Esterification of Rhodinol Fraction with Acetic Anhydride using

Zeolite Catalyst

Gadis Dian Anggreini

1

, Mafud Cahayo

1

,

Masruri

2

, and

Warsito

1,2

1

Essential Oil’s Institute, Brawijaya University, Jl. Veteran Malang 65145, Malang, Indonesia

2

Department of Chemistry, Faculty of Science, Brawijaya University, Jl. Veteran Malang 65145, Malang, Indonesia

Keywords: Esterification, Rhodinol, Java Citronella Oil, Acetic Anhydride, Zeolite.

Abstract: This research has been conducted on the effect of esterification reaction in the chemical composition of

rhodinol fraction from java citronella oil (Cymbopogon winterianus). The reaction process in this research is

done at 230 ° C by using rhodinol fraction and acetic anhydride with zeolite as a catalyst. Based on the

research, the optimum reaction time is 1 hour and the optimum mole ratio of reactants is 1: 1. The% yield of

citronellyl acetate and geranyl acetate are 74.06% and 95.92%.

1 INTRODUCTION

Indonesia is a country rich in the diversity of essential

oil-producing plants. As many as 40 types of essential

oils produced from these plants have been traded and

one type of essential oil that has the potential to be

developed commercially is citronella oil (Gunawan,

2009).

Citronella oil consists of 40 components, but the

identity of citronella oil scent is only determined by

three compounds namely citronellal, citronellol, and

geraniol (Kaul et al., 1997).

Citronellal, citronellol, and geraniol are single

components that have a higher selling price than

fragrant citronella essential oils in the form of crude

oil (Aldrich, 2019). Separation of fragrant citronella

oil using batch scale vacuum fractionation distillation

has been able to separate the citronellal fraction and

rhodinol fraction (a mixture of citronellol and

geraniol) (Eden et al., 2018).

Citronellol and geraniol can be further enhanced

for its selling value by converting them into

compounds that are widely used in the food,

cosmetics and pharmaceutical industries, namely

citronellyl acetate and geranyl acetate (Claon and

Akoh, 1993).

Citronellyl acetate and geranyl acetate are ester

compounds that can be synthesized through an

esterification reaction between an acidic compound

and alcohol using an acid catalyst (Fessenden and

Fessenden, 1999). The HZSM-5 zeolite catalyst was

used in a previous study to synthesize isopentyl

acetate and succeeded in obtaining a yield of 95.1%

(Ma et al., 1996)

Therefore, to increase the higher selling value of

the rhodinol fraction obtained from citronella oil, it is

necessary to esterify the rhodinol fraction to obtain

citronellyl acetate and geranyl acetate.

2 METHOD

2.1 Esterification of Rhodinol Fraction

Rhodinol of 10 mL (citronellol = 0.02 mole and

geraniol = 0.01 mole) were taken into a 20 mL boiling

flask flat and then added 2.92 mL of acetic anhydride

(0.03 mole) and 0.14 g of zeolite. after that, the flask

is heated at 130°C with stirring using a magnetic

stirrer and after 1 hour the catalyst can be separated

by filtering.

The organic liquid from the previous reaction is

washed with distilled water repeatedly until the pH of

the water phase is equal to 7. after that, the organic

phase is separated and weighed.

The same method is used to find out the optimum

reflux times by repeating the previous method with

the variation of reflux time (2 hours and 3 hours). The

reflux time method that produces optimum citronellyl

acetate and geranyl acetate products is used to find

out the optimum mole ratio of acetic anhydride (0.06

mole and 0.9 moles) for this esterification reaction.

Dian Anggreini, G., Cahayo, M., Masruri, . and Warsito, .

Esterification of Rhodinol Fraction with Acetic Anhydride using Zeolite Catalyst.

DOI: 10.5220/0009957901230126

In Proceedings of the 2nd International Conference of Essential Oils (ICEO 2019), pages 123-126

ISBN: 978-989-758-456-5

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

123

2.2 Characterization using Gas

Chromatography Mass

Spectrometry (GC-MS)

Each sample was dissolved in n-hexane solvent in a

ratio of 1: 100, then 0.1 μL was taken and injected

using a syringe on GCMS-QP 2010S Shimadzu

instruments to obtain chromatogram and compound

prediction.

