Energy Consumption Modeling for Specific Washing Programs of

Horizontal Washing Machine using System Identification

Yongki Yoon

a

and Sibel Malkos¸

b

Washing Machine R&D, Arc¸elik A.S¸., Istanbul, Turkey

Keywords:

Energy Consumption, Energy Efficiency, Data Monitoring, State-space Model, System Identification.

Abstract:

This paper presents the application of an energy consumption modeling technique using a system identification

method regarding the washing program settings for a horizontal washing machine. The observer/Kalman

filter identification/eigensystem realization algorithm (OKID/ERA) method is employed to identify the linear

discrete state-space model by choosing the system order computed by the significant singular values. The

identified model is used as an estimator to figure out the energy consumption level for washing programs with

the full loading condition, and results show the feasibility of the method in energy consumption modeling.

1 INTRODUCTION

The electricity and the water consumption in the

washing machines are mainly dependent on the us-

age pattern of an end-user such as the washing pro-

gram, the temperature setting, the program duration,

the auxiliary functions and the laundry amount as well

as the capacity of the washing machine (Schmitz and

Stamminger, 2014; Afzalan and Jazizadeh, 2019). In

the European Union, horizontal washing machines

are commonly used for the laundry, while vertical

washing machines are mostly populated in the North

America, Asia and Australia. A vertical washing ma-

chine uses more water than a horizontal one, while the

latter consumes more power to control the water tem-

perature via a heater which is a high power consump-

tion device (Pakula and Stamminger, 2010; Bertocco

et al., 2020). In general, researches are mainly fo-

cused on the total energy consumption to provide

the energy-policy direction either in the residential

buildings or in the household appliances. Richardson

(Richardson et al., 2010) presented the annual energy

demand for the household appliances using the statis-

tics between the energy use and the occupant activ-

ity. In references (Bourdeau et al., 2019; Li and Wen,

2014), authors reviewed a data-driven method for the

purpose of the modeling and forecasting in a build-

ing sector and pointed out the popular approaches

such as statistical regression, k-nearest neighbors, de-

a

https://orcid.org/0000-0002-5277-1697

b

https://orcid.org/0000-0002-2159-5766

cision tree, support vector machines, artificial neural-

network, etc. A simplified model of the energy con-

sumption for horizontal washing machines was pro-

posed using a linear relationship regarding the age of

the end-user, the temperature setting, the capacity of

washer and the energy efficiency (Milani et al., 2015).

Recently, a modeling framework was shared by us-

ing a bottom-up activity to estimate the accurate en-

ergy consumption in residential buildings (Leroy and

Yannou, 2018). However, these researches have been

conducted to create the energy model for all types of

household appliances over a year or daily-base to fig-

ure out the optimal energy saving purpose. In house-

hold appliance sector, monitoring the power and the

energy consumption in real-time per unit will give

more flexibility to give the efficient product design

and development strategy.

Addressing the modeling strategy for new product de-

velopment, the system identification methodology is

the most favourable framework by system designers.

For several decades, this method has been an emerg-

ing research topic to characterize the system behavior

using the experimental data to overcome the knowl-

edge gap from the physics-based modeling in the en-

gineering fields (Ljung, 1999; Van Overschee and

De Moor, 1994; Juang and Pappa, 1985). However,

the limited studies were reported in a washing ma-

chine sector using this approach. Therefore we pro-

pose an innovative approach to develop the mathemat-

ical model in a systematic way and the prediction per-

formance of the energy consumption from the mea-

sured data for specific washing programs subjected

Yoon, Y. and Malko¸s, S.

Energy Consumption Modeling for Specific Washing Programs of Horizontal Washing Machine using System Identification.

DOI: 10.5220/0010511407210727

In Proceedings of the 18th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2021), pages 721-727

ISBN: 978-989-758-522-7

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

721

to the washing program type, the temperature setting,

the drum speed profile, the laundry amount, the un-

balanced load, the amount of detergent and the wa-

ter intake volume (Boyano et al., 2020). The goal of

this research is to develop a framework identifying the

mathematical model from the measured input-output

data sets during the washing cycles and to estimate the

energy consumption without a power sensor in order

to reduce the product cost.

