Evaluation of Physical Properties of Volcanic Scoria Powder Particles

as Concrete Mineral Additives

Willy Hermann Juimo Tchamdjou

1

*, Moulay Larbi Abidi

2

, Toufik Cherradi

2

,

Azzeddine Bouyahyaoui

2

and Didier Fokwa

3

1

Department of Civil Engineering and Architecture, National Advanced School of Engineering, University of Maroua,

Maroua, Cameroon

2

Department of Civil Engineering, Mohammed School of Engineers, Mohammed V University of Rabat, Rabat, Morocco

3

Department of Civil Engineering, Higher Technical Teachers’ Training College, University of Douala, Douala, Cameroon

Keywords: Volcanic scoria powder, particle size distribution, specific density, surface area and particle morphology.

Abstract: This study presents some physical properties relevant to volcanic scoria powder characterization. Specific

information on particle shape has been obtained using by 2-D images. The image analysis was used to identify

key controls on particle morphology, six shape parameters: elongation, circularity, solidity, roughness,

bluntness and luminance have effectively accounted for the morphological variance of powder particles. The

particle shape is evaluated according to these six factors. These parameters are scaled to values between 0 and

1.0. Morphological changes associated with variations in the relative size and shape of particles have been

quantified. According to results reporting by many authors, it is well known that particle shape analysis,

which includes the full range of available grain sizes can contribute not only to the measurements of particle

size and shape. But also in providing information on size-dependent densities, specific surface area by Blaine

air permeability and specific surface area by laser diffraction.

1 INTRODUCTION

Volcanic activities are common phenomena in

various parts of the world. Many deposits of volcanic

materials are unexploited. Volcanic scoria is a natural

volcanic material that is used in many areas such as

chemical granular additives, abrasives, dental

polisher, cosmetics, pigment, textile, cement,

ceramic, and glass industries. In these industries, fine

grinding of volcanic scoria granular is generally

needed. On the other hand, the development of high-

performance cement-based materials like self-

compacting concrete and reactive powder concrete

has increased the research on inert and semi-inert

powders. Today, the characterization of these

materials is an emerging subject (Juimo et al, 2017;

Tchamdjou et al, 2017a; Tchamdjou et al, 2017b;

Bouyahyaoui et al, 2018; Bouglada et al, 2019).

There are many studies focused on the

characterization of maximum packing of

supplementary cementitious materials (SCMs) in

cement-based systems. The related works generally

classified the factors that affect the matrix

compactness into four groups: particle morphology,

particle packing, interparticle spacing and matrix

rheology (Felekoglu, 2009; Arvaniti et al, 2015a;

Bouyahyaoui et al, 2018). Particle size and particle

shape are closely related to the reactivity of SCMs.

Industrial by-products, their partial replacement of

cement in concrete mixes represents a substantially

offset by the consequent environmental impact. The

size and shape characterization of irregular particles

is a key issue in many fields of science (Bagheri et al,

2015) and engineering (food, pharmaceutics,

minerals, biology, astronomy,…), which is often

associated with large uncertainties (Felekoglu, 2009;

Bagheri et al, 2015; Liu et al, 2015; Bouyahyaoui et

al, 2018; Dioguardi et al, 2018). The important

characteristics of powders are the particle size

(granulometry) and particle shape (morphology).

Technological properties of powders depend on their

granulometry and particle morphology (Pavlović et

al, 2010).

To date, only a few studies have been published

on particle size and particle shape parameters of

mineral powders using as SCMs (Hackley et al, 2004;

Felekoglu, 2009; Michel and Courard, 2014; Bagheri

et al, 2015; Klemm and Wiggins, 2017; Bouyahyaoui

et al, 2018). Technological properties of mineral

powders (bulk density, flowability, surface area, etc.),

as well as the potential areas of SCMs, depend on

these characteristics (Mikli et al, 2001). It also has

been known that powders may improve the particle

packing density of cementitious system, and

superplasticizers help to obtain the desired

rheological properties by increasing the workability

without causing segregation in fresh state (Bouglada

et al, 2019) and improve the mechanical properties

and durability by reducing the water/cement ratio.

Some of these powder materials are either industrial

by-products or unprocessed materials. They provide

environmental relief because industrial by-products

are being recycled and hazardous emissions released

into the atmosphere due to cement production are

reduced, raw materials are preserved and energy is

saved (Felekoglu, 2009). Besides, inert and semi-inert

powders such as grounded volcanic scoria can be

alternatively employed for high-performance mortar

and concrete mixture designs (Juimo et al, 2017).

More recent works have addressed the effects of

volcanic scoria powder addition on rheological

properties of cement paste (Tchamdjou et al, 2017a;

Tchamdjou et al, 2017b; Bouglada et al, 2019).

Powders are problematic materials in the

application of particle size analysis (Felekoglu,

2009). Generally, sizing techniques work best over a

limited size range. The optimum range of particle size

analysis varies according to many factors, including

detector sensitivity and the assumptions associated

with the underlying principle of measurement

(Felekoglu, 2009; Arvaniti et al, 2015b). Most

commercial methods are designed specifically for a

range of particle size, and work best with

homogeneous spheres. The degree to which

irregularity affects the results vary with the technique

employed, and is not well understood or exactly

accounted for in many methods (Ferraris et al, 2002;

Orhan et al, 2004; Hackley et al, 2004; Felekoglu,

2009; Bagheri et al, 2015). The morphology of raw

powder includes its particle size distribution (PSD),

specific surface area (𝑆

or 𝑆

) and particle shape.

The PSD can be determined by sieves analysis, laser

diffraction (LD) and image analysis (IA). The

industrial method to determine 𝑆

is Blaine Air

Permeability test (Niesel, 1973; Arvaniti et al,

2015a). The evaluation of particle shape needs

complex techniques such as the LD and the IA

(Bagheri et al, 2015; Arvaniti et al, 2015b). Individual

particle features should be captured by IA to derive

the shape descriptors (Ilic et al, 2015; Abazarpoor et

al, 2017; Bouyahyaoui et al, 2018).

In this paper, in addition to the PSD by the LD,

the particle shape and surface morphology of volcanic

scoria powders (ground at different grades) were

analyzed by using IA. Some conventional commands

of image IAs were employed. Accurate

measurements of volcanic powder particle

morphology are critical to improving both the

understanding of packing processes and the ability to

predict particle behavior and the workability of

mortar and concrete when using as SCMs.

2 EXPERIMENTAL

2.1 Powders Samples

Volcanic materials used in this experimental research

were supplied from natural deposits of ‘Djoungo’

(Cameroon). The choice was based on their abundant

availability and accessibility. Four volcanic scoria

groups according to the colour of scoria (black, dark-

red, red, and yellow) have been collected. The

collected sample was firstly sieved using the 5 mm

stainless steel sieve of 20 cm diameter to separate

large volcanic scoria (5–100 mm in order) to fine

volcanic scoria (≤5 mm). Volcanic scoria aggregates

used were between 20 to 50 mm particle size. The

volcanic scoria sample was performed on the material

dried in an open air environment during 24 h and in

the oven at 105 °C during 24 h for the removal of

moisture in the rocks (Juimo et al, 2016).

