Logical Workflow Analysis based on Multiple Criteria Decision

Analysis: Industrial Application for a Make to Order Environment

Soukaina Oujana

1a

, Lionel Amodeo

2b

and Farouk Yalaoui

2c

1

Brodart Packaging, 42 Rue de la Paix, 10000 Troyes, France

2

Laboratory of Industrial Systems Optimization (LOSI), University of Technology of Troyes, 12 Rue Marie Curie, CS42060,

10004 Troyes Cedex, France

Keywords: Multiple Criteria Decision Analysis, Workflow Analysis, Process Mapping, Production System, Scheduling.

Abstract: The aim of this study is to analyze the possible application of multiple criteria decision approach for a relevant

workflow analysis in a French printing company. An important result and contribution of this paper will be

precisely to show that MCDA could be an important decision tool to analyze and identify the main stream for

make to order environment. An overview of the logical structure of the process on how things actually operate

on the production, is presented. To summarize, this paper demonstrates and presents a new approach for using

MCDA for a workflow analysis and discusses its application in a real case study where production faces

various variations.

1 INTRODUCTION

The characterization of a production system is one of

the most important steps before any improvement or

optimization approach.

In industry, we meet a variety of different

workshops and thus of productions systems. The most

adopted in industry are: flow shop (FS), Job Shop (JS)

and Open Shop (OS); see (Metaxiotis et al., 2001),

(Komaki et al., 2019), (Mohan et al., 2019), for a

review.

Table 1: Abbreviations.

MCDA Multiple criteria decision anal

y

sis

MTO Make to order

MCABC Multiple criteria ABC classification

MCIC

Multiple criteria inventory

classification

AHP Anal

y

tic hierarch

y

process

From a scheduling perspective, the aim of a good

workflow process characterization is to identify and

determine the workshop configuration, in order to

apply suitable and appropriate scheduling rules.

a

https://orcid.org/0000-0003-0915-2388

b

https://orcid.org/0000-0003-0250-7959

c

https://orcid.org/0000-0001-7360-2932

However, for MTO environment, and due to the

constantly fluctuating stream, the analysis of the

whole workflow become very difficult. To address

this problem, we used MCDA in order to analyze the

process, step-by-step, in detail, across all the product

families. The basic idea is to identify and outline the

main production stream. Thus, minimizing the

number product families required to represent the

manufacturing process.

MTO companies are very complex, the flow of

material is highly fluctuating and flexible. This

flexibility is seen as a key characteristic of successful

organizations (Scherrer-Rathje et al., 2014). Several

factors lead to increase this flexibility, such as an

ever-changing landscape of customer demand or a

wide range of customized products. However, this

flexibility produces diversity and create variations

that makes it hard to manage from a scheduling

perspective. In contrast, Accurate scheduling plays

also an important role in the success of MTO

companies (Lödding et al., 2014). The first step

before any scheduling approach is to characterize and

determine the process configuration, this step requires

a thorough understanding of critical and strategic

product families. For MTO organizations that deals

Oujana, S., Amodeo, L. and Yalaoui, F.

Logical Workflow Analysis based on Multiple Criteria Decision Analysis: Industrial Application for a Make to Order Environment.

DOI: 10.5220/0010248604010407

In Proceedings of the 10th International Conference on Operations Research and Enterprise Systems (ICORES 2021), pages 401-407

ISBN: 978-989-758-485-5

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

401

with thousands of products, it is unrealistic to provide

equal consideration to each product. That’s why

product classification is crucial in order to give more

importance to the most valuable ones and focus into

the main factors. ABC analysis utilizes hierarchical

categorization, the products are partitioned into 3

classes so that their management becomes easier.

In this work we used MCDA based on ABC

principle, in order to analyze the manufacturing

process step-by-step in detail across all its product

families. The main role of this classification in our

case study is to makes it easier to deal with and to

understand a manufacturing process that faces

variations, by breaking it down into three segments.

A successful segmentation will allow to point out the

most valuable ones, thus it becomes easier to focus,

and apply accurate priority rules.