2 PROBLEM STATEMENT

In order to predict and analyze the energy consump-

tion in a washing machine, a mathematical model is

necessary to clarify its characteristics from the mea-

sured data sets. Therefore, an identification process is

required to relate how the input affects the output. In

this research, we consider that a washing machine is

a black-box system for an energy consumption mod-

eling induced by multiple input variables such as a

washing program type (P), a temperature setting (T ),

a profile of motor speed (ω

d

), a laundry amount (m

l

),

an amount of detergent (m

d

), an amount of water

(V ), and so forth in equation (1). In order to address

the multiple inputs and the single output relationship,

we employ an observer/Kalman filter identification

(OKID) working on the time-domain in Figure 1.

E = f (P,T,ω

d

,m

l

,m

d

,V ) (1)

Black-Box

Model

OKID/ERA

u(k) y(k)

u(k)

y(k)

ˆ

A,

ˆ

B,

ˆ

C,

ˆ

D, G

Figure 1: The system identification process.

Taking into consideration of the real application,

we relate the input physical quantities in equation (1)

to the low-level mechanical actuators subjected to a

heater on-time, a pre-wash valve on-time, a main-

wash on-time, a pump on-time, and a profile of motor

speed.

3 DATA AND METHOD

3.1 Data

Firstly, the washing program types were selected

based on widely used programs in the European

Union via Amazon Web Services (AWS) connected

by HomeWhiz IoT ecosystem developed by Arce-

lik. The QUICKWASH and the BEDDING programs

were popularly chosen washing programs by the cus-

tomers, therefore we have collected the input-output

data sets for these washing programs from the same

washing machine with the full load case (9 kg of

etamine fabric) described in Table 1 and the test setup

environment in Figure 2.

Table 1: A washing machine configuration for the test.

Washing Program BEDDING QUICKWASH

Test Condition Load Amount (kg) 9 9

Load Type etamine (70×70cm) etamine (70×70cm)

Spin Speed (rpm) 1000 1400

Temperature (

◦

C) 40 40

Current Total Max. Current (A) 8.4 8.4

Washing Motor Current (A) 0.52 0.6

Spinning Motor Current (A) 2.67 2.5

Power Washing Motor Power (W) 110 86

Total Max. Power (W) 1912 1870

Water Level Main Wash (lt) 21.17 21.10

1. Rinse (lt) 19.44 -

2. Rinse (lt) 19.55 -

Softener (lt) 19.50 21.10

Total Water Consumption (lt) 89.60 43.12

Spin Speed Washing RPM 54 75

Main Wash Spinning RPM 300-617 840

1. Rinse Spin RPM 300-615 -

2. Rinse Spin RPM 300-618 -

Final Spin RPM 300-1020 839

Duration Total Program Duration (min) 110 40

Figure 2: Overview of the test station.

