region. These values serve as a

database for the risk assessment of collaborative work

cells and have been adopted by ISO/TS 15066 (2016).

Several studies by Behrens and Pliske (2019) gave

indications for further refining and expansion of these

thresholds. To execute such a risk assessment, the

whole system (robot, gripper, workpiece) must be

analysed regarding potential collision situations,

based on the programmed paths, work environment

and possible human behaviour. For the identified

cases, forces and pressures are measured with

designated devices, that are available from different

manufacturers. Problematic in this procedure is the

requirement of a prototypical cell for the

measurements, which requires already a high-quality

concept of the planned system. Such measurement

devices have a load cell integrated, that measures the

force development over time to generate a time-

dependent force graph with a respective software.

Pressures are measured with sensitive foils, that are

placed on top of the device. Small air bubbles burst

during the collision event, discolouring the film

dependent on the intensity. By scanning each foil, the

results can be digitized for visualization and further

analysis. Additionally, to the device itself,

exchangeable damping materials (K1) and springs

supplement the simulation of body parts by their

combination of material characteristics and spring

constants.

As mentioned earlier, this procedure is situation-

individual and therefore difficult to generalize,

especially regarding the upfront determination of

compliant robot operating speeds. This leads to a

static risk consideration that is specific for a

designated case without adaption capabilities.

Operation in dynamic environments (i.e., deviating

workpieces), as described in Eder et al. (2014), would

require a permanent re-evaluation of the risk

assessment. Such safety-adaptive systems would

need a solid classification of risk cases as well as a

thorough robot behavior modeling. In the current

research, different approaches analyze quasi-static

and transient contact cases, presented as follows.

To characterize collisions, Haddadin et al. (2017)

presented a multi-phase procedure with the

classification criteria force's direction and intensity as

well as occurrence, severity, and duration. Vemula et

al. (2018) introduce the power flux density as a metric

under consideration of energy transfer and contact

duration. Furthermore, a rapid contact model is

presented and tested. Svarny et al. (2020) developed

a collision force map that is three-dimensionally

dependent on the robot’s operating space. Empirical

measurements with the cobots UR10e and KUKA

LBR Iiwa analyze the impact of robot pose, distance,

and velocity. Several crash tests with different

industrial robots have been executed by Haddadin et

al. (2011), emphasizing robot mass and velocity and

singularity forces during clamping. Further crash tests

were conducted by Weitschat (2019) under the use of

a robotic airbag protecting the workpiece to analyze

its effect on the resulting forces and pressures. Force

calculation models for quasi-static cases were

published by Ganglbauer et al. (2020) and Kovincic

et al. (2019). Virtual force sensors and simulations

were presented in Shin et al. (2019) and Yen et al.

(2019).

Empirical Analysis of the Impact of Additional Padding on the Collaborative Robot Velocity Behavior in Transient Contact Cases

