Actors, Collaboration, and Interaction Mechanisms in Supply Chain

for Circular Economy: A Literature Review

Ruth Nattassha, Yuanita Handayati, Togar M. Simatupang, and Manahan Siallagan

School of Business and Management, Bandung Institute of Technology, Jl. Ganesa 10, Bandung, Indonesia

Keywords: circular economy, supply chain actors, supply chain collaboration, supply chain interaction

Abstract: The loss of economic value from wastes of various industries can be prevented through the implementation

of circular economy concepts, in which the wastes are processed to become resources for the same industry

or other industries. From several existing cases, it is apparent that implementing the concepts of circular

economy in supply chain processes could face several obstacles, especially in terms of supply chain actors,

their collaboration, and their interaction. To find if other implementations meet similar obstacles, how they

solve it and define possible research opportunities in this subject, this research sought to conduct a literature

review on the existing research regarding implementation of circular economy concepts in the supply chain,

from the perspective of supply chain actors along with their collaboration types and interaction mechanism.

Several possible future research is identified from the conducted literature review: the importance of

horizontal-type collaboration in supply chain implementing circular economy, the matter of actors and

interaction in industry-specific context, and also the impact of cultural context on the behavior of actors and

the impact to supply chain output.

1 INTRODUCTION

The matter of wastes has been the concern of various

industries. In the agri-food industry, for example,

there is the existence of inevitable by-products

through the production processes, such as the

cowhide and manure in the production of beef meat

(van der Vorst et al., 2005). In the manufacturing

industry, the wastes could come both from the

production processes, in the form of production

wastes such as water wastes and defective products,

and also from consumption processes in the form of

remains of the product after consumption, such as the

packaging of the products. In the construction

industry, the wastes come from the remains of

construction processes, such as the stones, plaster,

and other materials coming from the destruction and

construction of buildings.

All the wastes that have mentioned above are

generally immediately dispatched to the landfill.

There are no other processes that could take them as

resources for further functions. This situation can

result in the loss of the possibility to gain economic

value from the wastes. Said loss of possibility could

be avoided through the implementation of circular

economy concepts. Pearce and Tuner (1989),

described that in a circular economy system, the

wastes would not be discarded directly but become

resources for other processes instead (EM

Foundation, 2012). In return, the wastes coming from

these other processes would then provide resources

for the original process, making the whole economy

system follow the example of the feedback-rich living

system. The wide possibility of this concept, along

with the rising concern towards health and

environment, encourages various research regarding

its implementation.

Implementing the circular economy requires some

changes to the existing economic system. Several

research has been conducted in that matter. Smith-

Gillespie (2017) and Lewandowski (2016) defined

the changes of the business model when integrating

the circular economy concepts using the business

model canvas methodology. Moreno et al. (2016)

defined the strategies which could be used to design

businesses in a circular economy. In the term of

performance measurements, Iacovidou et al. (2017)

and Walker et al. (2018) defined the metrics and

measures to evaluate the performance of businesses

in regards to the dimensions of the circular economy

concept. In the topic of supply chain management,

Masi et al. (2017) have developed a systematic

Nattassha, R., Handayati, Y., Simatupang, T. and Siallagan, M.

Actors, Collaboration, and Interaction Mechanisms in Supply Chain for Circular Economy: A Literature Review.

DOI: 10.5220/0009963705870597

In Proceedings of the International Conference of Business, Economy, Entrepreneurship and Management (ICBEEM 2019), pages 587-597

ISBN: 978-989-758-471-8

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

587

literature review on the supply chain configuration in

the circular economy system. In the article, the

enablers and inhibitors of circular economy

implementation are discussed, along with the types of

supply chain configurations that could be

implemented in a circular economy system.

However, there is a lack of literature review

regarding the interaction between stakeholders and

the behavior of the stakeholders in the supply chain

implementing the circular economy. In the

classification developed by Pomponi and Moncaster

(2017), the relationship between stakeholders in the

supply chain could be addressed as the societal aspect

of the circular economy, while the behavior of

stakeholders could be addressed as the behavioral

aspect. Meanwhile, the stakeholders or actors within

the supply chain, what they do, and the interaction

between them are some of the most important factors

to be regarded for the supply chain (Van der Vorst,

2005). This is because, in practice, the interaction of

supply chain actors and behavior of each actor could

affect the outcome of the supply chain. For example,

in the research of Handayati et al. (2016), it is

demonstrated that even in one location, there would

be a variety of farmers' behavior in executing the

standard operation procedure. The difference in

executing standard operation procedure results in the

difference of farming yield, in which farmers who

comply with the standard operation procedure gain

better yield both in quality and quantity than the ones

who do not comply.

The importance of analyzing the interaction

between supply chain actors and the behavior of these

actors is also addressed in an existing systematic

literature review conducted for the circular economy

implementation in the supply chain. In Farooque et al.

(2019), there is identified a large knowledge gap and

very high importance regarding the collaboration and

coordination in the supply chain implementing the

circular economy. Several of the identified research

opportunities are in identifying the incentives and

strategic value alignment, collaboration and

coordination mechanism, supply chain management,

and knowledge management within the supply chain.

In relation to the implementation of circular

economy in the supply chain, the importance of

addressing the actors, their behavior, and their

interaction is also shown in the recent preliminary

study conducted to a company attempting to apply the

concepts. The company, OrganicFe Co., produces

organic fertilizer, which is processed from fruit and

vegetable wastes by utilizing black soldier fly larvae.