MCABC is a well-known technique traditionally

used for inventory management. It is based on the

Pareto principle (Pareto, 2007) which denotes that

approximately 80% of the effects come from 20% of

the causes. This classification, allows to divide items

into three different classes A-B-C according to their

importance for a selected criterion. Category A is the

smallest one but account for the greatest amount of

the selected criterion. In contrast, class C items are

relatively large in number, but make up relatively

small amount the criterion. Items between classes A

and C are categorized in category B.

The main aim here is to analyze the process

workflow from a new perspective, through all its

product families allowing managers to get a clear

picture of where the greatest contribution can be

made. For the underlying problem two criteria were

selected, namely, Sales revenue (SR) and Quantity

produced (Q), these criteria are the most

representative for the studied process. The objective

here is to make a coordinated classification by

combining both SR and Q in order to point out the

main flow that represents the most relevant product

families, the strategic ones, that account for a high

sales revenue and high quantity produced.

Summarizing, this paper addresses the use of bi-

criteria ABC analysis in classifying product families.

We aim here at providing information about the

choice of the key criterion as well as the methodology

follows to manage the items in each category. The

results indicate that ABC classification could be a and

efficient tool for understanding the workflow process

it enables to pinpoint the key elements of a business

so that they can be appropriately managed.

The paper is structured as follows. In the next

section we review briefly the existing literature on

ABC analysis. Section 3 presents the methodology

followed, starting with a brief description of the scope

of the study, and then data collection, and ending with

data analysis. We then present and discuss the main

results derived from the analysis. Finally, we end up

the paper with a conclusion as well as future research

directions.

2 LITERATURE REVIEW

It is clear that there vast differences among different

configurations of production processes: job shop,

flow shop, open shop… because the differences

among them have an important implications for the

choice of the production planning and scheduling

system (Silver et al., 2016).Therefore an appropriate

characterization and identification of process

configuration is an important step in order to define

accurate scheduling rules. According to (Kurtzberg et

al., 1994), To manage highly complex manufacturing

enterprises, ABC utilizes hierarchical, dynamic

modeling with recursive control and optimization. At

each hierarchical level, the process is partitioned into

logical groups so that treatment is simplified and

manageable. Further, ABC minimizes the number of

parameters required to represent the manufacturing

process and ranks contributions of variables to the

process by significance.

The objective in this work is to use ABC principle

which is defined as a powerful decision-making tool

that identifies items that have a significant impact on

an overall criterion (Yu, 2011). The use of this

classification tool will allow to identify the major

product families -class A- that represents potentially

the largest value and provides us with an insight of

the process configuration that represents the most

important and valuable product ranges.

ABC analysis uses most of the time the dollar

usage criterion. However, several researchers have

proposed methods that consider other factors than

annual dollar usage. (Benito E. Flores et al., 1987)

were the first researchers who outlined the

importance of considering multiple criteria in the

ABC analysis. They introduced the idea of a matrix-

based approach for the multi-criteria ABC

classification. A joint criteria matrix was put forward

within the ABC framework by means of considering

two criteria, their approach was tested on an industrial

application. They highlighted that the use of the

matrix can provide managers with an explicit method

for taking a range of criteria into account. Other

various approaches for addressing the MCDA

problem have been proposed in the literature for the

purpose. (Cohen et al., 1988) and (Ernst et al., 1990)

ICORES 2021 - 10th International Conference on Operations Research and Enterprise Systems

402

have used cluster analysis to group similar items. The

analytic hierarchy process (AHP) (Saaty, 1987) has

been employed in many MCIC studies (F.Y. Partovi

et al., 1993) (Gajpal et al., 1994).Heuristic

approaches based on artificial intelligence, such as

genetic algorithms (Guvenir et al., 1998) and artificial

neural network (Fariborz Y Partovi et al., 2002), have

also been applied to address the MCIC problem.