217

3 MATERIALS AND METHODS

3.1 Risk Assessment and Experimental

Setup

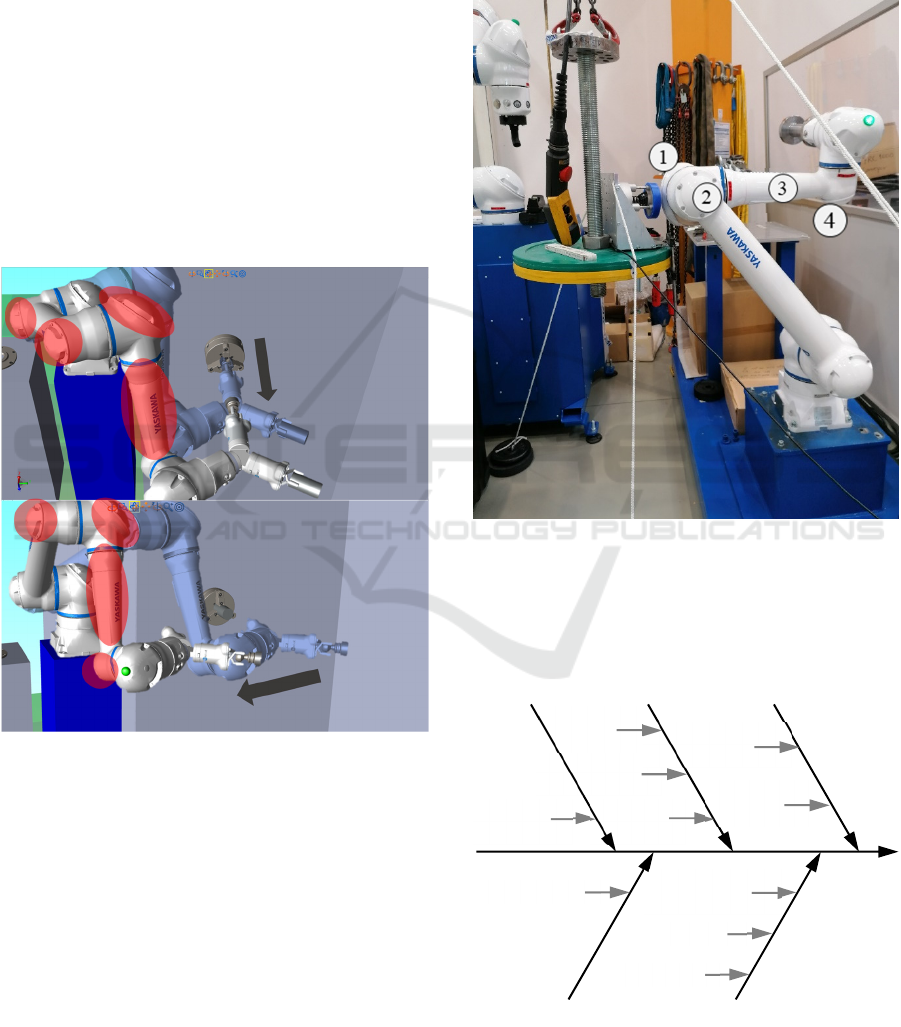

A preliminary risk assessment of lathe machine

tending applications identified multiple transient

contacts based on typical movement sequence

simulations. For both the feed motion (insert and take

out the workpiece) and the movement between door

and feed position, the cobot can collide with the

operator at the marked areas, illustrated in Figure 1.

The transparent position represents the start point,

while the opaque one shows the target coordinate.

Assuming a robot installation on a 900mm high

pedestal, the motions will likely be executed at the

operator's shoulder height. Therefore, this body part

is emphasized in this paper.

Figure 1: Potential Transient Risk Areas.

A Yaskawa HC10DT IP67 cobot installed on a

900mm high pedestal bolted to the ground was used

for the experiments. To replicate the identified values,

the software version YAS4.12.01A(EN/DE)-00 can

be used. For realistic reproduction of the transient

collision case, a special design guarantees free

oscillation and is adjustable in weight to match the

shoulder mass properties of m=40kg. Therefore, a

large locating bolt with a thread was used to install

different weight plates with a screw nut. This unit was

connected to the steel tracks of a 0,5t crane,

minimizing friction and providing a sufficiently long

pendulum. On top of the plates, the measurement

device PILZ PRMS has been fixed using screw

clamps. The pedestal-crane-combination has been

adjusted to simulate a realistic shoulder height of

1450mm. For reproducible results, ropes were

attached to the device to guide the recoil movement

and maintain a certain rebound angle.

Figure 2: Measurement Setup for Shoulder Simulation with

1 Elbow Big Cap, 2 Elbow Small Cap, 3 Forearm and 4

Wrist Cap.

3.2 Considered Influencing Factors

Figure 3: Ishikawa Diagram with Influencing Factors on the

Maximum Allowed Collaborative Speed.

Sensor

Sensitivity

Machine Method

Collision

Case

Contact

Case

Measured

Feature

(Hu)Man

Body Region

Attached

Workpiece

Additional

Padding

Material

Measurement

Spring

Thickness

Damping

Material

ICINCO 2021 - 18th International Conference on Informatics in Control, Automation and Robotics

218

To collect possible influencing factors on the

maximum allowed collaborative speed (MACS), an

Ishikawa diagram has been created based on the 5M’s

machine, method, material, (hu)man, and

measurements. For further specification, detailed

characteristics have been assigned that are used as a

basis for experiment planning and design.