The grinding was performed in a disk mill. Each

powder obtained has been described by a two-

component code designation: the letter reflecting

powder color as black (B), dark-red (DR), Red (R)

and yellow (Y) followed by the ‘np’ reflecting natural

powder or natural pozzolan (Juimo et al, 2017).

2.2 Measurement Methods

2.2.1 Gas Pycnometer and Blaine Air

Permeability (Blaine Fineness, BF)

The density of mineral powders or SCMs is employed

in particle size analysis when there is a need to

convert from volumetric particle size measurements

to mass percentages of particles in a given size range

(Arvaniti et al, 2015a). In this work, the density of

powders was performed on a Gas Pycnometer. This

method measures the density by determining the

volume of inert gas that can be introduced into a

sample chamber of a defined size which contains a

known mass of powder. Automatic Gas Pycnometer

has long been identified as the instrument of choice

to accurately measure the true density of solid

materials by employing Archimedes’ principle of

fluid displacement, and Boyle’s Law of gas

expansion (Niesel, 1973; EN 196-6, 2010). Helium

inert gas, rather than a liquid, is used since it will

penetrate even the finest pores and eliminate the

influence of surface chemistry. This ensures quick

results of the highest accuracy. Helium is generally

used as the displacement gas due to its size and

generally inert behavior. Other gases, such as

nitrogen are also routinely used with no measurable

sacrifice of performance. The detail data of testing

conditions and Gas Pycnometry test results of the

measurement processes are present in Table 1.

Benefits of the use of Helium Gas Pycnometer are:

non-destructive analysis, fast and accurate results (in

as little as 1 minute), reliable and reproductive results,

a wide range of sample volumes and configurations,

the instrument has a small footprint and uses a small

amount of gas-pressurized (smaller than 20 Pa, as

shown the Table 1).

The fineness of the grinding can be determined

according to the Blaine technique and is indicated as

the specific surface. The Blaine Air Permeability

apparatus serves exclusively for the determination of

the specific surface area (𝑆

) of powders. The Blaine

fineness (BF) value is not a measure of granulometric

distribution (Means PSD). The BF can therefore be

used only to a limited degree to evaluate the

suitability of a type of test material for a certain use.

𝑆

or BF value was measured by the Blaine Air

Permeability apparatus in this study. The Blaine Air

Permeability tester is used for the measurement of the

𝑆

or BF value of powders as presented by Michel

and Courard (Michel and Courard. 2014) based on the

air permeability method. The time 𝑡 (s) necessary for

a volume of air to flow through a packed bed of

particles is recorded (Michel and Courard. 2014).

The European Standard EN 196-6 (EN 196-6,

2010) gives the evaluation of 𝑆

with Kozeny-

Carman constant by Equation (1):

𝑆

,

𝐾

𝜀

⁄

𝜌

1𝜀

𝑡

⁄

0.1

𝜂

⁄

(1)

where 𝜀 is the porosity of the packed bed of

powder, 𝜂 is the viscosity of air (Pa.s) and 𝜌

the

density of the solid (g/cm

3

). The constant 𝐾

(g

1/2

.cm

3/2

.s

-1

), which is a characteristic of the

apparatus, is determined with a calibration cement

powder linked up to standard reference material.

Assuming that the air is compressible (Michel and

Courard. 2014), the Kozeny-Carman constant can be

used to give a more accurate relationship for the

apparatus constant by Equation (2).

𝐾

0.1𝜌

𝐷

𝑘𝐶

𝐷

𝐿

(2)

where 𝜌

is the density of the manometer fluid

(g/cm

3

), 𝐷

and 𝐷

are the inner diameters of the

cell and of the tube (cm), respectively, 𝑘 is the

Kozeny constant, 𝐿

is the height of the packed

bed of powder (cm). 𝐶

is a term which takes into

account air compressibility due to pressure drop

between the opposite sides of the sample; it depends

on atmospheric pressure and geometrical

characteristics of the instrument. Kozeny constant (𝑘)

is related to the shape of particles and the bed

tortuosity.

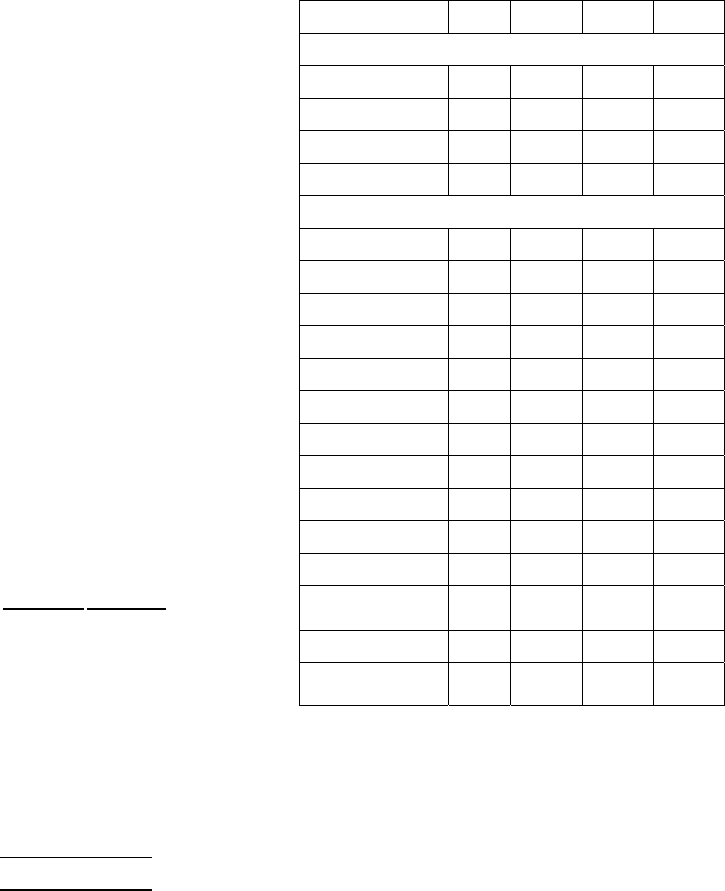

Table 1: Helium gad pycnometer and Blaine air

permeability testing conditions, and results.

