Techno-economic Feasibility Analysis of Replacement of Existing

Power and Steam Generators at Arun LNG

Bondan Adi Nugroho, Dijan Supramono, and Widodo Wahyu Purwanto

Department of Chemical Engineering, Engineering Faculty, University of Indonesia, Indonesia

Keywords: Power Plant, Steam Generator, Tariff, Fuel Gas, Availability.

Abstract: Demands for electricity and steam at the Arun LNG Refinery Gas Processing Facility are 158,400,000

kWh/year and 180 tons/hour of steam produced by 3 (three) units of Gas Turbine Generators (GTGs) and 3

(three) units of Heat Recovery Steam Generators (HRSGs) at the generating unit at Arun Gas Processing

Plant. The problem with electricity and steam generations at present is the high gaseous fuel requirement,

namely 13.14 MMSCFD to process 30 MMSCFD of gas sold. The scarce availability of spare parts and

several time operation interruptions (blackout) are also problems in the existing plant. The purpose of this

research is to build a new generation unit at the separated from the existing GTGs and HRSGs with more

efficient electricity generation and steam generation units and high level of availability. Replacement is

carried out based on analysis of various generation alternatives, namely new GTG units & HRSG and boiler

unit, new Gas Engine Generator (GEG) units & HRSG and a boiler unit, and connection to PLN (State

Electricity Company) electricity network + a boiler unit. The results show that the installation of new GTG

units & HRSG and a new boiler would require the gas fuel of 12.88 MMSCFD, which is 0.26 MMSCFD less

than that of existing generations, and offer the least electricity generation tariff of $ 0.221/kWh and steam

generation tariff of $ 0.0019/ton using cash flow economic method. The installation can support the operation

and gas production activities at the ArunGas Processing Plant until the end of contract for the next 19 years.

1 INTRODUCTION

In carrying out its activities, the Arun Gas Processing

Plantconsumes 158,400,000 kWh of electricity/year

and 180 tons of steam / hour. The Arun power plant

managed by PertaArun Gas (PAG) has 8 GTG units,

with a capacity of 22 MW each installed in 1972. Six

of the GTGs have been equipped with HRSG to

produce steam. Currently operating, to meet plant

requirements or utility demand, three GTG units are

operated for gas processing and regasification needs.

In operating the three GTG + HRSGs, 9.64

MMSCFD is needed for GTG and 3.5 MMSCFD for

HRSG as supplementary firing. In fulfilling the

electricity and steam generation, 13.14 MMSCFD of

gas consumed as fuel to meet the demand for

electricity and steam at Arun Gas Processing Plant is

very large compared to gas sales of 30 MMSCFD.

The low availability of power and steam is also a

problem in itself, indicated by several times of black

out.

In the present research, the need for gas

processing operations at the Arun Gas Processing

Plant is expected for the next 19 years (block contract

ends), the replacement of the current GTG and HRSG

with replacement units to meet electricity and steam

needs efficiently and with a high level (Ganapathy,

1996) of availability so that Gas and Condensate

production in Block B Field and NSO Field can take

place.

