Application of Machine Learning Methods to Improve of the Roller

Press Performance in the Pelletizing Process

Thiago Nicoli de Abreu

1,2 a

, Andrea G. Campos Bianchi

3b

and Saul Emanuel Delabrida Silva

3c

1

Programa de Pós-Graduação em Instrumentação, Controle e Automação de Processos de Mineração (PROFICAM),

Universidade Federal de Ouro Preto (UFOP) and Instituto Tecnológico Vale (ITV), Ouro Preto, Brazil

2

Vale S.A., Vitória, Brazil

3

Departamento de Computação (DECOM), Universidade Federal de Ouro Preto (UFOP), Ouro Preto, Brazil

Keywords: Modeling, Machine Learning, Data Mining, Database, Roller Press, Pelletizing.

Abstract: In recent years, the technology of the roller press has become very useful in the pelletizing processes to

comminute the pellet feed and increase the specific surface of the iron ore. It is known that the surface gain

is directly related to the productivity and quality gains in the pelletizing process. In view of its importance,

the increase in efficiency of the press becomes increasingly necessary, mainly due to its direct impact on the

production chain. The large number of variables involved in its operation demonstrate that conventional

methods and the knowledge of this process can be improved. For this, the work identifies the variables with

the highest production in the specific surface gain, develops a classification model to determine rules of

optimal operation settings and presents a model for the prediction of the specific surface variable, seeking

gains in determining performance of this asset.

1 INTRODUCTION

At the beginning of the 1990s, a series of pelletizing

industrial plants began to implement the Roll Press in

industrial circuits for pressing iron ore and pellet feed.

This was an important advance in the area of

comminution and mineral processing (Barrios, 2014).

One of the greatest benefits of the Roller Press in the

pelletizing process is the increase in the specific

surface gain, a property that directly contributes to the

improvement of the physical and mechanical

properties of the pellets and the quality of the finished

product. When a material has a high specific surface,

the greater the capillarity of the vessels, resulting in a

more compact, more finished pellet with better

mechanical resistance (Silva, 2008).

The inefficiency in the steps prior to the pressing

process, possible problems with the adjustment of the

operating parameters and the operational unavailability

of this equipment (due to failures) are some of the

factors that impact the performance of this equipment

in terms of increasing the specific surface of the ore.

a

https://orcid.org/0000-0001-5940-1632

b

https://orcid.org/0000-0001-7949-1188

c

https://orcid.org/0000-0002-8961-5313

The low efficiency of the press results in disturbances

for the next stages of the process, mainly in the

pelletizing stage (formation of pellets), causing losses

in production and even plant shutdowns. A mining

company may incur losses corresponding to millions

of dollars in a few hours due to its production

stoppage. Besides, an inappropriate manufactured

product can lead to rework or non-compliance with

the customer's quality requirements.

The presses operation is complex because it

involves the combination of dozen variables. This

leads to an exponential combination of setups for

human decisions without computer support. In

addition, the variations in the characteristics of the

production process, in the previous and subsequent

stages, physical and chemical characteristics of the

ore and process restrictions introduce new production

scenarios.

This work proposes an analysis of the roller press

in a pelletizing plant, seeking to answer the following

questions: what are the main factors that interfere

directly or indirectly in the efficiency of this

equipment? What are the possible setups (setting of

Nicoli de Abreu, T., Bianchi, A. and Silva, S.

Application of Machine Learning Methods to Improve of the Roller Press Performance in the Pelletizing Process.

DOI: 10.5220/0010443906770684

In Proceedings of the 23rd International Conference on Enterprise Information Systems (ICEIS 2021) - Volume 1, pages 677-684

ISBN: 978-989-758-509-8

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

677

operating values) for the greatest gain in the process?

The study was performed in a database installed in a

mining company. The responses lead to improvement

and increased productivity (production volume) and

the specific surface of the ore.

Data mining techniques were used to identify the

variables with the greatest influence on the gain of the

press and a classification model to determine optimal

operating setups of the roller press was developed.

Our main findings and contribution are:

● Identify the most influential variables in the

pressing process.

● Identify the rules for decision making using

different values of optimal setups of

operation of the roller press.

● Develop a classification model to predict the

specific press surface.

The rest of this paper is organized as follows:

Section 2 describes the main challenges for operating

the roller press in the pelletizing process. Section 3

describes the work related to the use of computational

intelligence techniques in this same process. Section

4 describes the materials and methods that were used

to develop this work. Section 5 describes the results

obtained and discussions carried out with the use of

machine learning techniques to: determine the most

relevant variables, obtain the rules of optimal setups

and the prediction model of the specific press surface.

Section 6 describes the conclusions after the analysis

carried out.