Test/Parameter Bnp DRnp Rnp Ynp

Helium Gas Pycnometer (*mean of 04 measurements)

Weight (g) 1.400 1.698 1.956 1.776

Sample (Vol.) 8.676 8.676 8.676 8.676

Ref. (Vol.) 6.321 6.3215 6.3215 6.3215

Density* (g/cm³) 2.888 3.014 2.920 3.029

Blaine Air Permeability (°mean of 03 measurements)

T(°C) 21.6 21.6 21.6 22.1

HR (%) 65.5 65.5 65.5 64.5

Weight (g) 2.68 3.35 2.90 2.94

Porosity 𝜀

0.50 0.41 0.47 0.48

𝜂 (x10

-6

Pa.s)

18.29 18.29 18.29 18.29

𝜌

(g/cm

3

)

1.04 1.04 1.04 1.04

𝐷

(cm)

1.268 1.268 1.268 1.268

𝐷

(cm)

0.590 0.590 0.590 0.590

𝑘 (cm.s

2

)

340 340 340 340

𝐿

(cm)

1.478 1.479 1.478 1.480

𝐶

(x10

3

Pa)

99.86 99.86 99.86 99.19

𝐾

(g

1/2

.cm

3/2

.s

-1

)

2.49 2.49 2.49 2.49

Time t (s) 0.74 4.21 0.45 0.05

𝑆

, Blaine°

(cm

2

/g)

3596 4482 4674 5227

Equation (2) clearly points out that the apparatus

constant depends on several parameters including

hygrometric conditions, but also the height of a

packed bed of particles: these should be selected in

accordance with operational conditions to avoid

serious misinterpretation. That’s why they propose to

calculate Kozeny constant (𝑘) linked up to standard

reference material and to measure 𝐿

and 𝐶

for each new test (Niesel, 1973; Michel and Courard.

2014; Arvaniti et al, 2015a).

Table 1 presents also general parameters

described below as used during Blaine Air

Permeability testing of powders (Bouyahyaoui et al,

2018). The porosity of the packed bed 𝜀 of powder

during the Blaine Air Permeability testing ranges

between 0.41 - 0.50 (41 to 50 %) as reported in Table

1. Juimo et al. (Juimo et al, 2016) are reported that

VSA size between 20-50 mm can present up to 51%

of porosity. These results show that the porosity of

volcanic powder is also higher like the porosity of

volcanic scoria aggregates (Juimo et al, 2016).

According to that fact, the porosity of volcanic scoria

can be supposed to be a higher-scale porosity

(Bouyahyaoui et al, 2018).

2.2.2 Laser Diffraction (LD)

The granulometry of powders can be determined by

many methods (sieve analysis, LD, IA, etc.), but the

question is how adequately they describe the powder

granulometry (Mikli et al, 2001). Mikli et al. (Mikli

et al, 2001) reported that the evaluation of the fine

powder granulometry (with particle size less than 50

μm) is more difficult and the results of the sieve

analysis do not describe adequately the powder

granulometry. For this reason, the first method used

here to describe powder granulometry is LD. LD

which is based on a complex theory of interaction

between monochromatic light and individual

particles. This involves the detection of the angular

distribution of light scattered by a set of

monodispersed spherical particles to provide a

‘sphere’-equivalent size diameter distribution using a

reverse optical scattering-based model calculation

(Michel and Courard. 2014).

In LD, the angular distribution of light is

measured after passing through an optically dilute

dispersion of suspended particles. The LD system

determines the PSD based on a volumetric basis. The

volumes of particles are calculated using the density

of scattered laser light. This technique is widely used

in dust and mineral industry, with water and

dispersive agent to a special cell where the laser light

is sent (Felekoglu, 2009; Orhan et al, 2004). Different

optical models are commonly used to build the PSD

weighted by apparent volume (volume of an

equivalent sphere of diameter D), such as Mie theory-

based and Fraunhofer models (Michel and Courard.

2014; Varga et al, 2018).

Fraunhofer approximation is a simplified

approach and the knowledge of refractive index and

absorption coefficient is not required, since it is

assumed that the measured particles are relatively

large (over 25-30 μm - about 40 times larger than the

wavelength of the laser light) and opaque (Varga et

al, 2018). Fraunhofer approximation model was used

during the wet dispersion measurement processes.

Wet dispersion measurements were performed using

a Mastersizer 2000 instrument coupled to a Hydro

2000S wet dispersion unit. Volcanic scoria powders

were dispersed in a sodium pyrophosphate solution.

Then, the samples were transferred to a dispersion

unit that contained deionized water. LD was repeated

three times on each powder sample.

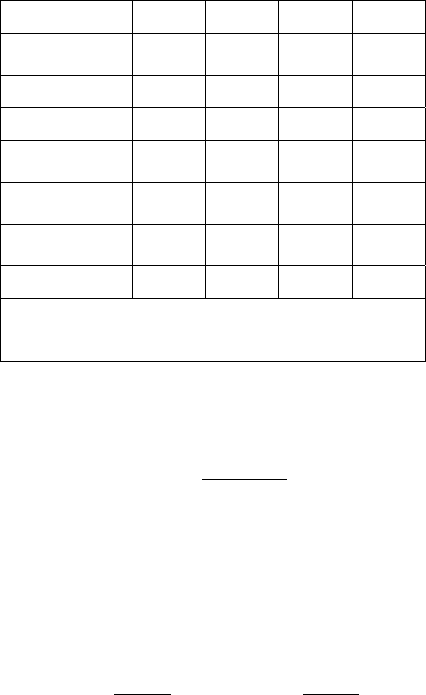

General measurement conditions by Mastersizer

2000 instrument of powders are given in Table 2. The

concentration of particles in deionized water ranged

between 0.0082 to 0.0112, with a particle refraction

index and absorption equal to 0. The refraction index

of deionized water was 1.33.

Table 2: General measurement conditions for the laser

diffraction (LD) of each powder.

Sample Name Bnp DRnp Rnp Ynp

Concentration

(%)

0.0112 0.0088 0.0104 0.0082

Dispersant RI 1.33 1.33 1.33 1.33

Stirrer speed 2,870 2,870 2,870 2,870

Ultrasonic

level

50 50 50 50

Residual –

weighted (%)

1.019 0.874 0.880 1.073

Obscuration*

(%)

15.40 17.02 18.03 14.76

Pump speed 2,870 2,870 2,870 2,870

RI : Refractive Index ; *Percentage of incident light

that is attenuated due to extinction (scattering and/or

absor

p

tion

)

b

y

the

p

articles

An estimation of another specific surface area

(𝑆

) is calculated using data from the PSD by LD

measurement, following the Equation (3).

𝐾

𝑆

6

𝜌

.𝐷

3,2

(3)

where the volume to surface mean diameter

𝐷

3,2

of the sample is calculated from the size

distribution curve by means of Equation (4), and

volume mean diameter 𝐷

4,3

in which 𝑛

corresponds to the number of particles of diameter 𝑑

.

These equations assume that the particles are

spherical and that they are not porous.