In trying to market their products to the farmers, they

found several obstacles, mainly in their approach to

the farmers: farmers in some area would only buy the

fertilizer if they had seen a successful usage

conducted by neighbor, while farmers in other areas

would not buy the fertilizer if they had seen their

neighbor using it first—because they did not want to

be seen as 'followers.' This difference in behavior

requires the company to take different approaches in

their interaction, and should they take the wrong

approach, the farmers would not purchase the

fertilizer. Farmers not purchasing the product result

in the failure to implement circular economy

concepts, as the produced fertilizer is not used and

thus not having economic value.

Another case of failure to implement the circular

economy in the supply chain comes from a company

implementing holistic farming practices, EcoOrganic

Co. There, the wastes from farming practices,

including crops and fish farming, are processed by

worms to create organic fertilizer. Similar to

OrganicFe Co., while the production of fertilizer can

happen, targeted customers of the fertilizer would not

purchase it. In the case of EcoOrganic Co., their target

market is the local residents around the company. The

local residents would gladly accept the fertilizers if

they gain it for free, but they would not purchase it.

The implementation of the circular economy in this

case also fails when the result of the circular economy

process, the utilization of waste to become fertilizer,

is not used in the system.

However, the implementation could successfully

be done by IntegratedFood Co. IntegratedFood Co.

can implement circular economy concepts in their

integrated companies, in which the livestock sector

and fruits production sector of the company are

collaborating to handle their wastes. The goal of this

company is to achieve “zero waste” in their processes,

something that is currently achievable due to the fact

that both sectors are located in the same area and that

the sectors are within the same company, so the

circular economy practices are implemented by actors

under the same company.

With these examples of successful and not-yet-

successful implementation of circular economy in the

supply chain, it is suspected that the actors of these

particular cases are the key: their behavior, their

expectation of the supply chain practice, which

affects their behavior, and their interaction with the

other supply chain actors. The question is, does it

happen too with other applications of circular

economy in the supply chain? Do they find similar

obstacles, or do they not try to address the actors of

their supply chain in particular?

Thus, this research is conducted to find the current

state-of-the-art in the research regarding the actors'

ICBEEM 2019 - International Conference on Business, Economy, Entrepreneurship and Management

588

behavior and interaction in the implementation of the

circular economy in the supply chain. First, the key

concept of the circular economy and supply chain is

discussed. Afterward, the methodology by which the

literature review was conducted is defined. Then, the

result of the literature review is presented, along with

the possible research coming from the identified

knowledge gap in the state-of-the-art. Finally, a

conclusion and further research for this particular

topic will also be discussed.

2 CIRCULAR ECONOMY AND

SUPPLY CHAIN

2.1 Circular Economy

The circular economy concept is adapted from the

living systems, which are called as feedback-rich

systems (EM Foundation, 2012). The term feedback-

rich is used to describe the living systems for

naturally there are no wastes which would remain as

wastes. In natural systems, when wastes return to

nature, they would be further processed by the

organism to become the resources for other living

organisms. An example of this would be the lifecycle

of animals. When animals defecate or die, their

wastes or corpses would be processed by bacteria to

become nutrients in soils. The nutrients are used by

the plants to grow, and later the plants would become

feedings for the animals. Such a concept is the goal of

a circular economy, in which the wastes from one

process should be utilized as much as possible to

become resources for other processes. With this, the

number of wastes that are really not useful and have

to be disposed of to the landfill would be minimized.

Other than decreasing the number of wastes, this

system would also lead to a sustainable system, the

final goal of the circular economy concept. A system

is called sustainable when, by having a diversity of

flowing materials and processes within the system, it

could provide for itself indefinitely.

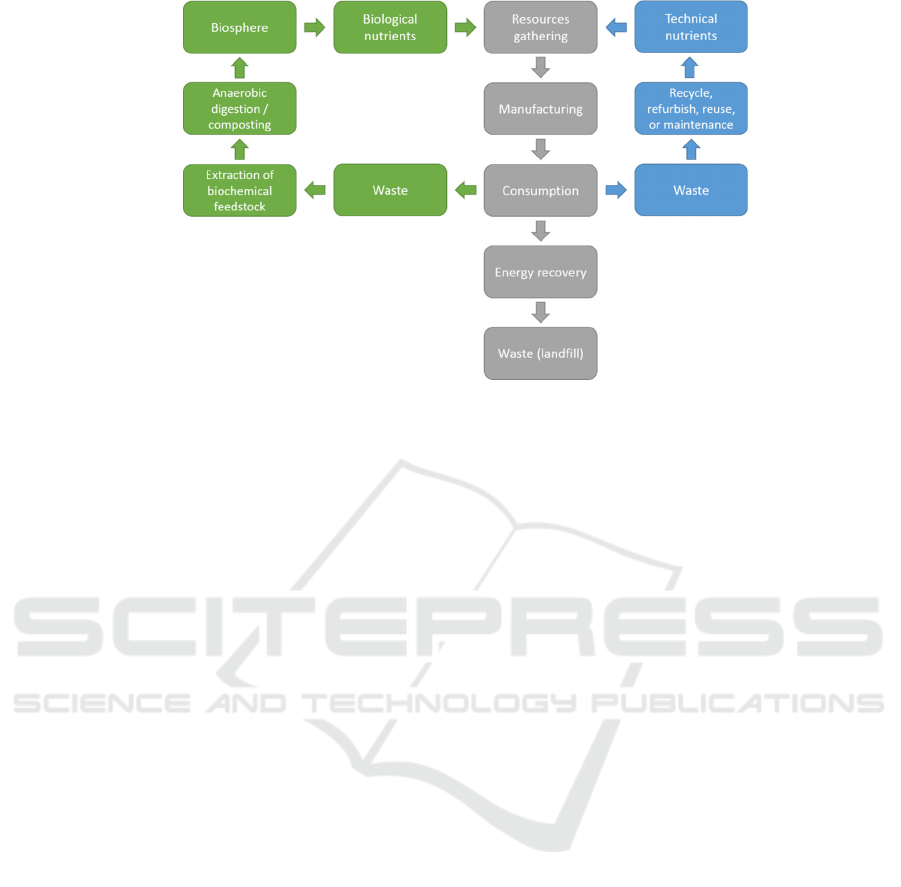

The workflow of the circular economy framework

is illustrated in Figure 1. There are two possible

cycles that could happen in the circular economy

depend on the material type: biological cycle and

technical cycle. The degradable, organic materials

will go through the biological cycle, which consists

of extraction and composting processes and resulting

in biological nutrients. The technical cycle will take

care of undegradable materials, in which said

materials are processed through the recycling

processes, which actually has many forms:

maintenance, reuse, refurbish, or actual recycle.