2 PROBLEM STATEMENT

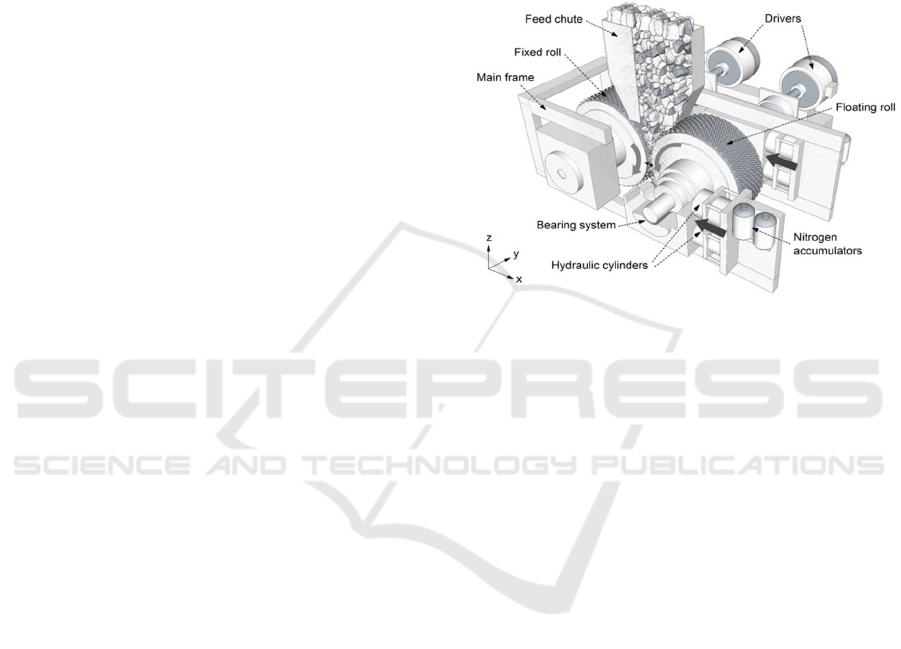

The Roller Press consists of two rollers rotating in

opposite directions, one roller called a fixed roller,

rotating on a fixed axis, and the other as a mobile

roller, which rotates on a mobile axis that performs a

translation movement towards the fixed roller

through a hydraulic system (Figure 1). This system

allows a variation of the specific compression force

exerted on the bed of particles between the rollers.

The material feed is introduced in the opening

between rollers, where the comminution of the

particles occurs through the interparticle force

breaking mechanism.

Due to the complexity of this equipment, variables

such as working pressure of the rollers, clearance

between the rollers, feed rate, level of the press rail,

humidity of the pressed ore, speed of the rollers, torque

and current of the motors, among others, need be

parameterized (manipulated by the equipment

operator) and monitored during its operation.

This scenario of multiple variables to be

controlled emphasizes the need for a study of

intelligent computational methods that can cooperate

in the adjustments and in the best decision making in

their operation. Therefore, the knowledge to operate

the roller press is a major factor in fulfilling its

objective, which is to increase the specific surface of

iron ore. Dependence on human action just to control

and maintain an operational standard in the face of all

the complexity for analysis is practically impossible.

Figure 1: Diagram of the roller press. Source: Barrios

(2014).

For the period of data evaluated for this work, the

plant under analysis had 11.22 hours of stoppage and

273.37 hours of lost or reduced production.

Considering the average production value of the plant

at 700 t/h and the commercial price of a ton of iron

ore as US$ 100.00/t, the estimated value of economic

loss was approximately US$ 785,000.00. The main

cause related to loss of production is related to the low

values of specific surface after the pressing process.

Another factor of great attention is related to the

measurement of the specific surface of the pressed

pulp. Currently, this measurement is performed in the

laboratory, in the interval of 4 hours, by means of

manual collection performed in the post-circuit phase

of pressing. This aspect causes a delay in the

perception of the performance of this equipment,

delaying corrections of possible failures and

anomalies during the operation. Decision-making

becomes late due to the lag in this measurement.

Thus, predicting the classification of this

measurement online would be a more agile way of

evaluating the performance of the equipment and the

process in real time.