2 THEORETICAL FRAMEWORK

2.1 GTG Conditions Benchmarking

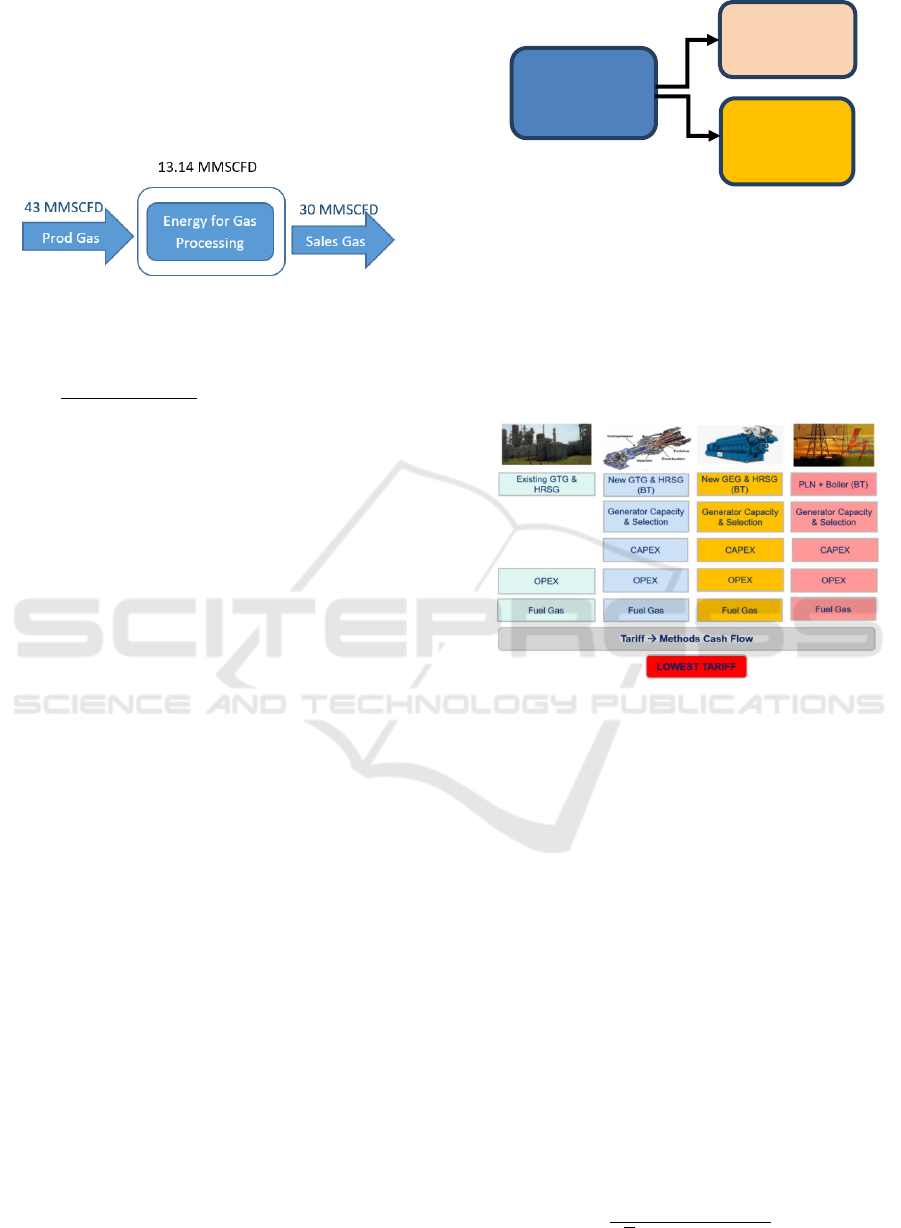

Figure 1 shows a diagram of the utility fuel gas

requirements used for gas processing at the Arun Gas

Processing Plant.In comparison, the JOB Tomori

Sulawesi field requires 6 MW of electricity to

produce 340 MMSCFD, while processing gas at Arun

Gas Processing Plantrequires 2.5 MW of electricity to

process 20 MMSCFD of gas. However, an absolute

comparison cannot be used because the gas

processing facility at the plant is very large in size,

12

Nugroho, B., Supramono, D. and Purwanto, W.

Techno-economic Feasibility Analysis of Replacement of Existing Power and Steam Generators at Arun LNG.

DOI: 10.5220/0010786500003317

In Proceedings of the 2nd International Conference on Science, Technology, and Environment (ICoSTE 2020) - Green Technology and Science to Face a New Century, pages 12-16

ISBN: 978-989-758-545-6

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

which was designed for 450 MMSFD of gas/train but

only processes 30 MMSCFD of sold gas at present.