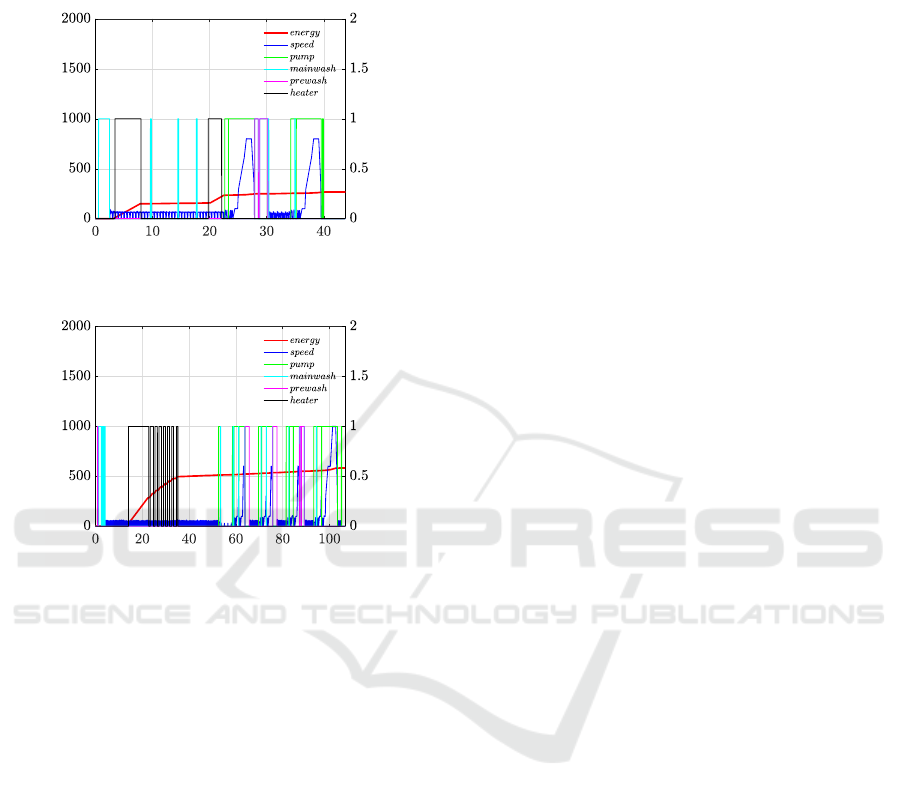

Figures 3-4 show the measured data set regarding

the washing program selection. In the both figures,

during the heater activation to reach the targeted water

temperature (40

◦

C), it consumes most of the energy

between (3-8) minutes and (20 − 22) minutes for the

QUICKWASH program, and between (14-33) min-

utes for the Bedding program. Afterwards, the second

highest energy consumption is caused by the motor

run, and also the amount of water volume in the drum

affects the motor power consumption. Additionally,

the amount of water volume in a washing machine

is determined by the amount of detergent dosage, the

pre-wash valve on-time, the main-wash valve on-time

and the drain pump on-time. Therefore, some of the

inputs are dependent to the others, and this effect will

be simplified via the linear system identification pro-

cess. In this research, a model to be identified is the

multiple-inputs and the single-output (MISO) system

subjected to u ∈ R

5

, y ∈ R

1

. In order to apply the sys-

tem identification, we collected following input and

output data sets as follow.

ICINCO 2021 - 18th International Conference on Informatics in Control, Automation and Robotics

722

u = [drum speed, heater on-time, prewash valve

on-time, main-wash valve on-time, pump on-time]

y = energy consumption

Time [min]

Energy Consumption / Motor Speed

Valve ON-OFF

Figure 3: Input-output data for the QUICKWASH program.

Time [min]

Energy Consumption / Motor Speed

Valve ON-OFF

Figure 4: Input-output data for the BEDDING program.

3.2 Method

This section reviews the OKID/ERA method (Juang,

1994) to identify the system characteristics using the

input-output data histories of a horizontal washing

machine. Consider a discrete linear time-invariant

system in a state-space form as below,

x(k + 1) = Ax(k) + Bu(k)

y(k) = Cx(k) + Du(k) (2)

where x(k) ∈ R

n

is the system state, y(k) ∈ R

m

is

the output, u(k) ∈ R

r

is the input, and the system ma-

trices are defined as A ∈ R

n×n

, B ∈ R

n×r

, C ∈ R

m×n

,

D ∈ R

m×r

.

By assuming the zero initial condition of the state,

the sequence of the above equations can be written as,

x(k) =

k

∑

i=1

A

i−1

Bu(k − i)

y(k) =

k

∑

i=1

CA

i−1

Bu(k − i) +Du(k) (3)

Then, the output y(k) can be decomposed into the

system Markov parameters (Y ) and the upper triangu-

lar input matrix (U) as below,

y = YU (4)

where y ∈ R

m×l

, Y ∈ R

m×rl

, U ∈ R

rl×l

, and k =

l − 1

From the above equation (4), Y represents the ma-

trix composed of the pulse responses known as the

system Markov parameters to be identified in equa-

tion (5).

Y =

D CB CAB · · · CA

l−2

B

(5)

The upper triangular input matrix is defined as

U =

u(0) u(1) u(2) · ·· u(l − 1)

u(0) u(1) · · · u(l − 2)

u(0) · ·· u(l − 3)

.

.

.

.

.

.

u(0)

and the output vector y is measured as

y =

y(0) y(1) · · · y(2) y(l − 1)

Equation (5) can be directly derived from equation

(2), however, it is not easy to measure the full states of

the system and it does not guarantee the fast compu-

tation and also robust convergence if the data length l

is too large. To solve these issues, the observer gain

matrix G is employed to the state equation (5) to re-

shape the system eigenvalues so that one can obtain

the desired system behavior.

x(k + 1) = Ax(k) + Bu(k) + Gy(k) − Gy(k)

= (A + GC)x(k) + (B +GD)u(k) − Gy(k)

(6)

Then, we can design the new system containing

the observer gain G in the system below,

x(k + 1) =

¯

Ax(k) +

¯

Bv(k) (7)

where

¯

A = A + GC,

¯

B =

B + GD −G

,

v(k) =

u(k) y(k)

T

.