Table 1: Influencing Factors on the Maximum Allowed

Collaborative Speed.

5 M’s Criteria Characteristics

Machine

(Robot)

Robot

Collision

Geometr

y

Elbow Big Cap, Elbow

Small Cap, Forearm,

Wrist Ca

p

Sensor

Sensitivit

y

50N, 100N

Software

Version

YAS4.12.01A(EN/DE)-

00

Method Measured

Feature

Individual

Collision

Case

Transient

(Hu)man Body

Region

Shoulder

Force

Threshol

d

420N

Pressure

Threshol

d

320N/cm

2

Measurement Damping

Material

K1

Shore A 30

S

p

rin

g

K2 35N/m

m

Thickness 14m

m

Material Padding None, Neoprene, Foa

m

3.3 Experimental Design

To cover the predefined risk cases, four different

robot outer contours have been tested regarding

collision forces and pressures: the two elbow caps, the

forearm, and the wrist cap of the cobot (see Figure 2).

This setup was designed to deliver insights on worst-

case scenarios where one of the robot's least favorable

edges collides with the measurement device. While

the hard edge has been used for tests with the big

elbow cap, this type of collision was not reproducible

for the smaller caps since the cap radius does not

allow a collision with the cap edge. Instead, contacts

with the round outer contour of the small caps were

targeted. Therefore, the big elbow cap delivers a

smaller contact area than the small caps. As can be

seen in Figure 1, different movement types are

assigned to the respective contact areas. While tests

with the big elbow cap utilize mainly the 2

nd

robot

axis for linear movement execution, the other cases

predominantly use the 1

st

axis.

Furthermore, measurements have been conducted

with different protective measures on the collision

surface: no protection, neoprene padding (thickness:

5mm), and foam padding (expanded polyethylene

foam profile, thickness: 140mm, see Figure 4.). While

the neoprene protection was attached with a velcro

fastener, the foam protection had to be attached with

adhesive tape. Using these three different paddings,

the impact of the damping characteristics regarding

material and thickness on the MACS is analyzed.

Figure 4: EPE Foam Profile.

According to DGUV (2017) and ISO/TS 15066

(2016), a spring constant of k=35N/mm, blue silicone

damping material with shore A 30 hardness, and a

thickness of 14mm must be used for the measurement

device to match the shoulder.

According to the PRMS manual, three force

measurements per series are recommended to

counterbalance the device’s inaccuracies. To provide

scientific and statistically valid results, ten

measurements run have been performed. From these

data, the maximal and minimal values each have been

considered as outliers and therefore excluded. Based

on the eight remaining values, the average has been

calculated, which serves as a comparison basis with

the threshold values. The documented average

environment conditions of 60% humidity and 21°C

temperature lie within the stated tolerance of 35%-

80% and 17°C to 35°C. Following the manual, 30

minutes waiting time between pressure foil

measurement and scanning has been adhered to.

For worst-case scenario consideration, a

workpiece with maximum payload utilization was

used. Therefore, a steel shaft with 110mm in

diameter, 230mm in length, and 6,041kg weight was

manufactured and attached.

To determine the MACS, iterative velocity

adjustment loops with a predefined scaling of 10mm/s

led finally to one threshold-compliant and one

violating speed, while the last conform one is the

MACS. For valid results, the distance between the

Empirical Analysis of the Impact of Additional Padding on the Collaborative Robot Velocity Behavior in Transient Contact Cases

219

programmed start and endpoint must be sufficiently

high to guarantee that the robot reaches its predefined

velocity. Furthermore, the second coordinate must lie

at a fair distance behind the collision point to avoid

decelerating the cobot before impact. Correct

configured tool data and regularly calibrated torque

sensors ensure consistent measurement quality. As

robot-dependent factors, different sensor sensitivity

settings, adjustable in the safety controller with force

limits in N, were used. For this research, 100N and

50N were considered.