3 RESULT

3.1 Component Analysis of Rhodinol

Fraction

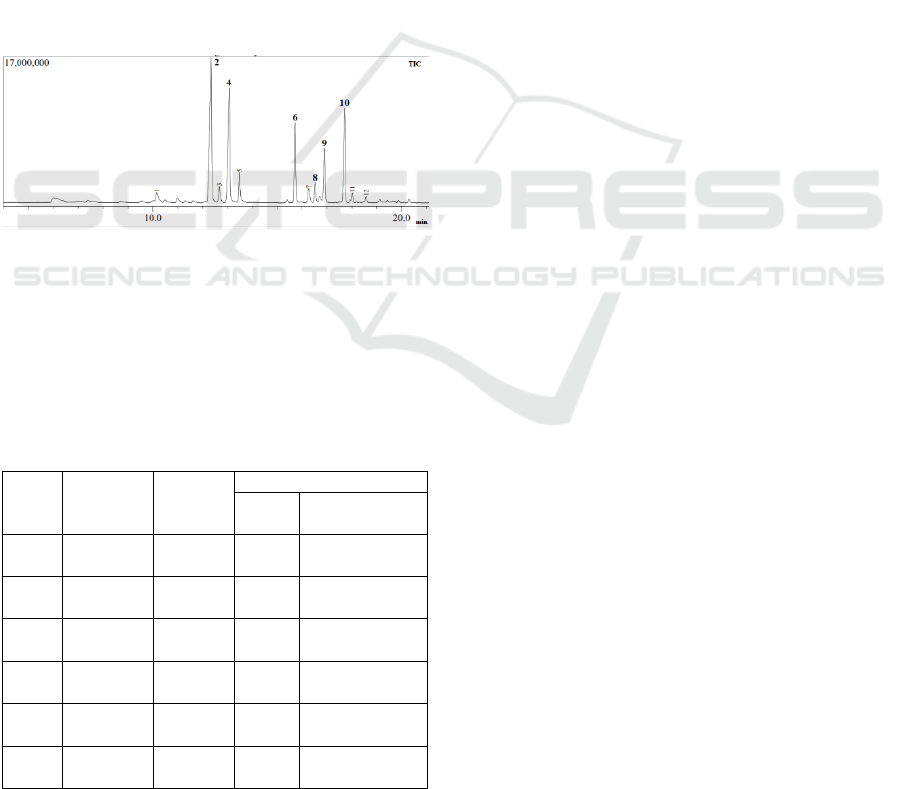

Figure 1 is a chromatogram that we obtained from the

GC-MS instrument, from that figure we can observe

that there are 12 peaks found in the rhodinol fraction.

Figure 1: Chromatogram of rhodinol fraction.

Six peaks in figure 1 is a component that we

should focus on because we would observe the

different before and after esterification reaction, the

effect of variation time reaction and mole ratio acetic

anhydride, for more details look at table 1.

Table 1: Tabulation from chromatogram of rhodinol

fraction.

Peak

Time

Retenion

(min)

Area

(%)

Estmation

SI Compound

2 12,34 31,51%

SI:

97

Citronellol

4 13,08 21,50%

SI:

97

Geraniol

6 15,71 11,10%

SI:

97

Citronellyl

Acetate

8 16,51 2,26%

SI:

97

Geranyl

Acetate

9 16,89 7,19%

SI:

96

β-Elemen

10 17,71 14,18%

SI:

97

Caryophyllene

3.2 Synthesis of Esters (Citronellyl

Acetate and Geranyl Acetate)

