Seamless Integration of Hardware Interfaces in UML-based MDSE Tools

Lars Huning

1

, Timo Osterkamp

1

, Marco Schaarschmidt

2

and Elke Pulverm

¨

uller

1

1

Institute of Computer Science, University of Osnabr

¨

uck, Wachsbleiche 27, 49090 Osnabr

¨

uck, Germany

2

Faculty of Engineering and Computer Science, University of Applied Sciences Osnabr

¨

uck, Germany

Keywords:

Automatic Code Generation, Embedded Systems, Hardware Interfaces, Model-Driven Software Engineering.

Abstract:

Model-Driven Software Engineering (MDSE) promotes the use of models for software development. One ap-

plication of MDSE is the development of embedded systems, whose size and complexity are growing steadily.

Usage of MDSE for embedded systems often consists of creating high-level architectures, e.g., with the Uni-

fied Modeling Language (UML), while the actual implementation of the system is done manually. One reason

for this is the semantic gap between high-level UML models and the low-level programming associated with

microcontrollers, i.e., imperative programming at the register level. This paper proposes an approach for

the seamless integration of hardware interfaces, e.g., GPIOs or UARTs, in UML-based MDSE tools. This

enables developers to create their application continously in the MDSE tool, instead of resorting to manual

programming outside the environment of the MDSE tool. For this, we present an approach that describes how

object-oriented hardware abstraction layers may be seamlessly integrated in MDSE tools. Furthermore, we

provide a GUI tool for hardware interfaces that enables the initial configuration of these interfaces. An auto-

matic code generation approach may subsequently be used to generate the initialization code for the hardware

interfaces of a microcontroller. We present a use case for our approach in which the software application of an

embedded system is ported to several other microcontrollers from different manufacturers.

1 INTRODUCTION

The size and complexity of embedded systems has

been increasing rapidly in the last years (Trindade

et al., 2014). For example, a modern car may con-

tain more than seventy electronic control units and

run more than 100 million lines of code (Charette,

2009). In the past, a growth in size and complexity of

desktop applications has led to the adoption of object-

oriented paradigms and programming languages, e.g.,

Java and C++. Subsequently, object-oriented mod-

eling techniques, e.g., the Unified Modeling Lan-

guage (UML) (OMG UML, 2017), as well as Model-

Driven Software Engineering (MDSE) (Brambilla

et al., 2012) have been proposed to further deal with

the growing size and complexity of systems. MDSE

and object-oriented techniques are also increasingly

adopted in the embedded domain, e.g., for auto-

matic code generation (Huning et al., 2020) or safety-

critical applications, such as medicinal devices (Kim

et al., 2013). However, at the time this paper is writ-

ten, model-driven approaches in the embedded do-

main are mainly used to design high-level architec-

tures. The actual implementation is still done man-

ually (Kim et al., 2013). One of the reasons for

these manual implementations is the semantic gap be-

tween high-level models and the implementation plat-

forms (Kim et al., 2013). This is also true for low-

level hardware interactions with the platform, e.g.,

hardware drivers or board support packages. These

low-level elements rarely conform to object-oriented

paradigms, which makes a seamless integration with

the high-level architecture created with MDSE tools

difficult, as the interaction with hardware drivers may

only be represented in UML in a very limited fashion,

i.e., via non-object-oriented, static references. While

it is possible to automatically generate code skele-

tons of the high-level architecture with MDSE tools,

and subsequently implement the hardware interac-

tions manually, this type of development may quickly

lead to a divergence between the model and the source

code (Selic, 2008). This reduces the benefits ob-

tained by modeling. This paper, in contrast, advo-

cates for the full code generation of application with

the help of MDSE tools, by bridging the gap between

object-oriented modeling of the high-level architec-

ture and low-level interaction with the hardware. For

this, we provide an approach for the seamless inte-

Huning, L., Osterkamp, T., Schaarschmidt, M. and Pulvermüller, E.

Seamless Integration of Hardware Interfaces in UML-based MDSE Tools.

DOI: 10.5220/0010575802330244

In Proceedings of the 16th International Conference on Software Technologies (ICSOFT 2021), pages 233-244

ISBN: 978-989-758-523-4

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

233

gration of an object-oriented Hardware Abstraction

Layer (HAL) in MDSE. Furthermore, this paper in-

troduces a tool for automatically generating the hard-

ware initialization of hardware interfaces, e.g., Gen-

eral Purpose Input/Output (GPIO) or Analog Digital

Converter (ADC). The generated hardware initializa-

tion may be seamlessly integrated with MDSE tools,

thereby allowing developers to interact with hardware

in an object-oriented fashion in MDSE tools. Thus,

developers for embedded systems may fully profit

from the advantages promised by MDSE, e.g., an in-

crease in developer productivity and a decrease in the

number of bugs within the system (Bunse et al., 2007;

Kashif et al., 2009).

HALs provide a uniform interface for interacting

with the hardware of microcontrollers, e.g., hardware

interfaces such as GPIO, ADC or Universal Asyn-

chronous Receiver Transmitter (UART). This enables

developers to use the same interface for interacting

with the hardware of different microcontrollers. This

reduces the level of detail to which a developer has to

understand the inner workings of a specific microcon-

troller. This is not only important when developers

start a project with a microcontroller that is unfamil-

iar to them, but also for legacy applications. In some

industries, long-lasting delivery commitments exist,

e.g., providing spare parts for as long as a decade.

During this time frame, the type of microcontroller

used for a specific product may no longer be sold by

its manufacturer. Therefore, the application has to be

ported to another microcontroller. In case the appli-

cation was initially developed with a HAL, it may

be sufficient to exchange the underlying implemen-

tation of the hardware interfaces in order to port the

application to the new microcontroller. On the other

hand, if no HAL was used for development, e.g., the

hardware is accessed directly via registers by code

snippets that are scattered across the whole applica-

tion, the entire application may need to be modified.

Thus, a HAL may not only ease the training period

for developers facing an unfamiliar microcontroller,

but also improve the portability of embedded systems.

While there exist several HALs, e.g., (ARM Lim-

ited, 2021a; ARM Limited, 2021b), they often do not

adhere to an object-oriented programming paradigm,

which makes integration with an UML-based MDSE

tool difficult. Even those few HALs that are object-

oriented, e.g., (modm., 2021), do not consider inte-

gration with MDSE tools. Due to their non-trivial size

and complexity, which includes a multitude of tem-

plates and generator files that ultimately generate the

HAL, their integration with MDSE tools remains dif-

ficult. This paper introduces an object-oriented HAL

and a development workflow that enables a seamless

integration of this HAL into MDSE tools.

While a HAL provides a uniform interface for ac-

cessing the hardware interfaces of a microcontroller,

these hardware interfaces also often have to be ini-

tialized prior to their usage. For example, the ex-

act pin which a UART uses for data transmission

needs to be specified. For more complex hardware

interfaces, this initialization is a non-trivial process in

which the order of initialization statements is of im-

portance. While there exist Graphical User Interface

(GUI) tools that aim to simplify and partially auto-

mate this task, e.g., (ST Microelectronics, 2021a; In-

fineon, 2021b), these tools are often limited to micro-

controllers from a specific manufacturer. Moreover,

the code generated automatically by these tools, is not

object-oriented and thus once again hard to integrate

with UML-based MDSE tools. This paper presents

a novel GUI tool for specifying the configuration of

how hardware interfaces should be initialized. For

this, we introduce an Extensible Markup Language

(XML)-based format for describing microcontrollers

and their configurations that is independent of a spe-

cific manufacturer. Furthermore, we provide an au-

tomated workflow that describes how the automati-

cally generated code from these configurations may

be seamlessly integrated into the development with

MDSE tools.