4 RESULTS

4.1 Theoretical Considerations

Firstly, the MACS will be determined by applying the

respective equations defined in ISO/TS 15066. Table

2 shows the relevant factors and obtained input data

for the human shoulder joint as well as the selected

robot contact areas.

Table 2: Factors for Transient Velocity Calculations.

Facto

r

Symbol Value Unit

Transfer Energy

𝐸 2,5

∗

Maximum Contact

Force

𝐹

420 𝑁

Maximum Contact

Pressure

𝑝

3.200.000

Effective Spring

Constant

𝑘 35.000

Contact Area Elbow

𝐴

1,05

∗10

𝑚

Contact Area Arm

𝐴

1,6∗10

𝑚

Contact Area Cap

𝐴

9,621

∗10

𝑚

Relative Speed

𝑣

calculated

Allowed Speed

Robot Elbow

𝑣

calculated

Allowed Speed

Robot Ar

m

𝑣

calculated

Allowed Speed

Robot Ca

p

𝑣

calculated

Reduced Mass

𝜇 calculated 𝑘𝑔

Effective Mass of the

Human Bod

y

Re

g

ion

𝑚

40 𝑘𝑔

Effective Mass of the

Robot

𝑚

calculated 𝑘𝑔

Effective Payload of

the Robot System

𝑚

6,041 𝑘𝑔

Total Mass of

Movin

g

Robot Parts

𝑀 58 𝑘𝑔

Based on this information, the MACS of the transient

contact case is calculated based on energy, maximum

permissible force, and maximum permissible

pressure. These results will be compared and

discussed with experimentally measured values.

Preliminary Calculations:

𝑚

=

𝑀

2

+𝑚

=35,041𝑘𝑔

(1)

𝜇=

1

𝑚

+

1

𝑚

=18,678𝑘𝑔

(2)

Calculations based on Energy:

𝐸=

1

2

𝜇𝑣

(3)

𝑣

=

2𝐸

𝜇

=0,517

𝑚

𝑠

(4)

Calculations based on Permissible Force:

𝑣

=

=0,519

(5)

Calculations based on Permissible Pressure:

𝑣

=

∗

=0,415

(6)

𝑣

=

∗

=6,332

(7)

𝑣

=

∗

=3,808

(8)

While the energy- and force-based calculations lead

to nearly similar results, the pressure-based

calculations deviate with a factor between 0,8 and

12,3. Consequently, the forces and energies are the

theoretical limiting factors, while pressure could be

strongly increased according to the calculated results.

