Metrology and Standardization of High Speed Pluggable Optical

Interconnects

Robert Ferguson

1

, Irshaad Fatadin

1

, Ka-Ming Liu

1

, Irene Barbeito

1

, Christian Hart

1

, Richard Pitwon

2

and David Robinson

3

1

National Physical Laboratory, Teddington, TW11 0LW, U.K.

2

Resolute Photonics, Northover House, 132a Bournemouth Road, Chandlers Ford, Eastleigh, SO53 3AL, U.K.

3

Arden Photonics, Royston House, 267 Cranmore Blvd, Shirley, Solihull, B90 4QT, U.K.

rpitwon@resolutephotonics.com, david.robinson@ardenphotonics.com

Keywords: Electro Optical Circuit Board (EOCB), Polymer Waveguides, Attenuation, Encircled Flux, BER.

Abstract: This paper describes research carried out under EURAMET project 14IND13 on the characterization of short-

range optical interconnect technology. This paper aims to disseminate to the wider communications sector the

primary importance of metrology and the need for standards associated with these emerging technologies.

The focus of the research is the functional performance of embedded polymer waveguides. The results of

various crucial parameters are described and their relevance and influence upon existing national and

international standards discussed.

1 INTRODUCTION

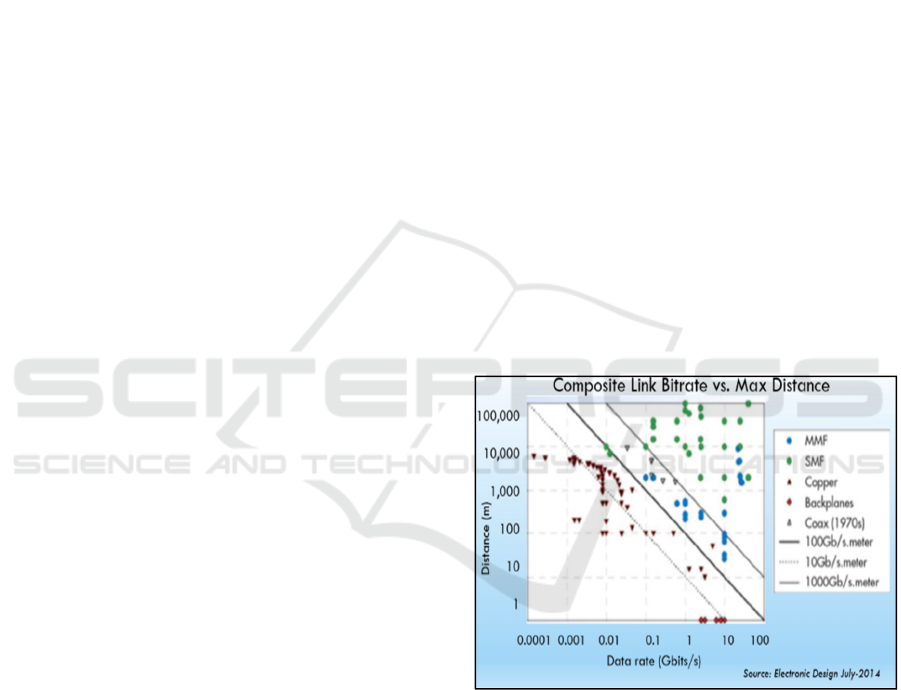

Continuing high growth in the world’s data traffic has

led to many improvements in fibre and detector

technologies (Hogan, 2017). Along with these

developments has been the need to develop optical

short range or ‘intra-rack’ links within data centres to

reduce the bandwidth bottleneck thereby providing

seamless connectivity from external optical

networks/data centres through to inter pod, cluster

and rack level (Senko, 2020). Optical links on a

pluggable daughter board offer vastly improved data

transfer speeds compared with copper based electrical

interfaces which are fundamentally limited in terms

of bitrate over distance to ~100Gb/s/m compared to

optical interfaces (>1000Gb/s/m). These optical links

can be incorporated into PCB boards and are known

as electro-optical circuit board (EOCB’s).