To summarize, there have been many

contributions in the literature which have

concentrated on the application of ABC classification

for inventory control. However, and to the best of our

knowledge, it has been rarely studied for a relevant

process analysis. In this paper, we are striving to

propose a simple joint criteria matrix based on

(Benito E. Flores et al., 1987) method, in an MTO

environment, in order to categorize product families

into classes that require somewhat different strategies

for planning and scheduling. This classification

allows to reflect the main flow and provide managers

with a thorough understanding of critical and strategic

product families, allowing to focus attention, and give

more importance to them.

3 METHODOLOGY

This section provides a brief overview of the case

study and describes the use of MCABC for an

industrial company for its process analysis.

3.1 Case Study

Our study was conducted in a packaging printing

company based in France. That mainly uses make to

order policy, characterized by multiple flows that

merge. Mapping and analyzing the whole process at

the same time is not easy and usually not even

feasible. Thus, the mapping process should begin

from the main strategic flow. This company produces,

converts and prints flexible packaging. Some

examples of products manufactured are: pouches,

reels, sheets and labels. Each product P goes through

several processing operations depending on its

product family or manufacturing operating range,

such as printing, coating, perforation and lamination.

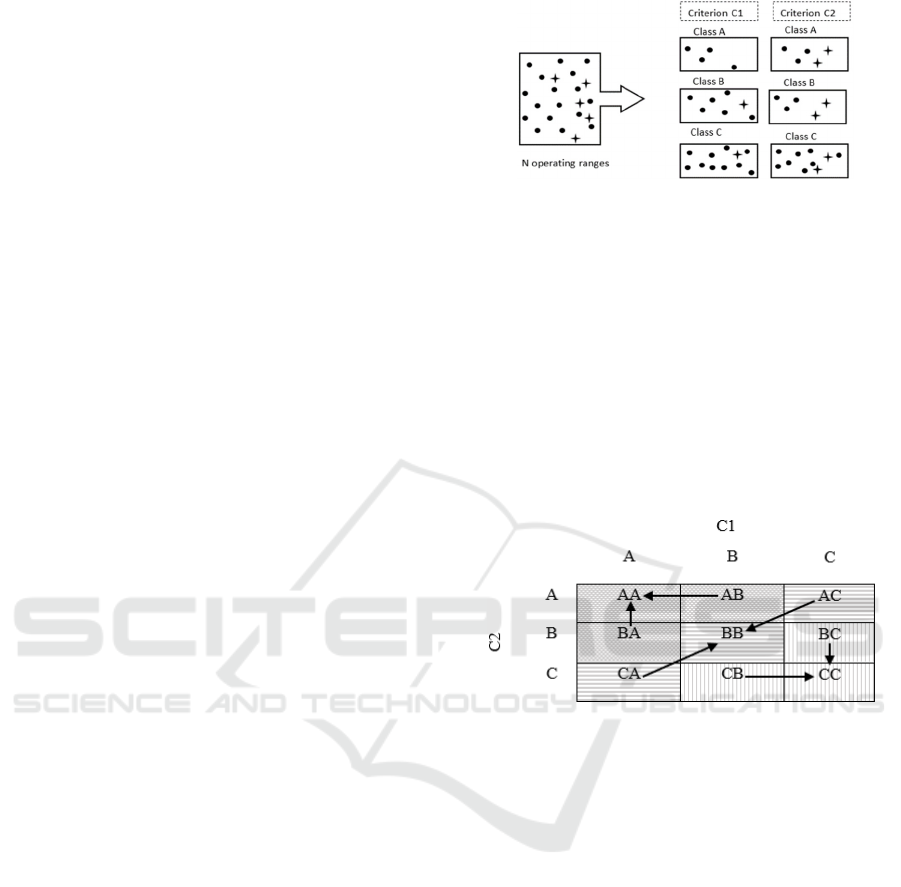

Assume that we have N ranges of manufacturing

g (g =1,…, N), that have to be classified as A, B or C,

according to 𝐶

criteria .In particular let the

performance of the 𝑛

operating range in terms of

each criteria be denoted as 𝑋

. Let us also assume

that the larger the score of an item g in terms of these

criteria is, the greater is the chance that the item be

classified as an A class item.