Therefore, in order to reduce the amount of electricity

and steam generated, it is necessary to replace the

oversized equipment into equipment that suits the

current gas production needs

.

Figure 1. Energy requirement for gas processing

The ratio of energy requirement to gas sold is

13.14 𝑀𝑀𝑆𝐶𝐹𝐷

30 𝑀𝑀𝑆𝐶𝐹𝐷

100% 43.8 %

2.2 Heat Rate Comparison

With a fuel gas gross heat value (GHV) specification

of 1074,774 BTU/SCF to produce power demand of

20,600 kWh requiring gas fuel of 9.46 MMSCFD,

then the heat rate of the Gas Turbine Generator is

18.503 BTU/kWh. This is much larger than the GTG

GE Frame-3 specification GHV which is 3,113

kcal/kWh or 12,345.12 BTU/kWh. In other words,

the existing GTG is not efficient.This paper will

discuss tariffs of power and steam generations in

which for the need of very large steam, Combine Heat

and Power (CHP) option is feasible to apply. This

paper includes an alternative use of electricity from

PLN which will be combined with a boiler to find out

whether this alternative is cheaper than the

conventional CHP.

2.3 Separation from Existing GTG

Arun Power Plant generates 30.6 MW with a Fuel

Consumption of 14.5 MMSCFD. The power

generated is intended for gas processing and

regasification with load distribution shown in Figure

2.Therefore, replacing the existing GTG for gas

processing also means separating the generation

system to be built from the Arun Power Plant units

and also separating the load distribution network such

as substation and distribution cables. However,

because steam is required and can be created in a

HRSG, a new unit must be equipped with steam

generation unit either as a new HRSG unit or a boiler

to produce 180 tons/hour of steam.

