Process-aware Decision Support Model for Integrating

Internet of Things Applications using AHP

Christoph Stoiber and Stefan Schönig

University of Regensburg, Germany

Keywords: Internet of Things, Decision Model, Business Process Improvement, Analytical Hierarchy Process.

Abstract: Following the trend of Industry 4.0 and Cyber-Physical Systems (CPS), many industrial companies perform

costly projects to integrate Internet of Things (IoT) applications aiming at beneficial business process

improvements. However, deciding on the right IoT projects is challenging and often based on unilateral

assessments that lack the required profoundness. A suitable method for deciding on specific IoT applications

is required that incorporates the desired goals and considers the underlying process details. We therefore

propose a structured decision model that considers IoT application clusters, anticipated Business Process

Improvement (BPI) goals, and details of the process where the application should be implemented. At first,

specific IoT application clusters are developed by conducting an extensive literature review. These clusters

are examined regarding several characteristic such as their value proposition or technical aspects. Using this

information, an Analytical Hierarchy Process (AHP) model is proposed, that incorporates the main objective,

relevant BPI dimensions, and the formulated application clusters. To validate our approach, we applied the

model to an actual business process of a leading industrial company.

1 INTRODUCTION

With more than 34 billion IoT devices, the number

has more than tripled from 2012 to the year 2018

(Burhan, 2018). And although IoT is anticipated to

have massive benefits for companies, a survey of

more than 500 business executives revealed, that 90%

of organizations are remaining in the proof of concept

or even early-stage planning phases for IoT projects

(Bosche, 2016). This lack of IoT application maturity

can be explained by the complexity of IoT

technologies and the extent of included components.

This complexity is the reason that adopting IoT

technologies is quite different compared to adopting

other technologies, which leads to a scarcity of

decision models and procedures that support a proper

selection of suitable IoT applications (Boos, 2013).

This challenge will be addressed within the text at

hand, by proposing a structured decision model for

selecting IoT applications. To determine an

appropriate decision basis, it is necessary to be aware,

that most companies highly focus on Business

Process Orientation (BPO), as this paradigm resulted

in significant positive impacts for adopting

enterprises (Willaert, 2007). Therefore, a major part

of the value generated by IoT applications is based on

Business Process Improvements (BPI) and its core

performance measures cost, quality, time, and

flexibility (Dumas, 2018). Incorporating the

underlying process is increasingly considered as an

important preliminary for IoT applications. Janiesch

et al. (2017) stated process-aware integration of IoT

applications as one of the main challenges for

companies initiating IoT projects. In addition, while

analyzing existing decision support models, it became

apparent, that a decision model must be goal-oriented

and incorporate best-practice experiences of already

implemented applications to find high acceptance

among decision makers in companies (Bradley,

2013). As there have already been hundreds of

industry-related and domain-specific IoT applications

successfully implemented, they should be analyzed

and aggregated to serve as blueprints for further

applications. These applications can be allocated into

distinct clusters according to their main constituents

such as the used technologies, their value

propositions, and other attributes described in

subsection 2.2. This structured clustering can then be

used within a quantitative and goal-oriented model to

create a priority for possible IoT projects.

To the best of the authors’ knowledge, there has

been no research that addressed a structured decision

Stoiber, C. and Schönig, S.

Process-aware Decision Support Model for Integrating Internet of Things Applications using AHP.

DOI: 10.5220/0010400208690876

In Proceedings of the 23rd International Conference on Enterprise Information Systems (ICEIS 2021) - Volume 1, pages 869-876

ISBN: 978-989-758-509-8

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

869

model for integrating IoT applications, which also

considered actual IoT application clusters and

anticipated process improvement goals. Existing

approaches either focus on on key learnings from

other industrial use cases (Bradley, 2013) or suggest

frameworks to build up an IoT strategy, which is

derived from the company's major business goals (Li,

2012). The work at hand closes this research gap by

providing a decision model, that includes two main

contributions, i) an extensive literature analysis and

synthesis of sucessfully implemented IoT

applications including a systematic clustering, and ii)

a decision model based on the Analytical Hierarchy

Process (AHP), that supports companies to prioritize

relevant application clusters according to their

potentials for business process improvement. The

model can be used to investigate potential IoT

applications for a specific process or a set of related

processes. The paper is organized as follows. Section

2 presents the rigorous literature review on IoT

applications as well as a clustering. In section 3, the

AHP model and its constituents are addressed. After

developing an AHP instance for the relevant topic, it

is evaluated in section 4, based on an actual process.

Section 5 summarizes the contribution and formulates

a future research agenda.