Figure 1: ABC classification.

Complex computational tools are needed for

multi-criteria ABC classification (Ramanathan,

2006). (B.E. Flores et al., 1986) have developed a

joint criteria matrix in the case of two criteria, the

combination of these two criteria leads to the

definition of nine distinct product classes ranging

from AA (upper grade) to CC (lower grade). The

model can be represented in a practical way in the

form of a joint matrix criteria, as shown in Figure 2.

As indicated by the arrows, the classification rule for

a AB and BA with AA, AC and CA with BB and BC

and CB with CC (Chen et al., 2008).

Figure 2: Bi-criteria joint matrix.

3.2 Multiple Criteria Analysis

For this particular study, the steps to conduct this

classification were as follows: 1) Key criteria

selection, 2) Data collection 3) Data analysis.

3.2.1 Key Criteria Selection

This work began with selecting key criteria that fulfil

and characterize the studied organization. It is

recognized that there is no universal methodology for

criteria selection. The main idea is the selection of an

optimal manufacturing process which considers the

most significant and important criteria for the

process. Thus, the problem has to be observed as a

multi‐criteria problem. These criteria depend on the

nature of the industry and may include: average

revenue, lead time, demanded volume, total delay …,

they should meet management’s objectives and be the

most representative for the process

For the underlying organization, let us consider

two criteria: annual revenue (AR) and the demand

Logical Workflow Analysis based on Multiple Criteria Decision Analysis: Industrial Application for a Make to Order Environment

403

volume (DV) per product range. These criteria are the

most relevant for the studied organization because:

- The sales revenue (SR): SR Is the yearly amount

realized by a group of products that have the same

manufacturing operations. It allows to visualize

clearly the importance of the different ranges for

the company. It makes it possible to determine

which ranges make the biggest contribution for

the overall revenue.

- Demand volume (DV): is the average yearly

quantity produced per product family. Provides

details about the products that occupies the most

the workshop. In this way, it is possible to

understand how the total quantity is distributed

among different product types.

3.2.2 Data Collection

The monthly data of all the tasks involved in the

production process were obtained from the industry

for a period of one year, using SQL query.

The data collected has been analysed using the

Excel sheet, the products were grouped into families

according to their operating ranges. A product family

is defined as a group of products that pass through

similar processing steps.

The overall data of the product families involved

in the production system were interpreted, and

summarized based on two criteria: the sales revenue

and the produced quantity.

The sales revenue associated with each product

family was obtained using (1), and the quantity

produced was calculated using (2).

- Calculation of sales revenue per operating range

SR (𝐺

):

S

R

G

= l

Q

P

∗UP

P

,∀ G = G

(1)

- Calculation of the quantity produced per

operating range Q

G

:

Q

G

= l

Q

P

,∀ G = G

(2)

According to each criterion, the operating ranges

were ranked in descending order starting with the

largest value to the smallest. The cumulative

percentage was then calculated and two distinct

Pareto distributions were performed.

For each product family 𝐺

, the percent of

quantity produced Q and the selling revenue is

mentioned in Table 2.

Table 2: MCABC using annual Euro usage, and produced

quantity based on a joint matrix.

