Enabling Predictive and Preventive Maintenance using IoT

and Big Data in the Telecom Sector

Tahir Mahmood and Kamran Munir

Department of Computer Science and Creative Technologies, Faculty of Environment and Technology,

University of the West of England, Bristol, BS16 1QY, U.K.

Keywords: Predictive Maintenance, Telecom, IoT, Big Data, Prediction Model.

Abstract: Telecom sector has always been working hard to improve network quality to satisfy end user services. Fixing

telecom network errors (hardware and software) precisely and quickly is a main factor to improve quality of

services. Telecom operators are spending a lot of budget on ad hoc maintenance to fix these errors. This paper

presents a framework using internet of things (IoT) and big data to enable predictive and preventive

maintenance, which have been applied in the telecom sector. A telecom network consists of radio nodes,

transport network, switching centres and civil infrastructure; and in this paper, focus is on the maintenance of

Radio Access Network (RAN). A challengeable task for telecom operators has been to maintain radio nodes

as these are installed on different locations. This framework for predictive maintenance is modelled using

active and historical data from telecom equipment as well as data collected from IoT devices and sensors. The

major benefit of implementing this framework has been a control on the time and cost of the maintenance by

pre-planning maintenance activities and related budget.

1 INTRODUCTION

Telecom industry is spending bulk part of their

budget for the maintenance of their network. This

maintenance cost is called operational expenditure

(OPEX). Telecom operators are trying to increase

their profit by reducing the OPEX cost of their

network. Due to competition, technology change and

productivity gains (Ciriani and Jeansjean, 2019), it is

observed that there is variation in growth rate and

profit in all industries related to technology. Also,

telecom industry is becoming less profitable due to

the competition between operators and technology

variation, which is evolving day by day. There is

another reason behind reduction of OPEX cost as it

has no link with the output e.g., whatever telecom

company will spend on maintenance, there is no

guarantee that their sale or profit would increase.

According to an earlier study (Takao and Ryoji, 2002)

presented in the Telecommunication Development

Plan, telecom companies should be trying to reduce

the maintenance cost by re-organisation their field

operation team’s. We aimed to develop a predictive

and preventive maintenance framework for telecom

using IoT and big data. Using this framework telecom

companies can re-design their network maintenance

processes that will help to reduce their operational

cost and increase network stability. We have

developed a list of descriptions related to telecom

operation and maintenance activities and how these

operation and maintenance can be transformed in a

predictive maintenance model. Our work has evolved

around following key aspects: (1) telecom base

station equipment and infrastructure; (2) procedures

to collect data of telecom equipment; (3) telecom

network operation and maintenance departments and

field engineer hierarchy; (4) telecom network errors,

alarms triggering and collection; (5) transformation

of telecom network active maintenance to predictive

maintenance; (6) telecom maintenance engineer

effort and time for telecom network maintenance; and

(7) significant effects of predictive maintenance on

telecom network performance.

2 SYSTEMS MAINTENANCE

Telecommunication is the transmission of voice and

data over the wires and the wireless (radio layers)

network (Gunawardena and Weihua, 2014). It is also

known as the technology that enables one user to

connect

with other user for the exchange of voice and

Mahmood, T. and Munir, K.

Enabling Predictive and Preventive Maintenance using IoT and Big Data in the Telecom Sector.

DOI: 10.5220/0009325201690176

In Proceedings of the 5th International Conference on Internet of Things, Big Data and Security (IoTBDS 2020), pages 169-176

ISBN: 978-989-758-426-8

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

169

data. Base station sites consist of transmitter and

receiver equipment, rectifier to covert AC power to

dc-48 volts, battery banks, air conditioner, RF cables,

Oil storage (used for generators) and generators to

generate electricity in case of commercial electric

power failure. Table 1 shows the equipment which

involves in the building of a base station.

Table 1: Base Station Site Equipment.