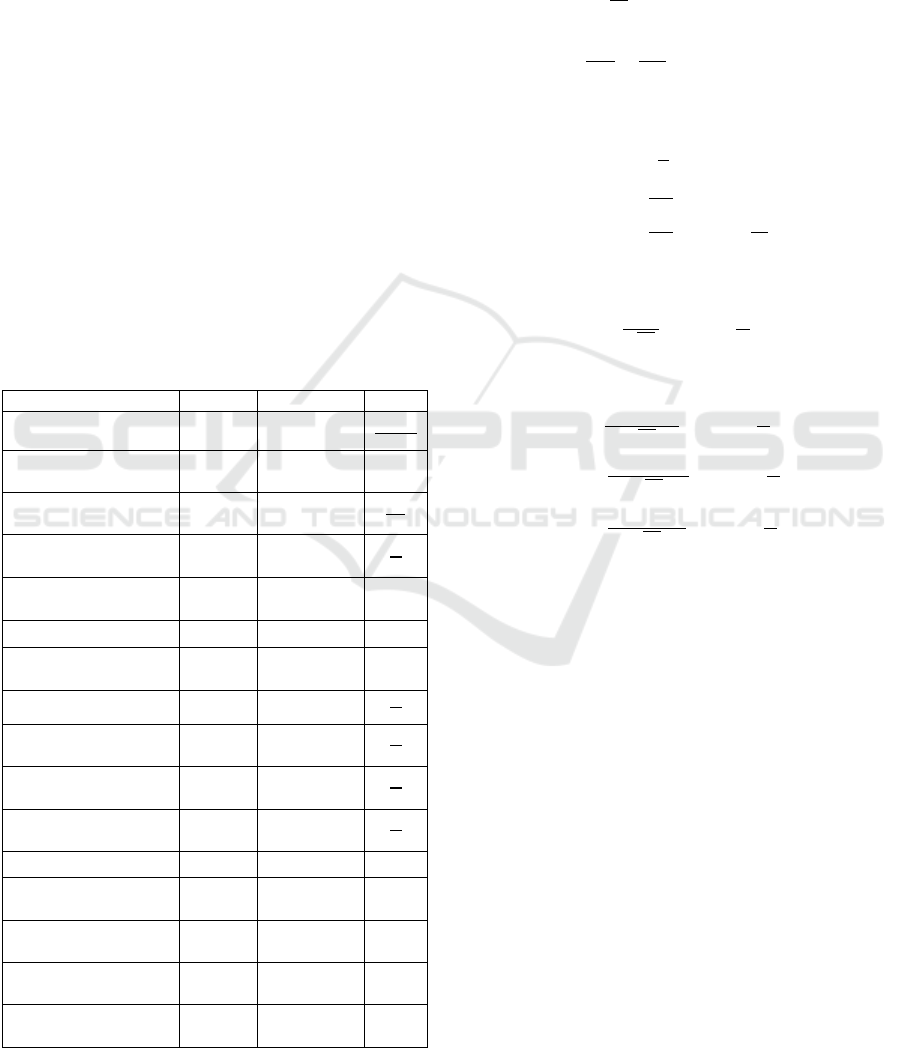

4.2 Experiment on Elbow Big Cap

Without protective measures, the maximum speed is

mainly restricted by the pressure limit, which has

been surpassed at 70mm/s, leading to a MACS of

60mm/s. However, with protective measures, the

MACS climbs up to 720mm/s with neoprene and

770mm/s with foam padding. This can be explained

by an even pressure distribution on a greater surface

compared to measurements without protection.

Furthermore, the MACS with a force limit of 50N

was slightly higher than measurements with 100N for

protective measures while having no effect when

using no padding.

ICINCO 2021 - 18th International Conference on Informatics in Control, Automation and Robotics

220

Figure 5: Setup for Elbow Big Cap.

4.3 Experiment on Elbow Small Cap

The pressure threshold has not been reached in this

experiment for all three setups, while the force has

been exceeded at 890mm/s to 920mm/s depending on

the used padding. Measurement results with 50N

deliver higher MACS compared to the 100N force

limit, irrespective of the protective measures. No

clear tendency on the dependency of MACS and the

protective measure could be identified.

Figure 6: Setup for Elbow Small Cap.

4.4 Experiment on Forearm

Pressure thresholds were undercut with all

measurement series. The highest MACS have been

registered for 100N force limit and measurement

without protection at 750mm/s. With a force limit of

50N, the MACS could not be reached for neoprene

and foam protection since the high torque sensor

sensitivity triggers a protective stop of the robot

during high acceleration.

Figure 7: Setup for Forearm.

4.5 Experiment on Wrist Cap

As expected, observed MACS are lower than those of

the small elbow cap because the collision point is

further away from the robot base resulting in a higher

lever. The highest MACS was registered for the 50N

force limit in combination with foam protection.

Without protection, results were lower for both sensor

sensitivities.

Figure 8: Setup for Wrist Cap.

