Overview of Ship Dynamic Positioning Control System

Xiaoyu Wang

1, a

1

School of Energy and Power Engineering, Wuhan University of Technology, Wuhan 430063, China

Key

words: Marine Engineering; Dynamic Positioning; Control; Research Progress.

Abstract: Ship dynamic positioning control system is one of the important technologies in shipping industry. With the

continuous development of the economy, the requirements of ship field for dynamic positioning control

system are higher and higher. This paper will briefly introduce the composition, working principle, controlling

algorithm research progress and research status of ship dynamic positioning system.

1 INTRODUCTION

With the rapid development of global economy, the

world's land resources are gradually in short supply.

In order to obtain more abundant oil, rare metals and

other resources, the human development field has

been expanding to the ocean, promoting the

development of ships and marine engineering, and the

technology of dynamic positioning has been

gradually developed. In recent years, with the

continuous extension of marine engineering to the

deep level, many kinds of ships emerge in an endless

stream, and the ship's control system is also

increasingly perfect. As one of the more advanced

ship operation control system, the dynamic

positioning system is more and more widely used in

military ships, modern ocean platforms, scientific

research ships, tugs and diving rescue boats.

According to statistics, China's annual market

demand for dynamic positioning control costs about

2 billion yuan, with more than 200 potential dynamic

positioning control ships (Xiaobin Qian, 2018).

2 DYNAMIC POSITIONING

CONTROL SYSTEM

Ship's dynamic positioning system is a typical closed-

loop control system, including measurement system,

propulsion system, power system and control system.

Its working principle is to obtain the deviation

between the current ship state and the expected state

through the measurement system, and the control

system processes and calculates the required thrust.

The propulsion system uses multiple thrusters from

multiple angles to provide the corresponding power,

which is used to resist and eliminate the interference

of wind, wave, current and other environmental

forces in the ship operation, so as to make the ship

stay in the designated sea area as much as possible.

This system originates from offshore oil and gas

platforms (Xiaobin Qian, et.al, 2017). The main

functions of ship dynamic positioning control system

include station keeping, auto pilot, joystick, heading

control, follow target, auto track, etc.