These materials actually could come from any stages

of the chain, including the manufacturing stages. The

materials that cannot go through both cycles will be

disposed to the landfill after going through the energy

recovery processes.

There are also several principles for the circular

economy, according to the EM Foundation (2012).

The first one is to design out waste, in which the

design of products should also consider whether the

wastes of said product could be useful for other

processes. This leads to the second principle: waste is

food, in which these wastes should be considered as

resources for the processes in the system. The next

principle is to build resilience through diversity. As

mentioned before, the sustainable system provides

itself through the diversity of flowing materials and

processes. In an economic system, this could be

presented by enriching the system through the

diversity of supply chains being connected to provide

for each other. This also leads to the principle of

thinking in systems, determining which parts of the

systems should give feedback to the other parts; in

this case, parts are the processes. The last principle

for this system would be to rely on energy from

renewable sources, as they are mostly more efficient

and emit fewer wastes that cannot be processed than

the unrenewable ones.

2.2 Supply Chain: Actors,

Collaboration, and Interaction

Mechanism

The actors of the supply chain differ for each case.

However, they can usually be grouped based on the

processes of the supply chain. Ayers (2006) defined

the five supply chain processes: plan, source, make,

deliver, and return. The planning process includes all

planning activities for the other processes. The source

process is the process encompassing all activities for

procuring the sources used in manufacturing the

products. The making process is the process for

activities in product manufacturing. Afterward, the

products are delivered to various receivers, such as

the retailer and the consumers, through the delivery

process. Finally, the return process is related to the

activities involving returning the products to the

manufacturer.

Actors, Collaboration, and Interaction Mechanisms in Supply Chain for Circular Economy: A Literature Review

589

Figure 1: Workflow of the circular economy framework (EM Foundation, 2012)

Collaboration in the supply chain happens when

there is a joint effort from two or more independent

companies to achieve greater success in running the

supply chain than both of them working separately

(Simatupang and Sridharan, 2002). There are three

types of collaboration in the supply chain: vertical,

horizontal, and lateral (Simatupang and Sridharan,

2002; Barratt, 2004). Vertical collaboration happens

inside a particular connected supply chain, between

the suppliers, the manufacturing companies, delivery

processes, and customers. Horizontal collaboration

happens between companies, in which these

companies are either unrelated or in a competing

relationship. Finally, there is the lateral collaboration

in the supply chain, which combines both vertical and

horizontal collaboration. The kind of collaboration to

be considered in a case, with the goal of achieving the

best results in the supply chain, will depend on the

strategic aims and capabilities of all the collaborating

companies.

In supply chain collaboration, there are five

elements to be considered (Simatupang and

Sridharan, 2008). First is the collaborative

performance system, which defines the metrics used

to measure the performance of the supply chain along

with the target for each metric. The target of these

metrics is derived from the joint goal of the supply

chain. Afterward, there is information sharing

between the participating companies, in which they

should communicate the necessary information

concerning supply chain processes. Then, there

should be decision synchronization between

collaborating supply chain participants. This is to

ensure that the performance of the supply chain can

be measured by something they have agreed on, and

all participants have an idea of the final goal for the

supply chain. Afterward, incentive alignment

between supply chain actors is also something

required to achieve supply chain collaboration. The

incentive for supply chain actors should be assigned

based on their performance in regards to the

determined overall goal of the supply chain. And

finally, there should be an innovative supply chain

process, which can ensure the flow of goods and

information without obstacles.

These five elements of collaboration in the supply

chain can be derived to become the interaction

mechanisms of supply chain actors (Sridharan and

Simatupang, 2013). When there is a collaborative

performance system, then there should be a

mechanism to ensure that the metrics used in the

performance system are agreed on and understood by

the supply chain actors, which leads to the

performance accountability mechanism. Then, for the

information sharing to happen, there should be a

willingness from participants to share, along with the

availability of the means to share, such as the usage

of technology. Decision synchronization is the next

interaction mechanism, in which the supply chain

actors work and discuss together as a team to make

decisions for the supply chain activities, to achieve

the overall supply chain goal. As for the innovative

supply chain processes, to ensure that the flow of

products and information is without obstacles, there

should be the mechanism of process integration

within the supply chain. And finally, to ensure that

the supply chain actors can fulfill their individual

interests as well as working to achieve the joint goal

of the supply chain, an incentive alignment

mechanism is also required.

ICBEEM 2019 - International Conference on Business, Economy, Entrepreneurship and Management

590

3 METHODOLOGY

A search for research literature was conducted in the

Scopus database. Scopus database was chosen

because of the wide coverage, currently 36,377 titles

from 11,678 publishers. The literature in Scopus is all

peer-reviewed, establishing their trustworthiness. The

search is conducted using the query of "circular

economy" AND "supply chain," as this research

focuses on the supply chain in the circular economy.