The observer gain matrix G is chosen to make the

system matrix

¯

A to be Hurwitz, and this means that

for some sufficiently large p,

¯

A

k

≈ 0 for time steps k ≥

p. The Kalman filter makes the computation faster to

obtain the observer gain matrix G such that G = −K,

where K is the Kalman gain matrix.

The output equation from the updated system in-

cluding the non-zero initial condition can be written

as

¯y(k) = C

¯

A

k

x(0) +

k

∑

i=1

C

¯

A

k−i

¯

Bv(k − i) +Du(k) (8)

Energy Consumption Modeling for Specific Washing Programs of Horizontal Washing Machine using System Identification

723

Similarly, we can decompose output as below since

the initial condition is negligible due to

¯

A

k

≈ 0

¯y =

¯

Y

¯

V (9)

where ¯y ∈ R

m×(l−p)

,

¯

Y ∈ R

m×[(m+r)p+r]

,

¯

V ∈

R

[(m+r)p+r]×(l− p)

.

Firstly, we compute the observer Markov parame-

ter matrix

¯

Y from equation (10) by taking the pseudo-

inverse.

¯

Y = ¯y

¯

V

†

(10)

where

¯

V

†

=

¯

V

T

¯

V

¯

V

T

−1

¯y =

y(p) y(p + 1) · ·· y(l − 1)

¯

Y =

D C

¯

B C

¯

A

¯

B · ·· C

¯

A

p−1

¯

B

¯

V =

u(p) u(p + 1) · · · u(l − 1)

v(p − 1) v(p) · ·· v(l − 2)

v(p − 2) v(p − 1) · ·· v(l − 3)

.

.

.

.

.

.

.

.

.

.

.

.

v(0) v(1) · ·· v(l − p − 1)

Secondly, the system Markov parameters (Y ) can

be recovered from the observer Markov parameters

(

¯

Y ), and the observer Markov parameters are also ex-

pressed with the system matrices and the observer

gain matrix as below,

¯

Y

0

= D

¯

Y

k

= C

¯

A

k−1

¯

B

=

C (A + GC)

k−1

(B +GD) −C (A + GC)

k−1

G

(11)

or

¯

Y

k

=

h

¯

Y

(1)

k

−

¯

Y

(2)

k

i

(12)

By the induction process, the system Markov pa-

rameters are obtained in equation (13).

Y

0

= D

Y

k

=

¯

Y

(1)

k

−

k

∑

i=1

¯

Y

(2)

i

Y

k−i

f or k = 1, 2,· · · , p

Y

k

= −

p

∑

i=1

¯

Y

(2)

i

Y

k−i

f or k = p + 1, p + 2,∞ (13)

Now, using the eigensystem realization algorithm

proposed by Juang and Pappa (Juang and Pappa,

1985), The Hankel matrix composed of the observer

and the system Markov parameters can be constructed

in equation (14).

H(k −1) =

Y

k

Y

k+1

· · · Y

k+β−1

Y

k+1

Y

k+2

· · · Y

k+β

.

.

.

.

.

.

.

.

.

.

.

.

Y

k+α−1

Y

k+α

· · · Y

k+α+β−2

(14)

The Hankel matrix can be also represented by us-

ing the system Markov parameters in equation (15).

H(k − 1) =

C

C

A

· · ·

CA

β−1

A

k−1

h

B AB · · · A

β−1

B

i

= OA

k−1

C (15)

where C and O denote the controllability and the ob-

servability matrices, respectively. From the Hankel

matrix, a singular value decomposition is performed

to obtain the unitary matrices (U

n

,V

n

) and a singular

value matrix (Σ

n

) for k = 1.

H(0) = U

n

Σ

n

V

T

n

(16)

The singular value matrix (Σ

n

) contains the n number

of singular values whose magnitudes are bigger than

zero such that σ

1

≥ σ

2

≥ · · ·σ

n

> 0. At this stage, one

can check the relative magnitude of the singular val-

ues, and eliminate the values which are not significant

to the system performance (i.e., characteristics), and

determine the system order.