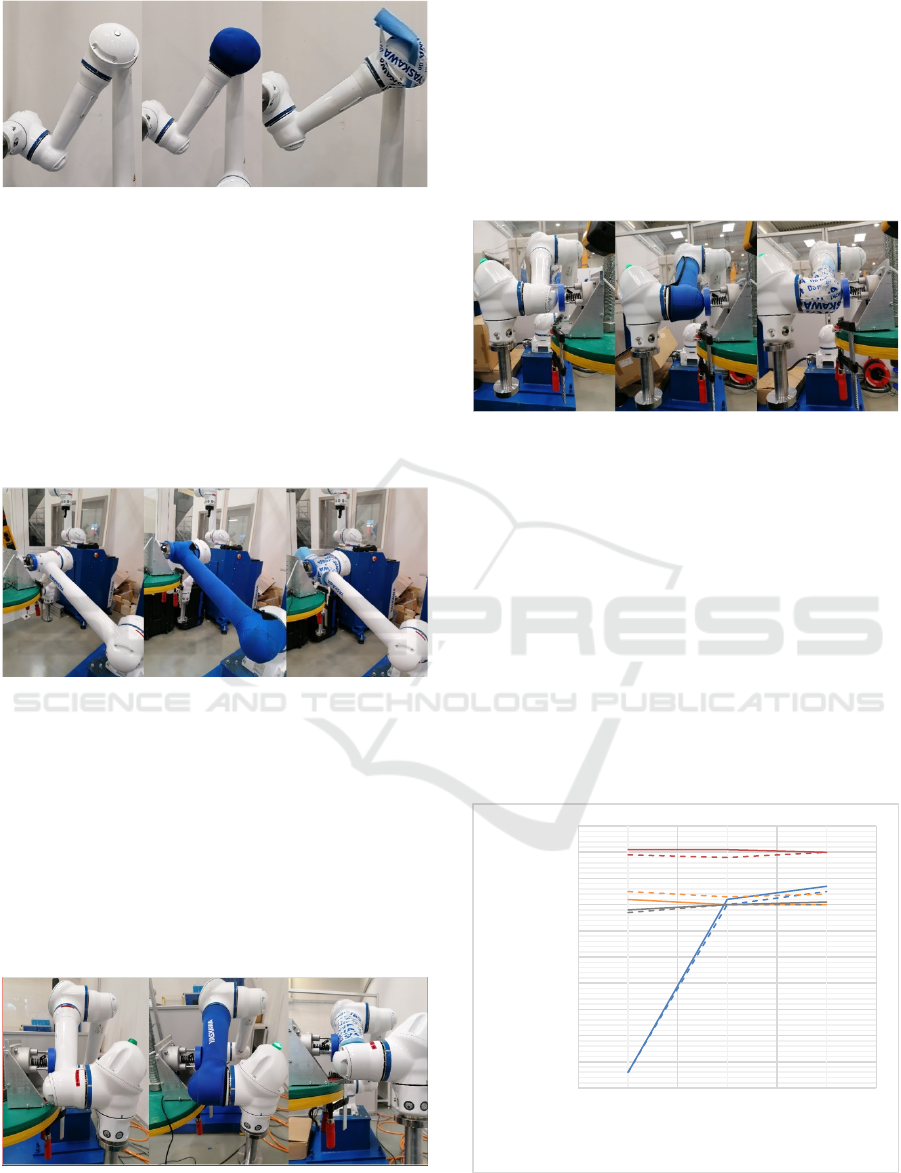

4.6 Summary

Additional padding on the respective collision surface

can drastically increase the maximum allowed

collaborative speed, if critical areas with small

surfaces (big elbow cap) are present. For the other

three cases, a clear influence of protective measures

on the MACS could not be verified. Whereas the

neoprene cover could not evidently reduce occurring

force compared to the setup without protection,

attaching EPE foam profiles on the collision surface

showed significant force reduction. Overall, the

pressure threshold has been exceeded only for the big

elbow cap without padding.

Figure 9: MACS by Protective Measures and Force Limit:

50N – Full, 100N – Dotted, Elbow Big Cap – Blue, Elbow

Small Cap – Red, Forearm – Green, Wrist Cap – Black.