Range % SR % Q

ABC classification

Optimal

Classification

SR Q

G1 20% 16% A A A

G2 10% 12% A A A

G3 8% 9% A A A

G4 7% 7% A A A

G5 7% 6% A A A

G6 7% 5% A A B

G7 7% 3% A A B

G8 6% 3% A A B

G9 5% 2% A A B

G10 5% 2% A A B

G11 4% 2% B B B

G12 3% 2% B B B

G13 3% 7% A B A

G14 2% 2% B B B

G15 2% 2% B B B

G16 2% 1% C B C

G17 2% 1% B B B

G18 2% 9% B B A

G19 2% 1% B B C

G20 2% 3% B B B

G21 2% 3% B B B

G22 1% 2% B C B

G23 1% 10% B C A

G24 1% 1% C C C

G25 0% 5% B C A

G26 0% 1% C C C

G27 0% 1% C C C

G28 0% 0% C C C

G29 0% 0% C C C

G30 0% 0% C C C

G31 0% 0% C C C

G32 0% 0% C C C

G33 0% 0% C C C

G34 0% 0% C C C

G35 0% 0% C C C

G36 0% 0% C C C

G37 0% 0% C C C

G38 0% 1% C C C

G39 0% 2% C C B

ICORES 2021 - 10th International Conference on Operations Research and Enterprise Systems

404

Table 2: MCABC using annual Euro usage, and produced

quantity based on a joint matrix (cont.).

G40 0% 1% C C C

G41 0% 4% B C A

G42 0% 0% C C C

G34 0% 0% C C C

G44 0% 0% C C C

G45 0% 2% C C B

G55 0% 0% C C C

G56 0% 0% C C C

G57 0% 0% C C C

G58 0% 2% C C B

G59 0% 2% C C B

G60 0% 2% C C B

G61 0% 3% B C A

G62 0% 0% C C C

G63 0% 0% C C C

G64 0% 0% C C C

G65 0% 0% C C C

The operating ranges are categorized into A, B

and C classes, where class A contains the strategic

ranges, that should receive the most important

attention. B class items are less important and C class

items are of very low importance

Class A workflow map was then drawn allowing

to vizualize clearly the flow structure of the major

product ranges that contribute the most to the success

of the company.

3.2.3 Data Analysis

Once items have been grouped into clusters, the target

value stream can be identified by simply drawing all

class A product families.

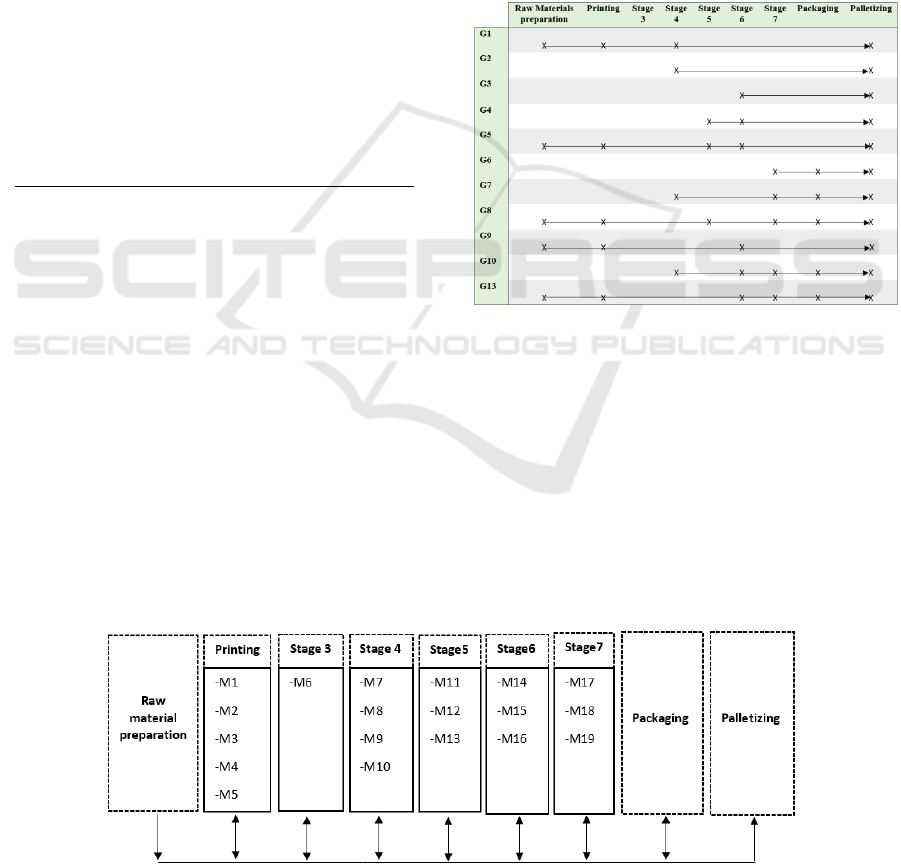

The close examination of class A map has

revealed a regularity in the logical structure of the

flow (Figure 3) which is characterised by a linearity.