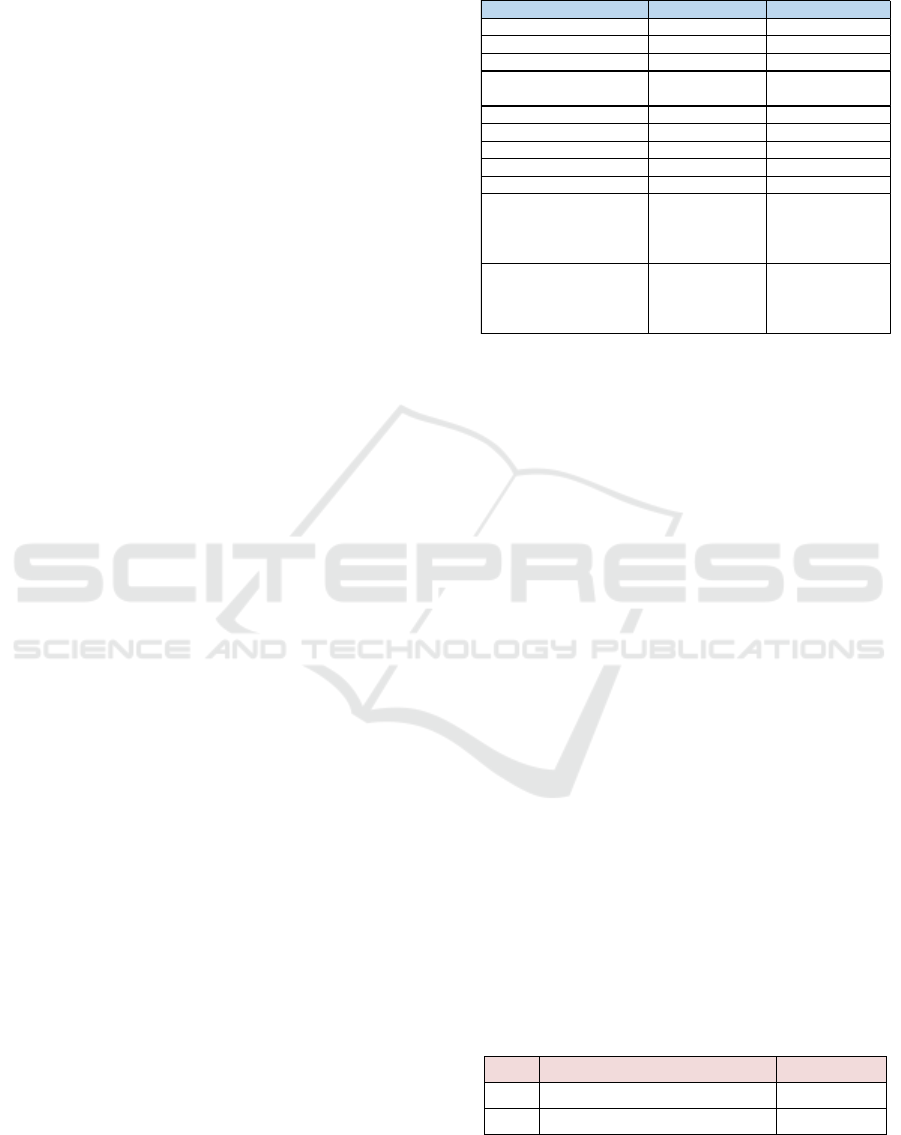

Figure 2. Load Distribution at Arun LNG Plant

The alternative generation utilities chosen were a

new GTG and HRSG unit + Boiler, a new Gas Engine

Generator (GEG) and HRSG + Boiler, and PLN

electricity + Boiler. Figure 3 shows calculation

aspects for technoeconomic calculation. From the

economics point of view and availability analysis, the

best option is chosen among those alternatives.

Figure 3. Generator Replacement Methods.

3 RESEARCH METHODS

Figure 3 represents flow for selecting alternative

generator with the smallest tariff to be chosen to

replace the existing power plant. Steps of calculations

are as follows.

3.1 Find New Generator Capacity

From the data on the total load of Arun LNG Plant

equipment can be found:

1. Continuous Load (kWh)= 20,600 kWh

2. Total Peak Load (kWh)

Peak Load (kW) =

x.Continuous(kW)+y.Intermittent(kW)+z.Sta

ndby (kW)

(1)

3. Biggest motor starting

𝐼

𝑘𝑊

1000

√

3 𝑉𝜂𝑐𝑜𝑠𝜑

(2)

Power Plant

Unit-90 30.6

MW+ 180 TPH

Steam

Regasification

10 MW

Gas Processing

20.6 MW + 180

TPH Steam

Techno-economic Feasibility Analysis of Replacement of Existing Power and Steam Generators at Arun LNG

13

𝐼

600% 𝐼

(3)

where:

𝐼

=Motor starting current (A)

𝐼

=Motorrated current on full load(A)

η =Motorrated efficiency on full load(%)

cos φ=Motorrated power factor on fullload(%)

V=Ratedvoltage(V)

𝑘𝑊

=RatedkW (kW)

3.2 Select Generators

Table 1 shows a comparison of the efficiency,

capacity, availability and performance of each

Combine Heat & Power (CHP) technology

currently. With the availability of new generators set

at 99%, from the data in Table 1, the availability of

a GTG unit is 72% - 99%. By taking the average

availability value of 85.5%, it takes more than one

GTG unit to produce 99% availability. The similar

case for GEG. With 86 - 98 % availability, it needs

more than one GEG unit to achieve 99%.

3.3 Calculate CAPEX and OPEX

CAPEX can be calculated using Table 1 or by market

survey. OPEX can also use Table 1 or use general

Operation and Maintenance (O&M) cost for power

generation such as time to Major Inspection.