In summary, this paper provides the following

novelties:

• An approach for the seamless integration of an

object-oriented HAL with MDSE tools.

• A GUI tool for automatically generating hardware

initializations for microcontrollers, whose output

may be seamlessly integrated with MDSE tools.

• A practical demonstration of our approach by de-

veloping an application with the previously men-

tioned concepts for microcontrollers from NXP,

Infineon and ST Microelectronics.

The remainder of this paper is organized as follows:

Section 2 provides an overview of the development

workflow to be used with our approach. Section 3

introduces the GUI tool for specifying the initializa-

tion configuration of hardware interfaces, while Sec-

tion 4 introduces the object-oriented HAL. Section 5

describes the integration of these contributions with

MDSE tools. A practical demonstration of our ap-

proach is described in Section 6, where the approach

is used to create an embedded system for microcon-

trollers from different manufacturers. We describe re-

lated work in Section 7. Section 8 concludes our pa-

per.

ICSOFT 2021 - 16th International Conference on Software Technologies

234

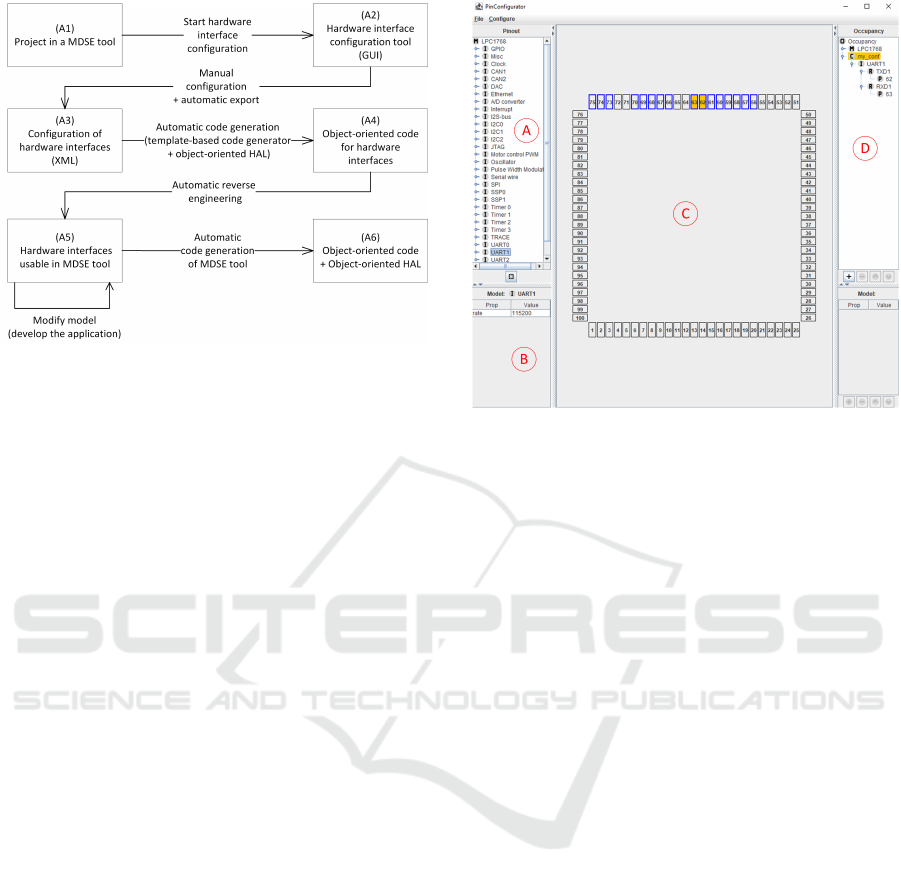

Figure 1: Overview of the development workflow used in

this paper.

2 OVERVIEW OF THE

APPROACH

This section presents an overview of the development

workflow used for the approach presented in this pa-

per. The workflow is shown in Figure 1. Only one

direction of the workflow is shown, with one phase

smoothly transitioning into the next. In practice, iter-

ations and returning to a prior phase for modifications

is often necessary. In order to improve the legibility

of the figure, this is not shown in Figure 1.

At the beginning of the workflow, a project within

an MDSE tool exists, i.e., a set of UML diagrams

that describe the structure and behavior of the appli-

cation (cf. (A1) in Figure 1). The diagrams may al-

ready describe the whole application minus the hard-

ware interactions. Alternatively, the diagrams may

be empty at this point in time and modified later in

step (A5) of the workflow shown in Figure 1. From

this MDSE tool, a separate GUI tool may be started

(cf. (A2) in Figure 1). This tool enables develop-

ers to specify the hardware interfaces their applica-

tion uses, as well as configure the initialization for

these hardware elements. The tool is described in de-

tail in Section 3. Once the developer has finished his

configuration,it may be exported automatically as an

XML file (cf. (A3) in Figure 1). The XML file serves

as the input to a code generation engine, that gener-

ates source code for the exported configurations of the

hardware interfaces (cf. (A4) in Figure 1). The gen-

erated source code utilizes an object-oriented HAL,

which is introduced in Section 4 of this paper. The

employed HAL interfaces may subsequently be im-

ported into the MDSE tool via automatic reverse engi-

neering. This way, the HAL interfaces, and therefore

Figure 2: Screenshot of the GUI tool developed in this paper

for the purpose of configuring the hardware initialization of

microcontrollers.

hardware interactions, are accessible to developers

within the MDSE tool in an object-oriented fashion

(cf. (A5) in Figure 1). As the hardware is now acces-

sible within the model, a developer may now develop

the whole application within the model in an object-

oriented manner. With our approach, the developer

is no longer required to include manual references to

low-level hardware interactions at the register-level.

Once this process is finished, the MDSE tool is capa-

ble of generating the source code for this application

automatically. For compilation, the implementation

of the HAL interfaces for the actual microcontroller

used in the project has to be linked with the generated

source code (cf. (A6) in Figure 1).

3 PinConfig TOOL

This section describes a novel GUI tool designed

to configure the hardware interfaces of a microcon-

troller. It is used in steps (A2) and (A3) of the work-

flow described in Section 1. The tool is referred to as

PinConfig tool for the remainder of this paper. Sec-

tion 3.1 presents the actual GUI of the tool, while Sec-

tion 3.2 describes how the characteristics of micro-

controllers are stored internally. Section 3.3 presents

the XML format used to store the configurations for a

specific microcontroller in a specific project.

Seamless Integration of Hardware Interfaces in UML-based MDSE Tools

235

3.1 Graphical User Interface

Figure 2 shows the GUI of the PinConfig tool.