2 IoT APPLICATION REVIEW

The methodology to survey the state of research is a

structured procedure proposed by vom Brocke et al.

(2009). The literature search itself was conducted

according to the Preferred Items for SLRs and Meta-

Analysis (PRISMA) statement, which improves the

traceability of the actual search process (Liberati,

2009).

2.1 Literature Search

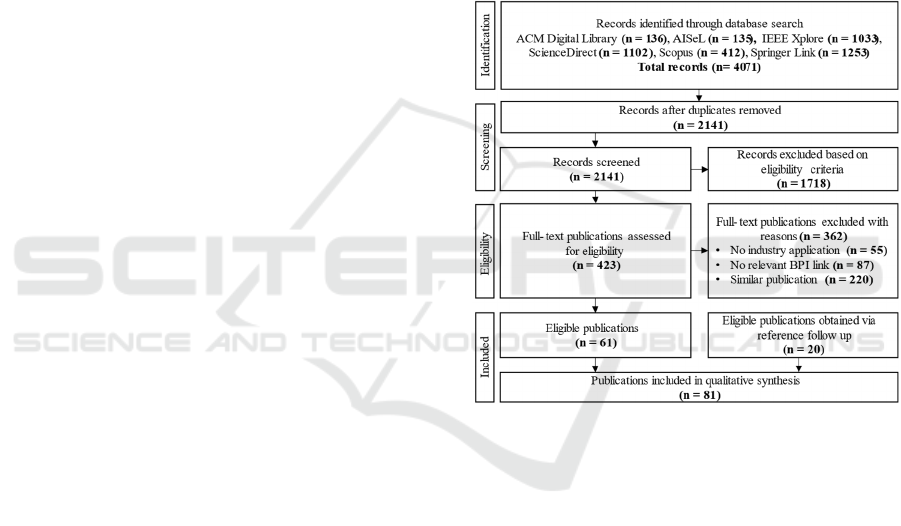

Figure 1 shows the results of the literature search

within a PRISMA flow diagram. The method

gradually reduces the number of publications by

assessing the eligibility using predefined criteria.

At first the search string (“IoT” OR “CPS”) AND

(“BPI” OR “Process Improvement” OR “Process

Optimi?ation” OR “Process Automation” OR

“Application” OR “Process Improvement”) as well

as the written-out forms have been formulated. To

incorporate and consider preferably all relevant

journals and conference proceedings of the research

area, ACM Direct Library, AISeL, IEEE Xplore,

ScienceDirect, Scopus, and Springer Link have been

queried. According to the PRISMA statement, four

criteria were defined that a paper needs to achieve to

be eligible for this review. The publication must i) be

a peer-reviewed research paper published in a journal

or conference proceeding, ii) propose an evaluated

solution or real industry application, iii) have relevant

links to BPI or BPM, and iv) be relevant and up to

date. As criteria ii) and iii) are assessed in a rather

qualitative manner, criterion iv) is defined as a

publication date after 2015 and a minimum number

of 50 citations. However, if a publication is assessed

as highly relevant, the violation of these quantitative

criteria is tolerated. A high degree of relevance is

given, when a publication was published in a top

journal and offers a contribution that cannot be

obtained from other eligible publications.

Figure 1: PRISMA Flow Diagram.

Considering criteria i) and iv), 1718 records were

removed because of a publication date before 2015,

low number of citations, or the lack of a peer-review.

Eventually, 423 publications were assessed for

eligibility based on their abstracts and, if relevant, full

texts. Among them, 55 articles did not describe an

actual industry solution that can be used for further

analysis. Another 87 publications had no specific link

to BPI or did not offer any process orientation at all,

and 220 articles mentioned a use-case that is

remarkably similar to at least another one under

consideration. In total, 81 publications were assessed

to be eligible including 20 articles obtained from

reference follow up.

2.2 Cluster Analysis

After the literature search and selection, a two-step

literature analysis framework is applied to derive

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

870

insights and eventually identify clusters within the set

of publications. At first, the publications are

categorized in a concept matrix according to Webster

and Watson (2002), which gives a first overview of

central issues of the contributions. Secondly, a cluster

analysis is performed by applying a Multiple

Correspondence Analysis (MCA) and a Hierarchical

Clustering on Principal Components (HCPC). To

categorize all publications according to their main

attributes, a concept matrix with five dimensions and

23 subdimensions has been created. The dimensions

correspond to concepts for classifying the

publications and consist of further subdimensions.

According to Bloom et al. (2018), IoT systems

can be fundamentally divided into four areas of

application, maintenance, process control, supply

chain, and infrastructure.

Table 1: Concept Matrix.