PLN tariff can be calculated using this formula

𝑎𝑏

𝑐 𝑒

𝑎𝑏

𝑓

(4)

Where

a is the price of non-subsidized electricity

b is the premium customer prices

c is the peak load

d is the peak load price

e is the duration of the peak load

f is the total hours outside peak load

Table 1. Comparison of CHP Technology Parameters, Cost,

and Performance

Source: Catalog of CHP Technologies, EPA, 2017

3.4 Calculate Fuel

From Specification of Generator with current Gross

Heat Value, fuel gas consumption for Power

Generation of Arun LNG Plant can be found. Exhaust

gas from power generation can be used to produce

steam at HRSG with HYSYS simulation (Paoli,

2009). Boiler needs to satisfy steam requirement

at 180 tons/h with 10.5 kg/cm

2

pressure (Oland,

2004).

3.5 Calculate Tariff

Tariff calculation needs basis data to obtain weighted

average cost of capital (wacc). From wacc value,

investment rate of return (irr) on free cash flow can be

determined

4 RESULTS AND DISCUSSION

4.1 Generator Capacity

From Peak Load and Motor Starting calculation,

generator capacity can be summarized in Table 2 and

for Arun LNG Plant load is 20,939.81kW.

Table 2. Dedicated Load Generator Capacity

No.

Description kW

1 Peak Load 20,939.81

2 Load during motor starting 17,926.23

Technology ReciprocatingEngine GasTurbine

ElectricEfficiency(HHV) 27‐41% 5‐40%

TotalEfficiencyCHP(HHV) 77‐80% near80%

EffectivePowerEfficiency 75‐80% 75‐77%

SpecificCapacity 0.005‐10

0.5‐uptohundred

MW

InstallationCHPPrice($/kWe) 1,500‐2,900 670‐1,100

Non‐fuelO&Mprice($/kWhe) 0.009‐0.025 0.006to0.01

Availibility 96‐98% 72‐99%

Timetooverhaul 30,000‐60,000 >50,000

FuelPressure(psig) 1‐75 n/a

FuelGas

NaturalGas,biogas,

LPG,sourgas,waste

industrialgas,

manufacturedgas

all

OutputThermal

RoomHeater,Hot

water,chiller,LP

steam

processsteam,

enviromentheater,

hotwater,water

cooler

ICoSTE 2020 - the International Conference on Science, Technology, and Environment (ICoSTE)

14

4.2 Fuel Consumption

4.2.1 Two Units of New GTG + HRSG

With 2 units of GTG running simultaneously, each

unit of GTG carries 50% of the load. In this scheme,

the ArunGas Processing Plant burden, both dedicated

and sharing, will be taken by the new GTG units with

capacity of 20,600 kW each.In the market, a generator

capacity that is close to 20,600 kW is a GTG brand

LM2500 DLE with a capacity of 21.8 MW chosen

(GE Power, 2019). Fuel Gas Consumption can be

calculated by HYSYS Simulation.From the

simulation obtained, one unit of LM2500 DLE with

ambient air flow input of 123 tons/h can produce a

generation load (net power) of 10,300 kW with fuel

gas consumption of 2.51 MMSCFD. The exhaust gas

of this generation is hot with a temperature of 539

o

C

which will be used to produce steam in a HRSG. The

steam capacity generated in the HRSG is 24.34 tons/h

per unit. Net efficiency GTG from simulation is 40.29

% which is higher from the specification because it

neglects other losses like mechanical losses.Due to

the demand for steam at the Arun Gas Processing

Plant as much as 180 tons/h, an additional boiler unit

is required to meet the demand for steam.

With 2 units of GEG running simultaneously,

each unit of GTG will carry 50% of the load. In this

scheme, Arun LNG Plant burden, both dedicated and

sharing, will be taken by the new GEG units with a

capacity of 10,300 kW each.In the market, a generator

capacity close to 10,300 kW is a GTG brand

Jenbacher J920 flextra with a capacity of 10.4 MW

chosen. Fuel Gas Consumption can be calculated with

HYSYS Simulation by using 2 unit J920 Flextra with

ambient air flow input of 10.39 tons/h, the units can

produce a generation load (net power) of 5,000 kW

with fuel gas consumption of 1.19 MMSCFD. The

exhaust gas is hot (609

o

C) which will be used to

produce steam in a HRSG. The steam capacity that

can be generated in HRSG is 3.001 tons/h per unit.