Panel A contains a list view, where the current mi-

crocontroller that is configured is displayed on top

(LPC1768 (NXP, 2021a) in Figure 2). In the remain-

der of the list view, the different hardware interfaces

of the microcontroller are displayed. In Figure 2, the

UART1 interface of the LPC1768 is selected. Panel

B shows additional configuration values for the inter-

face currently selected in panel A. In Figure 2, this is

the baudrate of the UART selected in panel A.

Panel C shows the board layout of the microcon-

troller and enables users to select the pins to use for

the hardware interface highlighted in panel A. The

pins that may be chosen are highlighted with a blue

border, while the pins that have actually been cho-

sen are marked yellow. In Figure 2, the pins 62 and

63 are configured as a transmitting and receiving pin

for UART1 respectively. Figure 2 shows a Quad Flat

Package (QFP) structure of the pins of the microcon-

troller, i.e., the pins are located at the sides of the mi-

crocontroller. The tool also supports the Ball Grid Ar-

ray (BGA) structure, where the pins are located under

the bottom of the chip.

Panel D shows the currently configured hard-

ware interfaces of the microcontroller. In Figure 2,

UART1 is configured to use the pin 62 for transmis-

sion (TXD1) and pin 63 for reception (RXD1). The

purpose, for which a pin is used, e.g., marking pin 62

as TXD1, may be selected in a separate submenu.

3.2 Representing Microcontrollers

The GUI presented in Section 3.1 contains a variety

of information about the microcontroller that is con-

figured, e.g., the board structure, the available hard-

ware interfaces and the roles these interfaces may per-

form. This section describes a novel XML file that is

used to describe the structure of the microcontroller

internally. Listing 1 shows the general structure of

the XML file.

At the start of the XML file (lines 1-6) in Listing 1,

the basic information about the microcontroller, e.g.,

its name, the number of its pins and the board lay-

out (e.g., LQFP or BGA) is stated. The information

about the hardware interfaces is divided among the

following tags, <interfaces>, <roles> and <pins>.

The <interfaces> tag represents an actual interface,

e.g., a UART, while the <pin> tag represents the

pins that are available on the microcontroller. The

<role> tag serves as a foreign key between these el-

ements, thereby enabling the PinConfig tool to high-

light which pins are available for a specific interface

1 < m i c r o c o n t r o l l e r i d =” l pc 1 7 6 8”>

2 <i n f o>

3 <name>LPC1768</name>

4 <p i n co u n t >100</ p in c o u n t>

5 <pack a ge>LQFP</p a ckage>

6 </ i n f o>

7 <i n t e r f a c e s >

8 <!−−c f . L i s t i n g 2−−>

9 </ i n t e r f a c e s >

10 <r o l e s >

11 <!−−c f . L i s t i n g 3−−>

12 </ r o l e s >

13 <p i ns>

14 <!−−c f . L i s t i n g 4−−>

15 </ p in s>

16 </ m i c r o c o n t r o l l e r >

Listing 1: General XML structure for representing a micro-

controller.

1 < i n t e r f a c e i d =” u a r t 0”>

2 <p r o p s>

3 <p r o p name=” r a t e ”>115200</ prop>

4 <!−− . . . −−>

5 </ p r o p s>

6 <name>UART0</name>

7 <r o l e s >

8 <r o l e i d =” tx d 0”></ r o l e >

9 <!−−...−−>

10 </ r o l e s >

11 </ i n t e r f a c e >

Listing 2: The structure of the <interface> XML element.

on a given microcontroller.

Listing 2 shows the <interface> tag. Besides

the name of the hardware interface it belongs to (cf.

UART0 in line 6 in Listing 2), the tag also contains the

properties of this hardware interface. For example, in

line 3 of Listing 2 the property rate is defined, indicat-

ing that the interface UART0 contains a property that

represents the baudrate of the UART. The following

value (115200) represents a default value that may be

changed in the GUI described in Section 3.1. Lines 7-

10 of Listing 2 indicate the possible roles the UART

may perform.

While roles are referenced via their id in the in-

terface elements, they are defined in their own XML

elements. This is shown in Listing 3. Besides intro-

ducing the id that is also referenced by the interface

elements (cf. line 1 in Listing 3), the roles may con-

tain a set of properties (cf. line 2-5 in Listing 3), a

note that contains the information from the data sheet

of the microcontroller (cf. line 6 in Listing 3) and a

symbol for this role that is shown in the GUI of the

tool (cf. line 7 in Listing 3).

Listing 4 shows the pin element, which gives each

pin a name (cf. line 3 in Listing 4) and a position on

the board, which may be obtained from the data sheet

ICSOFT 2021 - 16th International Conference on Software Technologies

236

1 < r o l e i d =” tx d 0”>

2 <p r o p s>

3 <p r o p name=” t y p e”>O</ p rop>

4 <!−−...−−>

5 </ p r o p s>

6 <n o t e>T r a n s m i t t e r f o r UART0. < / n o t e>

7 <symbol>TXD0</symbol>

8 </ r o l e >

Listing 3: The structure of the <role> XML element.

of the microcontroller (cf. lines 4-7 of Listing 4). Fur-

thermore, each pin may reference a set of roles, e.g.,

txd0 in line 9 of Listing 4.

1 <pi n i d =”98”>

2 <p r o p s> </props>

3 <name>98</name>

4 <p o s i t i o n >

5 <x>0</x>

6 <y>23</y>

7 </ p o s i t i o n >

8 <r o l e s >

9 <r o l e i d =” tx d 0 ”/>

10 <!−−...−−>

11 </ r o l e s >

12 </ p i n>

Listing 4: The structure of the <pin> XML element.

3.3 Representing Hardware

Configurations

The GUI described in Section 3.1 is capable of cre-

ating an XML file in which the current configura-

tions regarding the pins and properties are exported.

The structure of the XML file is shown in List-

ing 5. The XML tags used in Listing 5 are similar

to those introduced in Section 3.2. However, where

the tags in Section 3.2 describe the possible configu-

rations for a microcontroller, the tags in Listing 5 re-

fer to a specific configuration for a specific project in

which the microcontroller is used. Therefore, some

tags have the prefix configured prepended. The tag

<configured interface> describes the specific config-

uration for an interface (a UART in line 3-19 of List-

ing 5). The tag <configured role> describes the con-

figuration of a specific role that the interface is config-

ured for (in contrast to a possible role, which the inter-

face may be configured for, as in the <role> tag intro-

duced in Section 3.2). This includes the pin on which

the role is actually performed (<configured pin>),

e.g., pin 98 in line 15 of Listing 5). The <prop> tag is

still employed to provide further configurations, e.g,

the baudrate for the configured UART (cf. line 6 in

Listing 5).

1 <o ccup a ncy>

2 <c o n f i g u r e d i n t e r f a c e s >

3 <c o n f i g u r e d i n t e r f a c e >

4 <name>UART0</name>

5 <p r o p s>

6 <p r o p name=” r a t e ”>115200</ prop>

7 </ p r o p s>

8 <c o n f i g u r e d r o l e s >

9 <c o n f i g u r e d r o l e >

10 <p r o p s>

11 <p r o p name=” t y p e”>o</prop>

12 </ p r o p s>

13 <symbol>TXD0</symbol>

14 <c o n f i g u r e d p i n >

15 <id >98</id>

16 </ c o n f i g u r e d p i n >

17 </ c o n f i g u r e d r o l e >

18 </ c o n f i g u r e d r o l e s >

19 </ c o n f i g u r e d i n t e r f a c e >

20 <!−−...−−>

21 </ c o n f i g u r e d i n t e r f a c e s >

22 </ o c cupa n cy>

Listing 5: XML structure of the export format describing

the hardware configurations selected by the developer.