Reference Dimensions Subdimensions Rel. Freq.

Bloom et al.

(2018)

Application

Area

Maintenance

Process Control

Supply Chain

Infrastructure

13%

58%

26%

3%

Kortuem et

al. (2010)

Smart Thing

Type

Process-aware

Policy-aware

Activity-aware

32%

24%

45%

Tschofenig

et al. (2015)

Communication

Backend-Data Sharing

Device-to-Gateway

Device-to-Cloud

Device-to-Device

11%

55%

34%

11%

Patterson

(2017)

Human

Involvement

Full Automation

Action Implementation

Decision Selection

Information Analysis

Information Acquisition

3%

21%

24%

42%

11%

Tai Angus

Lai et al.

(2018)

Value Creation

Complex Auton. Systems

Inf. Sharing & Collaboration

Opt. Resource Consumption

Automation

Decision-Making Support

Situational Awareness

Tracking and Monitoring

8%

34%

21%

45%

45%

50%

39%

Kortuem et al. (2010) have identified three

different types of smart things, that reflect basic

design and architectural principles. Activity-aware

things understand events and activities, policy-aware

things can reflect, whether activities and events are

compliant with organizational policies, and process-

aware things can place activities and events in the

context of processes. IoT systems can consist of small

local networks up to global networks, while different

network architectures are used. The Internet

Architecture Board (IAB) has proposed four possible

models, in which IoT devices can be networked

(Tschofenig, 2015). Patterson (2017) described

another categorization dimension, the type of human

involvement to classify the degree of automation. The

last dimension represents the type of value creation

that is provided by the IoT application. Tai Angus Lai

et al. (2018) identified eight different areas of value

creation by IoT, which serve as subdimensions for the

concept matrix. The 81 eligible publications were

then categorized according to at least one

subdimension of each dimension. The rightmost

column of Table 1 shows the relative frequency of the

specific subdimension for all analyzed publications.

The MCA has then been used as a preprocessing to

transform the categorical binary variables from the

concept matrix into continuous ones, that are then

used within an HCPC to find distinct clusters in the

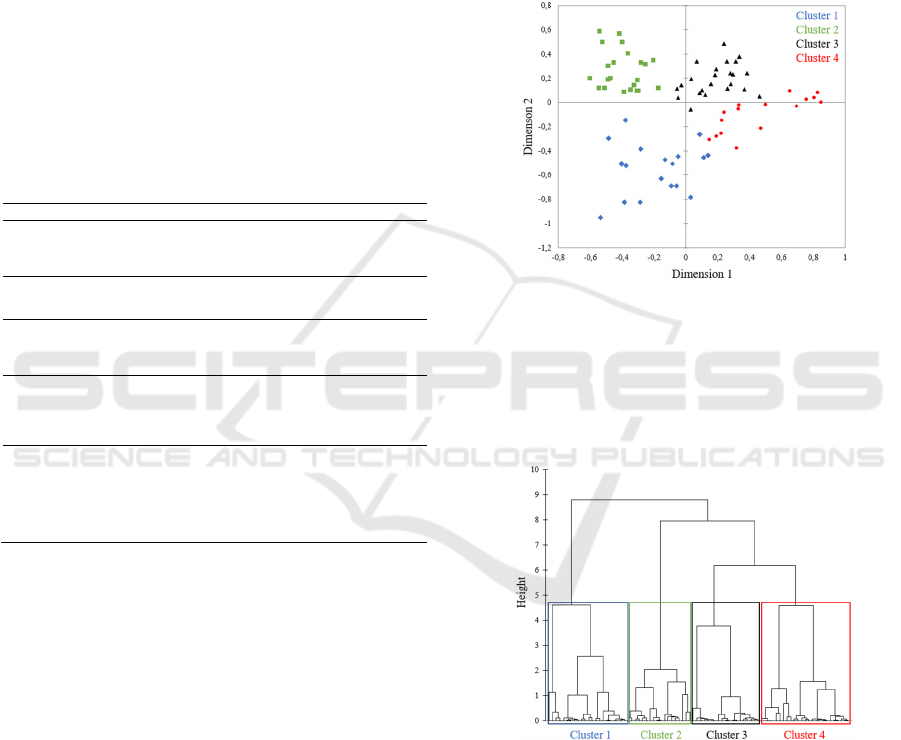

data set, see Figure 2.

Figure 2: MCA Factor Map.

The data is plotted in a two-dimensional space

depending on their similarity to each other. The

greater the distance between the individual data

points, the more different the items are in relation to

the dimensions of the concept matrix.

Figure 3: Dendrogram of Cluster Analysis.