Broadly EOCBs fall within three categories:

Fibre-optic laminate, polymer waveguides (Ingham et

al., 2006) and planar glass waveguides (Pitwon,

2016). In the work presented in this paper, we focused

on the characterisation of the polymer waveguides

and studied the thermal impact on three key

parameters; namely EF, total attenuation and bit error

ratio (BER).

Figure 1: Technology Summary of Link Bitrate vs

Distance.

2 INDUSTRIAL NEED

As the technology rapidly develops there is a

corresponding need to provide characterisation of

these boards for the key operational parameters such

as attenuation, isolation (crosstalk) and BER as well

as a need to provide standardisation through the

activities of international standards bodies. The

market research firm CIR states, ‘…the lack of

Ferguson, R., Fatadin, I., Liu, K., Barbeito, I., Hart, C., Pitwon, R. and Robinson, D.

Metrology and Standardization of High Speed Pluggable Optical Interconnects.

DOI: 10.5220/0010171900630067

In Proceedings of the 9th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2021), pages 63-67

ISBN: 978-989-758-492-3

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

63

standards has held back growth in optical engine use.

If such standards emerge, CIR expects the market for

optical engines could reach $1.2 billion by 2022’

(Lightwave Staff article, 2017). Significant recent

work within the International Electrotechnical

Commission (IEC) technical committee 86, has

improved standardisation of critical measurements as

well as the adoption of a reliable measurement

definition system for optical interconnects. This is a

crucial prerequisite for future commercial adoption of

optical circuit board technology (IEC 62496-2:2017

(E) - Optical circuit boards - Basic test and

measurement procedures - Part 2: General guidance

for definition of measurement conditions for optical

characteristics of optical circuit boards). As stated in

62496-2:2017 (E), ‘Independent repeatability of

waveguide measurements is still very difficult to

achieve due to the lack of clarity on how

measurement conditions are specified…such a

definition system shall capture sufficient information

about the measurement conditions to ensure that the

results of measurement on an identical test sample by

independent parties will be consistent within an

acceptable margin of error’.

A clear understanding of the measurement

condition goes hand in hand with an understanding of

the functional performance of an EOCB. While work

has been carried out in assessing passive boards by

industry and academic institutions for a number of

years (Selviah, 2010), less work has been carried out

to understand a boards performance at operational

temperatures. Industry led discussions have shown a

need to investigate the potential effects of applying

thermal hotspots to EOCB’s to simulate expected

electric components integrated within the board.

These components may well be central processor

units (CPU’s) or transceivers. Parameters such as

attenuation, BER and the Encircled Flux (EF) can be

measured during applied and controlled thermal

loading. Effects upon the change in refractive index

(Δn/Δt) as well as the combined stresses on the

mechanics of the board structure are important areas

of investigation that need to be understood as

specifications and standards develop and board

technology improves and becomes more complex.

3 CHARACTERIZATION

The principal instrument used to assess the functional

performance of embedded waveguides is the Variable

Launch System providing a flexible platform to

permit a range of NA’s and spot sizes to be focused

onto the entrance facet of a particular waveguide

(Ives et al., 2011). Transmission through the

waveguide is then received on an IR camera and the

image analysed in a variety of ways to provide

assessments of total attenuation, isolation and EF.

Combining this platform with a suitable unit to apply

a controlled thermal load to a mounted EOCB,

provides a powerful way of assessing the functional

performance of waveguides on a particular board with

respect to the simulation of thermal effects of

incorporated electrical components. The unit chosen

to provide thermal controlled loading was a

Thermostream ATS – 505 purchased from inTEST

Thermal Solutions, Corporation, USA. The

temperature range demanded by the EOCB functional

environment was determined to be ~ -5 to 80°C (IPC-

TM-650, 1997).