Item Name Indoor/ Outdoor Area

Air Conditioner Indoor Civil Infrastructure

AC Power System Indoor Civil Infrastructure

Base Station Indoor Telecom Equipment

Battery Bank Indoor Civil Infrastructure

DC Power System Indoor Civil Infrastructure

Rectifier Indoor Civil Infrastructure

RF Cables In/outdoor Telecom Equipment

RF Combiners Indoor Telecom Equipment

RF Module Indoor Telecom Equipment

Tower Outdoor Civil Infrastructure

Tower Base Outdoor Civil Infrastructure

To control maintenance activities in telecom

network, Hoang and Hai (2013) elaborated that every

telecom operator has a structure of teams who are

involved in telecom base station’s maintenance,

which include:

network operation centre (NOC),

NOC team to monitor alarms 24/7, field operation

team for planned maintenance, field operation team

for reactive maintenance, alarms from telecom

equipment comes to NOC system via management

link. This management link used to perform software

upgrade and downgrade for telecom equipment in

addition of alarms monitoring. Currently, telecom

operators are doing planned and reactive maintenance

of base stations. Current maintenance is carried out

only when NOC team observed one of the following

situations: equipment stops working, equipment starts

to give critical/service effecting alarms, equipment

starts to crash, Software starts to give alarms and

software starts abnormal behaviour.

3 PREDICTIVE MAINTENANCE

Predictive maintenance means monitoring the

equipment to avoid future failure and as soon as

equipment performance is degrading then

maintenance is scheduled to avoid down time. Yousef

et al. (2017) proposed a methodology for building a

Node Failure Prediction Model, which can help to

implement node failures predications to take the

precautionary measures. This node is called optical

switch in telecom and used to transport voice and data

traffic. In our work, data collection by real monitoring

of optical switch is explored and then three different

models of machine learning are implemented to

predict the optical switch maintenance. Using the

decision tree, ensemble model and logistic regression,

data is trained and then prediction for optical switch

maintenance is triggered.

In order to build a telecom operator network there

are three types of sections: radio, transport and core

sites. Multiple devices are used to set up an end to end

telecom operator network. However, in the existing

work only one device of transport is considered to

base prediction maintenance. From a telecom

operator point of view, spending money only for one

device maintenance solution is usually not worthy.

Telecom operators are often looking to find a solution

which can cover most part of their maintenance. Our

work considers radio sites which covers most part of

telecom network and optical switches are part of radio

sites. Using the proposed framework, telecom

operators can cover the optical switch maintenance as

well, by adding the data from optical switch to the

predictive model. Our predictive maintenance

framework also has the flexibility to add data from

different sources as well as from optical switch.

3.1 Predictive Maintenance in Power

System

In (Sisman and Mihai, 2017). failure of power supply

system is predicted using a statistical analysis of the

power system. By using a statistical analysis method

(such as the

Pareto analysis, etc.) and failure risk

assessment (through the intelligent techniques e.g.,

fuzzy graphs, artificial intelligent, etc) critical

components can be identified and monitored. Our

work covers power system as well as radio and

transport equipment. The prediction maintenance for

power supply system is not useable for telecom

operators. This is because a framework for predictive

maintenance in telecom, should have the capability to

first merge different kind of data into predive

maintenance system to trigger maintenance flags.

3.2 Framework and Related Data

Availability, Access, Exploration

and Processing

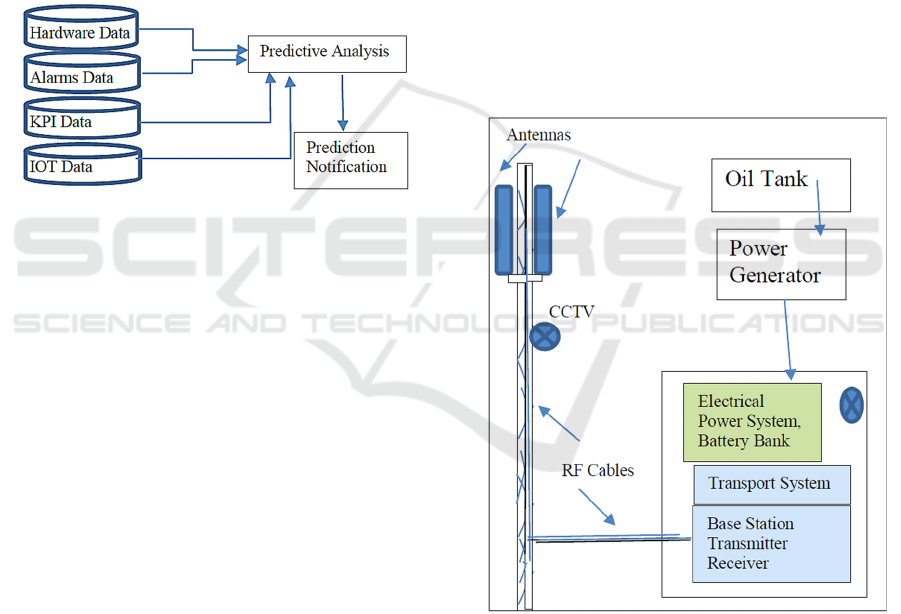

Our framework (as shown in Figure 1) has four steps

to deliver predictions i.e., (a) access and explore

data; (b) process data; (c) develop predictive

framework; and (d) integrate analytics with system.