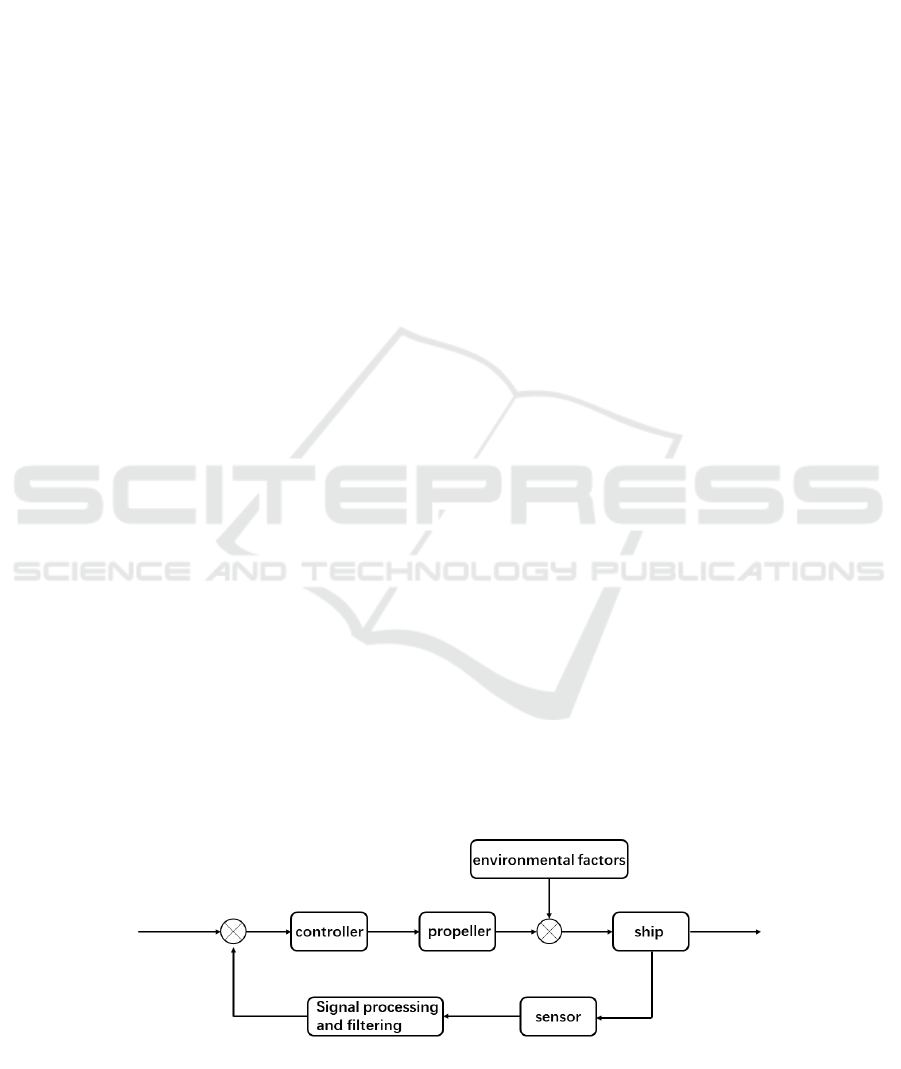

Figure 1: The structural diagram of the ship's dynamic positioning system.

54

Wang, X.

Overview of Ship Dynamic Positioning Control System.

DOI: 10.5220/0010022100540056

In Proceedings of the International Symposium on Frontiers of Intelligent Transport System (FITS 2020), pages 54-56

ISBN: 978-989-758-465-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Compared with the traditional mooring system,

the ship dynamic positioning system has the

following advantages: High positioning accuracy,

outstanding flexibility, higher safety and reliability,

fast positioning, no seabed and water depth, etc. the

limited cost is fixed, the cost of traditional offshore

platform will not increase with the increase of water

depth, the system has strong controllability, can

effectively avoid the dangerous situation generated in

the traditional anchoring process, and can produce

rapid response to the interference of the environment

(Minjie Zheng, 2018). The structural diagram of the

ship's dynamic positioning system is shown in Fig. 1.

3 SYSTEM COMPOSITION

3.1 Measurement System

This system plays an important role in the precise

work of the whole dynamic positioning system. It can

be said that the measurement system is the

performance guarantee of the dynamic positioning

system. The measurement system is divided into two

systems, reference system and sensor. The reference

systems commonly used in dynamic positioning of

ships are mainly satellite positioning, underwater

acoustic positioning and tension locking systems.

3.2 Propulsion System

This system is the actuator of the dynamic positioning

system. When the dynamic positioning system is

started, the system will make a positive response to

the command sent by the control system, and generate

appropriate forces and moments to eliminate the

interference of the surrounding environmental forces

on the position of the ship. Maintain the running track

or position of the ship.

3.3 Control System

The workload of this system is very heavy and it is

the key part of the whole system. By measuring the

deviation of the system to deal with the accurate

calculation of the power distribution problem. The

control effect in the control system is often reflected

in the control technology. The ship's motion control

technology has been constantly updated and

improved. From PID control when the dynamic

positioning system just appeared, it has experienced

adaptive control, optimal control, robust control, to

the most advanced and extensive English intelligent

control. Intelligent control has gradually replaced the

traditional control technology (Rong Zhen, 2012).

4 RESEARCH PROGRESS OF

SHIP DYNAMIC POSITIONING

CONTROL ALGORITHM

From the emergence of dynamic positioning

technology now, the core of dynamic positioning

control algorithm research and development can be

divided into three stages. The first stage is to use the

classical PID control algorithm to realize the control

of the working ship, and to control the free degree

movement of the ship in three aspects: sway, surge

and yaw. In the second stage, the combined control

method of filtering and optimal control is used. This

method improves the security and robustness to a

certain extent, and is widely used in modern

commercial ships. However, this control method has

large errors and the calculation process is too

complex (Cong Liu, 2018). The third stage is to use

the new intelligent control algorithm, including

robust control, nonlinear model predictive control,

neural network control and fuzzy control. They have

higher positioning accuracy, can ensure the reliability

of position information obtained by measurement,

and make the ship gradually move towards intelligent

development in the direction of dynamic positioning

(Dandan Wang, 2010).