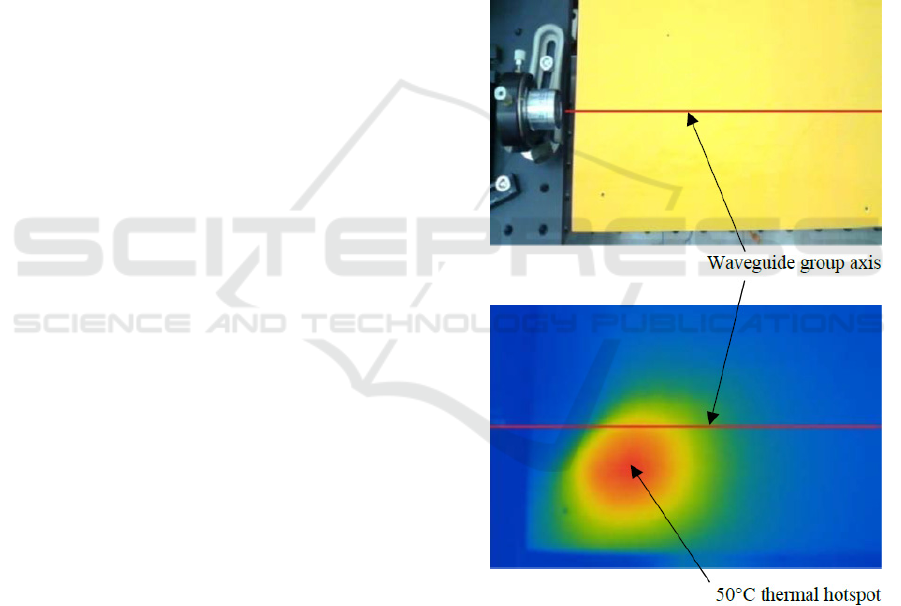

Figure 2: Visible and infra-red images of an example

thermal hotspot on the EOCB using the Thermostream

nozzle and selected circular shroud.

The siloxane (Kai Su et al., 2005) polymer

waveguides of the test EOCB were produced

photolithographically and mounted on an FR4

substrate board. Each waveguide supports many

modes so there is necessarily an importance placed on

the nature of the light that enters the guide as this will

determine modal and energy distribution exiting the

PHOTOPTICS 2021 - 9th International Conference on Photonics, Optics and Laser Technology

64

guide. Ideal launch conditions should occur if the

light is distributed through the whole core (IEC

61300-1, 2016). With multimode waveguides, launch

conditions may typically be characterized as being

underfilled or overfilled, neither of which are

considered optimal as both can result in measurement

variations. Knowing and controlling the launch

condition is therefore important to make sense of any

measurements upon parameters that help characterize

link losses and bandwidth utilisation.

In order to assess the launch conditions of the

NPL system, an Arden Photonics’ Modal Explorer

MPX-1 was placed to accommodate the 850 nm

launch spot. By altering the launch NA and spot size

of the system preliminary measurements showed the

EF was within prescribed EF templates as stipulated

in IEC 61280-4-1/Ed3/CD:2015. Modal conditioning

was also incorporated into the variable launch system

to ensure conformity to key recommended launch

profiles as defined in Table 1 of IEC 62496-2:2017

(E). The ‘L2’ launch profile was preferred ‘…in

which the modal profile is generated, which complies

with the restricted launch EF requirements of IEC

61280-4-1/Ed3/CD:2015’ (Ibid.) and to achieve this

launch profile, modal conditioning was used (IEC

61300-1, 2016). The source was passed into a 5m

graded index multimode fibre (GI-MMF) which is

wrapped 20 times around a 38 mm diameter mandrel.

The output of the mandrel is then passed through a

commercial mode conditioner supplied by Arden

Photonics, producing a mode filtered optical intensity

profile, which complies with EF requirement of IEC

61280-4-1. This is then used as the input to a 5 m GI-

MMF, which is wrapped 20 times around the 38 mm

diameter mandrel to produce a mode-stripped optical

intensity profile at the GI-MMF launch facet. Once

the launch condition has been established

measurements could be carried out for the

attenuation, EF and BER of selected waveguides.

4 RESULTS

4.1 Total Attenuation across the

Thermal Range

The board was mounted on a large translation stage

and secured using silicone gel pads that provided a

method to prevent the board from moving during the

measurement runs and to counter any possible low

frequency vibrations. Careful alignment was

necessary to ensure that the launch spot was centrally

located on the front facet of the selected waveguide.

The receive board was brought into place and

alignments carried out to ensure the image of the

illuminated waveguide was projected onto the centre

of the CCD. The signal image was analysed to find

the centre of the intensity and the total power was

found by summing all the pixels contained within a

circular area around this centre. The diameter of this

virtual pinhole was adjusted to capture all the light

exiting these waveguides. In the case of these

relatively large waveguides a 150 µm virtual pinhole

was used. To calculate attenuation, the ratio of the

total input to the input image reference was divided

by the ratio of the total output to its reference. This

measurement technique provided the insertion loss of

the waveguide under test, which includes intrinsic

waveguide loss and coupling losses. The results for a

selected waveguide are shown below.