This results in 305 articles. Through abstract

screening, it was found that 25 of them were articles

of systematic literature review, and they were

analyzed to observe the subjects of existing literature

reviews on circular economy and supply chain. The

implementation of circular economy concepts have

been researched quite thoroughly – from the

configuration of supply chain to support circular

economy, how the concepts are used in specific

supply chains management function such as

procurement and production, until the measurement

tool of the circularity aspects in the supply chain and

barriers to the implementation along with the possible

drivers that might make industries switch to circular

economy.

However, none of them specifically discusses the

actors of the supply chain process and their

interaction. While Corrado and Sala (2018) talk about

the current issues about food waste in the supply

chain, about how they were handled and the amount

of several types of food waste, it is also mentioned

that non-optimal coordination between supply chain

actors might result in more food waste. The matter of

supply chain coordination and collaboration in

circular economy implementation is also highlighted

as a very urgent research topic with a large knowledge

gap in the currently available literature by Farooque

et al. (2019). It also should be noted that Jabbour et

al. (2019) discussed the human side of circular

economy implementation. However, the research is

more focused on adopting the aspects of green human

resource management to firms' business models.

While the human resource management in a firm is

also important to be noted in the implementation of

circular economy concepts, collaboration in the

supply chain is more focused on the interaction

between actors of each supply chain process, in which

the actors of a process might be composed of more

than one firm.

Thus, for this research, the actors of the supply

chain implementing circular economy and their

interaction become the focus. After excluding the

literature review ones, the remaining 280 articles are

then also screened based on their abstract, whether

they mention a case of implementing a circular

economy in the supply chain or not. From the abstract

screening, 155 papers remain, with some being

literature review articles. These 155 papers are then

get screened further for the existence of actors'

characteristics and interaction in the supply chain

implementing circular economy within the content of

the articles. From the second screening process, 35

articles remained, and they will be further classified

and analyzed.

The articles are reviewed based on these aspects:

1. The supply chain processes and the actors

involved in each process. If there are other

involved stakeholders who might not

directly work as a part of the supply chain

(such as the government body), it should

also be analyzed.

2. Collaboration and interaction mechanism

between actors. What kind of collaboration

is conducted by the supply chain actors?

What interaction mechanism exists

between the actors?

3. Context of research, especially industry

and area of application (continent). The

circular economy activity conducted in

each research will also be considered in this

section.

4. The method used in the research and

findings of the research. If there is a model,

such as the mathematical model, what is the

goal of the said model? How can the

implementation of circular economy

concepts be stated as being better than the

current condition? In what aspects?

4 LITERATURE REVIEW

RESULT AND DISCUSSION

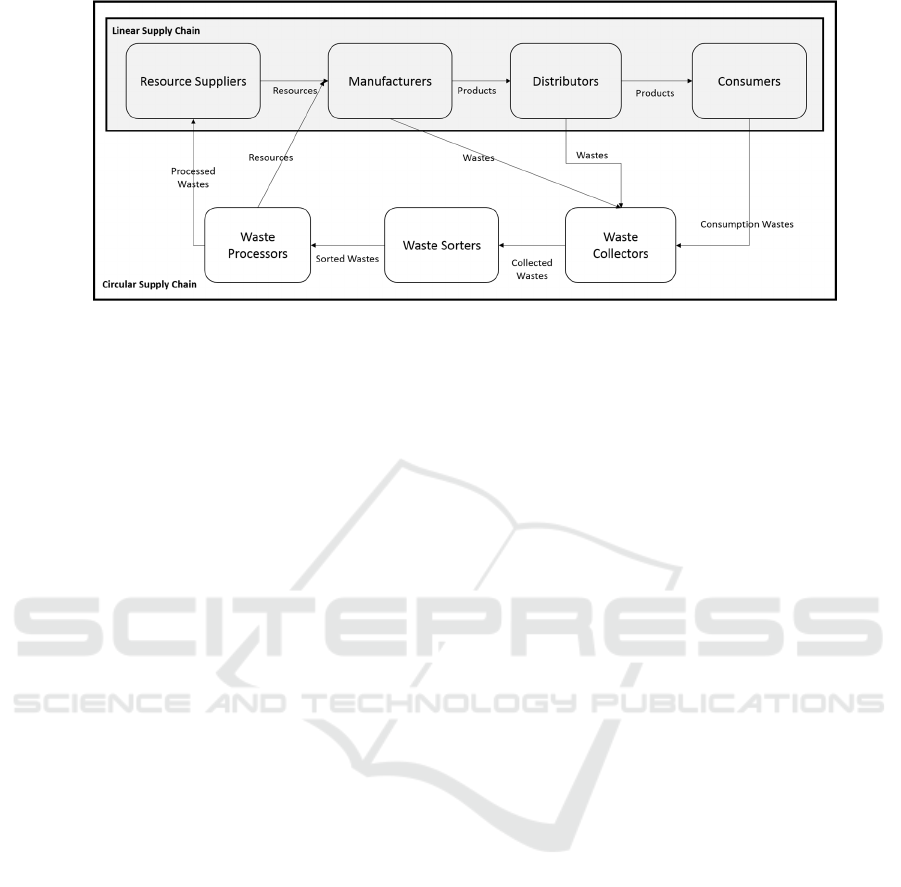

4.1 Actors of Supply Chain

Implementing Circular Economy

The existing research was also reviewed based on the

actors involved in the supply chain defined in the

research. Figure 2 illustrates the general model of

actors in a supply chain implementing the circular

economy. Basically, there are two stages involved:

the usual linear supply chain actors, which consist of

resource suppliers, manufacturers, distributors, and

consumers; and the waste management actors, which

consist of waste collectors, waste sorters, and waste

processors.

Actors, Collaboration, and Interaction Mechanisms in Supply Chain for Circular Economy: A Literature Review

591

Figure 2: Actors of supply chain implementing circular economy

The resource suppliers are expected to gain the

supply materials through the means agreed within the

contracts with the manufacturers (de Oliveira, 2019).