𝐷

3,2

∑

𝑛

𝑑

∑

𝑛

𝑑

𝑎𝑛𝑑𝐷

4,3

∑

𝑛

𝑑

∑

𝑛

𝑑

(4)

The 𝑆

obtained by Blaine Air Permeability was

compared by 𝑆

obtained based on data from PSD by

LD.

2.2.3 Image Analysis (IA)

IA has made a decisive breakthrough in the recent

years to become a reference technique in the field of

combined size and shape analysis of particles

(Gregoire et al, 2007; Arvaniti et al, 2015b; Jia and

Garboczi, 2016). The IA is a method for the

measurement of particle size and shape distributions.

For the measurement of particle size and

morphometric characterization, an Occhio 500 Nano

image analyzer has been used.

The Occhio 500 Nano image analyzer is an optical

analyzer for the characterization of the particle

morphology on a two-dimensional projection area

(𝐴). The instrument includes an integrated vacuum

dispersion system and a high-quality optical

component which allows assessing size and shape of

a set of dispersed particles. Few milligrams of

particles are dispersed on to a circular glass slide

which is moved in front of a collimated violet

backlighting (Michel and Courard. 2014).

Pictures of individual particles capture with a

higher resolution camera fitted with a telecentric lens

(Arvaniti et al, 2015b). A full description of the

instrument and all relevant features can be found at

Occhio’s website (http://www.occhio-usa.com).

After performing automated static IA by Occhio 500

Nano image analyzer, it is possible to identify key

controls on particle morphology using size and shape

parameters obtained. Size parameters (inner

diameter, area diameter, width, length, max distance,

geodesic length) describe a geometrical object

independently of its shape. Size factor descriptors,

illustration and definition generally employed are

presented in Table 3.

The morphology of a powder particle is

characterized by shape description (elongation,

circularity, solidity, roughness, bluntness (with the

calypter), luminance) or quasi-quantitatively, for

example, by means of geometrical shape parameters.

Shape factor descriptors, illustration and definition

generally employed are presented by Table 4.

Table 3: Size factor descriptors, illustration and definition generally employed.

Size descriptor Symbol Definition Illustration

Number of particles the of

p

owder sam

p

le

𝑁

The number of particles contained in the testing sample.

Projection area

𝐴

The perimeter of the convex hull (𝑃

) is the perimeter length

of the convex hull (envelope) that bounding the particle.

Area of the convex hull

𝐴

The area of the convex hull (𝐴

) is the area of the smallest

convex hull that contains the projection of the particle.

Perimeter of the convex hull

𝑃

The perimeter length of the convex hull (envelope) that

bounding the particle.

Inner Diameter

𝑋

The inner diameter (𝑋

) is the diameter of the maximum

inscribed circle (the maximum circle lying completely inside

the particle) or the biggest circle inscribed into the projection

area of the Particle.

Area Diameter

𝑋

The area diameter (𝑋

) is the diameter of a circle having the

same area as the particle.

Width and Length

𝑊

𝐿

The width (𝑊

) and the length (𝐿

) are defined as the

projection of the particle on the inertia ellipse minor and

major axes, respectively.

These are Feret diameters in the direction of the inertial

ellipse axes. Aspect Ratio (𝐴

) is defined as ratio of width by

length. 𝐴

Max Distance

𝑋

The max distance (𝑋

) is the maximum distance found

within the particle.

Geodesic length

𝑋

The geodesic length (𝑋

) is a better approximation of the

particle length and width of a very long and concave particle

(fiber).

Table 4: Shape factor descriptors, expression and definition generally employed.

Shape descriptor Definition / Expression

Elongation (𝐸

)

Elongation (𝐸

) is defined as the ratio between the width and the length of the particle. 𝐸

1

Circularity (𝐶

)

Circularity (𝐶

) is the degree to which the projection area of the particle is similar to a circle,

considering the smoothness of the perimeter. Values are in the range [0, 1]. 𝐶

Solidity (𝑆

)

Solidity (𝑆

) is a measure of the overall concavity of the projected area of the particle. Solidity is the

object area divided by the area enclosed by the convex hull. Values are in the range [0, 1]. 𝑆

Roundness (𝑅

)

Roundness (𝑅

) is a useful parameter for describing the similarity degree of a particle to a circle.

Values are in the range [0, 1]. 𝑅

Roughness (𝑅

)

(Occhio

Roughness)

Roughness (𝑅

) is the ratio of smooth reference to the particle projection area. This is the Roughness

index. Roughness is the amount of material to be removed from the shape before getting a smooth

surface. Values are in the range [0, 1]. 𝑅

Bluntness (𝐵

)

(Occhio

Bluntness)

Bluntness Index (𝐵

) is the expression of a “maturity in the abrasion process”. It is based on a very

accurate measure of local curvature and takes into account the fact that very acute asperities wear off

almost instantaneously as compared to blunt ones. This had been observed for a long time by

geologists working on natural stream sediments. From their observations and definitions, visual

charts (Krumbein/Sloss) had been defined and largely diffused among scientists and engineers.

Values are in the range [0, 1]. 𝐵

√

, which: 𝑉

∑

1

Luminance (𝐿

)

Luminance (𝐿

) is the mean value of the luminance of pixel inside the projection area of the particle.

The luminance is the mean greyscale level of the particle. Value ‘0’ corresponds to a black particle,

when the value increases the particle is more and more clear. Values are in the range [0, 1].

The shape parameter characterizes mainly the

shape, without considering the size (Mikli et al, 2001;

Jia and Garboczi, 2016). The description of each

parameter in Table 3 and Table 4 is based on Occhio

500 Nano image analyzer manufacturer

(www.occhio.be).

The question of representativity of analysis

samples by the IA has not been discussed in statistical

terms. The IA is based on the measurement of each

particle; the accuracy of a size and shape distribution

has to be formulated in number of particles (𝑁

) and

not in terms of sample weight or duration of the

analysis.

The adequate particle number is linked to the

shape of the distribution curve and its extension or

range (Gregoire et al, 2007). Volcanic scoria powders

tested by the IA had respectively: 24,268 particles for

Bnp, 32,302 particles for DRnp, 22,562 particles for

Rnp and 25,041 particles for Ynp. Morphology of

powder particles was performed by the IA by 2D

projection.

The bulk results data of these IA tests have been

reported firstly by Bouyahyaoui et al. (Bouyahyaoui

et al, 2018). In this work, their statistical analysis

were performed with the view to providing some

correlations between several physical properties of

particles from volcanic scoria powders for more

understandings.

3 RESULTS AND DISCUSSION

3.1 Principal Properties

The principal characteristics mean of VS powders

performed by Helium Gas Pycnometer, Blaine Air

Permeability, LD and static IA are reported in Table

5. The powders obtained have a density between 2.8

and 3.1 g/cm

3

and SSA Blaine between 3,500 and

5,300 cm

2

/g, which are comparable to OPC fineness

(Bouyahyaoui et al, 2018; Juimo et al, 2017).