4 GENERATION OF

INITIALIZATION CODE FOR

HARDWARE INTERFACES

The goal of this paper is a seamless integration of

hardware accesses in UML-based MDSE environ-

ments. For this, the hardware has to be represented

in an object-oriented fashion (cf. Section 4.2), while

low-level code statements should be generated auto-

matically wherever possible (cf. Section 4.3 and 4.4).

For this purpose, this paper refers to a specific project

structure and certain key files, which are introduced

in Section 4.1. The aspects described in this section

belong to the steps (A4) and (A5) of the development

workflow presented in Section 2.

4.1 Project Structure

The generation process described in Section 4 makes

use of several file types. This section presents an

Figure 3: Overview of the different files used in Section 4.

Seamless Integration of Hardware Interfaces in UML-based MDSE Tools

237

overview of these files (cf. Figure 3). The appli-

cation itself is developed in the directory app. For

this, an object-oriented HAL may be used to access

the hardware. The interfaces of this HAL are stored

in the directory interface. These interfaces only have

to be defined once and may be reused for all micro-

controllers that have been considered during the cre-

ation of the HAL. The implementation of these inter-

faces depends on the specific microcontroller used in

the project and may be found in the directory inter-

nal. This implementation has to be created manually

once per microcontroller. It is reusable for all projects

that utilize the same microcontroller. The initializa-

tion code for the hardware interfaces is contained in

platform.h and platform.cpp (cf. Listing 8 and 9 intro-

duced in Section 4.3). These two files are generated

automatically from the file platform template.xml (cf.

Listing 10 introduced in Section 4.4). The structure of

platform template.xml is similar for every microcon-

troller, but requires controller-specific additions that

specify the exact commands available for the hard-

ware initialization of the specific controller.

In case an existing application should be ported

to another microcontroller, only two manual steps are

necessary. The content of the directory internal has to

be changed to the implementation for the new micro-

controller. Furthermore, platform template.xml has to

be replaced by the version specific to the new micro-

controller. In case the original microcontroller used to

develop the application and the new microcontroller

to which the application is ported provide similar ca-

pabilities, the application itself (inside the app direc-

tory) does not require any changes for the porting pro-

cess.

4.2 Object-oriented HAL

The PinConfig tool described in Section 3 may be

used to configure and automatically generate the ini-

tialization code for hardware interfaces (cf. Sec-

tion 4.4 for the automatic generation). Without this,

developers would have to deal with low-level code

constructs in MDSE tools. However, besides the ini-

tialization code for the hardware interfaces, develop-

ers also have to interact with low-level code in or-

der to access the hardware interfaces at runtime, e.g.,

to query the state of a GPIO. This section presents

an object-oriented HAL that may be integrated with

MDSE tools (cf. Section 5), thereby eliminating this

type of low-level code interactions at runtime as well.

As a complete HAL that encompasses virtually ev-

ery available hardware interface is a task associated

with a tremendous amount of work and resources, we

choose to limit ourselves to some of the most com-

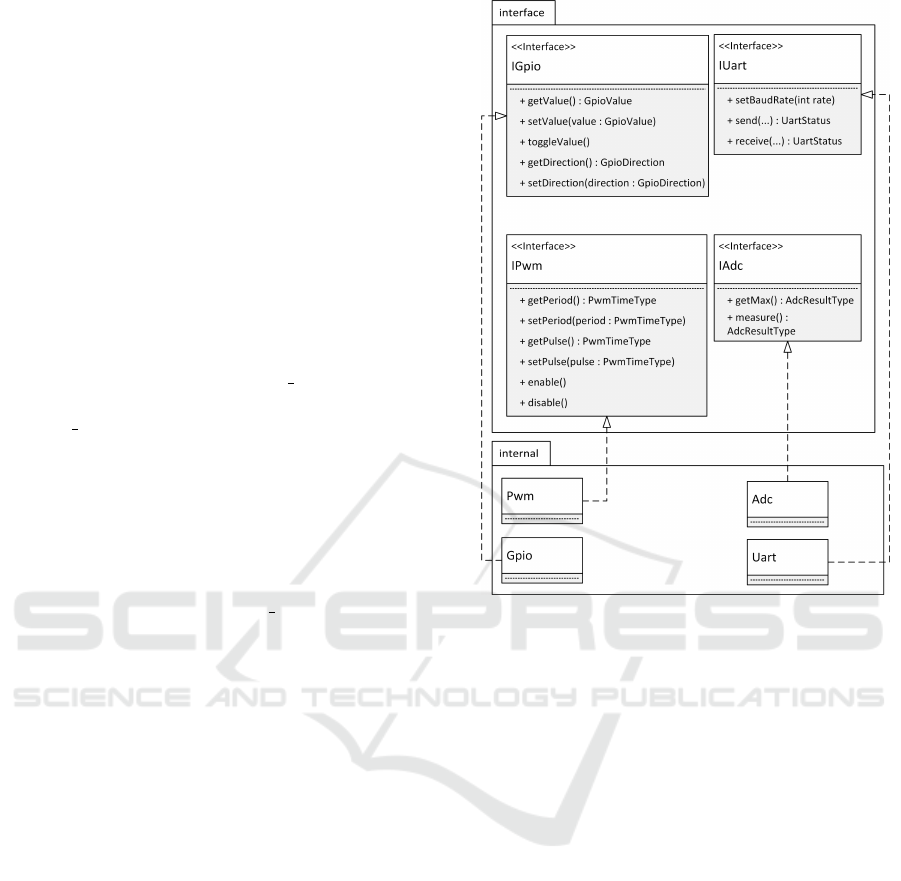

Figure 4: UML 2.5 class diagram of the structure of the

HAL. Three dots (...) are used as method parameters for

method signatures that are too long for the Figure. The Fig-

ure omits some template parameters (cf. Listing 7 and its

description).

mon hardware interfaces in this paper, namely GPIO,

ADC, UART and Pulse Width Modulation (PWM).

Other hardware interfaces may be integrated into the

HAL following the same principles.

In order to create the HAL, we studied mi-

crocontrollers from different manufacturers concern-

ing the previously mentioned hardware interfaces.

We studied microcontrollers from the manufactur-

ers Microchip (Microchip, 2021), Infineon (Infineon,

2021c), NXP (NXP, 2021a), ST Microelectronics (ST

Microelectronics, 2021b) and Espressif (Espressif,

2021). While the usage possibilities of the hardware

interfaces for the studied microcontrollers at runtime

is relatively consistent (e.g., a UART may send or re-

ceive data), the configuration of these hardware inter-

faces often differs more strongly between the differ-

ent microcontrollers. Therefore, the HAL presented

in this paper only abstracts the runtime usage of the

aforementioned hardware interfaces. Characteristics

that are related to the initial configuration and usually

remain constant during the execution of the applica-

tion, still require some controller-specific code. This

code is integrated via an automatic code generation

ICSOFT 2021 - 16th International Conference on Software Technologies

238

process and is explained in Section 4.4.