The exact process map with all details cannot be

disclosed due to confidentiality reasons. A macro

logical workflow process is developed in Figure 4. It

shows the current state map that was constructed; the

boxes in the map represent the processing steps and

the number inside the box is the number of machines

at each process. The machines are grouped by stage E

(e = 1,…, 9). Each stage E is made up of a set of me

machines (me ⩾1) of the same trade, of the same

production capacity or of different production

capacity, Called mixed parallel machines (hybrid).

The logical workflow map offers a clear outlook on

the process configuration, it outline the most relevant

stream, so that adequate scheduling rules can be

properly applied .

Figure 3: Class A workflow.

Class A workflow mapping highlights that the

workflow tend to be linear, e.g. there is no going back

to an earlier stage. but flexible in the sense that from

a product to another one, the operating ranges

involved might be different. The operating ranges of

each product is predefined according to the

processing requirements. We note very well that all

the ranges of class A are linear, this means that this

zone can be assimilated to a flexible and hybrid Flow

shop workshop with skipping (following the

manufacturing range).

Figure 4: Logical workflow.

Logical Workflow Analysis based on Multiple Criteria Decision Analysis: Industrial Application for a Make to Order Environment

405

4 CONCLUSIONS

It is not easy to analyze the workflow in the case of

complex production processes characterized by

multiple flows that merge. To address this problem,

the basic idea in this study was to execute a thorough

process analysis through all product families in order

to identify the main flow using MCABC, under two

criteria: Selling revenue and quantity produced, these

criteria are the most relevant for the studied firm. This

aggregation has allowed to reduce significantly the

number of product families requiring extensive

management attention.

The analysis of the different ranges involved in

the studied process, has allowed to obtain, analyze,

and reflect on a set of information of high importance

and understand the complexity of the process. This

work contributed to a better knowledge of the

company, bringing a greater degree of detail on the

evolution of the industrial activity, allowing to verify

the importance of certain ranges, and highlight those

with high value for the company. To summarize, this

work enables us to define the appropriate

configuration of the process: Hybrid and flexible flow

shop, which have an important role in defining

suitable scheduling rules taking into account the most

significant parameters.

As future research, we try to compare the logical

workflow to the physical layout, and then, to propose

an arrangement of machines that suits the main

logical flow which will enable the manufacturing

process to be carried on efficiently.

REFERENCES

Chen, Y., Li, K. W., Marc Kilgour, D. and Hipel, K. W., A

Case-Based Distance Model for Multiple Criteria ABC

Analysis, Computers & Operations Research, vol. 35,

no. 3, pp. 776–96, March 1, 2008. DOI:

10.1016/j.cor.2006.03.024

Cohen, M. A. and Ernst, R., Multi-Item Classification and

Generic Inventory Stock Control Policies, Production

and Inventory Management Journal, vol. 29, no. 3, pp.

6–8, 1988.

Ernst, R. and Cohen, M. A., Operations Related Groups

(ORGs): A Clustering Procedure for

Production/Inventory Systems, Journal of Operations

Management, vol. 9, no. 4, pp. 574–98, 1990. DOI:

10.1016/0272-6963(90)90010-B

Flores, B. E. and Whybark, D. C., Multiple Criteria ABC

Analysis, International Journal of Operations and

Production Management, vol. 6, no. 3, pp. 38–46, 1986.

Flores, Benito E. and Whybark, D. C., Implementing

Multiple Criteria ABC Analysis, Journal of Operations

Management, vol. 7, no. 1–2, pp. 79–85, 1987. DOI:

10.1016/0272-6963(87)90008-8

Gajpal, P. P., Ganesh, L. S. and Rajendran, C., Criticality

Analysis of Spare Parts Using the Analytic Hierarchy

Process, International Journal of Production

Economics, vol. 35, no. 1–3, pp. 293–97, 1994.