As for the manufacturers, the design of products

should also consider the waste processing method for

the product wastes, as well as the material, flows for

the consumption wastes (Bernon et al., 2018; Tate et

al., 2019; Franco, 2017). Distributors include the

wholesalers and retailers involved in the distribution

of the products, while the consumers are the end

customers of the products.

It also should be noted that for each role, there

could be more than one actor. The company in the

research of Unal et al. (2019), for example, has more

than one waste suppliers for their activities. It is also

exhibited in the research of Batista et al. (2018) there

waste collectors and recyclers working for one

company can also be more than one. As for the waste

collectors, there are also forms of both formal and

informal associations, showing that the collectors are

mostly individual agents.

There are various other stakeholders involved in

the supply chain implementing the circular economy.

The first one being mostly highlighted is the

government, with their involvement in the supply

chain, is mostly for establishing regulations that push

for circular economy adaptation, as well as the

bureaucracy for obtaining incentives for applying the

circular economy. University and research centers are

also mentioned, mostly for inventing products and

introducing new processes for better circular

economy implementation. Hogeboom et al. (2018) is

the only research to focus on the investors, in which

the research is introducing a framework that could be

utilized by the investors to give insights for assessing

companies to invest.

Through observing the overall distribution of

supply chain actors in circular economy

implementation, it is apparent that the most discussed

actors of the supply chain in implementing circular

economy are the waste management actors, along

with resource gathering actors. This should be due to

the fact that the circular economy is highly concerned

with how waste is managed, along with how they can

be used as resources either by the original main

process or the other processes. Manufacturing actors

are concerned in the circular economy mostly because

they handle the product design, and the product

design should either utilize the resources gained from

waste processing or devised to enable the product

wastes to be processed by the waste management

system.

4.2 Collaboration Type and Interaction

Mechanism in Supply Chain

implementing Circular Economy

As previously defined in Section 2, there are three

types of collaboration in the supply chain: vertical,

horizontal, and lateral. From the review, it was found

that most of the research, 24 out of 35 articles,

consider the vertical collaboration in their supply

chain. This is mostly caused by the fact that

implementing the circular economy in the supply

chain is mostly focused on the chain involving the

flow of products and waste. Hence they are more

focused on defining the vertical collaboration parts of

the supply chain.

However, there is also research in which the

supply chain considers lateral collaboration when

implementing the circular economy concepts. The

lateral collaboration, when being considered in

research, can come in the form of collaboration

between the main company and academic institutions

or research centers (Batista et al., 2018; Bernon et al.,

2018). This collaboration happens when the company

seeks to research on developing new methods in

ICBEEM 2019 - International Conference on Business, Economy, Entrepreneurship and Management

592

better implementing a circular economy. Other than

with researching institutions, the lateral collaboration

also considers government bodies, in which both the

push and the support to implement the circular

economy concept in supply chain practices might

come from the government (Batista et al., 2018; de

Oliveira, 2019; Lapko et al. 2018). The lack of

regulation on circular economy implementation from

the government might hinder the success of

implementation, as it can also affect the aspect of

incentives for the supply chain actors (Veleva &

Bodkin, 2018). Both of the researching institutions

and government bodies are part of the unrelated

companies in horizontal collaboration. As for the

collaboration between competing companies, none of

the researched literature tries to consider this kind of

collaboration.

Only one research considers horizontal

collaboration, which is the research of Ali et al.

(2019). In this research, the collaboration happens

between automobile company and building

construction company. The metal scrap wastes from

an automobile company are to be used in building

construction. As these companies should have been

unrelated, their collaboration can be defined as fitting

the horizontal collaboration type.

The research is also considered based on the

interaction mechanism considered in the research:

whether it is practiced in the research or highlighted

as the necessary mechanism to ensure the success of

circular economy implementation in the supply chain.

Of the 35 research, the process integration

mechanism and information sharing mechanism are

mostly practiced or become a concern for the supply

chain actors if they want to implement the circular

economy implementation. For the process integration

mechanism, it is caused by the fact that for the

implementation to be successful, the wastes have to

be processed to become resources, and the resources

must be used either by the original processes or by

other industries. This requires integration in both the

waste management processes and resource

procurement. As for the information sharing, it

especially becomes a concern to increase the

willingness of supply chain actors to participate in the

supply chain, through sharing the information of

circular economy implementation benefits, such as in

the research of Patricio et al. (2018).

Incentive alignment comes as the third most

discussed interaction mechanism. Other than the lack

of information, the incentives which will be gained by

the supply chain actors from the implementation are

considered necessary for the supply chain success.

This is because there is the possibility that the actors

would be unwilling to participate if they do not see

the benefit of implementing supply chain concepts,

especially because the implementation would require

additional processes and efforts, which might

possibly increase the cost of supply chain processes.

Other than that, the research is generally not

concerned with decision synchronization and

performance accountability yet, as only 5 articles

address the former, and 3 articles address the latter.

This might be due to the fact that the other three

interaction mechanisms are considered to be more

important in the current state of circular economy

implementation in the supply chain.

While there are only five interaction mechanisms

defined for the base of literature review, apparently

there is also interaction mechanism in the form of

contracts (Batista et al., 2018; Fischer and Pascucci,

2017; Maab and Grundmann 2018). Contracts can be

considered as encompassing several of the already

defined interaction mechanism, as in the contract, the

incentives for supply chain actors are defined, along

with the agreement of the supply chain actors for the

terms which could show the existence of decision

synchronization aspect. In further analyzing the

interaction between supply chain actors for

implementing the circular economy concepts, this

mechanism could become a key for better success.