Due to the demand for steam at Arun Plant gas

processing facility of 180 tons/h, an additional boiler

unit is required.

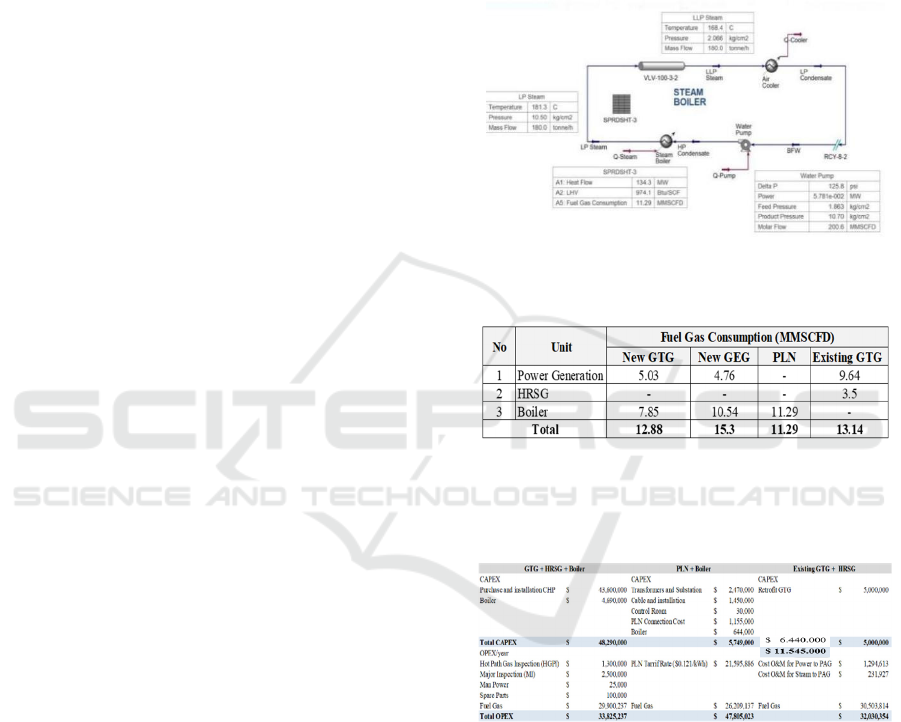

4.2.2 PLN + Boiler

Using PLN power, grid installation capacity for peak

load is 20,939.81 kWh. With premium costumer, the

power comes from 150 kV transmission line from two

sub-stations in order to maintain high availability, all

steam will be produced by boilers. The schematic

diagram of boiler system in this alternative is shown

in Figure 4. Fuel Required is 11.29 MMSCFD. From

calculations and simulations, fuel gas consumption in

each alternative to produce 20,600 kW power and 180

tons/h of steam is as shown in Table 3.For economic

evaluation based on fuel gas consumption, GEG

alternative using GEG + HRSG+ Boiler uses 15.3

MMSCFD, which is higher than existing generation

of 13.14 MMSCFD in addition to CAPEX for new

unit. So, GEG alternative will be taken out from

alternative option.

Figure 4. HYSYS Simulation of Boiler

Table 3. Fuel Gas Comparison for Alternative Replacement

4.3 CAPEX and OPEX Calculation

Table 4. CAPEX and OPEX Comparison for Alternative

Replacement

Table 4 shows details of Capex and Opex as

alternatives. Hot gas path inspection of new GTG will

be carried out every 25,000 hours or 2.89 years and

major inspections will be carried out every 50,000

hours or 5.7 years. For daily operation of the GTG +

HRSG and Boilers, only manpower is needed to

perform visual inspections at a budget of $

25,000/year and spare parts is allocated $

100,000/year.