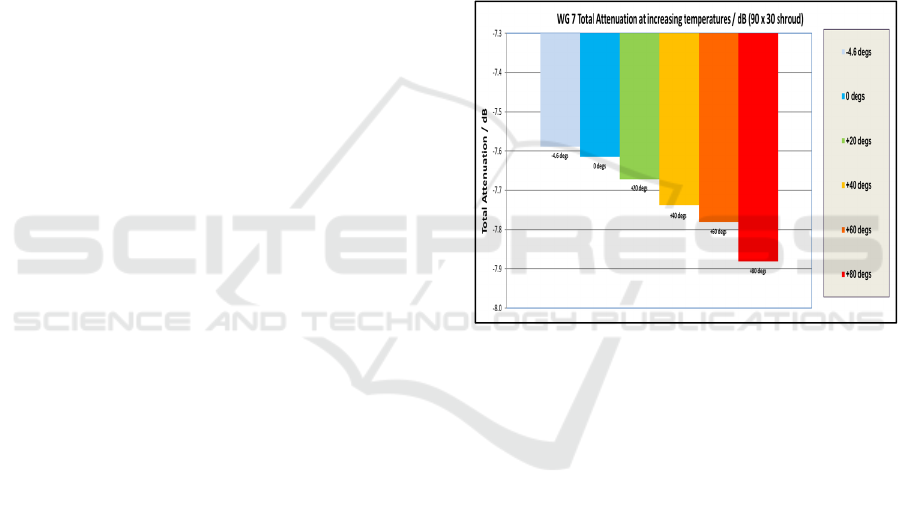

Figure 3: Total attenuation against temperature for a

particular waveguide.

The increase in applied thermal load indicates a

small, but observable increase in the total attenuation.

The maximum range of the measured total attenuation

was ~0.3 dB using the 90 x 30 mm shroud centrally

placed over the waveguide group. The expanded

uncertainties associated with the measurements are

estimated as ranging from U95 < +/- 0.1 dB at 20°C

and +/- 0.20 dB at 80°C. These are derived from

observed repeatable measurements and the

established system uncertainties (Ives et al., 2011).

4.2 Encircled Flux across Thermal

Range

The board was again setup to receive the controlled

launch condition ‘L2’. The MPX-1 was used at the

output facet of the waveguide and the focus

optimized. EF measurements were made covering the

same thermal range as for the attenuation

measurements and the same size of shroud and

Metrology and Standardization of High Speed Pluggable Optical Interconnects

65

position on the board. Measurements were carried out

on two waveguides (WG5 and 7) using 1000 averages

in order to capture the modal energy distribution. In

each case the ambient temperature was recorded. As

with the total attenuation, the increase in applied

thermal load indicates a small but observable shift in

the Encircled Flux profiles consistent with higher

order modes being decoupled from the guide due to

the effects of the increased thermal load upon the

guide and associated changes in the core cladding

refractive index ratio. Preliminary uncertainties

estimated for the EF measurements at the worst-case

repeatability of 80°C give a U95 of +/- 0.0045.