By LD, mean particle diameter (Dmed), mean

particle diameter of 10% of particles D(10), median

particle diameter D(50) and mean particle diameter of

90% of particles D(90) were measured to evaluate the

efficiency of the milling process. Using the PSD data

obtain by LD and Equations (3)-(4), 𝑆

evaluated are

ranging between 4,400 to 6,000 cm

2

/g.

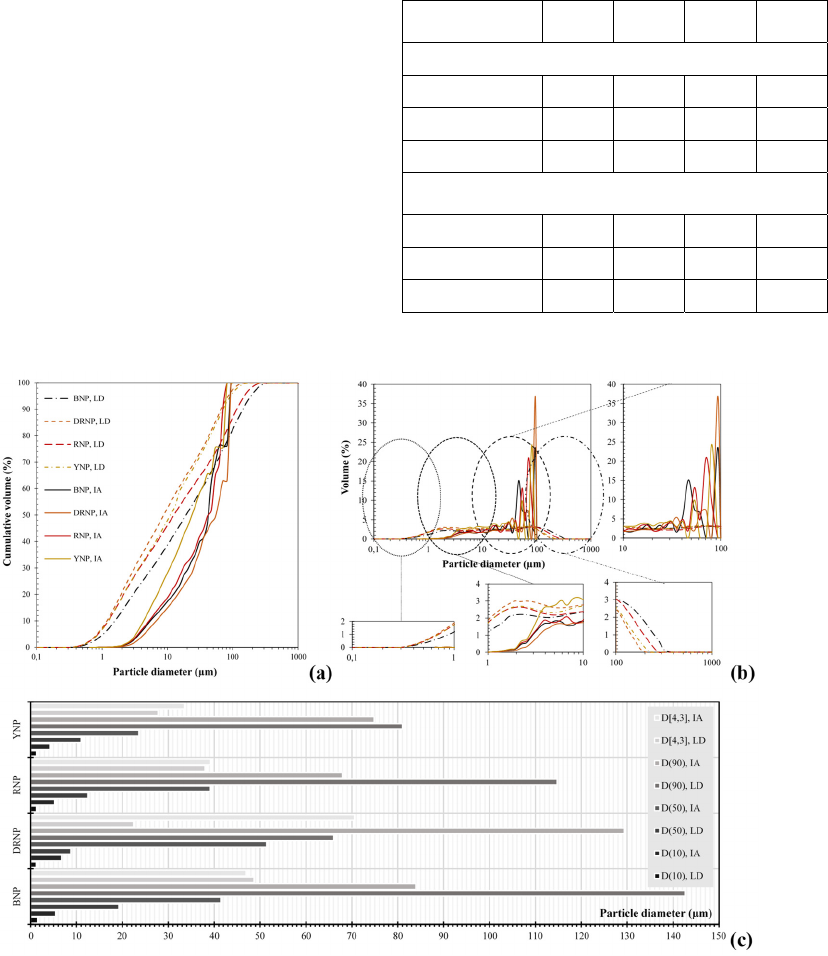

PSDs of powders were evaluated by using the LD

and IA. The PSDs of powders were plotted in Figure

1a and Figure 1b, respectively, and PSD main

significative measurement parameters are presented

by Figure 1c. In the LD technique, the angular

distribution of light is measured after passing through

an optically dilute dispersion of suspended particles.

This technique is widely used in dust and mineral

industry with water and dispersive agent to a special

cell where the laser light is sent (Felekoglu, 2009;

Orhan et al, 2004).

The inscribed disk diameter (𝑋

or 𝑋

) of each

particle is calculated in real time to build PSD curves

weighted by apparent volume (Gregoire et al, 2007),

making the assumption that particles have identical

flatness ratios, whatever their size (Michel and

Courard, 2014). Area diameter of particles was used

to plot PSD curve obtained by IA (cumulative volume

and by volume). The PSD profile shows a negligible

difference in the results by the two methods

(Abazarpoor et al, 2017). The main reasons for

differences between two PSD methods are as follows:

the considerate particle diameter by each

measurement process, the different shapes of the

particles; better insight into particles using the IA

method; insufficient dispersion of fine particles; fine

particles adhering to the bigger particles (Figure 1).

LD and 2D projection image by the IA are commonly

used the PSD measurement techniques, but the results

may not be representative of the strongly true

physical dimensions of the particles (Califice et al,

2013).

Table 5: Helium Particle Size Distribution Characteristics

of Powders by LD and IA.

Physical

p

roperties

Bnp DRnp Rnp Ynp

Granulometry by Laser Diffraction (LD)

Dmed (µm) 48.639 22.401 37.971 27.777

D[3,2] (µm) 4.706 3.318 3.674 3.621

𝑆

, LD (cm

2

/g)

4,414 5,999 5,593 5,470

Granulometry by images analysis (IA) (D: Area

Diameter

)

D

MEAN

(µm) 46.99 70.55 39.22 33.56

D

MIN

(µm) 0.593 0.593 0.593 0.593

D

MAX

(µm) 105.3 150.4 72.08 79.33

Figure 1: Theoretical PSD results by LD and IA: (a) cumulative volume curve, (b) volume curve and (c) principal PSD

descriptors.