Techno-economic Feasibility Analysis of Replacement of Existing Power and Steam Generators at Arun LNG

15

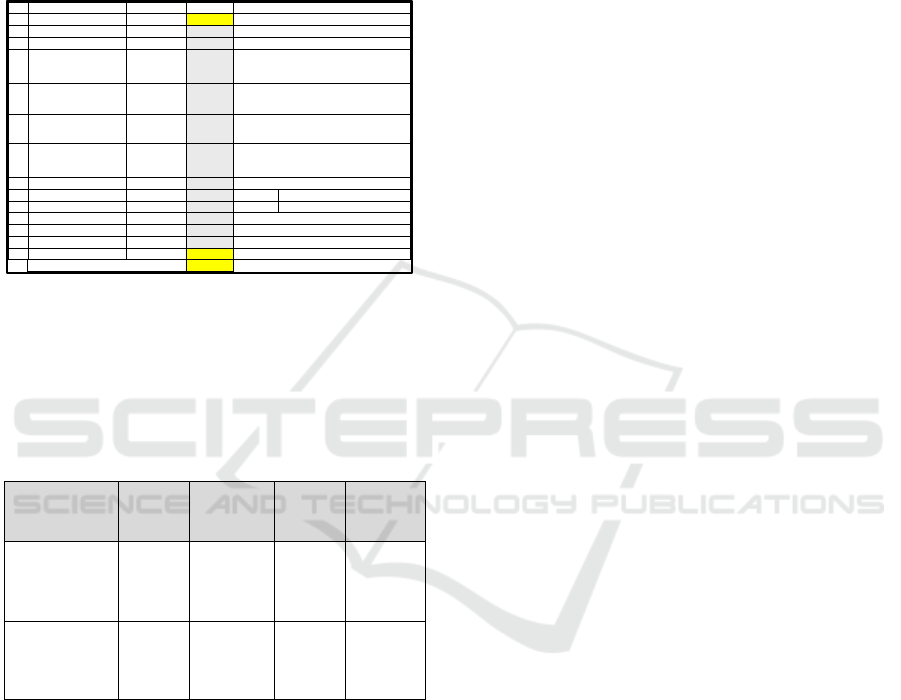

4.4 Tariff Calculation

Table 5 shows an example of IRR calculation from

New GTG + HRSG + Boiler with Debt share of 70%

and Equity share of 30% having WACC 8.78%. IRR

is 11%.

Table 5. IRR Calculation GTG

With free cash flow method, tariffs for Power and

Steam can be obtained using data of CAPEX and

OPEX (Lazard, 2017). With 19 years of operation and

the expected running of 360 days to produce power

and steam, then the tariffs for each alternative is as

shown in Table 6.

Table 6. Tariff Comparison for Alternative Replacement

Comparison GTG &

HRSG +

Boiler

GEG &

HRSG +

Boiler

PLN +

Boiler

Existing

GTG +

HRSG

Power Tariff

(USD/kWh)

0.221 0.282 0.310 0.205

Steam Tariff

(USD/ ton)

0.0019 0.0025 0.0027 0.0018

5 CONCLUSION

Alternative GTG units & HRSG + a boiler offer

electricity tariff of $ 0.221/kWh and a steam cost of

$ 0.0019/ton. The largest contributor to the tariff is

the purchase of units and their installation costing $

48,290,000, with a fuel gas consumption of 12.88

MMSFD.

Alternative GEG units & HRSG + a boiler offer an

electricity tariff of $ 0.282/kWh and a steam cost of $

0.0025/ton. The largest contributor to the tariff is the

use of fuel to produce steam in the boiler which

reaches 15.3 MMSCFD, greater than the current fuel

consumption. Moreover, operating cost of GEG is

high due to frequent maintenance schedules.