In this framework, both hardware and software

related data is used for predictive analysis. As

outcomes, notifications are triggered to declare areas

IoTBDS 2020 - 5th International Conference on Internet of Things, Big Data and Security

170

needed maintenance. In terms of access to data, we

have found that it is possible to collect data about

hardware, alarms, key performance indicators (KPI),

IoT (including CCTV, ultrasonic and temperature

sensor) from telecom network equipment and

infrastructure. Moreover, data from maintenance

servers, IoT devices, alarms, key performance

indicators and equipment manufacturers are

combined in the main data server. Processing

included scattering or to rearrange to bring the data

into standardise format, this standard data is then

processed to bring in a meaningful form which can

make sense from the maintenance point of view. In

predictive analysis, data is

processed, and prediction

notification are generated based on the defined

priority area(s) that require maintenance.

Figure 1: Overview of Predictive Maintenance Framework.

This framework for enabling predictive

maintenance suggests integration of the network

alarms and IoT data to storage disks. These storage

disks are integrated with both Hadoop/Hive and

power business intelligence (BI) system. This Power

BI system raises flags when a defined threshold is

crossed. This flag then triggers task(s) for field

engineers for maintenance.

4 METHODOLOGY

Due to the fact that it is impossible to self-raise faults

in Telcom network as no Telecom operator will allow

service suspensions, we have used simulations on the

bases of our theoretical or visible values obtained from

Telecom sector. However, we have collected original

maintenance data from telecom industry equipment as

well as their IoT data. Predictive maintenance default

values are obtained and used as input. This

maintenance input data is then processed i.e., either

degraded or increase in quality, and then predictive

maintenance results are observed. Our observations

were based on varying the input data from the input

sources to see the effects on the predictive maintenance

outcomes. Moreover, data generated by different

resources is analysed. The margin of error in predicted

results is covered by giving prediction using qualitative

input data. These data sources include both hardware

and software counters.

5 ENABLING PREDICTIVE

MAINTENANCE

This section discusses the process adapted to enable

predictive framework for the base station site.

5.1 Predictive Maintenance

Framework Implementation for

Base Station

In a telecom network all base stations are planned and

installed in almost a similar model i.e., their operation

and maintenance activities are similar. Therefore,

evaluating predictive and preventive maintenance for

one base station is largely applicable for all stations.

Figure 2: A typical Telecom Network Base Station Site.

As shown in Figure 2, a base station consists of

radio transmitter and receiver, transport system

device (optical switch or microwave link) and electric

power system. Base station transmitter and receiver

are the main equipment responsible for receiving and

transmitting the signals to end users. Electricity is

feed by commercial sources as well generated by on-

site generator. Generator used for electricity

production at site is dependant for oil stored in oil

Enabling Predictive and Preventive Maintenance using IoT and Big Data in the Telecom Sector

171

tank. Therefor maintenance and availability of oil

tank is very important. This electricity is AC

(alternating Current) which is converted to DC (direct

current) by electrifier. This is because base station

and transport system need -48v DC power as

mentioned by Kasper, Bortis, Deboy and Kolar

(2017). Base stations are also equipped with battery

banks which are used to store DC power. In the next

section each part of base station and prediction for

maintenance is explored.

5.2 Base Station Transmitter and

Receiver

Our requirements and design activities have

established that prediction for radio hardware failure

will be found by running diagnostic tests and then the

results will be feed to the big data prediction system.

Diagnostic test run through the hardware, check the

health of the hardware and give immediate outputs. If

a test case result is negative, then it means that the

related hardware or part of that hardware is faulty.

Radio equipment manufacturers have already

added a default capability that when diagnostic test

runs on a radio hardware, it checks the equipment

stability and performance of each part of the radio

module. The outcome of this test is either pass or fail.