Therefore, the estimated system matrices

(

ˆ

A,

ˆ

B,

ˆ

C,

ˆ

D) can be obtained in equation (17).

ˆ

A = Σ

−1/2

n

U

T

n

H(1)V

n

Σ

−1/2

n

ˆ

B = Σ

1/2

n

V

T

n

E

r

ˆ

C = E

T

m

U

n

Σ

1/2

n

D = Y

0

(17)

where E

T

m

and E

T

r

are consisted of the identity and

the zero matrices, which have different matrix dimen-

sion.

4 RESULTS

The system identification process has been performed

with three measurements for both QUICKWASH and

BEDDING programs from 9 kg capacity of a single

washing machine. Two of the three measurements

have been used to construct the discrete state-space

model using an OKID/ERA method for each wash-

ing program. The third measurement was used for the

validation of the identified model. The data process-

ing, the algorithm implementation, and the simulation

were carried out using MATLAB scripts (MATLAB

R2019a) with Control System Toolbox.

4.1 Model Selection

In general, the singular value represents the charac-

teristics of the system, and it is a reasonable criteria

ICINCO 2021 - 18th International Conference on Informatics in Control, Automation and Robotics

724

Table 2: The identified discrete state-space model.

QUICKWASH BEDDING

ˆ

A

0.8893 0.4491 −0.0631

0.2284 0.1618 −0.5788

−0.1193 0.6037 −0.0331

1.0157 0.2100 −0.0806

−0.1125 0.2362 −0.8358

−0.0155 0.5006 −0.2665

ˆ

B

−0.0005 −0.3207 0.0574 0.0107 0.0243

0.0010 −0.0727 0.0458 −0.0065 −0.0404

−0.0001 0.7456 0.2538 0.0133 −0.0082

−0.0002 −0.3592 0.0031 0.0055 −0.0029

0.0004 −0.2068 0.0043 −0.0020 0.0120

−0.0005 0.6957 −0.0116 0.0113 0.0101

ˆ

C

h

−0.5708 0.3617 0.0367

i h

−0.4659 0.2141 0.0726

i

ˆ

D

h

−0.0002 0.1861 0.0015 −0.0065 −0.0646

i h

0.0001 0.1439 −0.0023 0.0034 0.0010

i

G

h

1.7099 −0.0989 −0.1664

i

T

h

1.5168 −1.0481 −0.7498

i

T