The clusters have been created using the HCPC

and are visualized by different colours and data point

shapes. The results analysis has shown that optimally

four clusters can be formed. Another form of

visualizing the HCPC results is the dendrogram

shown in Figure 3. Here, the different distributions of

each cluster are shown in the form of exactly two

branches per level. The higher the tree, the higher is

the variance between the included publications.

Process-aware Decision Support Model for Integrating Internet of Things Applications using AHP

871

Based on this analysis, the publications of each

cluster have been examined again to investigate

similarities and interpret them. The results are

described in the following subsections.

2.2.1 Improved Information Exchange

The first cluster comprises 20 applications, in which

the IoT systems serve to collect information about the

process flow and the process environment. The smart

devices used for this cluster are mostly process-aware

and connected to the cloud via gateway. The gateway

only serves to forward data, while the analysis takes

entirely place in the cloud. The IoT devices perform

a context-sensitive communication and interaction

between several process entities such as machines or

employees. Due to the strong involvement of people

in the process, the benefits of IoT systems is not

automation but improved communication and

coordination of information, e.g., by using wearables.

Schönig et al. (2020) for example described a

production process in a cardboard factory and an

improved information exchange and visualization

using IoT sensors and smartwatches. Moreover,

König et al. (2019) illustrated the training of new

employees in a manufacturing company with the help

of smart devices.

2.2.2 Tracking and Tracing

Cluster 2 comprises 22 publications including IoT

systems for mainly tracking and monitoring solutions

using simple activity-aware devices, such as RFID

tags. The sensed data is mostly sent to a cloud for

further processing and provision of IoT services. One

focus is process improvement along the supply chain,

in which the continuous tracking of the involved

resources is particularly important. Chang et al.

(2019) describe a smart container for transporting

chemical waste products, so it can independently send

transport information to a cloud. Other publications

show applications in the manufacturing industry that

enable location monitoring of products and machines

(Valente, 2017) or unique identification using RFID

(Rasmussen, 2019). These applications provide an

improved transparency and therefore better process

quality, since a permanent traceability is guaranteed.

2.2.3 Faster Reaction to External Influences

Cluster 3 comprises 23 case studies, focussing on

identifying environmental factors and responding to

changes in a rapid way. The used smart things are

mostly policy-aware and can independently detect

deviations from predefined process rules. As soon as

these rules are violated, the things can trigger signals

which cause further reactions. Data processing is

often performed using cloud services or edge

computing. Ammirato et al. (2019) introduced an IoT

application to improve the security measures of a

bank. With the help of cameras and hybrid data

processing or image analysis in real time, threats can

be detected automatically at an early stage to initiate

countermeasures. Other applications based in the

agricultural industry comprise systems that measure

the environmental parameters of fields, such as

moisture, and can initiate appropriate actions, if

necessary (Celestrini, 2019).

2.2.4 Flexible Automated Systems

The last cluster comprises 16 case studies, which are

further scattered on the factor map. These

applications include more complex IoT systems than

those comprised in the other clusters. Li et al. (2017)

describe a completely autonomous system in which

the production materials can automatically

communicate with the equipment and transporting

machines to plan and schedule the production. In the

case study of Nikolakis et al. (2020), a set of robots

and humans can handle production material and are

both connected to a mutual network. By performing

the production planning and scheduling in a cloud, the

work steps can be planned when a new material

arrives, and appropriate instructions can be sent to the

robots or smart devices used by human. Also,

retrofitting and automating machines can be a major

step towards flexible process automation and IoT-

guided process execution (Murar, 2014).

3 DESIGNING THE AHP MODEL

3.1 AHP Setup

The AHP has been introduced as a theoretical

modelling technique for complex decision making

(Saaty, 1990). The user designs a multi-layer decision

tree including the main objective, relevant criteria

that affect the decision, and possible alternatives.

Subsequently, expert surveys are performed to collect

numerical data for every model layer. The criteria are

pairwise compared against each other regarding their

importance for achieving the objective. In the same

way, all alternatives are pairwise compared against

each other for every single criterion. Consequently,

the comparison data is processed to get a priority of

importance for each alternative.