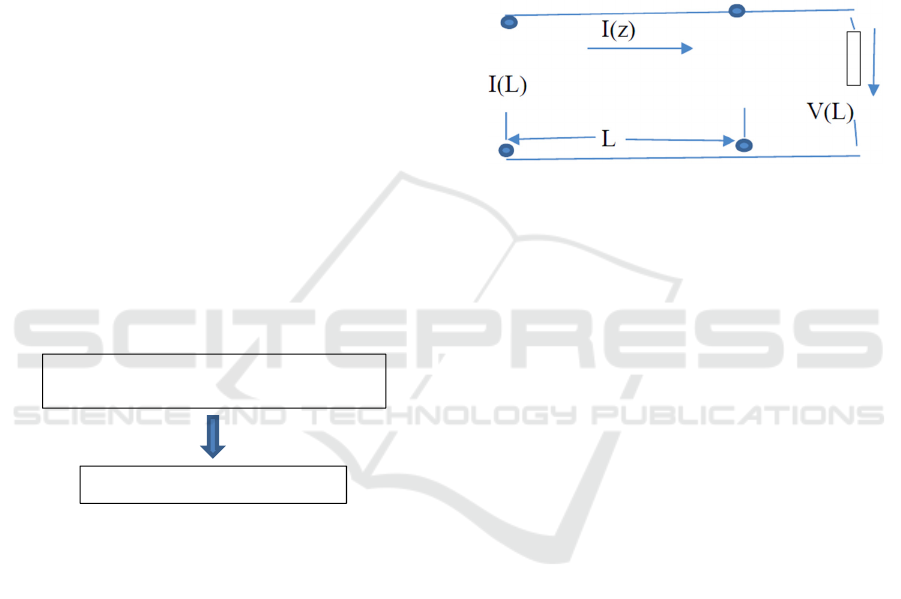

Figure 3: Prediction for a Radio Hardware Failure.

Figure 3 shows the diagnostic test and result feed

to predictive maintenance system. For diagnostic

tests, a script is prepared which runs the diagnostic

test on each radio module of the telecom base station

and collect the results of these diagnostic tests. These

results are in text format which are then transmitted

to big data predictive maintenance system. These test

results are in pass or fail format which reflects the

hardware health status. The predictive maintenance

system raises a flag for maintenance if the result is

failed.

5.3 Base Station RF Cables

The RF cables data are collected from two resources.

First from display sensor which shows the RF cable

and connector physical appearance. Human

intervention is required to check the physical

appearance and then to add this data in main database.

Second data for RF cables and connectors are be

collected from IoT devices. This data consists of

actual RF measurements like voltage standing wave

ration (VSWR), cable loss, return loss etc. These

results are collected automatically from base station

equipment and sent to main database. These results

are precise, and each measurement reflect the status

of the RF cable. Analysis triggers flags to predict if

RF cable(s) situation is degrade and going to get

worse if maintenance is not carried out.

Figure 4: Transmission line terminated with load.

In relation to the power transmission via RF

cables, power is represented by voltage (V) and

current (I). A Voltage V(z) and Current I(z) at any

point z is shown in Figure 4 when it travels through

the RF cables. Voltage and Current can be calculated

in load condition and at any point where it needs to

be measured. This RF power is travelled in sinusoidal

form and can be expressed in phasor form in an

equation 1 & 2 given below:

V(z)dz =− (R + jωL) I(z)

(1)

dI(z)dz = − (G +

j

ωC) V(z)

(2)

Where R is series resistance expressed in

(ohms/m) and L is inductance expressed in

(henrys/m) for both conductors, and G(siemens/m)

and C(farads/m) are shunt conductance and

capacitance per unit length. When RF power is

travelling via RF cable then this is given as follows:

V(z) = V + oe – γz + V− oeγz

(3)

I(z) = I + oe − γz + I – oeγz

(4)

Where Γ = α+jβ=√(R+jωL) (G+jωC) (5)

above is a complex propagation constant, with α

being the attenuation coefficient and β=2π/λ the wave

number, V + o and I + o are the voltage and current

amplitudes of the incident wave along + z direction,

V−o and I−o are the voltage amplitude and current

amplitudes of the reflected wave along−z direction,

and Z0 is the characteristic impedance of the

transmission line and is defined by:

Diagnostic Test on

Radio Hardware

Predictive Maintenance System

IoTBDS 2020 - 5th International Conference on Internet of Things, Big Data and Security

172

Z0 =

√

R + jωLG + jωC

(6)

When Rf signals travel in RF cables then the

output of power at exit end depends on the quality of

the RF cable or the performance of the RF cable. This

quality and performance of RF cables are measured

in form of variable measurements. These

measurements can be variable due to a fault or

leakage in the RF cables. In case of faulty or leaked

RF cable, the respective measurements will change

which eventually will affect the output of RF signals.