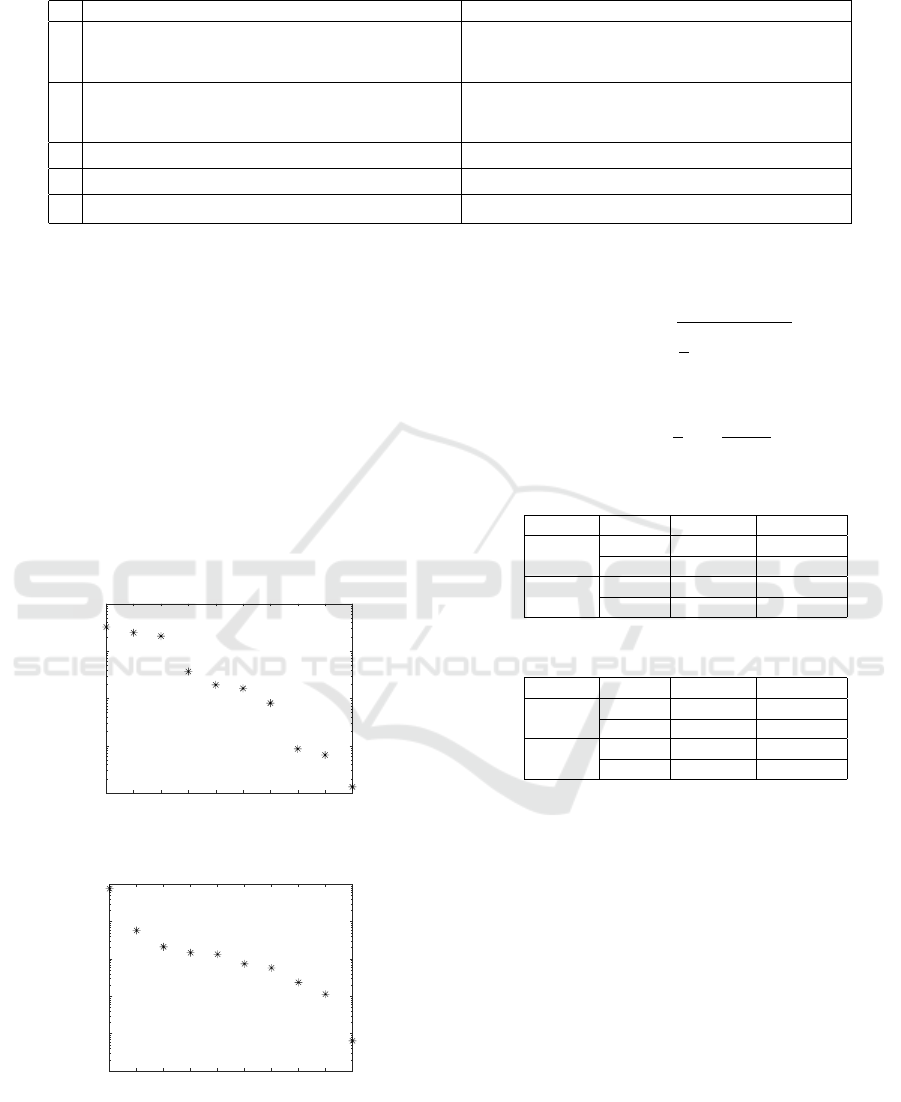

to determine the system size. Therefore, we initially

chose the system size as 10-th order as seen in Fig-

ures 5-6 and the singular values were computed from

the Hankel matrix. Thus, one can choose the system

order by checking the number of the dominant sin-

gular values. In this way, we can reduce the system

order since the rest of the singular values have less

impact to be the system behavior or it can be noise

effects. For the QUICKWASH program in Figure 5,

first three singular values are dominant compared to

the others, and for the BEDDING program, we chose

the first three values since the third and the forth ones

do not have big difference in magnitude. The identi-

fied mathematical models with observers (G) have the

three-degree of freedom described in Table 2.

1 2 3 4 5 6 7 8 9 10

Number of Singular Values

10

-8

10

-7

10

-6

10

-5

10

-4

Magnitude of Singular Values

Figure 5: The singular values for the QUICKWASH.

1 2 3 4 5 6 7 8 9 10

Number of Singular Values

10

-10

10

-9

10

-8

10

-7

10

-6

10

-5

Magnitude of Singular Values

Figure 6: The singular values for the BEDDING.

Both the identified state-space models are control-

lable and observable since we can obtain the full rank

from the controllability and the observability matri-

ces, respectively. Tables 3 and 4 show the accuracy of

the identified model in RMSE and MAPE.

RMSE =

s

1

n

n

∑

i=1

( ˆy

i

− y

i

)

2

(18)

MAPE =

1

n

n

∑

i=1

ˆy

i

− y

i

y

i

(19)

Table 3: Model accuracy for the QUICKWASH program.

Observer Test No. E

rmse

(Wh) E

mape

(%)

Test 1 0.1467 7.71 × 10

−4

Yes Test 2 0.1407 7.67 × 10

−4

Test 1 13.9991 6.6575

No Test 2 12.5445 5.9351

Table 4: Model accuracy for the BEDDING program.

Observer Test No. E

rmse

(Wh) E

mape

(%)