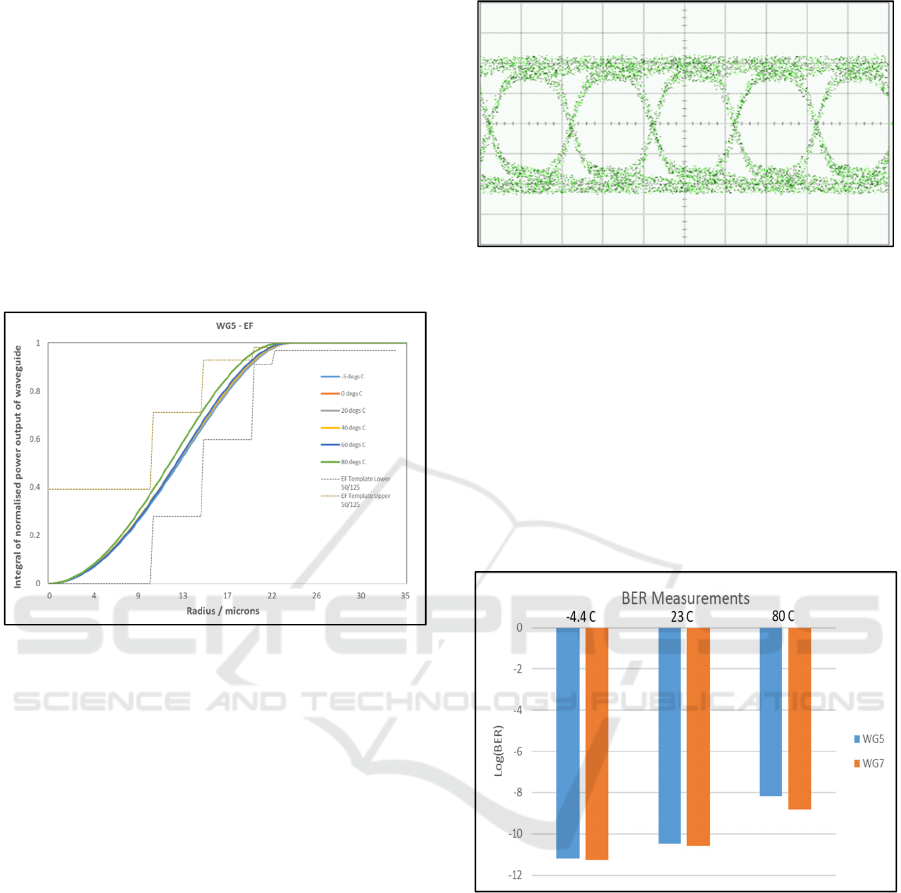

Figure 4: Encircled flux EF defined as the fraction of

cumulative near-field power to the total output power as a

function of radial distance from the optical centre of the

core. This progressive shift is significant as it approaches

and exceeds limits defined by EF templates (as specified in

IEC 61280-4-1/Ed3/CD:2015 at the elevated temperature of

80°C.

4.3 BER across Thermal Range

An arbitrary waveform generator was used to

generate a pseudo-random binary sequences (PRBS)

electrical signal to drive an SFP+ transceiver module.

The intensity modulated signal was launched onto

waveguides 2 and 7 of the board (WG2 and WG7).

The transmitted signal recovered from the photo-

receiver was analysed on a real-time oscilloscope

sampling at 20 GSa/s. An eye diagram of the

transmitted signal from the experimental setup is

shown in below.

Figure 5: Eye diagram of the transmitted signal.

The BER was measured at the operating

temperatures -4.4 ºC, 23 ºC and 80 ºC using the

Thermostream chamber and involved using the same

controlled launch conditioning ‘L2’ as that applied to

attenuation and Encircled Flux measurements. The

BER results are shown in Figure 5. Signal

degradation was observed for the transmitted data at

the extreme temperature of 80 ºC for both

waveguides. The reduction in performance can be

attributed to the increased total attenuation over the

temperature range.

Figure 6: BER measurements on two waveguides for the

operating temperatures -4.4 ºC, 23 ºC and 80 ºC.

5 CONCLUSIONS

The Data Centre Network has significantly increase

in speed, reduced in power and cost in the past 5

years. With continuous pressure to be faster and cost

effective, focus on optics is to overcome limitations

of copper in every aspect (speed and power). This has

encouraged the migration of optical interconnect onto

the board and device level. As the technology rapidly

develops there is a corresponding need to provide

characterisation of these boards for key operational

PHOTOPTICS 2021 - 9th International Conference on Photonics, Optics and Laser Technology

66

parameters such as attenuation, isolation (crosstalk)

and bit error ratio (BER) as well as a need to provide

standardisation through the activities of international

standards bodies. The market research firm CIR

states, ‘…the lack of standards has held back growth

in optical engine use. If such standards emerge, CIR

expects the market for optical engines could reach

$1.2 billion by 2022’ (Lightwave Staff article, 2017).