0

100

200

300

400

500

600

700

800

900

1000

None Neoprene Foam

MACS [mm/s]

Protective Measure

Empirical Analysis of the Impact of Additional Padding on the Collaborative Robot Velocity Behavior in Transient Contact Cases

221

5 CONCLUSIONS

In this paper, the influence of additional padding in

transient contact cases has been analyzed. Based on

the use case of lathe machine tending, different

contact cases were concluded in a preliminary risk

assessment, based on the required movements with

the respectively affected robot geometries as an

interfering contour. As a realistic body region, the

shoulder was assumed to collide with the robot during

either a feed motion between the machine’s door and

spindle feed position or between spindle feed and

spindle position. To cover robot-specific influencing

factors, force limits of 50N and 100N were tested. As

theoretical fundament, the maximum allowed

collaborative velocities were calculated with the

equations defined in ISO/TS 15066. A high result

deviation has been demonstrated depending on the

used metric (energy, force or pressure). Comparisons

to the empirically determined MACS values show

differences of 0,25m/s to 0,46m/s for the big elbow

cap, 0,38m/s to 2,91m/s for the elbow small cap,

0,18m/s to 5,6m/s for the forearm and 0,15m/s to

3,14m/s for the wrist cap. Due to the used test setup,

measurement deviations can be traced back to the

oscillation of the hanging construction during a

collision and the result accuracy of the pressure-

sensitive foils. The force limit settings (sensor

sensitivity) showed a small impact on the result since

the robot stops immediately when colliding.

Experiments on the forearm with a 50N force limit

were not feasible due to the robot sensors' self-

triggering at high velocities.

This study was executed with a selected cobot and

is therefore exclusively valid for this model. To help

building a broader database of the maximum allowed

collaborative speeds and to understand various

influencing factors, similar tests with other cobot

models are required in the future. For safety

engineering, this data would serve as a tool to

facilitate the risk assessment effort on-site to reduce

certification time and cost. Increased precision in the

upfront determination of compliant speeds improves

investment reliability since cycle times can be

approximated in an early project stage. Such a

database supports performance transparency of

different robot models regarding achievable cycle

times and helps the robot planner and end-user select

the most profitable cobot. Lastly, robot manufacturers

gain valuable insights for further R&D activities to

improve their products.

ACKNOWLEDGEMENTS

We thank Dr.-Ing. Roland Behrens (Fraunhofer IFF)

for consulting throughout the project, especially

regarding the measurement setup's suitability.

REFERENCES

Behrens, R.; Pliske, G. (2019): Human-Robot

Collaboration: Partial Supplementary Examination [of

Pain Thresholds] for Their Suitability for Inclusion in

Publications of the DGUV and Standardization.

Fraunhofer IFF, Otto von Guericke University Trauma

Surgery Clinic.

BIS Research (2016): Global Collaborative Robot

Hardware Market, Analysis & Forecast, 2016-2021

(Focus on Major Industries and Applications). BIS

Research. Available online at https://bisresearch.com/

industry-report/global-cobots-market-report-

forecast.html, checked on 5/14/2021.

Chemweno, P.; Pintelon, L.; Decre, W. (2020): Orienting

safety assurance with outcomes of hazard analysis and

risk assessment: A review of the ISO 15066 standard

for collaborative robot systems. In Safety Science 129.

DOI: 10.1016/j.ssci.2020.104832.

DGUV (2017): Collaborative robot systems: Design of

systems with "Power and Force Limiting" function.

Available online at https://www.dguv.de/medien/fb-

holzundmetall/publikationen-

dokumente/infoblaetter/infobl_englisch/080_collabora

tiverobotsystems.pdf, updated on 08/2017, checked on

3/12/2021.

Eder, K.; Harper, C.; Leonards, Z. (Eds.) (2014): Towards

the Safety of Human-in-the-Loop Robotics: Challenges

and Opportunities for Safety Assurance of Robotic Co-

Workers. The 23rd IEEE International Symposium on

Robot and Human Interactive Communication.

Edinburgh, UK, 25-29 Aug. 2014: IEEE.

Fraunhofer Institute for Industrial Engineering IAO

(2016): Lightweight robots in manual assembly - best

to start simply! Edited by W. Bauer, M. Bender, M.

Braun, P. Rally, O. Scholtz. Available online at

https://www.produktionsmanagement.iao.fraunhofer.d

e/content/dam/produktionsmanagement/de/documents/

LBR/Studie-Leichtbauroboter-Fraunhofer-IAO-2016-

EN.pdf, checked on 5/13/2021.