Alternative connection to PLN + a boiler offer an

electricity tariff of $ 0.31/kWh and a steam cost of $

0.0027/ton. The largest contributor to the tariff is the

PLN's tariff costing $ 21,595,886/year. Steam fuel

cost for boiler is $ 26,209,137/year. Alternative GTG

& HRSG + a boiler offer the least tariffs of both

electricity and steam generated compared to other

alternative units. Replacement of the existing GTG

unit and HRSG could be more economical when

applying steam descent activities at a gas processing

facility. This is because most of the generation

alternatives require a higher consumption of gas fuel

to produce steam compared to that for electricity

generation

.

REFERENCES

CHP Combine Heat and Power Partnership, 2017,

Catalogue of CHP Technologies, EPA.

Clarke Energy, 2019, Combined Heat and Power (CHP) –

Cogeneration,

Ganapathy, V. 1996. Heat-Recovery Steam Generators:

Understand the Basics. ABCO Industries.

GE Power. 2019. lm2500 50hz Fact Sheet Product

Specifications, American Accounting Association,

Committee on Concepts and Standards for External

Financial Reports, Statement on Accounting Theory and

Theory Acceptance. Sarasota.

Godswill, U. Megwai, R. 2016. A Techno‐Economic

Analysis of Biomass Power Systems Using Aspen Plus,

International Journal of Power and Renewable Energy

Systems (IJPRES), Vol. 3, Issue 2, pp. 25-36.

Lazard, 2017, Lazard’s Levelizedcost of Energy Analysis,

Version 11.0.

Oland, C. B., 2004, Guide to Combined Heat and Power

Systems for Boiler Owners and Operators, Oak Ridge

National Laboratory.

Paoli, N., 2009, Simulation Models for Analysis and

Optimization of Gas Turbine, MS Thesis in Chemical

Engineering, Universita di Pisa.

PHE NSB & PHE NSO, 2020, Daily Operation Routine

(DOR).

PHE NSB & PHE NSO, 2017 & 2018, Laporan Evaluasi

Pemeliharaan.

PHE NSB & PHE NSO. 2020. Lab Analysis Report.

No. Description Numbers

a TotalNilaiBasisAset,US$Dollar

RAB 49.370.123

b AssetDepreciation,(Year)

ELA 19

cinflationRate

Inf 1,31%

d RiskFreeRate,(%) Rf 2,13%

e

BasePremiumforMatureEquity

Market,(%)

BPMEM 5,70%

f

InternalCountryRiskPremium

(Indonesia)

ICRP 3,24%

g Beta β 1,079

hCostofEquity,(%)

Coe

11,78%

i DebtFunding,US$Dollar DB 34.559.086 70%

j EquityFunding,US$Dollar EQ 14.811.037 30%

k InterestOfDebt,(%) Indebt 10,00%

l IncomeTax,(%) IT 25,00%

m CostofDebt,(%) Cod 7,50%

n WACC,(%) WACC 8,78%

IRRonFreeCashFlowshouldbeequaltoIRR 11,00287800%

5YearAverageUSInflation

5YearAverage(1January2012‐1January2017)RiskFreeReturn

onInvestment(USTreasuryBond)10Years

Referensi

CAPEXCalculation

Assumption

WACC=(DB/(DB+EQ))*Cod+(EQ/(DB+EQ))*Coe

Asumsi70%Debt

Asumsi30%Equity

Assumption

5YearAverage(1January2012‐1January2017)Sizeoffluctuation

ininvestmentportfoliosorindividualinvestmentinstruments

com

p

aredtothemarket

(

stockmarket

)

Coe=Rf+β*(BPMEM+ICRP)

UU36of2008Article17Paragraph2

Cod=InterestofDebtx(1‐IncomeTax)

Indonesia5yearaveragecountryriskpremium2013‐2017

Average5YearsBasePremiumformatureequitymarket2013‐

2017

ICoSTE 2020 - the International Conference on Science, Technology, and Environment (ICoSTE)

16