4.3 Research Context

The majority of the research takes place in the

countries of Europe and America (Northern and

Southern America combined), with 19 research in

Europe and 8 research in America. The high amount

of research in Europe might be caused by the

government's initiative to adopt a circular economy in

Europe. As for in Asia, there is only two research,

taking place in India and China. This shows that there

is a research gap on research regarding actors’

interaction in the supply chain implementing the

circular economy in the context of Asia, especially in

developing countries.

Regarding the industrial context, the amount of

research in the agri-food industry is more or less the

same amount as the manufacturing industry, with the

former having 15 research and the latter having 16

research. Research with more than one industrial

context is either having multiple case study methods

in the research or the case study involve two

industries to facilitate the implementation of circular

economy concepts. An example of the latter is the

case of Ali et al. (2019), in which the waste of the

automotive industry is used in the construction

industry.

Actors, Collaboration, and Interaction Mechanisms in Supply Chain for Circular Economy: A Literature Review

593

Other than the industries, it is also important to

determine the activities of processes that make the

case adequate of being called "implementing the

circular economy." The key to the circular economy

concept is that the number of wastes discarded to the

landfill should be minimized as much as possible.

This results in the necessity to process wastes and use

them as resources.

The most used activity for circular economy

implementation is the reuse, remanufacturing, and

recycling process. In this process, used products go

through several processes (they might get repaired,

remanufactured, disassembled, or recycled) to

become resources in creating new products or the new

products themselves. This activity is mostly used by

the manufacturing industries. However, the agri-food

industries involved with the processing of product

packaging could also utilize this activity. The amount

of research utilizing this activity is the highest: 23 of

the 35 research contain the reuse, remanufacturing,

and recycling process.

There are other activities that could be done to

utilize wastes from other processes. The first one is

composting organic wastes to become fertilizer

(Borello et al., 2016; Borello et al., 2017; Chen et al.,

2019; Noya et al., 2017; Patricio et al., 2018; Perey et

al., 2018; Vlajic et al., 2018). The fertilizer could

then be used in the farming processes, which could be

done to either produce feeding for livestock farming

or food sources for the plant-based food product

supply chain. Feeding production from wastes is also

a highly-used waste handling process in the agri-food

industry, such as the utilization of wheat co-products

for animal feed (Principato et al., 2019).

Another possible circular economy process is by

giving the waste to other industries to be utilized,

such as the utilization of pig blood and butter in Noya

et al. (2017). There is also a method to resell the

products without the whole remanufacturing

processes (He et al., 2019). And finally, there is the

sustainable use of resources through energy and

resource recovery (Hogeboom et al., 2018; Vlajic et

al., 2018). The amount of these other processes is far

lower than the mostly used reuse-recycle-

remanufacture processes.

As previously mentioned, for both the agri-food

and manufacturing industries, there already exist

several research regarding the circular economy

implementation in their supply chain. However, in the

research of Farooque et al. (2019), it should be noted

that there is the possibility to find drivers and barriers

for a specific industry, compared to a broad category

such as agri-food and manufacturing. The drivers and

barriers for implementation can also come in cultural

context, which is related to the country or continent

context for the case study. This is highly important as

the cultural context of the case affects the supply

chain actors, which, as explained before, the behavior

of supply chain actors could affect the

implementation of circular economy concepts in the

supply chain.

4.4 Methods and Findings of the

Research

The subject of circular economy implementation in

the supply chain is still a growing body of knowledge

which requires inputs from the empirical facts in the

field. Thus, most of the research uses the case study

method, whether it is the multi-case study or the

single-case study. Generally, they are conducted in an

exploratory manner with the goal of finding the

insights from the current situation, either be it the

perspectives from existing players, possible barriers

and drivers for the implementation; also the possible

benefits from the implementation though not yet

applied. It is also interesting to note that while the

specific method of which the materials will be

processed varied on each case, there could be

categorized back to either the reuse-remanufacture-

recycle processes or agricultural resource gathering

processes (composting for gaining fertilizers,

processing to get animal feed).

Another popular goal in the research is to compare

the result from several scenarios: the current

condition and various implementations of the circular

economy processes. For this comparison, they usually

consider the best alternative to be the one with the

least economic cost (investment, operating), least

environmental effects (greenhouse gas emission,

acidification of water), and most profitable, which

sometimes can be attributed to the lower economic

cost. A comparison of the scenarios generally uses

data gathered through case study processes: an

examination of already existing data and gathering

information from key stakeholders. The data are then

further processed by the chosen means of scoring the

scenarios: lifecycle analysis, mathematical equations,

analytic hierarchy process, discrete event simulation,

system dynamic, an agent-based model.

In the matter of agent-based model, it is

interesting to note that Moreno et al. (2018) argue that

the methodology should be used when the research is

focused on the people, or the actors, of the system.

Thus, their research uses discrete event simulation to

analyze the flow of products. However, in the

research of Lieder et al. (2017), it is used to depict the

material flow of washing machine products, in which

ICBEEM 2019 - International Conference on Business, Economy, Entrepreneurship and Management

594

the agents are the washing machines, and the different

characteristics for each machine are their score in

their ability to be reused, recycled, or

remanufactured. Actually, it is not that uncommon for

the agent-based model to be used in the

manufacturing industry to model the products, just as

also shown by Nilsson and Darley (2006).

5 CONCLUSIONS

The circular economy is considered as one possible

solution to the matter of waste management in various

industries. However, the implementation of circular

economy concepts in the supply chain can face

several obstacles due to the behavior and interaction

of actors within the supply chain. Several of the

previously identified cases have shown this pattern,

in which both the behavior and the interaction of

actors can impact the actors' willingness to participate

in the implementation, which also will affect the

implementation success.