3.2 Particle Morphology Analysis

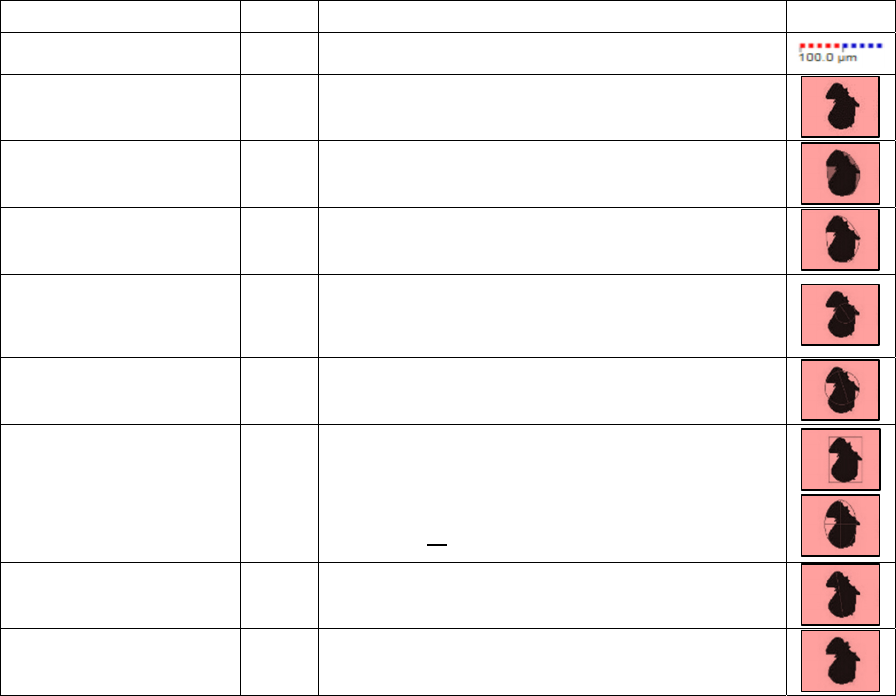

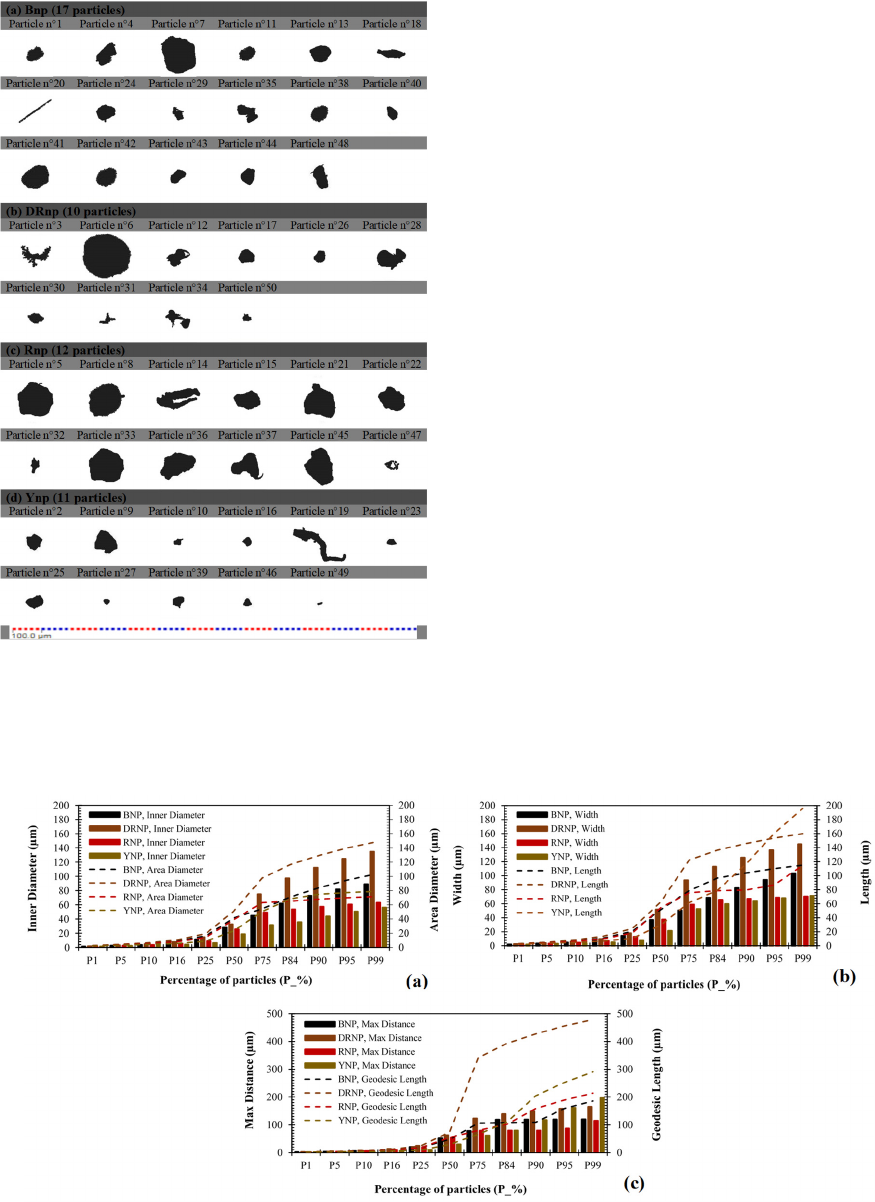

More than 50 images of powder particles were

identified. The main principal particles identified for

each powder are presented by Figure 2 (17 particles

from Bnp, 10 particles from DRnp, 12 particles from

Rnp and 11 particles from Ynp).

Figure 2: Some particles clearly identified and selected for

evaluation from the original images of powders (a) Bnp, (b)

Drnp, (c) Rnp and (d) Ynp.

The particle morphology was found to provide

reasonable accuracy for estimating the particle sizes

of highly porous particles (i.e. particles n°3, n°10,

n°12, n°14, n°47,…), where the distinction between

inter-particle and intra-particle porosity was made.

This important comment concerning inter-particle

and intra-particle porosity has been also reported by

Klemm and Wiggins (Klemm and Wiggins, 2017).

PSDs can be displayed by apparent volume and a

number or range of particles. Figure 3a shows the

distribution of inner diameter and area diameter of

particles of each powder. About 10% of the first very

fine particles of these powders have about the same

inner diameter and area diameter means. The area

diameter is always higher than the inner diameter

(Tierrie et al, 2016). The results show the inner

diameter used in the IA systems can perfectly

represent the sieve size of a particle (He et al, 2016).

Figure 3b shows the distribution of width and

length of particles of each powder. About 10% of the

first very fine particles of these powders have about

the same width and length means. The length is

always higher than the width.

Figure 3c shows the distribution of max distance

and geodesic length of particles of each powder.

About 5% of the first very fine particles of these

powders have about the same max distance mean and

geodesic length mean. The geodesic length is

generally always higher than the max distance.