Test 1 0.1331 1.48 × 10

−4

Yes Test 2 0.1291 2.00 × 10

−4

Test 1 10.2693 1.9780

No Test 2 10.2693 1.978

4.2 Model Validation

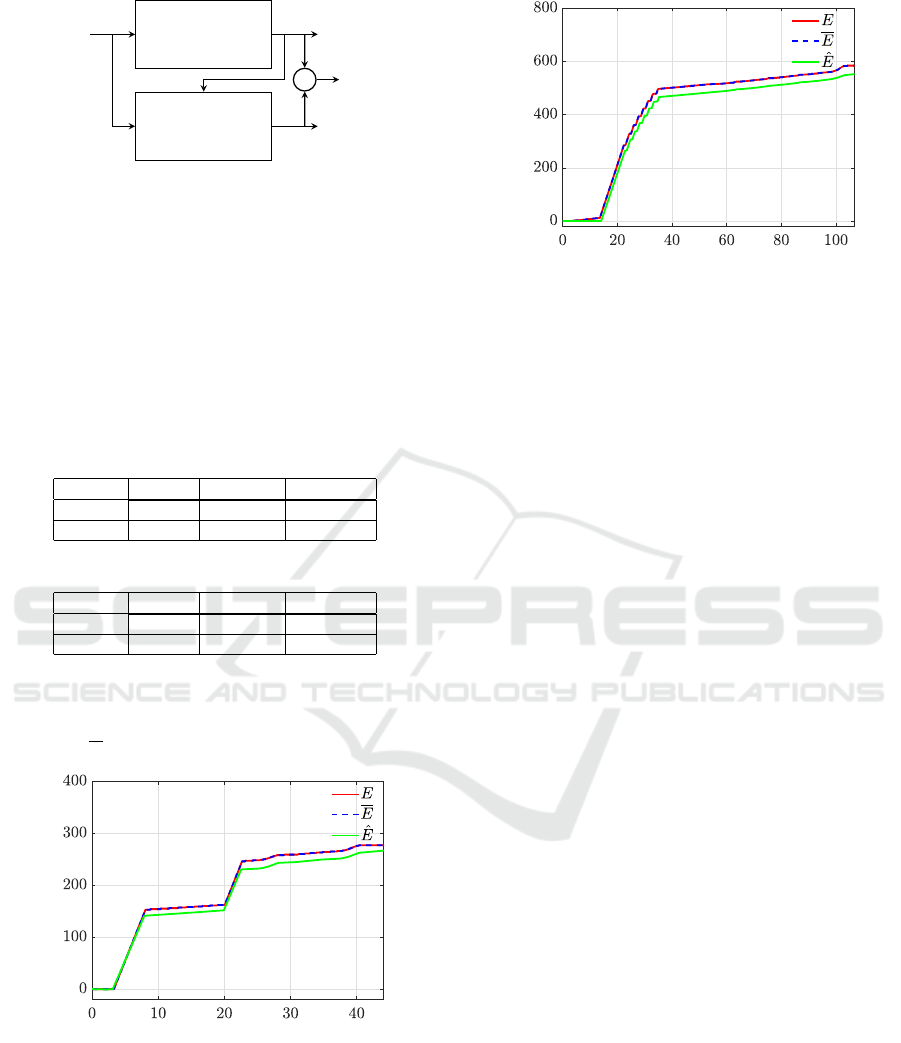

From the identified state-space model in Table 2, we

used the third measurement data, which was not in-

cluded for the system identification process, to vali-

date the prediction accuracy of the energy consump-

tion for both washing programs in Figure 7. Tables

5 and 6 indicate the errors in the RMSE and the

MAPE defined in equations (18)-(19). Both tables

show that adding an observer (G) provides the ac-

curate energy estimation since the augmented input,

v(k) =

u(k) y(k)

T

in equation (7), contains the

input measurement as well as the output via sensors.

That means the observer generates the optimal system

states by minimizing the error between the measured

energy consumption and the estimated one.

In Figure 7, the estimated output is defined by ˆy

k

at

each time step and the errors are calculated as below,

Energy Consumption Modeling for Specific Washing Programs of Horizontal Washing Machine using System Identification

725

Washing Machine

Identified Model

(

ˆ

A,

ˆ

B,

ˆ

C,

ˆ

D, G)

u

k

y

k

ˆy

k

+

−

e

k

Figure 7: The model validation.

In this research, however, we focused on identify-

ing the linear discrete state-space model and validat-

ing the accuracy of the model by comparing the pre-

dicted output to the measured one. The results show

that the identified MISO model without an observer

roughly follows the trend of the energy consumption

with the accuracy of 91.2% and 94.2% in MAPE for

the QUICKWASH and the BEDDING programs, re-

spectively.

Table 5: Validation for the QUICKWASH program.

Observer Test No. E

rmse

(Wh) E

mape

(%)

Yes Test 3 0.1435 7.48 × 10

−4

No Test 3 18.1276 8.8069

Table 6: Validation for the BEDDING program.