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

872

3.2 Design of Decision Tree

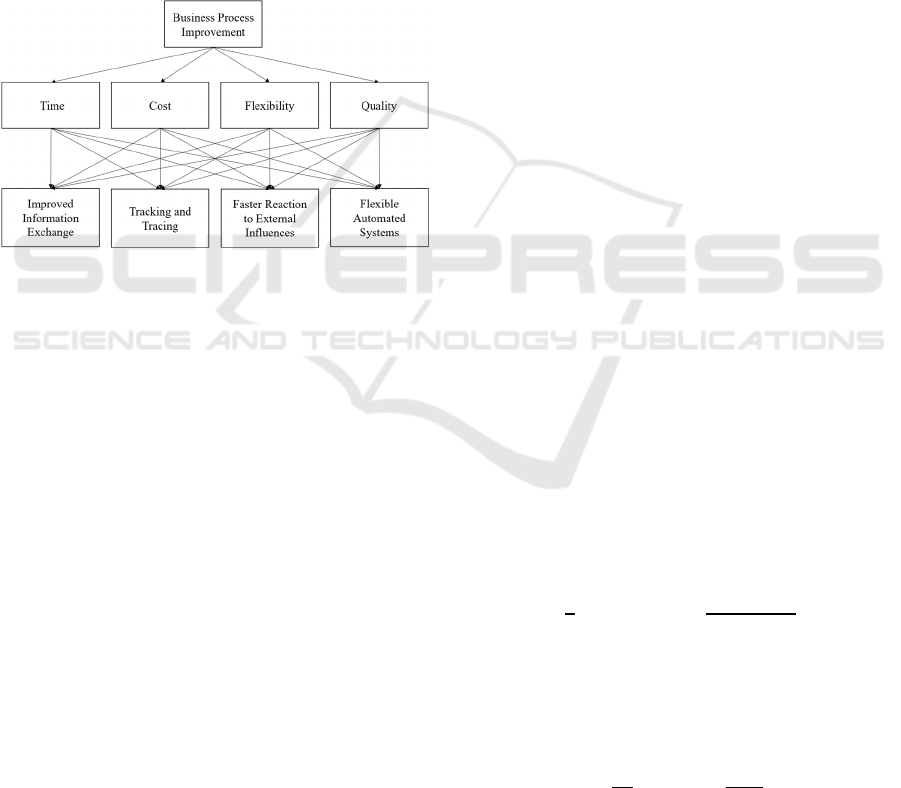

The first step of the AHP is to design the decision tree

by defining the decision problem and its objective,

decision criteria, and potential alternatives. In the

following, these three layers will be specified for our

model instance. The AHP model addressed in this

paper focuses on prioritizing potential alternatives

that may improve the underlying process. The top

layer of the AHP therefore is BPI as the main

objective. The second layer consist of respective

decision criteria, that influence the degree of

objective achievement. Popular Process Performance

Measures (PPMs) related to BPI are time, cost,

flexibility, and quality (Dumas, 2018).

Figure 4: AHP Decision Tree.

Thus, these four components are forming the second

layer of the AHP model. The third layer represents

possible alternatives to achieve the decision criteria

and therefore eventually the main objective. In this

case, the identified IoT application clusters are used

as relevant decision alternatives, as they are

representing aggregated manifestations of IoT

implementations. The complete AHP including all

layers is shown in Figure 4.

3.3 Data Collection

After designing the decision tree, data needs to be

collected by conducting a survey questionnaire for

experts and decision makers. This survey consists of

two parts, a pairwise comparison of the decision

criteria and a pairwise comparison of all alternatives.

The criteria must be evaluated in pairs to determine

the relative importance between them and their

relative weight to the main objective. Analog, the

alternatives must be evaluated in pairs to determine

the relative importance between them and their

relative weight to the decision criteria. The

participants need to indicate the relative importance

according to a 9-point comparison scale, with

increasing importance by increasing numbers. Filling

the comparison matrices, the diagonal cells always

contain number 1 as they represent the cell value

against itself. For a squared comparison matrix with

rows i and columns j, each matrix element a

i,j

has a

reciprocal value a

j,i

.

After conducting the survey, a three-step

procedure is performed on each matrix including (i)

gradually squaring the matrices, (ii) calculating the

eigenvector, and iii) repeating step i) and ii) until the

calculated relative weights differ only slightly

between two runs. The deviations between the

calculated weights decrease with increasing potency,

so that an approximation to the actual relative weights

is made progressively.

3.4 Results Calculation

At first, criteria weight scores W

C

are calculated,

which represent the relative importance of the criteria

and are mathematically described by the eigenvector.