The measurements collected in this section for

telecom RF cables health are in digits. These digits

correspond the health of RF cable. High value of digit

corresponds the bad health of RF cable and vice

versa. These results which are in mathematical

structure are feed to predictive maintenance system

which analytical is applied to get prediction for RF

cables maintenance.

5.4 Predictive Maintenance for Civil

Structure

In telecom sector, an important part of base station is

civil infrastructure. Civil infrastructure consists of

cooling systems, electric power from commercial

source, a rectifier to convert AC to DC power, system

for electric power generation (in case of commercial

power failure), battery bank (used in case of

commercial power failure), and concrete base (to

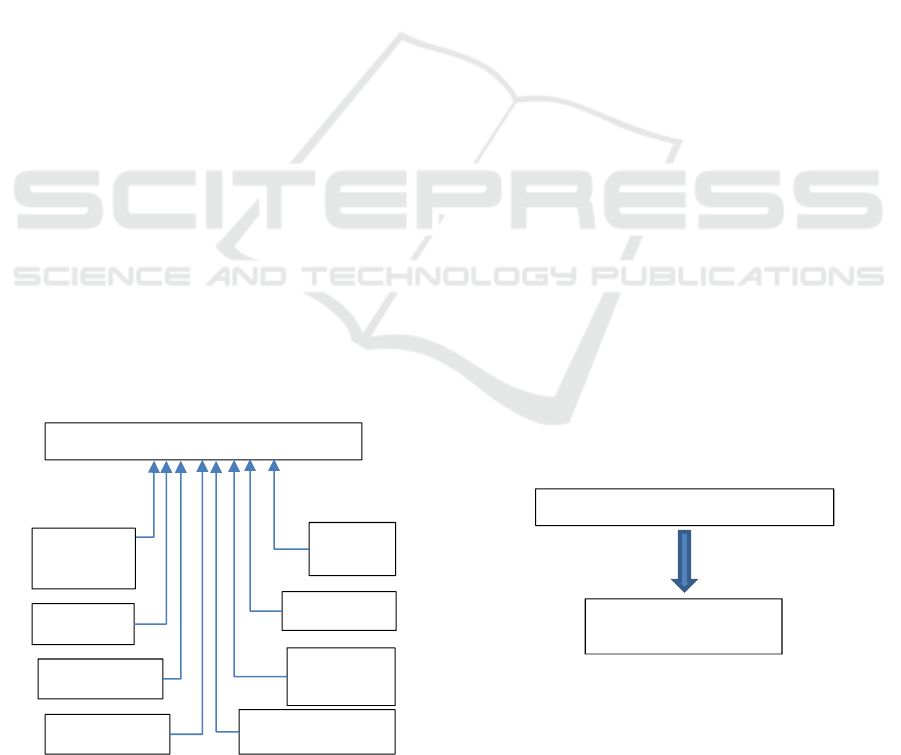

install tower on this). Figure 5 shows various sensors

in our predictive maintenance model, which covers

all areas of a civil infrastructure installed in a telecom

base station. In order to predict maintenance for base

station civil infrastructure, CCTV and sensors are

used which are installed on battery banks and send

live data to main database.

Figure 5: Prediction for base station infrastructure failure.

Base station telecom equipment needs -48 dc

voltage. The sensor on battery bank reads voltage of

battery bank and send these measurements to main

database on daily base. When this dc voltage data is

processed, trends are sent to power BI tool. Power BI

will raise flag if the voltage gets less than -48 volt. The

telecom equipment is considered working fine if

voltage is between the range of -48 to -53 dc volts. In

case a flag is raised for low voltage, maintenance

should be carried out as soon as possible to avoid

outage in a base station service. Moreover, a sensor is

also installed on oil tank to read the oil level. This reads

the oil level and measurements are feed to the system

which raises the flag for inappropriate oil levels.