This work proposes an analysis of the roller press

through artificial intelligence techniques to identify

the variables of greatest influence to determine the

gain of the press. Finally, it develops a classification

model to determine optimal operating

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

678

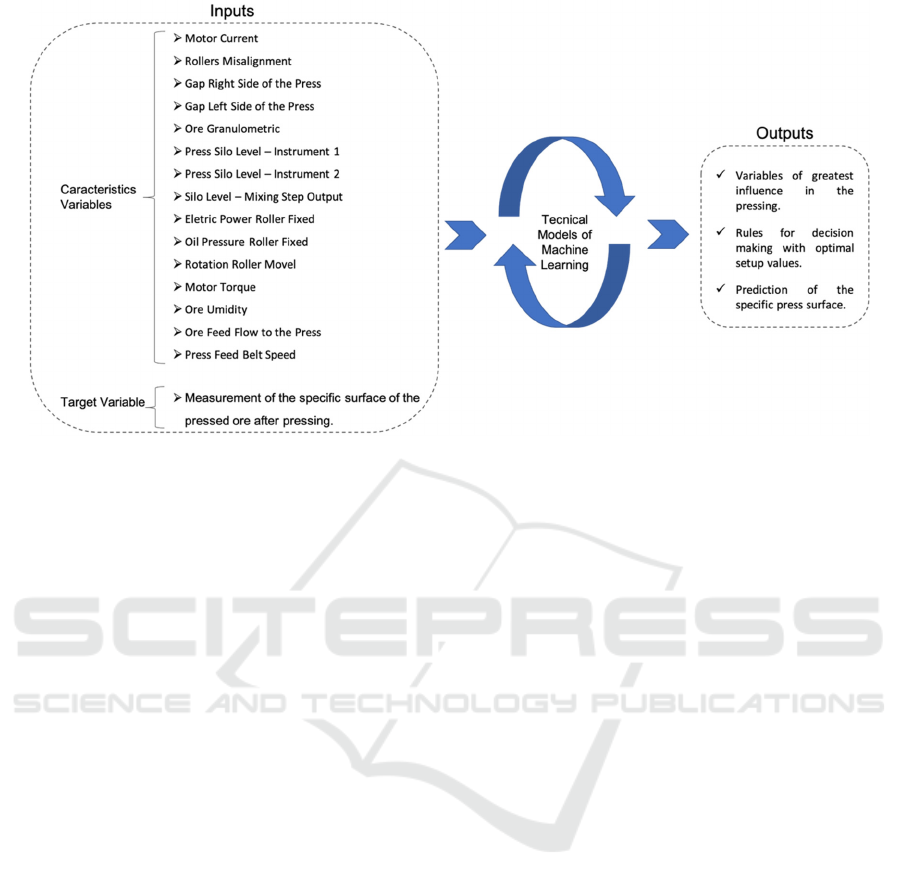

Figure 2: Overview of the concept applied in this project. Detailing of input variables, model learning and expected output

results.

settings for the roller press. This model will be used

to predict the specific surface variable of the pressed

pulp, seeking gains in determining the performance

of this asset.

3 RELATED WORK

Studies carried out in pelletizing processes, pressing

area and applications of mathematical models in

mining processes are essential as a reference and

development of this work. The models developed

until then did not consider the dynamics of the key

parameters during the operation of the press to

perform the forecast of the equipment performance

variables.

Campos (Campos, 2018), for example, discusses

the phenomenological mathematical model

developed by Torres and Cassali (Torres & Cassali,

2009) capable of predicting the capacity, power and

granulometric distribution of the product generated in

the equipment and address a series of tests at different

scales for pellet feed and iron ore pressing.

Vyhmeister (Vyhmeister et al., 2019), on the other

hand, presents a modeling study for roller press based

on predictive control model (MPC), showing that the

growing need for analysis in multivariable controls

for complex processes requires increasingly robust

and advanced strategies. Hasanzadeh and Farzanegan

(Hasanzadeh & Farzanegan, 2011) apply a method

based on genetic algorithms to estimate the

parameters of mathematical models developed for

roller presses, based on the model explained by

Torres and Cassali (Torres & Cassali, 2009).

Tohry (Tohry, Chelgani, Matin, &

Noormohammadi, 2020) presents a predictive model

for power draw prediction based on operating

parameters for an industrial ball mill. Still Tohry

(Tohry, Yazdani, Hadavandi, Mahmudzadeh, &

Chelgani, 2020) demonstrates in another work a

robust artificial intelligence technique to fill gaps

related to the modeling of energy consumption in

high pressure grinding rolls on an industrial scale.

In this context, is evident that there is a need to

develop accurate forecasting models to improve the

operations of roller press. In addition, most

representations of this equipment are based on steady

state models for offline design and optimization,

making them unsuitable for controlling online

process and optimization.

Therefore, this work shows that there is a great

potential yet to be explored in the use of the artificial

intelligence area with the iron ore pressing processes

in the industry.

4 METHODS AND MATERIALS

The data related to the pressing were extracted from

the private base of the pelletizing system of a plant of

a mining company collected at intervals of 10

minutes, over a period of 8 months. The resulting

database is a matrix with 32,998 records (rows) of 16

variables (columns).

Application of Machine Learning Methods to Improve of the Roller Press Performance in the Pelletizing Process