Ganglbauer, M.; Ikeda, M.; Plasch, M.; Pichler, A. (2020):

Human in the loop online estimation of robotic speed

limits for safe human robot collaboration. 30th

International Conference on Flexible Automation and

Intelligent Manufacturing (FAIM2021). In Procedia

Manufacturing 51, pp. 88–94. DOI: 10.1016/j.promfg.

2020.10.014.

Haddadin, S.; Albu-Schäffer, A.; Hirzinger, G. (2011): Safe

Physical Human-Robot Interaction: Measurements,

Analysis and New Insights. In Robotics Research,

pp. 395–407. DOI: 10.1007/978-3-642-14743-2_33.

ICINCO 2021 - 18th International Conference on Informatics in Control, Automation and Robotics

222

Haddadin, S.; De Luca, A.; Albu-Schäffer, A. (2017):

Robot Collisions: A Survey on Detection, Isolation, and

Identification. In IEEE Transactions on Robotics 33 (6),

pp. 1292–1312. DOI: 10.1109/TRO.2017.2723903.

Kovincic, N.; Gattringer, H.; Müller, A.; Weyrer, M.;

Schlotzhauer, A.; Kaiser, L.; Brandstötter, M. (2019):

A model-based strategy for safety assessment of a robot

arm interacting with humans. In Proceedings in Applied

Mathematics & Mechanics. DOI: 10.1002/pamm.

201900247.

Lasota, P. A.; Fong, T.; Shah, J. A. (2014): A Survey of

Methods for Safe Human-Robot Interaction. In

Foundations and Trends 5 (4), pp. 261–349. DOI:

10.1561/9781680832792.

Marvel, J.; Bostelman, R. (2014): A Cross-domain Survey

of Metrics for Modelling and Evaluating Collisions. In

International Journal of Advanced Robotic Systems 11.

DOI: 10.5772/58846.

Robla-Gómez, S.; Becerra, V. M.; Llata, J. R.; González-

Sarabia, E.; Torre-Ferrero, C.; Pérez-Oria, J. (2017):

Working Together: A Review on Safe Human-Robot

Collaboration in Industrial Environments. In IEEE

Access 5, pp. 26754–26773. DOI: 10.1109/ACCESS.

2017.2773127.

ISO/TS 15066:2016, 2016: Robots and robotic devices -

Collaborative robots.

Shin, H.; Kim, S.; Seo, K.; Rhim, S. (Eds.) (2019): A Real-

Time Human-Robot Collision Safety Evaluation

Method for Collaborative Robot. 3rd IEEE

International Conference on Robotic Computing (IRC).

Naples, Italy, 25.02.-27.02.: IEEE.

Svarny, P.; Rozlivek, J.; Rustler, L.; Hoffmann, M. (2020):

3D Collision-Force-Map for Safe Human-Robot

Collaboration (Preprint).

Vemula, B.; Matthias, B.; Ahmad, A. (2018): A design

metric for safety assessment of industrial robot design

suitable for power‑ and force‑limited collaborative

operation. In International Journal of Intelligent

Robotics and Applications 2, pp. 226–234. DOI:

10.1007/s41315-018-0055-9.

Villani, V.; Pini, F.; Leali, F.; Secchi, C. (2018): Survey on

human–robot collaboration in industrial settings: Safety,

intuitive interfaces and applications. In Mechatronics

55, pp. 248–266. DOI: 10.1016/j.mechatronics.2018.

02.009.

Weitschat, R. (2019): Industrial Human-Robot

Collaboration: Maximizing Performance While

Maintaining Safety. Dissertation. Universität Rostock.

Fakultät für Maschinenbau und Schiffstechnik.

Yen, S.-H.; Tang, P.-C.; Lin, Y.C.; Lin, C.-Y. (2019):

Development of a Virtual Force Sensor for a Low-Cost

Collaborative Robot and Applications to Safety Control.

In Sensors 19 (11). DOI: 10.3390/s19112603.

Empirical Analysis of the Impact of Additional Padding on the Collaborative Robot Velocity Behavior in Transient Contact Cases

223