5.5 Predict Maintenance for Telecom

Network Failure

Most of the telecom equipment vendors have

manufactured their own proprietary server to collect

alarms and log data from their equipment. In these

days major telecom vendors are Nokia, Ericsson and

Huawei. Huawei has main network control system

called U2000/U2020 and Nokia has Net-act. U2000

and net-act are providing statics of the network. These

network statics are called key performance indicator

(KPI). KPI’s given by U2000 and net-act are in same

format. Like both are giving data about calls and

throughput. These data sets include:

Call attempted

Call dropped

Call successful

Call failure

Total Throughput

Throughput in uplink

Throughput in downlink

Packet loss

Packet dropped

Figure 6: Network KPI’s to Big Data Predictive System.

It is important to note that the KPI’s mentioned in

this section are just example, there are a lot more

KPI’s who reflect the network performance. These

KPI’s are in text format which represent the stability

and performance of the telecom network. As shown

Sensors Data Collection

Power

Generator

Rectifier

Temperature

RF Cable

Battery

Ban

k

Tower/Pole

Oil Tank

Generator

RF Antennas

Network KPI’s (Measurements)

Predictive

Maintenance S

y

ste

m

Enabling Predictive and Preventive Maintenance using IoT and Big Data in the Telecom Sector

173

in Figure 6, KPI’s data generated from network

management system is sent to the predictive

maintenance system, where these data sets are

processed, and flags are raised when performance is

degraded by comparing it to the defined measures.

Once flag is raised, a notification is sent to network

operations team or network optimisation team for

further diagnostics.

6 DISCUSSION, ANALYSIS AND

LIMITATIONS

This section discusses our achievements, limitations,

related issues and prioritise in using an automated

telecom network predictive maintenance

infrastructure.

6.1 Telecom Base Station Equipment

and Infrastructure

In order to achieve predicative maintenance in

telecom sector, equipment and infrastructure

involved in building a telecom base station site is

explored. Figure 2 gives an overview for the telecom

base station equipment as well as civil infrastructure.

The telecom base station outdoor view explains the

tower at base station and antennas installed on tower.

There is one generator installed at the base station site

to generate electricity in case of outage in commercial

electricity. Also, electricity received from

commercial resources or from generator is alternate

current (AC) but telecom equipment needs direct

current (DC). For the purpose to convert AC to DC,

rectifier is used. The base station transceiver system

(BTS) is purely a telecom system, which is

responsible for processing the signals, data and

modulating the transmission and

received signals.

BTS is responsible for communication to end users as

well as to the main control system (Mobile Switching

System). The RF cables are used in base station site,

which connect BTS and antennas. Maintenance of RF

cables are also very important for the performance of

the base station.

6.2 Procedure to Collect Data from

Telecom Equipment

Section 2 presents telecom hardware data which

telecom vendor can provide. This data has full

production history of the equipment manufacturing

record, the batch (it belongs to) and related

manufacturing issues (if faced during the

manufacturing). Normally vendors don’t (fully) share

such information. Vendor usually only release

information about the production data and expiry date

of an equipment. This manufacturing data is stored in

predictive maintenance database to verify the

performance of the related equipment.

Table 2: Hardware Alarms.

Location of

Alarm

Alarm Type

Alarm raised

by Equipment

Historical Alarm on

this equipment

Site A RF module

Major, minor,

Critical

from one-month poor

site performance

Site A

Main

Processor

Major, minor,

Critical

from one-month poor

site performance

In Table 2, various types of alarms that a telecom

equipment can raise are presented. These alarms

feature is usually pre-added by telecom equipment

vendor. Telecom equipment vendor can add and edit

any alarm if necessary, by downloading software

patches. These alarms are in status of minor, major or

critical, depends on the effect of service it provides.

The network stability is measured by various key

performance indicator (KPI), and an example of is

shown in Table 3.

Table 3: KPI’s from base stations.

Location

Call Attempted

Call drop Rate

Data Packet Loss

Call Failure

Call Successful Rate

Handover attempted

Handover failure rate

Call drops due

to hardware failure

A 100 95%

50

packets

95 5% 100 93 95

B 100 100 0 0 100% 100 0 0

This KPI feature can be edited by a telecom

equipment vendor. Normally every telecom vendor is

following 3rd Generation Partnership Project (3GPP)

aspects for network performance (Release 15, 2018).