679

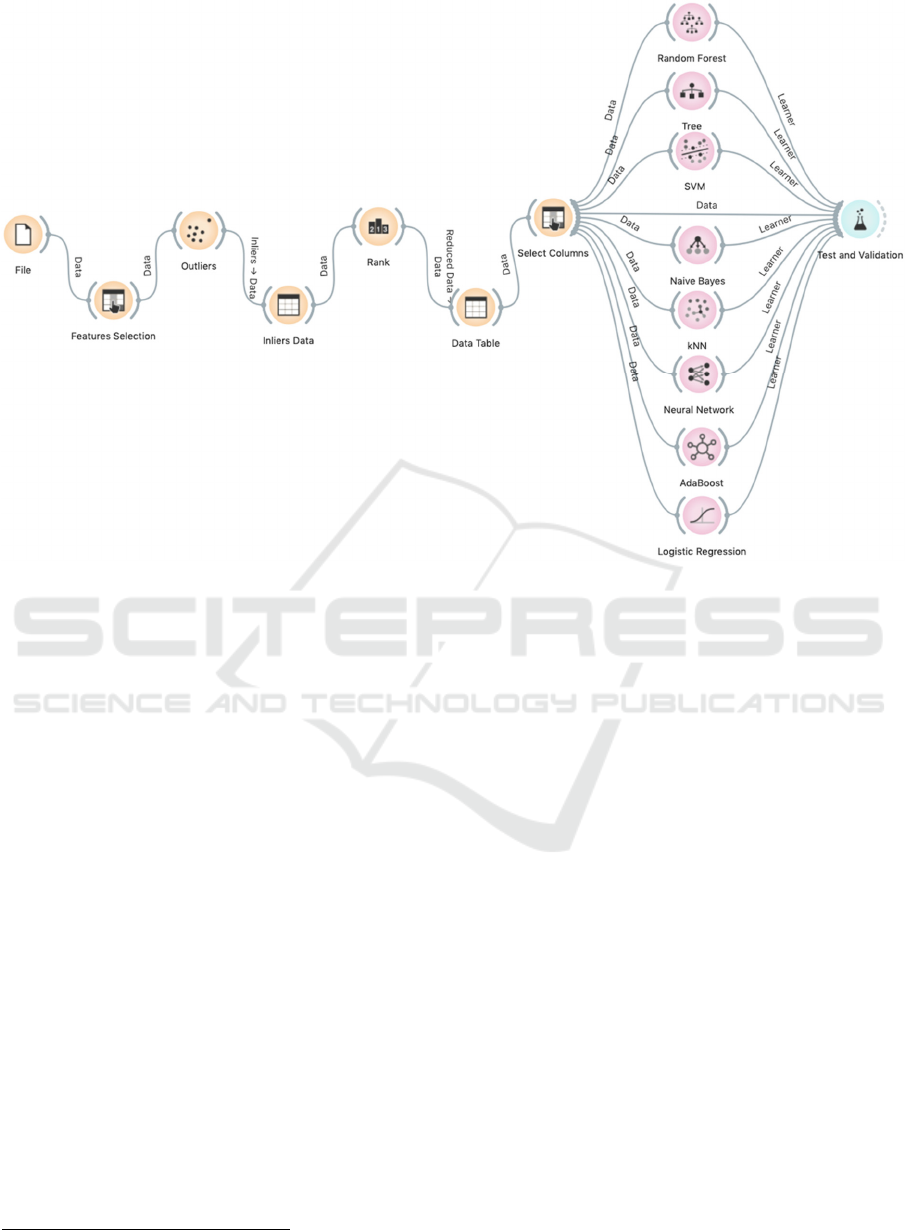

Figure 3: Modeling KDD processes in Orange software, showing all Orange processes and components used for modeling

and project development.

The columns represent the press plant variables.

The data was evaluated using the Knowledge

Discovery in Databases (KDD) process. The Orange

Data Mining

1

software was used for the development

of this work, exploring the components of machine

learning, data mining and libraries for classification

and regression (Viterbo et al., 2016) and (Naik,

2016). Figure 3 shows the flow performed on this

work.

The sequencing of the KDD processes was used

to determine the ranking of the variables of greatest

influence on the specific surface, to obtain the best

classification model and the rules for optimal setup of

the process variables.

The stage of data preparation is essential for this

process, where tools were used for selection (pressing

process rules and filters), outliers detection,

discretization and data normalization. Still according

to Shedroff (Shedroff, 1999), data “are the product of

discovery, research, collection and creation. It is the

raw material we find or create that we use to build our

communications "and information" makes data

meaningful to the public, because it requires the

creation of relationships and standards between the

data.

1

More information at: https://orange.biolab.si

The most significant variables for the gain of the

pressing process were identified using the Rank

component of Orange with evaluation of the selection

methods Information Gain, Information Gain Ratio,

Gini, Anova, chi-square (X2), ReliefF and Fast Based

Correlation Filter (FCBF).

The machine learning models tested were

Decision Tree (Tree), Support Vector Machine

(SVM), Naive Bayes, K-Nearest Neighbors (kNN),

Neural Network, AdaBoost, Logistic Regression and

Random Forest. The evaluation was performed

according to the performance measures CA -

classification accuracy and AUC - area under the

ROC curve.

The cross-validation sampling method for

learning, training and testing of the database was used

during the validation of the methods, with 10 folds as

a parameter.

5 RESULTS

The data were processed using the Outlier component

of Orange to exclude outliers. For each of the 16

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

680

variables, the selection of the Inliers and Outliers data

sets was obtained. Only Inliers data were used.