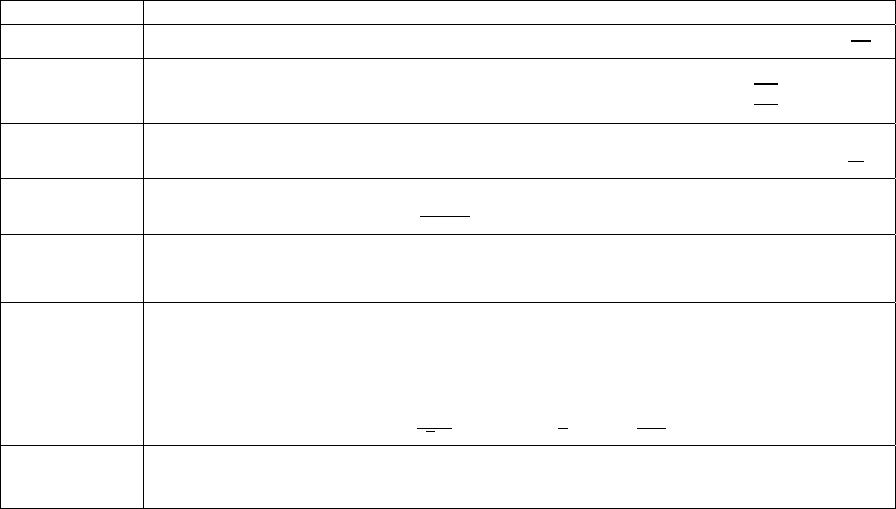

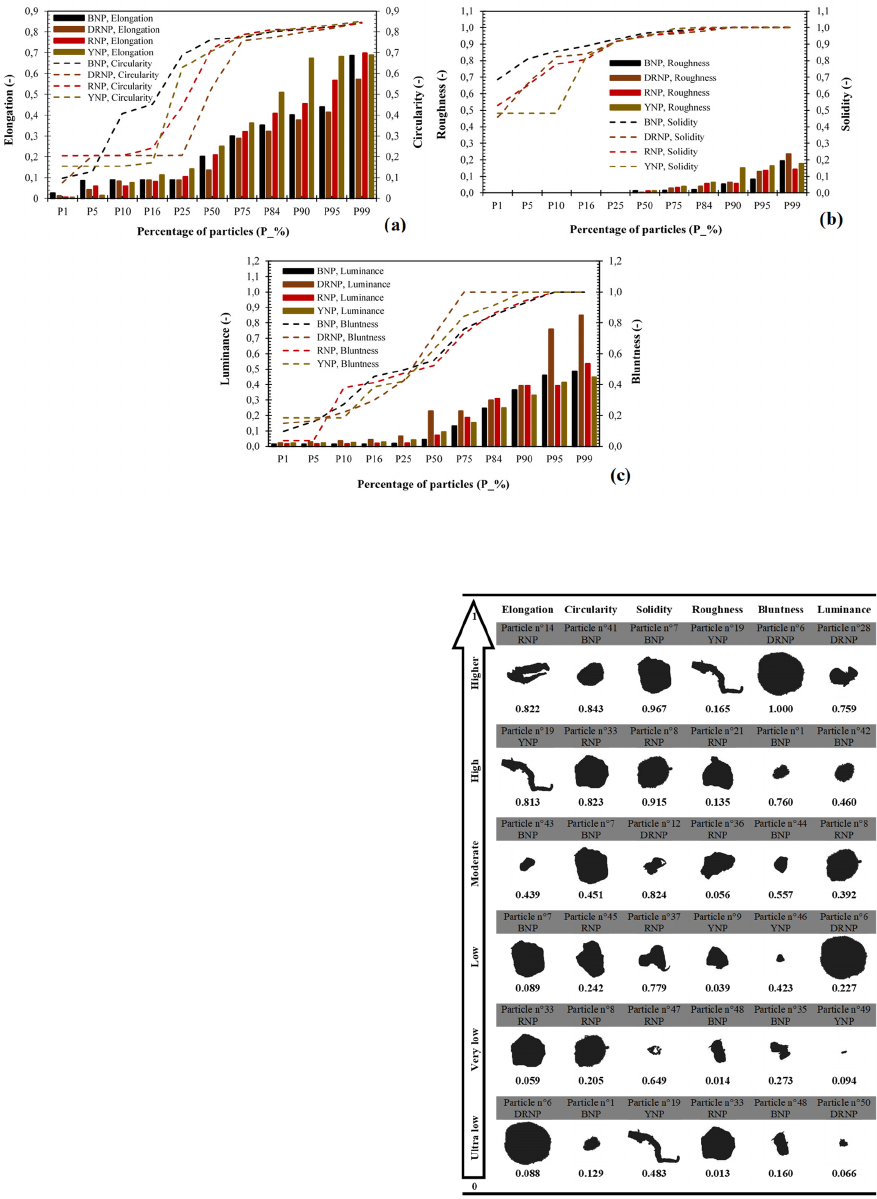

Figure 4a shows the distribution of elongation and

circularity of particles of each powder. The circularity

is always higher than the elongation. The particle

elongation appears to be quite low with 75 % of the

particles getting an elongation ratio lower than 0.40.

Figure 3: Distribution of (a) inner diameter and area diameter, (b) width and length, and (c) max distance and geodesic length

of particles of each powder.

Figure 4: Distribution of (a) elongation and circularity, (b) roughness and solidity, and (c) luminance and bluntness of particles

of each powder.

On the contrary, the particle circularity appears to

be high with 75% of the particles getting circularity

ratio higher than 0.40.

Figure 4b shows the distribution of roughness and

solidity of particles of each powder. The solidity ratio

is always higher than the roughness ratio. With all

particles getting a roughness ratio lower than 0.25 and

a solidity ratio higher than 0.45.

Figure 4c shows the distribution of luminance and

bluntness of particles of each powder. The bluntness

ratio is always higher than the luminance ratio. The

particle bluntness appears to be high with 75 % of the

particles getting a bluntness ratio higher than 0.40. On

the contrary, the particle luminance appears to be low

with 90% of the particles getting a luminance ratio

lower than 0.40. Figure 5 shows the general

classification according to shape parameters

considered, of 50 particles identified from IA set data.

The shape parameters are scaled to values between 0

and 1.0. Consider all powders, the higher value of

elongation, circularity, solidity, roughness, bluntness

and luminance are 0.822, 0.843, 0.967, 0.165, 1.000

and 0.759 respectively (Figure 5). The higher value to

express roughness of these particles is non-significant

(0.165) and indicates that these particles have

globally a bad roughness. In another part, the ultra-

low value of elongation, circularity, solidity,

roughness, bluntness and luminance are 0.088, 0.129,

0.483, 0.013, 0.160 and 0.066 respectively (Figure 5).

Figure 5: General classification of particles according their

shape parameters.

The ultra-low value to express solidity of these

particles is 0.483 and indicates that these particles

have globally a good solidity.

4 CONCLUSIONS

This study showed that the size estimation of

particulate material is a complicated matter. The

results highlight the fact that particle size

distributions may not be unique. Different techniques

can give a large range of different parameters which

need to be interpreted correctly. The choice of the

parameters also depends on the purpose of the

research. It is shown that particle shape analysis that

includes the full range of available grain sizes can

contribute not only measurements of particle size and

shape, but also information on size-dependent

densities and specific surface area. Based on these

results obtained after an experimental testing program

and an important data analysis, the following

conclusions can be drawn for the volcanic scoria

powders that have been tested here:

In addition to the PSD ; particle shape and surface

morphology of ground materials can be quantitatively

determined using the IA.

The particle size and the shape of these powders

can be quantitatively determined by using the IA

supported by digital analysis methods.

A methodology can be established to study the

particle size and shape distribution of SCMs.

Shape parameters provide quantitative,

meaningful and reproducible measurements of

particle morphology if chosen carefully.

A discrepancy was observed between the IA and

the LD size distributions toward both the lower and

upper sizes.

The grain size data of the volcanic scoria powders

are strongly dependent on shape parameters of

particles, and shape heterogeneity was different

between different size classes.

This description is absolutely needed for

understanding particles’ behavior in contact with

water when used in cementitious materials.

ACKNOWLEDGEMENTS

The first author would like to thank Mrs. Sophie

Leroy and Mr. Frédéric Michel, GeMMe research

engineers at the University of Liège (Belgium) for

their help in the testing program.