This literature review is thus conducted to find

state of the art regarding the actors within the supply

chain with the goal of implementing a circular

economy, along with the collaboration type of the

actors and the interaction mechanism they practice, or

they should practice. From the literature review, it is

apparent that the most important actors are the ones

involved in the waste management processes: the

waste collectors, waste sorters, and waste processors.

The integration of these actors with the resource

suppliers and manufacturers is also considered to be

important, in order to ensure the flow of resources

from processed wastes could be utilized by the

original process or the other industries. As for the

interaction mechanism, information sharing and

process integration are most discussed by the

literatures, considering that the current state of

circular economy implementation in supply chain is

mostly still in the stage of introducing circular

economy to the actors and inquire their participation

in the system, along with integrating the processes

especially in the stage of waste processing and

resource gathering.

There are several future research directions that

can be taken for this subject. First, there seems to be

a lack of horizontal collaboration in the supply chain

implementing the circular economy. Further research

can be conducted to find out whether this kind of

collaboration is actually necessary for implementing

a circular economy in the supply chain, or there is no

impact of such collaboration for the implementation.

The matter of collaboration between competitors can

also be further researched, especially if there is more

than one company that conduct waste management

processes. Other than that, there could be research in

a specific context, both in the industries narrower than

the agri-food or manufacturing umbrella and in the

geographical context, which is not already majorly

researched on. The latter can especially be conducted

to compare the impact of different cultures on the

actors’ behavior, which will, in turn, also affect the

success of circular economy implementation in the

supply chain.

REFERENCES

Ali, A.K., Wang, Y. and Alvarado, J.L., 2019. Facilitating

industrial symbiosis to achieve circular economy using

value-added by design: A case study in transforming

the automobile industry sheet metal waste-flow into

Voronoi facade systems. Journal of Cleaner

Production.

Ayers, J.B., 2006. Handbook of supply chain management.

Auerbach publications.

Barratt, M., 2004. Understanding the meaning of

collaboration in the supply chain. Supply Chain

Management: an international journal, 9(1), pp.30-42.

Batista, L., Gong, Y., Pereira, S., Jia, F. and Bittar, A.,

2018. Circular supply chains in emerging economies–a

comparative study of packaging recovery ecosystems in

China and Brazil. International Journal of Production

Research, pp.1-21.

Bernon, M., Tjahjono, B. and Ripanti, E.F., 2018. Aligning

retail reverse logistics practice with circular economy

values: an exploratory framework. Production

Planning & Control, 29(6), pp.483-497.

Borrello, M., Lombardi, A., Pascucci, S. and Cembalo, L.,

2016. The seven challenges for transitioning into a bio-

based circular economy in the agri-food sector. Recent

patents on food, nutrition & agriculture, 8(1), pp.39-47.

Borrello, M., Caracciolo, F., Lombardi, A., Pascucci, S. and

Cembalo, L., 2017. Consumers’ perspective on circular

economy strategy for reducing food waste.

Sustainability, 9(1), p.141.

Chen, W., Oldfield, T.L., Katsantonis, D., Kadoglidou, K.,

Wood, R. and Holden, N.M., 2019. The socio-

economic impacts of introducing circular economy into

Mediterranean rice production. Journal of cleaner

production, 218, pp.273-283.

Corrado, S. and Sala, S., 2018. Food waste accounting

along global and European food supply chains: State of

the art and outlook. Waste management, 79, pp.120-

131.

de Oliveira, M.C.C., Machado, M.C., Jabbour, C.J.C. and

de Sousa Jabbour, A.B.L., 2019. Paving the way for the

circular economy and more sustainable supply chains.

Management of Environmental Quality: An

International Journal.

Actors, Collaboration, and Interaction Mechanisms in Supply Chain for Circular Economy: A Literature Review

595

EM Foundation, 2012. Accelerating the scale-up across

global supply chains. Retrieved from

https://www.ellenmacarthurfoundation.org/assets/dow

nloads/publications/Ellen-MacArthur-Foundation-

Towards-the-Circular-Economy-vol.1.pdf

Farooque, M., Zhang, A., Thurer, M., Qu, T. and Huisingh,

D., 2019. Circular supply chain management: A

definition and structured literature review. Journal of

Cleaner Production.

Fischer, A. and Pascucci, S., 2017. Institutional incentives

in circular economy transition: The case of material use

in the Dutch textile industry. Journal of cleaner

production, 155, pp.17-32.

Franco, M.A., 2017. Circular economy at the micro level:

A dynamic view of incumbents’ struggles and

challenges in the textile industry. Journal of cleaner

production, 168, pp.833-845.

Handayati, Y., Simatupang, T.M., Perdana, T. and

Siallagan, M., 2016. A simulation of contract farming

using agent based modeling. Journal of Operations and

Supply Chain Management, 9(2), pp.28-48.

He, Y., Xu, Q. and Wu, P., 2019. Omnichannel retail

operations with refurbished consumer returns.

International Journal of Production Research, pp.1-20.

Hogeboom, R.J., Kamphuis, I. and Hoekstra, A.Y., 2018.

Water sustainability of investors: Development and

application of an assessment framework. Journal of

cleaner production, 202, pp.642-648.

Iacovidou, E., Velis, C.A., Purnell, P., Zwirner, O., Brown,

A., Hahladakis, J., Millward-Hopkins, J. and Williams,

P.T., 2017. Metrics for optimising the multi-

dimensional value of resources recovered from waste in

a circular economy: A critical review. Journal of

cleaner production, 166, pp.910-938.

Jabbour, C.J.C., Sarkis, J., de Sousa Jabbour, A.B.L.,

Renwick, D.W.S., Singh, S.K., Grebinevych, O.,

Kruglianskas, I. and Godinho Filho, M., 2019. Who is

in charge? A review and a research agenda on the

‘human side’ of the circular economy. Journal of

cleaner production.