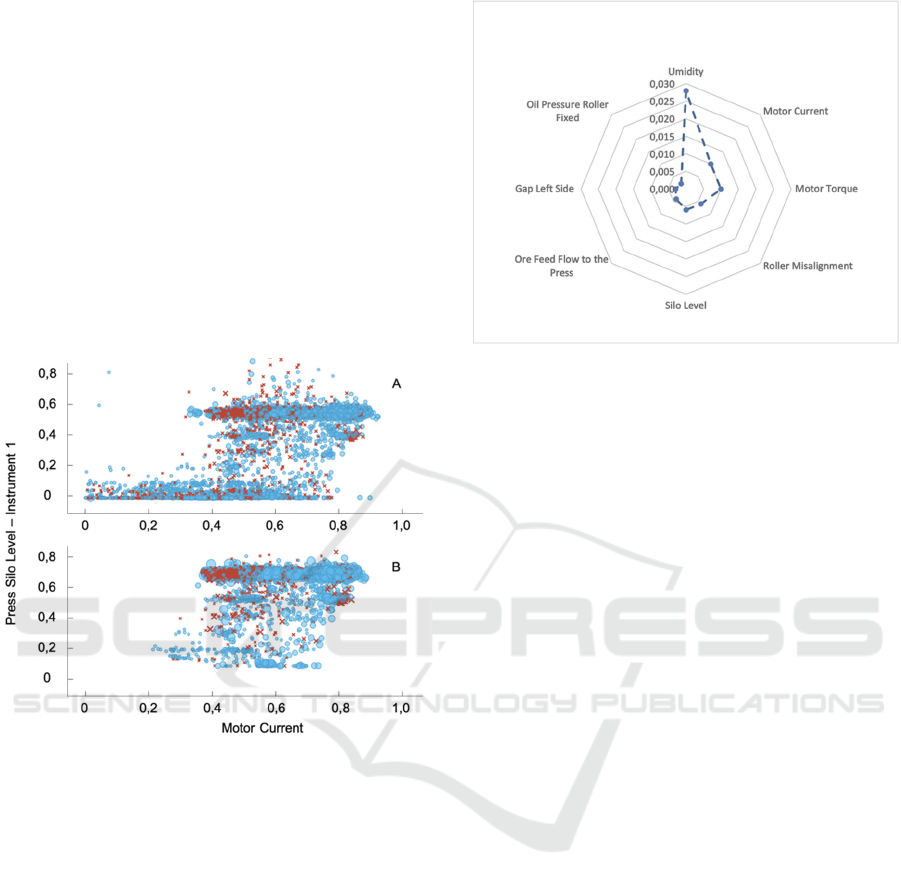

Comparing the variables “motor current” and

“press trough level”, for example, it is observed that

the Inliers data resulting from the execution of the

One-Class SVM algorithm with non-linear Outliers

detection kernel presents a considerable improvement

for the data set when compared to the original data

from the database (Figure 4). The same happens when

comparing the variables of engine torque, roll

misalignment and oil pressure, which confirms the

reduction of the standard deviation of the values after

the execution of the algorithm and the increase of the

average value due to the concentration of the resulting

data.

Figure 4: Exclusion of outliers of the roller press database.

Values and density of the database of the variable "Press

Silo Level – Instrument 1" in relation to the variable "Motor

Current". Figure A: without data treatment to exclude the

Outliers. Figure B: with data treatment to exclude the

Outliers.

5.1 Identification of the Most

Influential Variables in the

Pressing Process

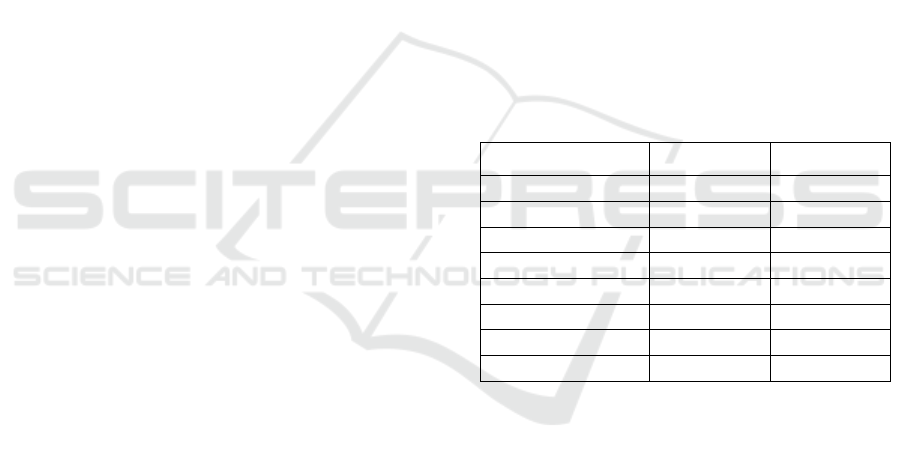

The ranking of the 8 most significant variables was

performed using the Gain Ratio method. Figure 5

shows the order of significance of the variables.

These results show that the ore moisture is the

variable of greatest interference in this process.

According to Saramak and Kleiv (Saramak & Kleiv,

2013), there is an optimum humidity range for each

granulometric distribution of the feed together, under

a certain operational condition, which directly

interferes with the ore comminution in the roller

press.

Figure 5: Ranking of the 8 most significant variables for the

specific result of the roller press.

The importance of measuring motor current,

ranked second by this method, opens a horizon for

discussion since there is currently no direct reference

to it, that is, it is not attributed the criticality of impact

on the process. This may allow a more careful study

of its impacts on the performance of the press, mainly

because it is an electrical quantity with high

dynamism for control and diagnosis. The engine

torque is the main control variable in the pressing

process used by the specialist system for optimizing

the plant under analysis. Therefore, this result

supports the validation of the control used in the

production process.

The variable of misalignment of the rollers is

related to the granulometric dispersion during the

comminution process, which can occur in the

application of a disproportionate force along the

rollers due to misalignment. This fact directly

interferes in the process of breaking the grains and

consequently in the gain of specific surfaces of the

press. Currently, this variable act only to protect the

equipment. From this result, the influence of this

measure can be discussed in more detail, considering

the degree of significance found.