REFERENCES

Abazarpoor, A., Halali, M., Hejazi, R., Saghaeian, M.,

2017. HPGR effect on the particle size and shape of

iron ore pellet feed using response surface

methodology, Mineral Processing and Extractive

Metallurgy, pp. 1-9.

Arvaniti, E. C., Juenger, M. C. G., Bernal, S. A., Duchesne,

J., Courard, L., Leroy, S., Provis, J. L., Klemm, A., De

Belie, N., 2015a. Physical characterization methods for

supplementary cementitious materials, Materials and

Structures, 48(11):3675–3686.

Arvaniti, E. C., Juenger, M. C. G., Bernal, S. A., Duchesne,

J., Courard, L., Leroy, S., Provis, J. L., Klemm, A., De

Belie, N., 2015b. Determination of particle size,

surface area, and shape of supplementary cementitious

materials by different techniques, Materials and

Structures, 48(11):3687–3701.

Bagheri, G. H., Bonadonna, C., Manzella, I., Vonlanthen,

P., 2015. On the characterization of size and shape of

irregular particles, Powder Technology, 270:141–153.

Bouglada, M. S., Naceri, A., Baheddi, M., Pereira-de-

Oliveira, L., 2019. Characterization and modelling of

the rheological behaviour of blended cements based on

mineral additions, European Journal of Environmental

and Civil Engineering, pp. 1-18.

Bouyahyaoui, A., Cherradi, T., Abidi, M. L., Tchamdjou,

W. H. J., 2018. Characterization of particle shape and

surface properties of powders from volcanic scoria,

Journal of Materials and Environmental Science,

9(7):2032-2041.

Califice, A., Michel, F., Dislaire, G., Pirard, E., 2013.

Influence of particle shape on size distribution

measurements by 3D and 2D image analyses and laser

diffraction, Powder Technology, 237:67–75.

Dioguardi, F., Mele, D., Dellino, P., 2018. A new one-

equation model of fluid drag for irregularly shaped

particles valid over a wide range of Reynolds number,

J. of Geophysical Res.:Solid Earth, 123:144–156.

EN 196-6., 2010. Methods of testing cement - Part 6:

Determination of fineness, European Standard.

Felekoglu, B., 2009. A new approach to the

characterisation of particle shape and surface

properties of powders employed in concrete industry,

Construction and Building Materials, 23:1154–1162.

Ferraris, C. F., Hackley, V. A., Aviles, A. I., Buchanan, C.

E., 2002. Analysis of the ASTM round-Robin test on

particle size distribution of Portland cement: Phase I,

Report no. 6883. Maryland: National Institute of

Standards and Technology (NISTIR).

Gregoire, M. P., Dislaire, G., Pirard, E., 2007. Accuracy of

size distributions obtained from single particle static

digital image analysis, Proceeding. PARTEC

Conference. Nürenberg, 4p.

Hackley, V. A., Lum, L-S., Gintautas V., Ferraris, C. F.,

2004. Particle size analysis by laser diffraction

spectrometry: application to cementitious powders,

Report no. 7097. Maryland: National Institute of

Standards and Technology (NISTIR).

He, H., Courard, L., Pirard, E., Michel, F., 2016. Shape

analysis of fine aggregates used for concrete, Image

Anal Stereol, 35:159-166.

Ilic, M., Budak, I., Vucinic, M., Nagode, A., Kozmidis-

Luburic, U., Hodolic, J., Puskar, T., 2015. Size and

shape particle analysis by applying image analysis and

laser diffraction-inhalable dust in a dental laboratory,

Measurement, 66:109–117.

Jia, X., Garboczi, E. J., 2016. Advances in shape

measurement in the digital world, Particuology, 26:19–

31.

Juimo, W. H. T., Grigoletto, S., Michel, F., Courard, L.,

Cherradi, T., Abidi., M. L., 2017. Effects of various

amounts of natural pozzolans from volcanic scoria on

performance of Portland cement mortars, International

Journal of Engineering Research in Africa, 32:36-52.

Juimo, W., Cherradi, T., Abidi, L., Oliveira, L., 2016.

Characterisation of natural pozzolan of "Djoungo"

(Cameroon) as lightweight aggregate for lightweight

concrete, GEOMATE, 11(27):2782-2789.

https://doi.org/10.21660/2016.27.1310 .

Klemm, A. J., Wiggins, D. E., 2017. Particle size

characterisation of SCMs by mercury intrusion

porosimetry, Fizyka Budowli W Teorii I Praktyce Tom

IX, Nr 1-2017, pp 5-12.

Liu, E. J., Cashman, K. V., Rust., A. C., 2015. Optimising

shape analysis to quantify volcanic ash morphology,

GeoResJ, 8:14–30.

Michel, F., Courard, L., 2014. Particle size distribution of

limestone fillers: granulometry and specific surface

area investigations, Particulate Science and

Technology, 32:334-340.

Mikli, V., Käerdi, H., Kulu, P., Besterci, M., 2001.

Characterization of powder particle morphology,

Proceedings of the Estonian Academy of Sciences,

Engineering 7(1):22–34.

Niesel, K., 1973. Determination of the specific surface by

measurement of permeability, Materials and Structures,

6(3):227-231.

Orhan, M., Özer, M., Işık, N., 2004. Investigation of laser

diffraction and sedimentation methods which are used

for determination of grain size distribution of fine

grained soils, G.U. Journal of Science, 17(2):105–113.

Pavlović, M. G., Pavlović, L. J., Maksimović, V. M.,

Nikolić, N. D., Popov, K. I., 2010. Characterization

and morphology of copper powder particles as a

function of different electrolytic regimes, International

Journal of Electrochemical Science, 5:1862–187.

Tchamdjou, W. H. J., Cherradi, T., Abidi, M. L., De

Oliveira, L. A. P., 2017a. Influence of different amounts

of natural pozzolan from volcanic scoria on the

rheological properties of Portland cement pastes,

Energy Procedia, 139:696–702. DOI:

10.1016/j.egypro.2017.11.274.

Tchamdjou, W. H. J., Abidi, M. L., Cherradi, T., De

Oliveira, L. A. P., 2017b. Effect of the color of natural

pozzolan from volcanic scoria on the rheological

properties of Portland cement pastes, Energy Procedia,

139:703–709. DOI: 10.1016/j.egypro.2017.11.275.

Tierrie, J., Baaj, H., Darmedru, P., 2016. Modeling the

relationship between the shape and flowing

characteristics of processed sands, Construction and

Building Materials, 104:235–246.

Varga, G., Kovács, J., Szalai, Z., Cserháti, C., Újvári, G.,

2018. Granulometric characterization of paleosols in

loess series by automated static image analysis,

Sedimentary Geology, 370, pp 1-14.