According to subsection 3.3, it is obtained by

normalizing the row totals of the squared matrix. The

normalization is done by dividing each value by the

total column sum. Secondly, the local weight scores

of the alternatives W

L

are calculated for every

criterion. Here, the weight scores W

L

represent the

relative importance of the different alternatives for

the specific criterion. Finally, the global weight of

every alternative W

G

is determined by multiplying

the matrix consisting of all local weights W

L

with the

vector of the criteria weights W

C

. The vector W

G

describes the relative importance of all alternatives

regarding their importance for achieving the main

objective. As the pairwise comparisons need to be

consistent respectively transitive, a consistency test

must be performed for every matrix to ensure data

quality. To do so, the principal eigenvalue λ must be

calculated (Saaty, 1990). For a completely consistent

matrix, λ is:

𝜆 =

1

n

x

i

n

i

with x

i

=

∑

a

j,i

EV

j

n

j-1

EV

i

(1

)

In this case, n is the order of the matrix and EV

represents the eigenvector. Subsequently, the

consistency index CI and consistency ratio CR can be

calculated:

CR =

CI

R

n

with CI =

λ

- n

n - 1

(2)

The CR and CI are based on the idea, that with

perfect consistency of the pair comparisons, to the

one maximum eigenvalue λ, which is equal to the

Process-aware Decision Support Model for Integrating Internet of Things Applications using AHP

873

dimension n of the matrix, an associated eigenvector

EV exists. To decide, if a specific matrix can still be

accepted, the consistency ratio CR is calculated. R

n

in

this formula refers to the so-called random index,

which is formed from randomly determined

reciprocal matrices. The random index R

n

is

dependent of the matrix order and can be taken from

respective tables that have been created based on

empirical tests, e.g., by Saaty (1990). For an

exemplary matrix of order four, the corresponding R

n

would be 0.89. A decision matrix is sufficiently

consistent if CR < 0.1. Before the results can be

calculated, all inconsistent matrices need to be

dropped. The remaining matrices of the participants

are then aggregated via geometric mean to ensure

reciprocity.

4 EVALUATION

4.1 Process Description

To evaluate the proposed decision support model, it

has been applied to an actual business process of an

industrial company. Together with an

interdisciplinary group of employees, a specific

process has been selected, that does not yet contain

any IoT technology and comprises several different

entities and interfaces that offer a wide range of

possible IoT use cases.

The underlying process is the processing of

customer material which is applied for materials that

are owned by the customers itself. The process

involves four organisational entities, the ERP system,

conveyors, and two types of operators, manufacturers

and quality assurers. To start the process, a purchase

order from a customer, that includes customer

material, needs to be received by the ERP system.

Fitting customer material is searched in the ERP

database. If there is no suitable material from that

customer in the warehouse, the purchase order is

declined, and the process ends with a request for

material to the customer. Having found matching

material, a retrieval order is sent to the conveyor

system to transport the material to the respective

workplace. Simultaneously, an information message

is sent to the manufacturers about the imminent

arrival. In some plants there are multiple

manufacturers wherefore the group needs to first

clarify, who will perform the task. As soon as the

responsible manufacturer has arrived at the

workplace and prepared the machines, the material is

processed automatically. After an estimated

processing time, the manufacturer is checking the

progress. Subsequently, the machines are stopped,

and the materials are transported back to the

warehouse. The quality assurer gets a notification to

analyse the processed material whereupon he moves

to the workplace and analyzes the parameters

according to the purchase order details. If the analysis

results are satisfying, the release order is sent to the

ERP system. In case of a failed analysis, rework must

be performed.

4.2 Applying the AHP Decision Model

4.2.1 Data Collection

The questionnaire was conducted from July 13

th

to

July 17

th

, 2020 with an interdisciplinary group of 15

employees of different positions. To cover persons

with process knowledge and experiences with IoT

technology, the group comprised four project

engineers, five process optimizers, three project

managers, and three foremen of the specific

production area. All employees have knowledge

about the process itself as well as experiences with

IoT technology acquired at previous projects. They

understand the basic value propositions of IoT

technology and have insights into potential BPI

options for the respective process. The questionnaire

consisted of three different steps. At first, the process

owner described all process steps and details in a joint

workshop to ensure that everybody has the same

understanding of general process issues and possible

areas of improvement. Secondly, another workshop

has been undertaken to discuss general IoT value

propositions and possible applications in depth.

Furthermore, the literature review of section 2

including the defined clusters and the comprised

publications were reviewed to identify first adaption

possibilities. Finally, the group had 24 hours to

perform the pairwise comparisons. After analyzing

the pairwise comparison matrices, two of them turned

out to be invalid due to CR values above the rigorous

threshold of 0.1.

4.2.2 Results Calculation

According to the structured procedure of section 3,

the criteria weights W

C

, local weights of alternatives

W

L

for all criteria, and global weights of alternatives

W

G

were calculated. Table 2 shows the already

squared comparison matrix for the decision criteria.

At first, the sum of all row values is added to a total

of 108.67. To obtain the eigenvector respectively

criteria weights W

C

, each row sum is divided by the

total 108.67. A corresponding calculation was

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

874

performed for the alternative matrices for each

criterion to get the local alternative weights W

L

.