Another important variable is the silo level,

resulting from the step prior to the pressing process,

the filtration step. This level has a direct impact on

the feed level of the press silo. According to Oliveira

(Oliveira, 2015) the press feed chute cannot limit the

flow of material to the compression zone, which

directly impacts the capacity and performance of this

equipment. Therefore, maintaining a constant level of

supply shows a strong indication and relevance in the

process.

Still according to Oliveira (Oliveira, 2015),

specific capacity is one of the main aspects of press

Application of Machine Learning Methods to Improve of the Roller Press Performance in the Pelletizing Process

681

performance, with granulometric distribution as one

of its factors of great importance. The operational

opening (directly proportional to the gap between the

rollers) has a high degree of influence on the particle

size distribution, being identified in the gap distance

variables on the left and right sides. The fact that they

are ranked in different positions opens up a discussion

about the possibility that the press is working in a

possible state of misalignment.

The oil pressure that is applied to the mobile roller

is another signaled variable with a high degree of

importance, which is responsible for adjusting the

pressure roller increase / decrease over the ore.

The rotation speed is currently used as the

manipulated variable (output variable) of the existing

PID controller (proportional-integral-derivative) to

control the level of the press feed silo (due to the

complexity of measuring this level, two instruments

were installed to validate these values), which aims to

maintain its stability for the ore pressing process.

Both variables were not ranked as the most important

for the process, demonstrating that possibly, due to

the stability of the PID control, it was not possible to

verify high interference of these variables from the

direct gain of the press. The fact that both level

measurements are ranked with the same weight shows

that the model is consistent in the classification and

ranking analysis. The result of classification of

electrical power confirms the low importance of this

quantity, as verified in the process today.

Finally, the result of classification of the ore

granulometry variable does not seem to be in

accordance with the expected, as this is of great

importance in the performance of the process.

According to Campos (T. M. Campos, Barrios,

Bueno, & Tavares, 2017) a series of challenges

involves the process of pressing the pellet feed from

the point of view of the granulometry of the product

and, in some cases, its high humidity. These facts

make it difficult to increase the surface area of the

material and cause greater difficulty in controlling the

process. Therefore, it is concluded that the database

for this variable must be verified and due to the fact

that they are values obtained by measurements

external to the process (information acquired at a very

high frequency), a study in instrumentation is

necessary to enable a measurement that allows data to

be obtained in shorter and more assertive intervals of

time.

Therefore, the results indicate consistency with

the implications of the pressing process and the

knowledge of the criticality classification of the

variables can allow a more assertive and optimized

decision making to improve this process. In addition,

variables that, at first, were not pointed out as

criticisms, they can be objects of study and analysis

for the best performance of the press. This indicates

that the application of ranking models in machine

learning can cooperate to optimize the gain of the

roller press.

5.2 Prediction of Classification of

Specific Press Surface

Comparing the eight machine learning models

evaluated, the Random Forest classifier model

initially presented the best results in terms of

precision, measured by the metrics CA = 0.875 and

AUC = 0.913. Several tests to increase the number of

trees in the Random Forest were performed and there

is stability in the values of CA = 0.901 and AUC =

0.957 after reaching the number of fifty trees. These

values show an excellent discrimination power,

indicating great assertiveness in the prediction of the

specific surface goal (> = 2.100g/cm³).

Table 1: Result of the evaluation of machine learning

methods.

Model AUC CA

Random Forest 0.957 0.901

KNN 0.896 0.845

AdaBoost 0.826 0.859

Tree 0.807 0.860

Neural Network 0.804 0.791

Naive Bayes 0.652 0.727

Logistic Regression 0.647 0.720

SVM 0.443 0.626

The determination of the most significant

variables and the subsequent model obtained by the

Random Forest method in the pressing process

demonstrate its effectiveness in the application of

artificial intelligence methods in the industry. This

result is in line with the result presented by Aldrich

(Aldrich, 2020), showing this technique is constantly

growing for use in analyzes of variable importance in

a wide range of technical disciplines, including the

mineral processing industries, such as in

comminution processes, object of this study. Still

according to Tohry (Tohry, Chelgani, et al., 2020),

the use of the Random Forest model can greatly

improve the prediction of the ball mill`s energy

consumption in mineral processing plants,

reinforcing the wide applicability of the techniques

used in this work.