Guvenir, H. A. and Erel, E., Multicriteria Inventory

Classification Using a Genetic Algorithm, European

Journal of Operational Research, vol. 105, no. 1, pp.

29–37, 1998.

Komaki, G. M., Sheikh, S. and Malakooti, B., Flow Shop

Scheduling Problems with Assembly Operations: A

Review and New Trends, International Journal of

Production Research, vol. 57, no. 10, pp. 2926–55,

May 19, 2019. DOI: 10.1080/00207543.2018.1550269

Kurtzberg, J. M. and Levanoni, M., ABC: A Better Control

for Manufacturing, IBM Journal of Research and

Development, vol. 38, no. 1, pp. 11–30, January 1994.

DOI: 10.1147/rd.381.0011

Lödding, H., Nyhuis, P., Schmidt, M. and Kuyumcu, A.,

Modelling Lateness and Schedule Reliability: How

Companies Can Produce on Time, Production Planning

& Control, vol. 25, no. 1, pp. 59–72, January 2, 2014.

DOI: 10.1080/09537287.2012.655803

Metaxiotis, K. S., Ergazakis, K. and Psarras, J. E., An

Elaborate Analysis of Production Systems in Industry:

What a Consultant Should Know, Industrial

Management & Data Systems, vol. 101, no. 4, pp. 185–

93, January 1, 2001. DOI:

10.1108/02635570110390170

Mohan, J., Lanka, K. and Rao, A. N., A Review of Dynamic

Job Shop Scheduling Techniques, Procedia

Manufacturing, vol. 30, pp. 34–39, January 1, 2019.

DOI: 10.1016/j.promfg.2019.02.006

Pareto, V., Considerations on the Fundamental Principles

of Pure Political Economy, Routledge, pp. 193, 2007.

Partovi, Fariborz Y and Anandarajan, M., Classifying

Inventory Using an Artificial Neural Network

Approach, Computers & Industrial Engineering, vol.

41, no. 4, pp. 389–404, February 1, 2002. DOI:

10.1016/S0360-8352(01)00064-X

Partovi, F. Y. and Burton, J., Using the Analytic Hierarchy

Process for ABC Analysis,

International Journal of

Production and Operations Management, vol. 13, no.

9, pp. 29–44, 1993.

Ramanathan, R., ABC Inventory Classification with

Multiple-Criteria Using Weighted Linear Optimization,

Computers & Operations Research, vol. 33, no. 3, pp.

695–700, March 1, 2006. DOI:

10.1016/j.cor.2004.07.014

Saaty, R. W., The Analytic Hierarchy Process—What It Is

and How It Is Used, Mathematical Modelling, vol. 9,

no. 3, pp. 161–76, January 1, 1987. DOI: 10.1016/0270-

0255(87)90473-8

Scherrer-Rathje, M., Deflorin, P. and Anand, G.,

Manufacturing Flexibility through Outsourcing: Effects

of Contingencies, International Journal of Operations

& Production Management, vol. 34, no. 9, pp. 1210–

42, January 1, 2014. DOI: 10.1108/IJOPM-01-2012-

0033

ICORES 2021 - 10th International Conference on Operations Research and Enterprise Systems

406

Silver, E. A., Pyke, D. F. and Thomas, D. J., Inventory and

Production Management in Supply Chains, CRC Press,

pp. 810, 2016.

Yu, M.-C., Multi-Criteria ABC Analysis Using Artificial-

Intelligence-Based Classification Techniques, Expert

Systems with Applications, vol. 38, no. 4, pp. 3416–21,

April 1, 2011. DOI: 10.1016/j.eswa.2010.08.127

Logical Workflow Analysis based on Multiple Criteria Decision Analysis: Industrial Application for a Make to Order Environment

407