Figure 4 shows a UML class diagram of the hard-

ware interfaces and the abstraction of their function-

ality that is used during runtime. For legibility pur-

poses, the number of methods per hardware interface

in Figure 4 is reduced to the most common functions

for each hardware interface. The idea of Figure 4

is that developers implement their application with

the respective interfaces from the interface pack-

age, thereby gaining independence from a specific

hardware platform. The implementations of these in-

terfaces exist in the package internal. These im-

plementations differ for different hardware platforms.

Therefore, in case an application written with the

interface package should be ported to another plat-

form, the internal package has to be replaced by an-

other package that implements the HAL functionality

for the new hardware platform. While Figure 4 shows

four hardware interfaces that have been realized in

the HAL presented in this paper (GPIO, ADC, PWM,

UART), the remainder of Section 4 only refers to the

GPIO interface for legibility purposes. Moreover, the

examples refer to the Infineon Aurix TC297 (Infineon,

2021a) microcontroller. The presented concepts may

be applied analogously to the other hardware inter-

faces shown in Figure 4.

Figure 4 shows data types specific to each hard-

ware interface, e.g., GpioValue and GpioDirection

for the interface IGpio. In this example, GpioValue

indicates the current digital value of the GPIO, while

GpioDirection indicates whether the specific GPIO

is configured as an input or output. Often, microcon-

trollers provide their own type definitions for these

values. The HAL shown in Figure 4 abstracts these

type definitions for the respective microcontrollers,

in order to provide a consistent API for develop-

ers regardless of the specific hardware platform on

which the application should be executed. For this,

a mapping between the abstracted data types and the

data types specific to microcontrollers is required. In

the context of this paper, this is achieved by the file

Types.h, which contains such mappings. Listing 6

shows an excerpt of this file for the GPIO interface.

In line 5 of Listing 6, the abstract type GpioValue

is defined as the specific type IfxPort State in case

the HAL is executed on an Aurix TC297 microcon-

troller. Line 6 and 7 of Listing 6 show another im-

portant concept contained in Types.h, i.e., the ab-

straction of constants. Constant values, e.g., for set-

ting a GPIO to a high (GpioHigh in Listing 6) or low

(GpioLow in Listing 6) voltage, may be used by de-

velopers to configure a GPIO in a designated way.

Similar to the abstraction of types, as explained for

GpioValue above, constants may be abstracted by the

1 # i f n d e f HOLMES TYPES H

2 # d e f i n e HOLMES TYPES H

3 name s pace h o lmes {

4 / / Gpio

5 t y p e d e f I f x P o r t S t a t e Gpio V alue ;

6 s t a t i c c o n s t Gp ioVa l ue GpioLow =

I f x P o r t S t a t e l o w ;

7 s t a t i c c o n s t Gp ioVa l ue G pioHigh =

I f x P o r t S t a t e h i g h ;

8 / / [ . . . ]

9 }

10 # e n d i f / / # i f n d e f HOLMES TYPES H

Listing 6: Excerpt of the type definitions used in the HAL

(Types.h).

HAL to increase the independence of the application

code from a specific hardware platform.

Listing 7 shows an excerpt of an example imple-

mentation of the GPIO interface realization. It uses

the types defined in Types.h. Moreover, template pa-

rameters are used to specify compile time constants

that refer to hardware aspects used by the hardware

interface. In Listing 7, this is the pin and the port

which the GPIO should use (line 4). In Figure 4,

these template parameters have been omitted to im-

prove legibility. Besides the template parameters that

specify hardware aspects, the methods provided by

the IGpio interface have to be overridden in the in-

terface realization. Listing 7 shows this exemplary in

lines 12-14 for the method setValue().

1 # i f n d e f HOLMES INTERNAL GPIO H

2 # d e f i n e HOLMES INTERNAL GPIO H

3 name s pace h o lmes {

4 t e m p l a t e <u i n t 8 t p o r t , u i n t 8 t p i n>

5 c l a s s Gpio : p u b l i c h olme s : : I G p i o {

6 p r i v a t e :

7 v o l a t i l e I f x P

*

p o r t ;

8 p u b l i c :

9 Gpio ( ) {

10 p o r t = ( I f x P

*

) (0 xF003A000u + 0

x100u

*

p o r t ) ;

11 }

12 v o i d s e t V a l u e ( Gpi o Valu e v a l u e ) {

13 I f x P o r t s e t P i n S t a t e ( p o r t , p i n ,

v a l u e ) ;

14 }

15 / / [ . . . ]

16 }

17 }

18 # e n d i f / / # i f n d e f HOLMES INTERNAL GPIO H

Listing 7: Excerpt of the implementation of the GPIO HAL

interface for the Aurix TC297 microcontroller.

4.3 Hardware Initialization

Section 4.2 introduced an object-oriented HAL that

requires hardware-specific values for the usage of an

Seamless Integration of Hardware Interfaces in UML-based MDSE Tools

239

object of the HAL. For example, the port and pin of

the respective GPIO have to be passed as template pa-

rameters in Listing 7. This type of information is al-

ready configured in the PinConfig tool described in

Section 3 and may therefore be generated automat-

ically from the corresponding export format of the

tool (cf. Section 3.3). Then, a set of type definitions

may be used to enable developers to access a respec-

tive GPIO via an identifier configured in the PinCon-

fig tool, thereby precluding that a developer has to

know the port and pin on which the GPIO operates.

These type definitions are stored in a file called plat-

form.h, which may be automatically generated (cf.

Section 4.4 for the generation process). An excerpt

of platform.h is shown in Listing 8. The $ signs in

Listing 8 indicate a placeholder variable that should

be replaced with an actual value, i.e., the actual port

on which the GPIO should operate.

1 # i f n d e f HOLMES PLATFORM H

2 # d e f i n e HOLMES PLATFORM H

3 name s pace h o lmes {

4 $ { g p i o h a l }

5 / / [ . . . ] more t y p e d e f i n i t i o n s

6 voi d i n i t ( ) ;

7 }

8 # e n d i f / / # i f n d e f HOLMES PLATFORM H

Listing 8: Excerpt of the type definitions that allow develop-

ers to refer to hardware interfaces with custom names (plat-

form.h). The $ symbol indicates a placeholder variable.

In line 4 of Listing 8 a placeholder, ${gpio hal},

is used to represent type definitions which provide

an alias for a GPIO on a specific port and pin.

The number of type definitions equals the number

of GPIO interfaces that have been configured in

the PinConfig tool presented in Section 3. These

placeholders may themselves contain more place-

holders, e.g., for specifying the specific port and pin

of the GPIO. Thus, ${gpio hal} consists of a num-

ber of statements of the following form: typedef

internal::Gpio<$port, $pin> $name;. The

values of the placeholders may be extracted automat-

ically from the output format of the PinConfig tool

described in Section 3.3. Thus, developers may spec-

ify a name for a specific GPIO they wish to use in the

PinConfig tool, which may subsequently be used by

the developers to instantiate an instance of the specific

GPIO within their program. Besides the type defi-

nitions, platform.h declares the init() method (cf.

line 6 in Listing 8), which configures the hardware in-

terfaces according to the output format of PinConfig

tool presented in Section 3.3. The definition of this

method may be found in the file platform.cpp, which

may also be automatically generated (cf. Section 4.4).