Table 2: Squared Comparison Matrix of Criteria.

Time Cost Flexibility Quality ∑ W

C

Time 4.50 19.5 9.82 23.00 57.82 0.53

Cost 1.07 3.99 2.41 5.91 13.38 0.12

Flexibility 2.15 9.00 4.49 12.5 28.14 0.26

Quality 0.78 3.30 1.26 4.00 9.34 0.09

Total 108.67 1

Eventually, the resulting matrix containing all

vectors W

L

for all criteria was multiplied with the

vector W

C

. Table 3 illustrates all vectors including

the resulting global weight vector W

G

and the final

alternative priorities.

Table 3: AHP Results.

Local Weights W

L

Criteria

Criteria Weight W

C

IE TT RI FS

Time 0.53 0.18 0.33 0.06 0.43

Cost 0.12 0.18 0.34 0.32 0.16

Flexibility 0.26 0.24 0.24 0.13 0.40

Quality 0.09 0.14 0.26 0.14 0.47

Global Weight W

G

0.19 0.30 0.11 0.39

Priority 3 2 4 1

The results show that time is the most important

criteria with a weight score of 0.53, followed by

flexibility (0.26), cost (0.12), and quality (0.09). The

alternative flexible automation systems (FS) reached

the highest weight for the criteria time (0.43),

flexibility (0.40), and quality (0.47). Tracking and

tracing (TT) was evaluated as the most relevant

alternative for criterion cost with a weight of 0.34.

With a score of 0.39, flexible automation systems is

the top priority alternative followed by tracking and

tracing scoring 0.30 on the second priority rank.

Priority 3 is improved information exchange with a

global weight score of 0.19, followed by faster

reaction to external influences with a score of 0.11.

4.3 Interpretation and Evaluation

The results of the AHP model have been discussed

with the participants in a subsequent workshop. The

most favoured decision criterion was time, which

stems from several process issues. Firstly, the lead

time is suffering from non-transparent transportation

and production times. The manufacturer is not aware

of the actual transport status and often arrives too

early or too late at the designated workplace.

Secondly, the production time is not calculated in

detail causing loops for checking the processing

progress. In addition, the quality assurer is obligated

to move to the workplace for analyzing the processing

results, which leads to a high time consumption.

Tracking the transport orders enables improved data

transparency and new possibilities for just-in-time

production scheduling. The manufacturers could get

better information about the arrival times of materials

and therefore obtain improved workflows.

Retrofitting machines could help manufacturers as

well as quality assurers to simplify their tasks and

reduce time consumption. Sensors with connectivity

capabilities will lead to reduced loops for progress

checking and manufacturers could get relevant

information wireless on their wearables. On this

basis, the process owners decided on further

investigating the IoT project ideas “location

monitoring of materials” and “machine retrofitting

towards connectivity”.

After discussing the results of the AHP, the

participants were asked to evaluate the model itself.

They should assess its main structure, feasibility, and

efficacy in a qualitative manner. All employees

highlighted the reasonable setup of the model, that

incorporates the underlying process, main BPI goals,

and actual application cluster. Three participants

resumed, that more clusters would lead to more

specific results. Two employees mentioned that

technical suggestions for IoT applications would be

beneficial. Regarding feasibility, the employees

described the procedure including the initial

workshops and the pairwise-comparisons as rather

easy to perform. However, the data analysis and

results calculation of the AHP are quite complex and

need to be done by experts. Altogether, the decision

model was assessed as highly effective for analyzing

the process and finding suitable IoT applications.

5 CONCLUSION

The proposed decision support model tackles the

challenge of integrating IoT applications in processes

based on best-practice application clusters and goal-

orientation. By providing an extensive literature

review and clustering, the main application

characteristics of industrial IoT applications have

been formulated. Based on this information, a

structured AHP can be applied to an underlying

process or a set of processes to create priorities for

application categories that fit best to achieve the main

objective. The work contributes to researchers, as it

paves the way for further extensions of the AHP and

future research regarding process-aware IoT selection

models. It also contributes to practical users, as it can

Process-aware Decision Support Model for Integrating Internet of Things Applications using AHP

875

be applied to concrete decision challenges. The

decision support model has been evaluated using an

actual process. The results and final discussion

proved the utility of the model and led to further

follow up with the identified application possibilities.

Future research could extend the model by providing

more application clusters and abstracting them to IoT

improvement patterns which describe the alternatives

in a more formal way. A limitation of the model is its

unclear generalizability, as it has only been applied to

one process instance.