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

682

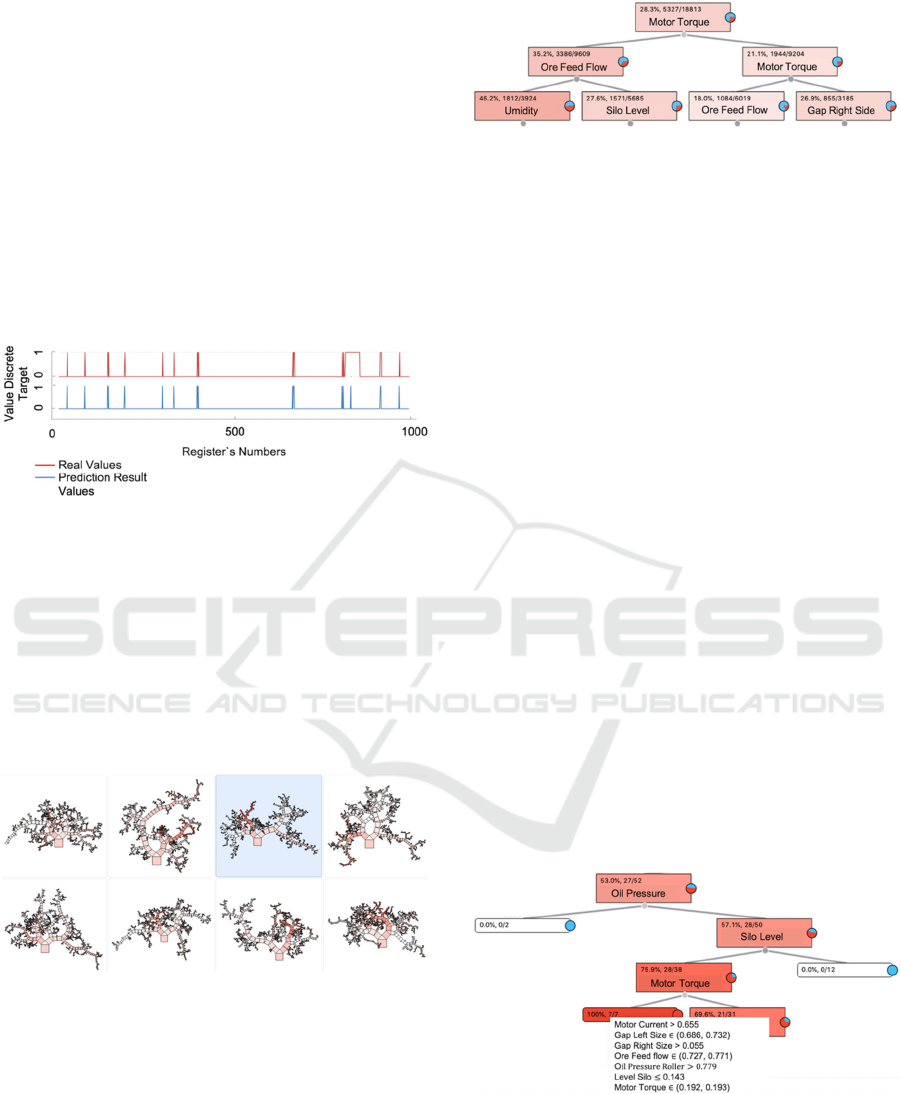

5.3 Validation of the Classification

Model of the Specific Press Surface

To validate the Random Forest model for

classification of the specific press surface, a new

database, with 1015 records, was used. The overlap

between the real and predicted values by the model

results in 93.69% of assertiveness.

Therefore, the model achieves the utilization

objective for a prediction of the press performance in

the process with high assertiveness, enabling its

application for measurement and adjustments in a

more agile way and, consequently, the improvement

for greater operational efficiency (Figure 6).

Figure 6: Comparison of real data (red) with the result

obtained by the Random Forest prediction model (blue).

5.4 Identification of Optimal Setup

Rules for Press Operation

The results that establish several rules to reach the

target of the specific surface value (values> = 2.100

g/cm³) were obtained from the Orange Pythagorean

Forest and Tree Viewer. Figure 7 shows 8 of the 50

trees generated by the model.

Figure 7: Pythagorean trees from the Random Forest model.

The tree selected for extracting the information in the Tree

Viewer component is highlighted, with the darker colors

being the branches that guide to reach the goal of the

prediction model.

A part of tree with the variables used for decision

making, containing the varied and conclusive results

to achieve the model's objective, is shown in Figure

8.

Figure 8: Decision tree levels from the Random Forest

model. Detail of part of the decision tree, three depth levels,

obtained from the result of the Random Forest model.

Highlighted is one of the final nodes to achieve the “target”

for the specific surface value. The variables belonging to

each square in the figure demonstrate the variables that are

used for decision making to achieve the goal of the model.

The 50 trees generated produce numerous

decision rules, varying the number of rules for each

of the trees. The Random Forest model creates several

smaller decision trees by selecting random subsets of

the characteristics in order to form a forest of trees

that make up the global solution. One of the rules

obtained from the example of one of the small

decision trees comprises 7 of the 8 characteristics

mapped in the model (Figure 9).

This result shows the values to be evaluated

during the operation of the press, allowing to know

some of the best setups for each verified condition. A

priori, the rule extracted from the model may allow a

control of the oil pressure variable when the roll

misalignments greater than 0.13 mm and less than

0.70 mm occur or when the gap on the left side of the

press exceeds the 5.44 mm value. So, for both

conditions above, the oil pressure increase must be

carried out until reaching a value greater than 94

kgf/cm² conditioned to the increase in torque (greater

than 82.01% and less than 82.45%) and motor current

(greater than 179.17 A), this when the ore feed flow

for the pressing process is greater than 604 t/h and

less than 633.85 t/h.

Figure 9: Result of decision tree obtained by the Random

Forest model. Detail of a small tree with highlighted

window shows one of the rules for reaching the goal of the

model, showing the values (normalized) of each variable to

be controlled to obtain the expected result for the process.