The structure of platform.cpp is shown in Listing 9.

1 ${ g p i o p r e }

2 s t a t i c v o id i n i t G p i o ( ) {

3 $ { g p i o h e a d e r }

4 $ { gp i o b o dy }

5 $ { g p i o f o o t e r }

6 }

7 / / [ . . . ] T e m pl a t es o t h e r h a r d w ar e i n t e r f a c e s

8 v o i d ho lmes : : i n i t ( ) {

9 i n i t G p i o ( ) ;

10 / / [ . . . ] I n i t i a l i z e o t h e r i n t e r f a c e s

11 }

Listing 9: Structure of the hardware initialization (plat-

form.cpp). The $ symbol indicates a placeholder variable.

In line 8-11 of Listing 9, the aforementioned init()

method is defined. In essence, this simply defers the

initialization process to the initialization methods for

each specific hardware interface. In Listing 9, such

a specific initialization method is shown in lines 2-

6. The placeholder ${gpio header} is replaced by

code that should only be executed once before the ini-

tialization of every GPIO. Conversely, ${gpio footer}

is replaced by code that should only be executed

once after the initialization of every GPIO. The

${gpio body} placeholder is replaced by the specific

configurations for each individual GPIO. An exam-

ple for this is the line IfxPort setPinMode((Ifx P

*)&MODULE P${port}, ${pin}, ${mode}) for the

Aurix TC297 microcontroller, which sets the port

and pin of the GPIO, as well as whether it is ini-

tially configured as an input or an output. The place-

holders of this line may once again be automatically

extracted from the output format of the PinConfig

tool presented in Section 3.3. Besides the aforemen-

tioned placeholders, line 1 of Listing 9 shows the

${gpio pre} placeholder, which may provide addi-

tional initializations that may be accessed from within

initGPIO().

4.4 Code Generation for Hardware

Initialization

Section 4.3 introduced the files platform.h and plat-

form.cpp, which contain the initialization code for the

hardware interfaces as configured with the PinConfig

tool presented in Section 3.1. This section shows how

those files are generated automatically. Listing 10

shows the structure of platform template.xml.

At the start of Listing 10 the template structure

of the files platform.h and platform.cpp is stored (cf.

the previously introduced Listing 8 and 9 for the re-

spective structures). The remainder of Listing 10 (cf.

line 10-25) contains information about the controller-

specific commands to initialize a hardware interface.

ICSOFT 2021 - 16th International Conference on Software Technologies

240

1 <c o d e g e n e r a t o r >

2 <h e a d e r f i l e >

3 <!−− Tem p l a t e h o l m e s p l a t f o r m . h

4 ( c f . L i s t i n g 8 )−−>

5 </ h e a d e r f i l e >

6 <s o u r c e f i l e >

7 <!−− Tem p l a t e h o l m e s p l a t f o r m . cpp

8 ( c f . L i s t i n g 9 )−−>

9 </ s o u r c e f i l e >

10 <i n t e r f a c e s >

11 <gpio>

12 <g p i o h a l >

13 t y p e d e f i n t e r n a l : : Gpio& l t ; $ { p o r t } ,

14 $ { p i n }&g t ; ${name } ;

15 </ g p i o h a l >

16 <g p i o p r e ></g p i o p r e >

17 <g p i o h e a d e r ></g p i o h e a d e r >

18 <g p i o b ody>

19 I f x P o r t s e t P i n M o d e ( ( I f x P

*

)& ;

MODULE P${ p o r t } , $ { pi n } , $ {

mode }) ;

20 </ g p io body>

21 <g p i o f o o t e r ></ g p i o f o o t e r >

22 </ g pio>

23 <!−− . . . −−>

24 </ i n t e r f a c e s >

25 </ c o d e g e n e r a t o r >

Listing 10: XML file used as a template to generate

the hardware initialization (platform template.xml). The $

symbol indicates a placeholder variable. Note that some

special characters have to be used because of the XML

syntax, e.g., < to represent the symbol <.

For example, in Listing 9 (platform.cpp), the template

variable gpio body is used to specify the initialization

process for each GPIO. In lines 18-20 of Listing 10,

the controller-specific commands for this initializa-

tion process are stored. Similarly, lines 12-15 define

the type definition required for the gpio hal template

variable that is used in Listing 8 (platform.h).

Generating the initialization files platform.h and

platform.cpp automatically may be achieved by it-

erating through every hardware interface configured

in the output format of the PinConfig tool (cf. Sec-

tion 3.3). For each hardware interface of the same

type X, e.g., GPIO, and for each sub-tag in the

<gpio> tag of Listing 10 (cf. lines 12-21, e.g.,

<gpio hal>), a string builder X

i

is created. For

example, a separate string builder X

i

is created

for the <gpio hal>, <gpio pre>, <gpio header>,

<gpio body> and <gpio footer> tags. The string

builders X

i

are appended with the content from the re-

spective sub-tags of Listing 10. During this append-

ing, the remaining placeholder values in Listing 10,

e.g., ${pin}, are filled with the configured values from

the output format of the GUI tool. Thus, once every

hardware interface that is configured in the output for-

mat of the PinConfig tool has been iterated through,

the string builders X

i

contain the initialization infor-

mation of every configured hardware interface. For

example, the string builder for ${gpio hal} contains

the type definitions for all configured GPIO interfaces

in the output format. The string builders X

i

may then

subsequently be used to replace the other placehold-

ers for platform.h and platform.cpp, which are stored

in lines 2-9 of Listing 10. Thus, the templates for

platform.h and platform.cpp no longer contain any

placeholders and the actual files platform.h and plat-

form.cpp may be generated by copy-pasting the con-

tent from the templates in a newly created file.

5 INTEGRATION WITH MDSE

TOOLS

The results from Section 4 allow developers to inter-

act with hardware in an object-oriented abstract man-

ner, as well as the automatic code generation of the

initialization code for hardware interfaces. However,

these elements are not yet integrated in an MDSE de-

velopment process, as the results from Section 4 only

exist as code. This section describes how this gener-

ated code, as well as the PinConfig tool described in

Section 3.1, may be integrated with MDSE tools.

Before the actual integration process is described,

we remark upon the heterogeneity of current MDSE

tools. As these tools are developed by different

providers, their customization options for developers

differ. Thus, integration of our approach with these

tools may differ slightly for each tool. However, the

principle is similar for each tool. In the following, the

provided examples are based on the MDSE tool IBM

Rational Rhapsody (Rhapsody, 2020).

1) Starting the Hardware Configuration Tool from

the GUI of the MDSE Tool. While the GUI tool

presented in Section 3 may be started as a standalone

application, it may also be started from an MDSE

tool. Furthermore, such an integration in the MDSE

tool allows for an integration of the subsequent code

generation process (cf. Section 4.4) in the MDSE

tool as well. In IBM Rational Rhapsody, this may

be achieved by the use of so called helper files that

may add entries to Rhapsody’s menus and execute ar-

bitrary Java code once such an entry is clicked.