REFERENCES

Ammirato, S., Sofo, F., et al., 2019. The potential of IoT in

redesigning the bank branch protection system. BPMJ,

25(7).

Bloom, G., Alsulami, B., et al., 2018. Design patterns for

the industrial Internet of Things. In 14

th

IEEE

International Workshop on Factory Communication

Systems (WFCS). IEEE.

Bosche, A., Crawford, D., et al., 2016. How Providers Can

Succeed in the Internet of Things. Bain&Company,

https://www.bain.com/insights/how-providers-can

succeed-in-the-internet-of-things.

Boos, D., Guenter, H., Grote, G., Kinder, K., 2013.

Controllable accountabilities: the internet of things and

its challenges for organisations. Behav. Inform.

Technol., 32.

Bradley, J., Barbier, J., Handler, D., 2013. Embracing the

Internet of Everything To Capture Your Share of $14.4

Trillion. Cisco White Paper.

Vom Brocke, J., Niehaves, A., et al., 2009. Reconstructing

the giant: On the importance of rigour in documenting

the literature search process. In 17th European

Conference on Information Systems, ECIS.

Burhan, M., Rehman, R., Khan, B., Kim, B., 2018. IoT

elements, layered architectures and security issues: A

comprehensive survey. Sensors, 18(9).

Celestrini, J., Rocha, R., et al., 2019. An architecture and its

tools for integrating IoT and BPMN in agriculture

scenarios. In 34

th

ACM/SIGAPP Symposium on Applied

Computing. ACM.

Chang, W., Su, J., et al., 2019. iCAP: An IoT-based

Intelligent Liquid Waste Barrels Monitoring System. In

11

th

Computer Science and Electronic Engineering

(CEEC). IEEE.

Dumas, M., Rosa, M., Medling, J., Reijers, H., 2018.

Fundamentals of Business Process Management (ed.).

Springer. Berlin, Heidelberg.

Janiesch, C., Koschmider, A., et al., 2017. The internet-of-

things meets business process management: Mutual

benefits and challenges. IEEE Trans. Syst. Man Cybern.

Syst., 6(4).

König, U., Röglinger, M., Urbach, N., 2019. Industrie 4.0

in kleinen und mittleren Unternehmen – Welche

Potenziale lassen sich mit smarten Geräten in der

Produktion heben? HMD, 56(6).

Kortuem, G., Kawsar, F., et al., 2010. Smart objects as

building blocks for the Internet of things. Internet

Comput., 14(1).

Li, Y., Hou, M., Liu, H., Liu, Y., 2012. Towards a

theoretical framework of strategic decision, supporting

capability and information sharing under the context of

internet of things. J. Inf. Technol. Manag., 13(4).

Liberati, A., Altman, D., et al., 2009. The PRISMA

statement for reporting systematic reviews and meta-

analyses of studies that evaluate healthcare

interventions: explanation and elaboration. BMJ.

Murar, M., Brad, S., 2014. Monitoring and controlling of

smart equipments using android compatible devices

towards IoT applications and services in manufacturing

industry. In 2014 IEEE International Conference on

Automation, Quality and Testing. Robotics.

Patterson, R., 2017. Intuitive Cognition and Models of

Human-Automation Interaction. Hum. Factors, 59(1).

Rasmussen, N., Beliatis, M., 2019. IoT based digitalization

and servitization of construction equipment in concrete

industry. In GIoTS. IEEE.

Saaty, T., 1990. How to make a decision: The analytic

hierarchy process. Eur. J. Oper. Res., 48(1).

Schönig. S., Ackermann, L., Jablonski, S., Ermer, A., 2020.

IoT meets BPM: a bidirectional communication

architecture for IoT-aware process execution. Softw.

Syst.Model., 19.

Tai Angus Lai, C., Jackson, P., Jiang, W., 2018. Designing

Service Business Models for the Internet of Things:

Aspects from Manufacturing Firms. AJMSE, 3(2).

Tschofenig, H., Arkko, J., et al., 2015. Architectural

Considerations in Smart Object Networking. Internet

Architecture Board (IAB).

Valente, F., Neto, A., 2017. Intelligent steel inventory

tracking with iot / RFID. In RFID-TA. IEEE.

Webster, J., Watson, R., 2002. Analyzing the Past to

Prepare for the Future: Writing a Literature Review.

MIS Quarterly, 26 (2).

Willaert, P., den Bergh, J., Willems, J., Deschoolmester, D.,

2007. The process-oriented organisation: A holistic

view developing a framework for business process

orientation maturity. In 5th International Conference

on Business Process Management, ACM.

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

876