Application of Machine Learning Methods to Improve of the Roller Press Performance in the Pelletizing Process

683

Therefore, from the discussion of this rule, one

realizes the power of analysis that is provided by the

machine learning model. The use of these models

demonstrates the ability to make decisions in the face

of varied process conditions and the correlation

between the most significant variables, allowing

gains with adjustments that drive the optimization of

the expected result of the press.

6 CONCLUSIONS

The results of this work make it possible to speed up

the predictive analysis of the performance of the roller

press, automating the correlation of information from

the various available systems and enabling the

diagnosis of the press performance in real time,

meaning a great advance since currently this

performance needs an analysis laboratory with results

available only in an interval of 4 hours.

In addition, it shows effective results of a

multivariate analysis, contrasting the human limitation

for the evaluation of numerous parameters. Thus, this

work allows the decision making of the technical and

operational team to be strengthened in order to support

the challenge of reducing costs and increasing revenue

and quality of the production process.

The applicability in the industry as well as its

scalability are highly possible, since the possibility of

implantation can be applied and customized for other

existing roller presses, for the other different

equipment in the pelletizing process (such as ball mill,

filters, pelletizing discs and others) and even different

processes, as long as they are evaluated for each need

and peculiarity.

Besides that, the prediction of the process

performance can open a wide discussion and

possibility of study for the prediction of the useful life

of this equipment adopting the various machine

learning techniques.

ACKNOWLEDGEMENTS

This study was financed in part by the Coordenação

de Aperfeiçoamento de Pessoal de Nível Superior -

Brasil (CAPES) – Finance Code 001, the Conselho

Nacional de Desenvolvimento Científico e

Tecnológico (CNPQ), the Fundação De Amparo a

Pesquisa Do Estado De Minas Gerais -

FAPEMIG grant code APQ-01331-18, the Instituto

Tecnológico Vale (ITV), the Universidade Federal de

Ouro Preto (UFOP) and Vale S.A.

REFERENCES

Aldrich, C. (2020). Process Variable Importance Analysis

by Use of Random Forests in a Shapley Regression

Framework. Minerals 10, 5. doi:https://doi.org/

10.3390/min10050420

Barrios, G., Tavares, M., Pérez-Prim, J. (2014). High

pressure grinding rolls simulation using the discrete

element method dynamic coupling interface. Paper

presented at the XXVII International Mineral

Processing Congress, Santiago, Chile.

Campos, T. M., Barrios, G. K. P., Bueno, G., & Tavares, L.

M. (2017). Desafios na modelagem da capacidade e

potência consumida da prensa de rolos. XXVII

Encontro Nacional de Tratamento de Minérios e

Metalurgia Extrativa, 1743-1753.

Campos, T. M. (2018). Modelagem matemática da prensa

de rolos aplicada à cominuição de minério de ferro.

Universidade Federal do Rio de Janeiro,

Hasanzadeh, V., & Farzanegan, A. (2011). Robust HPGR

model calibration using genetic algorithms. Minerals

Engineering, 24, 424-432. doi:10.1016/j.mineng.

2010.12.004.

Naik, A., Samant, L. (2016). Correlation Review of

Classification Algorithm Using Data Mining Tool:

WEKA, Rapidminer, Tanagra, Orange and Knime.

Procedia Computer Science, 85, 662-668. doi:10.1016

Oliveira, R. N. M. d. (2015). Performance analysis of the

HRCTM HPGR in pilot plant. (Master). Universidade

de São Paulo, São Paulo.

Saramak, D., & Kleiv, R. A. (2013). The effect of feed

moisture on the comminution efficiency of HPGR

circuits. Minerals Engineering, 43-44, 105-106.

Shedroff, N. (1999). Information Interaction Design: A

Unified Field Theory in Design. In R. JACOBSON (Ed.),

Information Design (pp. 267-292): The MIT Press.

Silva, L. (2008). Influência da umidade no processo de

pelotização. Faculdade do Centro Leste – UCL.

Tohry, A., Chelgani, S. C., Matin, S. S., & Noormohammadi,

M. (2020). Power-draw prediction by random forest

based on operating parameters for an industrial ball mill.

Advanced Powder Technology,, 31, 967-972.

Tohry, A., Yazdani, S., Hadavandi, E., Mahmudzadeh, E., &

Chelgani, S. C. (2020). Advanced modeling of HPGR

power consumption based on operational parameters by

BNN: A “Conscious-Lab” development. Powder

Technology, 381. doi:10.1016/j.powtec.2020.12.018

Torres, M., & Cassali, A. (2009). A novel approach for the

modelling of high-pressure grinding rolls. Minerals

Engineering, 22, 1137–1146.

Viterbo, J., Boscarioli, C., Bernardini, F., & Teixeira, M.

(2016). Avaliação de Ferramentas de Apoio ao Ensino

de Técnicas de Mineração de Dados em Cursos de

Graduação. In Anais do XXIV Workshop sobre

Educação em Computação, (pp. 11-20). Porto Alegre:

SBC. doi:10.5753/wei.2016.9644.

Vyhmeister, E., Reyes-Bozo, L., Rodriguez-Maecker, R.,

Fúnez-Guerra, C., Cepeda-Vaca, F., & Valdés-

González, H. c. (2019). Modeling and energy-based

model predictive control of high pressure grinding roll.

Minerals Engineering, 134.

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

684