Observer Test No. E

rmse

(Wh) E

mape

(%)

Yes Test 3 0.1575 8.19 × 10

−5

No Test 3 28.0675 5.8599

Figures 8-9 also graphically demonstrate that how

well the model with and without an observer estimates

the energy consumption, where

ˆ

E is without an ob-

server and E with an observer.

Time [min]

Energy Consumption [Wh]

Figure 8: Comparison of the energy consumption for the

QUICKWASH program.

Time [min]

Energy Consumption [Wh]

Figure 9: Comparison of the energy consumption for the

BEDDING program.

5 CONCLUSION AND FUTURE

WORK

In this research, we have studied the systematic mod-

eling technique for the energy consumption in a hor-

izontal washing machine using an OKID/ERA ap-

proach in the time-domain and the model reduction

process was carried out to reduce the computational

time by counting the dominant singular values ob-

tained from the Hankel matrix. The discrete lin-

ear time-invariant state-space models with the three-

degree of freedom were obtained and validated to see

the feasibility of the framework for the energy con-

sumption of the specific washing programs. From the

simulation results, the method can successfully gen-

erate the accurate model with the input-output mea-

surements. Especially, in the case of being used as

an estimator with Kalman gain (K = −G) in a feed-

back system to adjust the optimal system states, the

prediction accuracy in the energy consumption can be

significantly improved. For the future study, we will

consider medium and large capacity of washing ma-

chines under the different laundry amounts such as

quarter, half and full loading. The proposed model

will be integrated and deployed in the software stack

of washing machine to estimate the energy consump-

tion level without a power sensor to check the practi-

cal aspect.

REFERENCES

Afzalan, M. and Jazizadeh, F. (2019). Residential loads

flexibility potential for demand response using energy

consumption patterns and user segments. Applied En-

ergy, 254:113693.

Bertocco, M., De Dominicis, M., Favaro, I., Ferri, A.,

Ronchi, F., Salmaso, L., Spadoni, L., and Stellini, M.

ICINCO 2021 - 18th International Conference on Informatics in Control, Automation and Robotics

726

(2020). Impact of limestone incrustation on energy

efficiency of washing machine. Energy Efficiency,

13(1):1–15.

Bourdeau, M., qiang Zhai, X., Nefzaoui, E., Guo, X.,

and Chatellier, P. (2019). Modeling and forecast-

ing building energy consumption: A review of data-

driven techniques. Sustainable Cities and Society,

48:101533.

Boyano, A., Espinosa, N., and Villanueva, A. (2020).

Rescaling the energy label for washing machines: an

opportunity to bring technology development and con-

sumer behaviour closer together. Energy Efficiency,

13(1):51–67.

Juang, J.-N. (1994). Applied system identification. Prentice-

Hall, Inc.

Juang, J.-N. and Pappa, R. S. (1985). An eigensystem re-

alization algorithm for modal parameter identification

and model reduction. Journal of guidance, control,

and dynamics, 8(5):620–627.

Leroy, Y. and Yannou, B. (2018). An activity-based mod-

elling framework for quantifying occupants’ energy

consumption in residential buildings. Computers in

Industry, 103:1–13.

Li, X. and Wen, J. (2014). Building energy consumption

on-line forecasting using physics based system identi-

fication. Energy and buildings, 82:1–12.

Ljung, L. (1999). System identification. Wiley encyclopedia

of electrical and electronics engineering, pages 1–19.

Milani, A., Camarda, C., and Savoldi, L. (2015). A sim-

plified model for the electrical energy consumption of

washing machines. Journal of Building Engineering,

2:69–76.

Pakula, C. and Stamminger, R. (2010). Electricity and wa-

ter consumption for laundry washing by washing ma-

chine worldwide. Energy efficiency, 3(4):365–382.

Richardson, I., Thomson, M., Infield, D., and Clifford,

C. (2010). Domestic electricity use: A high-

resolution energy demand model. Energy and build-

ings, 42(10):1878–1887.

Schmitz, A. and Stamminger, R. (2014). Usage behaviour

and related energy consumption of european con-

sumers for washing and drying. Energy Efficiency,

7(6):937–954.

Van Overschee, P. and De Moor, B. (1994). N4sid:

Subspace algorithms for the identification of com-

bined deterministic-stochastic systems. Automatica,

30(1):75–93.

Energy Consumption Modeling for Specific Washing Programs of Horizontal Washing Machine using System Identification

727