5 RESEARCH STATUS OF SHIP

DYNAMIC POSITIONING

CONTROL SYSTEM

5.1 PID Control Technology

In the early 1960s, dynamic positioning system was

applied to the exploitation of marine resources. In

1961, PID control system was adopted by the first

batch of ships with dynamic positioning system in the

world. The system controls the three degrees of

freedom of the ship and calculates the required thrust

by measuring the deviation of the ship position and

heading angle. The advantages and disadvantages of

this method are very obvious. It has the advantages of

good stability, high security, simple calculation and

easy design. At the same time, it also exposes the

disadvantages of the control function of the controlled

object with variable parameters. When the ship and

the surrounding environment change, the parameters

of the PID control system must be reset.

Overview of Ship Dynamic Positioning Control System

55

5.2 Linear Optimal Control

Technology

Due to the poor control effect of some parts of the PID

control system, the research of linear optimal control

technology is promoted. The system divides the

mathematical model of a ship into high and linear

optimal control technology, which can effectively

solve the problem of phase lag in the first generation

of a dynamic positioning system. Moreover, response

speed and accuracy meet the requirements.

5.3 Nonlinear Control Technology

There are many non-linear factors that can't be

liberalized in the process of ship's fixed force

positioning. This technology can deal with the non-

linear factors in the process of ship operation, and can

deal with the non-linear problems directly. It is

precisely because this feature can effectively improve

the control performance and safety performance of

ship positioning work, and has a considerable

compensation for the interference in the external

environment.

5.4 Intelligent Control Technology

In recent years, with the rapid development of

computer related technology, artificial intelligence

has rapidly entered human life, and the development

of control theory has also been greatly promoted.

Only control technology has the characteristics of

imitating human to a certain extent, which has a good

effect on solving the problem of difficult to establish

a mathematical model. Because each intelligent

control technology has its own advantages, how to

use different intelligent control technologies together

is also an important research direction nowadays

(Yang Liu, 2013).

6 OUTLOOK AND SUMMARY

The control of the dynamic positioning system is

always difficult to achieve perfectly, because of the

nonlinear complexity of the ship system, the

uncertainty of the parameters of the model and the

external disturbance, and the change of the internal

state is not easy to measure. How to effectively solve

the above problems is an important research topic in

the field of control theory.

Dynamic positioning system is widely used in

ship control system. Compared with traditional

anchoring positioning, it has obvious advantages and

has gradually become a key technology in the field of

deep-sea ships and offshore platforms. China is rich

in marine resources and has an immeasurable

prospect of exploitation and utilization. The only way

to achieve sustainable development is to develop the

dynamic positioning ship control technology at a high

speed, which has important utilization value.

ACKNOWLEDGMENTS

This work was supported by the Fundamental

Research Funds for the Central Universities [WUT:

2019-ND-B1-13].

Author's research direction: New energy; Energy

management; Ship shore power.

REFERENCES

Cong Liu. Research on Application of Active Disturbance

Rejection Control for Dynamic Positioning Ships

Control ([D], Harbin Engineering University, China

2018).

Dandan Wang. Research on Relative Dynamic Positioning

Method between Rescue Vessel and Wreck Vessel

([D], Harbin Engineering University, China 2010).

Minjie Zheng. Research of Sampled-data Control for

Singular System and Its Application to Ship Dynamic

Positioning System ([D], Shanghai Jiao Tong

University, China 2018).

Rong Zhen. Design and Application of Daptive PID in Ship

Course Leading Autopilot ([D], Dalian Maritime

University, China 2012).

Xiaobin Qian. Research on Nonlinear Model Predictive

Control for Dynamic Positioning Ship ([D], Dalian

Maritime University, China 2018).

Xiaobin Qian, Yong Yin, Xiaofeng Sun, Xiufeng Zhang.

Overview of Ship Dynamic Positioning Simulator [J].

Journal of Chongqing Jiaotong University (Natural

Science), 2017, 36(02):108-114.

Yang Liu. Research on Intelligent Control and Thrust

Distribution for Dynamic Positioning ([D], Dalian

Maritime University, China 2013).

FITS 2020 - International Symposium on Frontiers of Intelligent Transport System

56