Significant recent work within the International

Electrotechnical Commission (IEC), principally

through the work of the IEC technical committee 86,

has improved standardisation of key measurements as

well as the proposed adoption of a reliable

measurement definition system for optical

interconnects. This is seen as a crucial prerequisite for

future commercial adoption of optical circuit board

technology. As stated in IEC 62496-2:2017 (E),

‘Independent repeatability of waveguide

measurements is still very difficult to achieve due to

the lack of clarity on how measurement conditions are

specified…such a definition system shall capture

sufficient information about the measurement

conditions to ensure that the results of measurement

on an identical test sample by independent parties will

be consistent within an acceptable margin of error’. It

is now the case that a Measurement Identification

Coding (MIC) system has been incorporated within

the standard with the principal aim to support

harmonization of global reference measurements of

these pluggable interconnects (IEC 62496-2, 2017).

A clear understanding of the measurement

condition goes hand in hand with an understanding of

the functional performance of an EOCB. While work

has been carried out in assessing passive boards by

industry and academic institutions for a number of

years (Selviah et al., 2010), less work has been carried

out to understand a boards performance at operational

temperatures. Industry led discussions have shown a

need to investigate the potential effects of applying

thermal hotspots to EOCB’s to simulate expected

electric components integrated within the board.

These components may well be central processor

units (CPU’s) or transceivers. Parameters such as

attenuation, BER and the Encircled Flux (EF) can be

measured during applied and controlled thermal

loading. Effects upon the change in refractive index

(Δn/Δt) as well as the combined stresses on the

mechanics and materials of the board structure are

important areas of investigation that need to be

understood as specifications and standards develop

and board technology improves and becomes more

complex. Optics has the potential to replace certain

functionality of electronics such as for optical

switching, optical storage and optical signal

processing. Continuous innovation in optics will

continue to be a big part of future DC networks but

will require corresponding metrological assessment

and standardization.

ACKNOWLEDGEMENTS

The work reported in this paper was funded by project

EMPIR 14IND13 and BEIS. This project 19SIP05

TTPWC has received funding from the EMPIR

programme co-financed by the Participating States

and from the European Union’s Horizon 2020

research and innovation programme, Funder ID:

10.13039/ 100014132.

REFERENCES

Hogan H, 2017. Photonics Spectra, p36.

Senko, 2020. Data Centre Network: Impact on Optical

Interconnect & Component Technology, Lightwave

Webcast.

Ingham, J. D., Bamiedakis, N., Penty, R. V., White, I. H.,

DeGroot, J. V., Clapp, T. V., 2006. Multimode siloxane

polymer waveguides for robust high-speed

interconnects, Conference on Lasers and Electro-

Optics and 2006 Quantum Electronics and Laser

Science Conference.

Pitwon, R., 2016. Advances in Photonic Interconnect for

Data Centre Subsystems, Seagate Systems, UK, 4th

Symposium on Optical Interconnect in Data Centres,

ECOC 2016, Düsseldorf, Germany.

Lightwave Staff article, 2017. Board-level optical

interconnects sales to hit $5.6 billion by 2022:CIR.

Selviah D et al, 2010. Integrated optical and electronic

interconnect PCB manufacturing research, Circuit

World, 36, 5–19.

Ives D et al, 2011. Development of a variable launch

attenuation and isolation measurement system for

optical waveguides, Applied Optics, Vol. 50, No. 22.

IPC-TM-650, 1997. Test Methods Manual, The Institute for

Interconnecting and Packaging Electronic Circuits,

Doc. No. 2.6.7, Rev. A.

Kai Su, Jon V. DeGroot, Jr., Ann W. Norris and Peter Y.

Lo., 2005. Siloxane Materials for Optical Applications,

Advanced Technologies and Venture Business, Dow

Corning Corporation, 2200 W. Salzburg Road,

Midland, MI, USA 48686. Proc. Of SPIE Vol. 6029

IEC 61300-1:2016 - Fibre optic interconnecting devices

and passive components – Basic test and measurement

procedures – Part 1: General and guidance.

IEC 62496-2:2017 (E) - Optical circuit boards - Basic test

and measurement procedures - Part 2: General guidance

for definition of measurement conditions for optical

characteristics of optical circuit boards.

Metrology and Standardization of High Speed Pluggable Optical Interconnects

67