Kalverkamp, M., 2018. Hidden potentials in open-loop

supply chains for remanufacturing. The International

Journal of Logistics Management, 29(4), pp.1125-

1146.

Krystofik, M., Luccitti, A., Parnell, K. and Thurston, M.,

2018. Adaptive remanufacturing for multiple

lifecycles: A case study in office furniture. Resources,

Conservation and Recycling, 135, pp.14-23.

Lapko, Y., Trianni, A., Nuur, C. and Masi, D., 2019. In

pursuit of closed‐loop supply chains for critical

materials: An exploratory study in the green energy

sector.

Journal of Industrial Ecology, 23(1), pp.182-

196.

Lewandowski, M., 2016. Designing the business models for

circular economy—towards the conceptual framework.

Sustainability, 8(1), p.43.

Lieder, M., Asif, F.M., Rashid, A., Mihelič, A. and Kotnik,

S., 2017. Towards circular economy implementation in

manufacturing systems using a multi-method

simulation approach to link design and business

strategy. The International Journal of Advanced

Manufacturing Technology, 93(5-8), pp.1953-1970.

Maaß, O. and Grundmann, P., 2018. Governing

Transactions and Interdependences between Linked

Value Chains in a Circular Economy: The Case of

Wastewater Reuse in Braunschweig (Germany).

Sustainability, 10(4), p.1125.

Masi, D., Day, S. and Godsell, J., 2017. Supply chain

configurations in the circular economy: A systematic

literature review. Sustainability, 9(9), p.1602.

Moreno, M., De los Rios, C., Rowe, Z. and Charnley, F.,

2016. A conceptual framework for circular design.

Sustainability, 8(9), p.937.

Moreno, M., Court, R., Wright, M. and Charnley, F., 2019.

Opportunities for redistributed manufacturing and

digital intelligence as enablers of a circular economy.

International Journal of Sustainable Engineering,

12(2), pp.77-94.

Nilsson, F. and Darley, V., 2006. On complex adaptive

systems and agent-based modelling for improving

decision-making in manufacturing and logistics

settings: Experiences from a packaging company.

International Journal of Operations & Production

Management, 26(12), pp.1351-1373.

Noya, I., Aldea, X., González-García, S., Gasol, C.M.,

Moreira, M.T., Amores, M.J., Marín, D. and

Boschmonart-Rives, J., 2017. Environmental

assessment of the entire pork value chain in Catalonia–

A strategy to work towards Circular Economy. Science

of the Total Environment, 589, pp.122-129.

Patricio, J., Axelsson, L., Blomé, S. and Rosado, L., 2018.

Enabling industrial symbiosis collaborations between

SMEs from a regional perspective. Journal of cleaner

production, 202, pp.1120-1130.

Pearce, D.W. and Turner, R.K., 1989. Economics of natural

resources and the environment. JHU Press.

Perey, R., Benn, S., Agarwal, R. and Edwards, M., 2018.

The place of waste: Changing business value for the

circular economy. Business Strategy and the

Environment, 27(5), pp.631-642.

Pomponi, F. and Moncaster, A., 2017. Circular economy

for the built environment: A research framework.

Journal of Cleaner Production, 143, pp.710-718.

Principato, L., Ruini, L., Guidi, M. and Secondi, L., 2019.

Adopting the circular economy approach on food loss

and waste: The case of Italian pasta production.

Resources, Conservation and Recycling, 144, pp.82-89.

Simatupang, T.M. and Sridharan, R., 2002. The

collaborative supply chain. The international journal of

logistics management, 13(1), pp.15-30.

Simatupang, T.M. and Sridharan, R., 2008. Design for

supply chain collaboration. Business Process

Management Journal, 14(3), pp.401-418.

Smith-Gillespie, A., 2017. Defining the Concept of

Circular Economy Business Model. R2piproject.eu.

Retrieved 1 April 2018, from

ICBEEM 2019 - International Conference on Business, Economy, Entrepreneurship and Management

596

http://www.r2piproject.eu/wp-

content/uploads/2017/04/Defining-the-Concept-of-

Circular-Economy-Business-Model.pdf

Sridharan, R. and Simatupang, T.M., 2013. Power and trust

in supply chain collaboration. International journal of

value chain management, 7(1), pp.76-96.

Tate, W.L., Bals, L., Bals, C. and Foerstl, K., 2019. Seeing

the forest and not the trees: Learning from nature’s

circular economy. Resources, Conservation and

Recycling, 149, pp.115-129.

Ünal, E., Urbinati, A., Chiaroni, D. and Manzini, R., 2019.

Value Creation in Circular Business Models: The case

of a US small medium enterprise in the building sector.

Resources, Conservation and Recycling, 146, pp.291-

307.

Van der Vorst, J., Beulens, A., & van Beek, P., 2005. 10.

Innovations in logistics and ICT in food supply chain

networks. Innovation in agri-food systems: Product

quality and consumer acceptance, 245.

Veleva, V. and Bodkin, G., 2018. Corporate-entrepreneur

collaborations to advance a circular economy. Journal

of cleaner production, 188, pp.20-37.

Vlajic, J.V., Mijailovic, R. and Bogdanova, M., 2018.

Creating loops with value recovery: empirical study of

fresh food supply chains. Production Planning &

Control, 29(6), pp.522-538.

Walker, S., Coleman, N., Hodgson, P., Collins, N. and

Brimacombe, L., 2018. Evaluating the environmental

dimension of material efficiency strategies relating to

the circular economy. Sustainability, 10(3), p.666.

Actors, Collaboration, and Interaction Mechanisms in Supply Chain for Circular Economy: A Literature Review

597