2) Integrating the HAL Into the MDSE Tool Via

Reverse Engineering. The HAL described in Sec-

tion 4 exists as source code. In order to use this code

in MDSE tools and enable an object-oriented access

Seamless Integration of Hardware Interfaces in UML-based MDSE Tools

241

Figure 5: Picture of the modified mBot platform as used in

this paper. The microcontroller on top of the mBot is an

Aurix TC297.

of hardware interactions, corresponding classes either

have to be created manually by the developer in the

MDSE tool or created automatically via the reverse

engineering functionality of the MDSE tool. In IBM

Rational Rhapsody, the reverse engineering process

may be executed automatically via a dedicated Java

API. Thus, in our prototype implementation, this pro-

cess is automatically performed after configuration

of the hardware interfaces via the PinConfig tool has

ended.

3) Include HAL and Platform Files During Com-

pilation. Once the code for the application has been

created from the model with the MDSE tool’s code

generation, the HAL and the automatically generated

platform.h and platform.cpp files have to be linked

during compilation.

6 USE CASE

We evaluated our approach for a small embedded ap-

plication example, i.e., a toy car that is capable of au-

tonomous driving. For this, we modify the Makeblock

mBot platform (Makeblock, 2021) with a custom con-

verter board. This converter board enables the use of

3.3V and 5V microcontrollers with the mBot, as well

as the use of the GPIO, UART, ADC und PWM hard-

ware interfaces. The GPIOs are used to control LEDs

and read digital values from sensors, i.e., an ultrasonic

sensor in this application. The ultrasonic sensor is

used to detect obstacles in front of the mBot. The

ADC is used to digitalize the luminosity levels mea-

sured by sensors below the mBot. This enables the

mBot to autonomously follow a set trajectory, pro-

vided the path of the trajectory contains a different

brightness level than the rest of the track. For exam-

ple, this may be achieved by printing a black line that

represents the path of the trajectory on white sheets

of paper. The PWM is used to control the motors of

the mBot, while the UART enables interaction with a

bluetooth chip. The bluetooth chip, in turn, is capable

of communicating with a smartphone application that

may be used to 1) control the mBot remotely, 2) start

its autonomous trajectory following driving mode and

3) enable the automatic obstacle avoidance enabled

through the ultrasonic sensors. Figure 5 shows an im-

age of the modified hardware platform with the Aurix

TC297 microcontroller connected.

For the purpose of this use case a software appli-

cation was created with an MDSE tool (IBM Ratio-

nal Rhapsody (Rhapsody, 2020)) that provides the ap-

plication logic for the functionality described above.

For hardware interactions, the HAL described in Sec-

tion 4 is used within the application model. In order

to show the effect of our approach on the portability

of applications, we selected five microcontrollers for

which the application should control the mBot. These

are a LPC1768 (NXP, 2021a), XMC4500 (Infineon,

2021c), STM32F4 (ST Microelectronics, 2021b) and

an Aurix TC279 (Infineon, 2021a). With the HAL

implementations for these microcontrollers, as de-

scribed in Section 4, the only step required for run-

ning the application on these different microcon-

trollers is the configuration of the hardware via the

PinConfig tool described in Section 3. By employ-

ing the code generation described in Section 4.4, the

remaining controller-specific code is generated auto-

matically. Thus, porting the application comes down

to specifying the hardware initialization for the new

microcontroller in the PinConfig tool.

7 RELATED WORK

This section describes related work to the approach

presented in this paper. This encompasses approaches

that describe a HAL, as well as approaches that gener-

ate some form of initialization code for the hardware

of microcontrollers.

Industrial tools that are capable of generating ini-

tialization code for the hardware of microcontrollers

include, e.g., (Infineon, 2021b; ST Microelectronics,

2021a; NXP, 2021b) . Most often, these tool are pro-

prietary and are developed by a specific manufacturer

of microcontrollers. In consequence, the tools only

support the configuration of microcontrollers for a

specific family of microcontroller, i.e., those offered

by the specific manufacturer. For example, (ST Mi-

croelectronics, 2021a) is limited to the configuration

ICSOFT 2021 - 16th International Conference on Software Technologies

242

of microcontrollers from ST Microelectronics. Our

approach, in contrast, provides a generic description

format for microcontrollers and their hardware inter-

faces (cf. Section 3) and may thus include microcon-

trollers from different manufacturers (cf. Section 6).

Furthermore, these tools do not consider the integra-

tion of the generated source code into MDSE tools

at all. This is exacerbated by the fact that most of

these tools do not create object-oriented source code.

Non-object-oriented source code is hard to integrate

with UML-based MDSE tools, as UML is an object-

oriented modeling language and supports non-object-

oriented concepts only in a limited fashion. Our ap-

proach, in contrast, couples the hardware initializa-

tion to an object-oriented HAL (cf. Section 4) and

may therefore be easily integrated into MDSE tools

(cf. Section 5).

Besides these industrial approaches, there are sev-

eral academic approaches for generating the initial-

ization code for the hardware interfaces of microcon-

trollers. In (Yunfei Bai et al., 2007; Bhanu et al.,

2009), an XML-based description methodology for

microcontrollers is described. It is intended for the

code generation of initialization code. However, their

description assumes direct hardware access for each

microcontroller, whereas our approach assumes the

usage of a HAL. Furthermore, their approach does not

generate object-oriented code and thus is hard to inte-

grate in MDSE tools. Nevertheless, their description

format served as an inspiration for our XML-based

description formats described in Section 3.

An approach that is limited to the generation of

source code for the MPC5644A microcontroller has

been presented in (Geng et al., 2012). Our approach,

in contrast, is extensible by design and may gener-

ate code for any microcontroller once the required

XML-files (cf. Section 3 and 4) are created. Fur-

thermore, their approach generates code for Mat-

lab/Simulink (MathWorks, 2021), while our approach

focuses on integration with UML-based MDSE tools.

Another approach for platform-independent

source code generation has been described in (Kim

et al., 2013). The platform-dependent characteristics

of the target platform are described with an Archi-

tectural Analysis Description Language (AADL),

which is supplemented by a code snippet repository.

Our approach, in comparison, uses an XML-based

format to describe the target microcontrollers and

relies on a HAL for the implementation of hardware

accesses instead of a code snippet repository. Due

to the use of an object-oriented HAL and UML, our

approach enables developers to work with UML-

based MDSE tools to develop their application. The

approach presented in (Kim et al., 2013), in contrast,

does not describe an integration with UML-based

MDSE tools and instead relies on other modeling

languages, e.g., Stateflow (MathWorks, 2021) or

UPPAAL (Behrmann et al., 2004).

Section 4 introduces an approach for the

seamless integration of object-oriented HALs into

MDSE. There exist other, non object-oriented HALs,

e.g., (ARM Limited, 2021a; ARM Limited, 2021b).

Due to their non-object-oriented nature, they are

harder to integrate with MDSE tools. The num-

ber of object-oriented HALs is relatively small,

e.g., (modm., 2021). Currently, these approaches do

not describe how they may be seamlessly integrated

with MDSE tools.