But some KPI’s can be proprietary to a vendor, which

they add to optimise network or these propriety KPI’s

help vendor to improve the network performance.

6.3 Telecom Network Operation and

Maintenance Departments and

Field Engineer Hierarchy

We have explored telecom current maintenance

design and it was found that telecom operators

perform maintenance activities both in planned and

reactive arrangements. Telecom vendor usually spend

a lot of money for their daily operational tasks. There

IoTBDS 2020 - 5th International Conference on Internet of Things, Big Data and Security

174

are usually two teams involved in daily maintenance

task. One does the planned maintenance activities,

who are not responsible to immediate alarms and only

visit the site according to planned date and observe if

there is any maintenance required. The other team is

the one which attend the base station for priority

maintenance e.g., if there

is a service failure alarm

triggered by the base station site.

6.4 Telecom Network Errors, Alarms

Triggering and Maintenance

In telecom sector, usually maintenance is carried out

when there is fault in network. Li, Lansburg and

Cocciantelli (2001) have explored the maintenance and

operations characteristics in telecom application. It is

found that two kinds of maintenance are adopted i.e.,

planned and proactive maintenance. Many telecom

operators have outsourced their operation and

maintenance activities. Takada, Tanji. Seki, Yamagoe,

Soejima and Tahara (2019) has explored the operation

and optimising based on SLA. To avoid the SLA, a

maintenance engineer visits the site according to the

maintenance plan which has been drafted for the site

maintenance, regardless the planned site required

maintenance or not. For proactive maintenance,

maintenance engineer receives the task from the NOC

team that a site raised alarms and needs to be fixed,

usually as soon as possible. Mostly these alarms are

about service failures, which means operator is losing

money due to outage in network. In order to overcome

the outage in the network services and to save the

maintenance engineer time, predictive maintenance

can help these maintenance engineers in upholding the

telecom network.

The key idea behind the predictive maintenance is

to get all possible alarms and historical data from

telecom equipment, including technical and non-

technical areas and make use of all these data sets. Big

data analytics can help getting accurate predictions

for needed maintenance. Data from civil

infrastructure (se discussed in Section 4) need to be

collected via IoT devices, which involved; for

example, sensors and CCTV monitoring. Moreover,

sensors can be used to detect the oil level in oil

storage

tank and to send the measurements back to

the system.

6.5 Issues and Limitations in Enabling

Predictive Maintenance on Telecom

Network

Enabling predictive maintenance could be expansive

in the start, but in the long run telecom operators can

increase their income by reducing the network issues

as well as by decreasing the time and cost for

maintenance. Challenges also arise in testing the

system as it may not be possible to test all live failures

until a failure occurs automatically. Moreover, in

order to enable this framework in telecom industry,

telecom operators need to plan implementation in

various small steps. Moreover, they will need to keep

running their manual (existing) maintenance

operations and structure. Even after enabling an

automated framework for predictive maintenance,

telecom operators will need to optimise this

framework to get accurate and quick predictions for

future maintenance. We cannot ignore the chances of

wrong of misleading predications made by the

automated system at-least in the initial period.

Therefore, there will still be a need to verify the

performance of the base station site when predictive

maintenance system triggers a required maintenance.

This usually done by verifying the counters and KPI’s

of the site, and manual verification is performed for

the civil infrastructure installed at a telecom site.

6.6 Verifications from Telecom Experts

We conducted a survey from senior telecom

professional engineers to get their opinion about the

need of predictive maintenance and its possible

effects on telecom network. Here is a partial snapshot

of the key results obtained from our survey:

72% (21 out of 29) telecom field engineers agree

that predictive maintenance is better option for

telecom industry

97% (28 out of 29) telecom field engineers has

agreed that predictive maintenance can bring

benefit for telecom industry.

93% (27 out of 29) telecom field engineers has

recommended that predictive maintenance can

improve the stability in telecom network.

97% (28 out of 29) telecom field engineers has idea

that predictive maintenance can reduce time and

cost for telecom network maintenance.

100% (29 out of 29) telecom field engineers agree

that historical alarms are beneficial for future

planning in telecom network.