8 CONCLUSION

MDSE tools are often based on UML and its high-

level object-oriented concepts. The interaction with

hardware, which usually occurs through low-level

program code at the register level, often requires a

change in abstraction levels for the developer. More-

over, due to the hardware interactions not being

object-oriented, MDSE tool support for such hard-

ware interactions is lacking. This paper proposes an

approach how object-oriented HALs may be seam-

lessly integrated into MDSE tools to enable develop-

ers to develop embedded systems in a holistic, object-

oriented fashion. For this, we introduce a GUI tool

to configure hardware interfaces and provide an auto-

matic code generation approach that uses XML-based

template files. The resulting code may be automat-

ically imported into MDSE tools. We evaluated our

approach by developing an application example for

microcontrollers from three different manufacturers

(NXP, Infineon and ST Microelectronics). Due to the

use of our HAL, the application code could be ported

to the other microcontrollers with a minimum of mod-

ifications.

Future work includes an automated generation of

the XML files describing the structure of microcon-

trollers for the GUI tool in which the hardware is con-

figured. Furthermore, we envision a SysML (Object

Management Group, 2019)-like frontend for the GUI

tool that enables developers to specify the hardware

configuration without leaving their MDSE tool.

ACKNOWLEDGEMENTS

This work was partially funded by the German Fed-

eral Ministry of Economics and Technology (Bun-

Seamless Integration of Hardware Interfaces in UML-based MDSE Tools

243

desministeriums fuer Wirtschaft und Technologie-

BMWi) within the project “Holistic model-driven de-

velopment for embedded systems in consideration of

diverse hardware architectures” (HolMES). The au-

thors would like to thank Adrian Richter for software

development assistance, as well as Johannes Trageser

and Lars Donner for helpful comments on the HAL

and its integration in MDSE tools.

REFERENCES

ARM Limited (2021a). Cortex Microcontroller Software

Interface Standard (CMSIS) https://developer.arm.

com/tools-and-software/embedded/cmsis (accessed

on 25th March 2021).

ARM Limited (2021b). Mbed OS.

https://os.mbed.com/mbed-os/ (accessed on 11th

March 2021).

Behrmann, G., David, A., and Larsen, K. G. (2004). A Tuto-

rial on Uppaal, pages 200–236. Springer Berlin Hei-

delberg, Berlin, Heidelberg.

Bhanu, G. P., Bai, Y., Tan, S. L., and Chng, E. S. (2009). A

Generic MCU Description Methodology with Depen-

dency Evaluation. In 2009 International Conference

on Signal Processing Systems, pages 565–569.

Brambilla, M., Cabot, J., and Wimmer, M. (2012). Model-

Driven Software Engineering in Practice. Morgan &

Claypool Publishers.

Bunse, C., Gross, H.-G., and Peper, C. (2007). Applying a

model-based approach for embedded system develop-

ment. pages 121–128.

Charette, R. N. (2009). This car runs on code. IEEE spec-

trum, 46(3):3.

Espressif (2021). ESP32. http://esp32.net/ (accessed on

18th March 2021).

Geng, P., Ouyang, M., Li, J., and Xu, L. (2012). Embedded

C Code Generation Platform for Electric Vehicle Con-

troller. Advanced Materials Research, 546-547:778–

783.

Huning, L., Iyenghar, P., and Pulvermueller, E. (2020).

A workflow for automatically generating application-

level safety mechanisms from UML stereotype model

representations. In Proceedings of the 15th Interna-

tional Conference on Evaluation of Novel Approaches

to Software Engineering - Volume 1: ENASE, pages

216–228. INSTICC, SciTePress.

Infineon (2021a). 32-bit AURIX™ Microcontroller

based on TriCore™. https://www.infineon.com/

cms/de/product/microcontroller/32-bit-tricore-

microcontroller/(accessed: 13th January 2021).

Infineon (2021b). Dave.

https://www.infineon.com/dgdl/infineon-

dave introduction-dt-v01 00-

en.pdf?fileid=5546d462636cc8fb01645f681d4713ed

(accessed on 11th March 2021).

Infineon (2021c). XMC4500. https://www.infineon.com/

cms/de/product/microcontroller/32-bit-industrial-

microcontroller-based-on-arm-cortex-m/32-bit-

xmc4000-industrial-microcontroller-arm-cortex-

m4/xmc4500/ (accessed on 19th March 2021).

Kashif, H., Mostafa, M., Shokry, H., and Hammad, S.

(2009). Model-based embedded software develop-

ment flow. In 2009 4th International Design and Test

Workshop (IDT), pages 1–4.

Kim, B., Phan, L. T. X., Sokolsky, O., and Lee, L. (2013).

Platform-dependent code generation for embedded

real-time software. In 2013 International Conference

on Compilers, Architecture and Synthesis for Embed-

ded Systems (CASES), pages 1–10.

Makeblock (2021). mBot.

https://www.makeblock.com/mbot (accessed on

9th March 2021).

MathWorks (2021). Matlab.

https://www.mathworks.com/products/matlab.html

(accessed on 18th March 2021).

Microchip (2021). ATMegaA328-PU. https://www.

microchip.com/wwwproducts/en/ATmega328P

(accessed on 19th March 2021).

modm. (2021). modm: a barebone embedded library gener-

ator. https://modm.io/ (accessed on 16th March 2021).

NXP (2021a). https://www.nxp.com/products/processors-

and-microcontrollers/arm-microcontrollers/general-

purpose-mcus/lpc1700-cortex-m3/512kb-flash-64kb-

sram-ethernet-usb-lqfp100-package:lpc1768fbd100

(accessed on 18th March 2021).

NXP (2021b). MCUXpresso.

https://www.nxp.com/design/software/development-

software/mcuxpresso-software-and-tools-

/mcuxpresso-integrated-development-environment-

ide:mcuxpresso-ide (accessed on 11th March 2021).

Object Management Group (2019). OMG Systems Mod-

eling Language Version 1.6. Technical report, Object

Management Group.

OMG UML (2017). OMG Unified Modeling Language

Version 2.5.1. Technical report, Object Management

Group.

Rhapsody (2020). IBM. Rational Rhapsody Developer.

https://www.ibm.com/us-en/marketplace/uml-tools

(accessed 20th August 2020).

Selic, B. (2008). Personal reflections on automation, pro-

gramming culture, and model-based software engi-

neering. Automated Software Engineering, 15(3-

4):379–391.

ST Microelectronics (2021a). STM32CubeMX.

https://www.st.com/en/development-

tools/stm32cubemx.html (accessed on 11th March

2021).

ST Microelectronics (2021b). STM32F4XX.

https://www.st.com/en/microcontrollers-

microprocessors/stm32f4-series.html (accessed

on 19th March 2021).

Trindade, R., Bulwahn, L., and Ainhauser, C. (2014).

Automatically generated safety mechanisms from

semi-formal software safety requirements. In Bon-

davalli, A. and Di Giandomenico, F., editors, Com-

puter Safety, Reliability, and Security, pages 278–293,

Cham. Springer International Publishing.

Yunfei Bai, Eng Siong Chng, and Gorthi Prashant Bhanu

(2007). An mcu description methodology for ini-

tialization code generation software. In 2007 Inter-

national Conference on Parallel and Distributed Sys-

tems, pages 1–7.

ICSOFT 2021 - 16th International Conference on Software Technologies

244