97% (28 out of 29) telecom field engineers agree

that KPI (voice and data measurements) are helpful

for future planning in telecom network

100% (29 out of 29) telecom field engineers has

recommended that enabling predictive maintenance

system for power infrastructure can improve the

outage in telecom network.

Enabling Predictive and Preventive Maintenance using IoT and Big Data in the Telecom Sector

175

100% (29 out of 29) telecom field engineers that

combining network alarms, KPI and environment

data are helpful for predictive maintenance in

telecom network.

97% (28 out of 29) telecom field engineers agree

that predictive maintenance is helpful in generating

more revenue for telecom industry.

7 CONCLUSIONS

Predictive maintenance in telecom can bring stability

in the network and increase in revenue. For the

purpose of incorporating predictive maintenance in

telecom network, research is carried out about active

maintenance structure and network entities which

require maintenance. Research is also carried to find

different sensors / IoT devices to monitor the telecom

network base station temperature, power system,

generator and oil. This framework for predictive

maintenance is modelled using active and historical

data from telecom equipment as well as data collected

from IoT devices and sensors. A survey is also carried

out to confirm that senior professional engineers

working in telecom network agree with the benefits

obtained through predictive maintenance in telecom

network. Results also show that enabling this

predictive maintenance framework in telecom

network can increase the stability and performance of

network which can lead to decrease in maintenance

cost and increase profit.

ACKNOWLEDGEMENTS

We acknowledge the huge support provided by the

engineers from British telecom (BT), EE Limited

Mobile, Ericsson and related third parties for sharing

requirements, data sets, equipment sheets,

images and

all related outcomes that are presented in this paper.

REFERENCES

A. H. Yousef, A. F. Fahmy and H. K. Mohamed, "On the

use of predictive analytics techniques for network

elements failure prediction in telecom operators," 2017

13th International Computer Engineering Conference

(ICENCO), Cairo, 2017, pp. 250-255.

A. Takada, N. Tanji. T. Seki, K. Yamagoe, Y. Soejima and

M. Tahara, "SLA Driven Operation - optimizing

telecom operation based on SLA, "2019 20th Asia-

Pacific Network Operations and Management

Symposium (APNOMS), Japan, 2019.

Berggren, C and Bengtsson, L. (2004) Rethinking

Outsourcing in Manufacturing: A Tale of Two Telecom

Firms. European Management Journal [online]. 22 (2)

[Accessed 10 December 2019].

Ciriani, S. Jeansjean, F (2019) Competition, technological

change and productivity gains. [Online]

https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3

410912

Hong, I. and Hai, D. (2013) Maintenance Support System

for Telecommunication Equipments [online]. Vietnam:

https://pdfs.semanticscholar.org/472e/de85e3666f0781

3fabf368db55ed42e20432.pdf. [Accessed 10

December 2019].

Gunawardena, S. and Weihua, Z. (2014). Modeling and

Analysis of Voice and Data in Cognitive Radio

Networks [online]. Canada: Springer International

Publishing. [Accessed 10 December 2019].

Kasper Matthias, Bortis Dominik, Deboy Gerald, Johann

W. Kolar, “Design of a Highly Efficient (97.7%) and

Very Compact (2.2 kW/dm3) Isolated AC-DC Telecom

Power Supply Module Based on the Multi-cell ISOP

Converter Approach”, IEEE Transactions on Power

Electronics, 2017, 32 (10), pp.7750-7769.

Release 15. (2018) 3GPP TS 32.401 – Telecommunication

management; Performance Management (PM);

Concept and requirements, 2018.

Sisman, G., Mihai, O. (2017) Monitoring the parameters of

the electronics devices to assure the predictive

maintenance of equipment, Bucharest, Romania, 23-25

March 2017. IEEE explore Digital Library.

Saini, M and Shlonsky, A (2012) Systematic synthesis of

qualitative research. 1st edition ed. United Kingdom:

Oxford University Press.

Stuart Lansburg, Jean-Michel Cocciantelli, "Ni-Cd Field

Experience Confirms Low Maintenance and Their

Operating Characteristics in Telecom Applications",

Proceedings of Intelec, 2001.

Takao Kawakami, Ryoji Sasaki, "The study on

Telecommunication development plan in Ethiopia",

JICA and ETC, 2002.

IoTBDS 2020 - 5th International Conference on Internet of Things, Big Data and Security

176