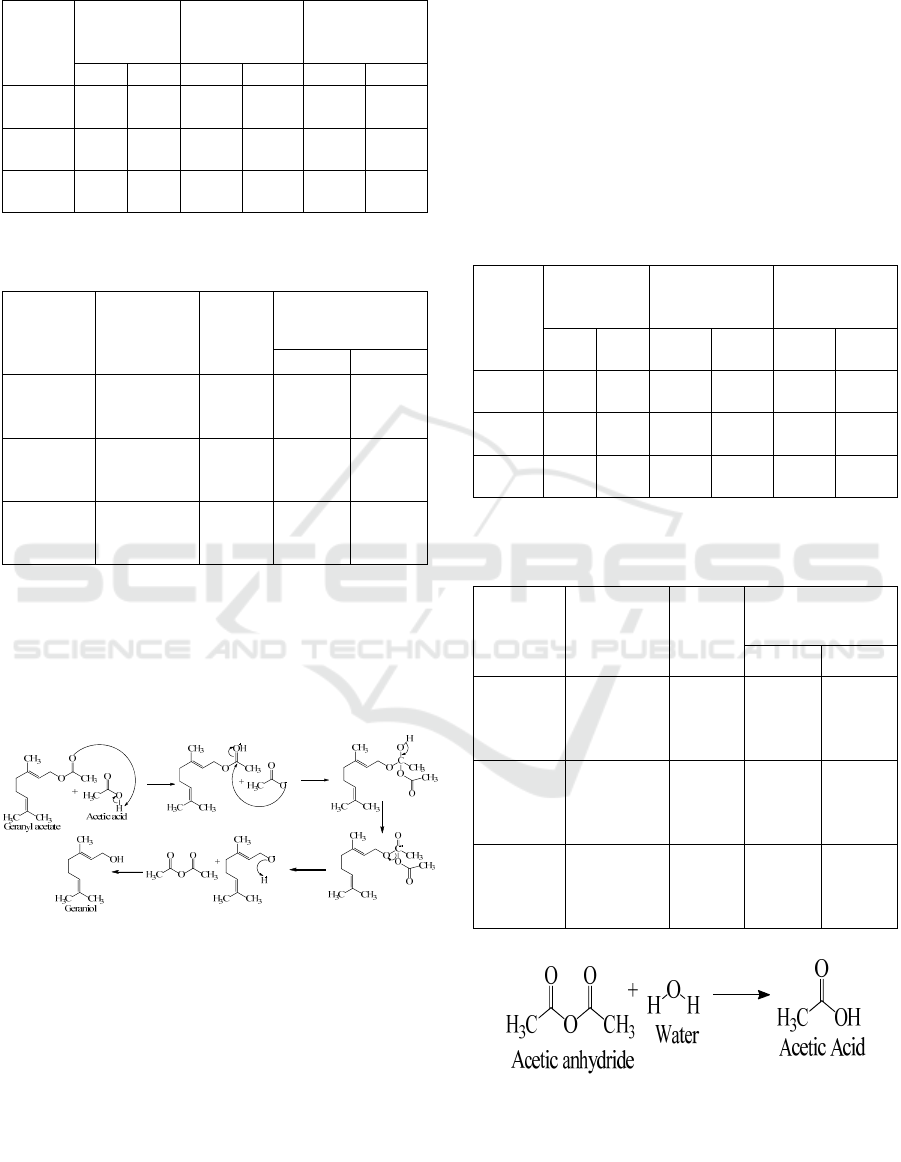

The synthesis of ester compounds (Citronellyl acetate

and geranyl acetate) is based on the Fischer

esterification reaction, which is the reaction between

the acetyl group (-COCH

3

) on the anhydride acetate

and the alcohol group (-OH). According to Fracotte

the formation of ester compounds using acetic

anhydride will produce a high% yield compared to

using acetic acid because the carbonyl group of acetic

acid is not strong enough as an electrophile to be

attacked by alcohol (Fracotte and Lohmann, 1989).

In the synthesis of citronellyl acetate and geranyl

acetate, the nucleophilic acyl substitution reaction

occurs. The use of the zeolite catalyst aims to reduce

the activation energy by changing the reaction

mechanism, which is to add the reaction steps.

Although the catalyst participates in the reaction

stage, at the end of the reaction process will be formed

again. With the lower value of the activation energy,

effective collisions that produce the product will

occur more frequently so the reaction goes faster. In

the reaction process, zeolite produces acylium ions

which act as electrophiles in the substitution reaction,

so that the acylium ion is easily attacked by O atoms

which are attached to hydroxyl groups from both

citronellol and geraniol. The hydroxyl groups in

citronellol and geraniol act as nucleophiles in the

presence of free electron pairs on the O atom, then the

hydroxyl group attacks the C atom of the carbonyl

group in the acylium ion to form oxonium ions. The

existence of this attack by nucleophiles causes the

substitution of H atoms in the hydroxyl groups from

citronellol and geraniol with acyl groups from acetic

anhydrides to form citronellyl acetate and geranyl

acetate.

At the end of the synthesis process, the liquid and

solid phases are produced. The solid phase is a zeolite

catalyst and can be separated by filtering. Meanwhile,

the liquid phase is containing esters (citronellyl

acetate and geranyl acetate) and acetic acid

compounds as byproducts.

3.3 Effect of Time on Rhodinol

Esterification Reaction with Acetic

Anhydride

Table 2 and table 3 are a tabulation of the data

produced by the esterification reaction with a fixed

number of mole of acetic anhydride but the varying

reflux time which is: 1 hour, 2 hours and 3 hours.

ICEO 2019 - 2nd International Conference of Essential Oil Indonesia

124

Table 2: Effect of Reflux time on Citronellyl Acetate (CA)

and Geranyl Acetate (GA) percentage.

Reflu

x time

(hour)

Before

Synthesis

(%)

After

Synthesis

(%)

synthesis

results (%)

CA GA CA CA CA GA

1

11,

1

2,2

6

48,3

3

26,0

4

37,2

3

23,7

8

2

11,

1

2,2

6

45,4

9

27,2

3

34,3

9

24,9

7

3

11,

1

2,2

6

47,1

1

10,4

9

36,0

1

8,23

Table 3: Effect of Reflux time on Citronellyl Acetate (CA)

and Geranyl Acetate (GA) %yield.

Quantity

Of

Rhodino

l

Quantity

Of Acetic

Anhydrid

e

Reflux

Time

(Hour

)

%Yield

CA GA

10 mL

(0,03

mol)

2,92 mL

(0,03 mol)

1

74,06

%

95,92

%

10 mL

(0,03

mol)

2,92 mL

(0,03 mol)

2

66,25

%

97,45

%

10 mL

(0,03

mol)

2,92 mL

(0,03 mol)

3

65,49

%

30,61

%

From Table 2 and Table 3 we could see that The

optimum reflux time to produce the highest %yield

citronellyl acetate and geranyl acetate yield is 1 hour.

Hydrolysis of esters by acetic acid is possible so that the

formed ester product can converts back into an alcohol

compound as the reaction time increases (Figure 2).

Figure 2: Reaction mechanism of hydrolysis ester (geranyl

acetate)

3.4 Effect of Mole Ratio on Rhodinol

Esterification Reaction with Acetic

Anhydride

Table 4 and table 5 are a tabulation of the data

produced by the esterification reaction with a fixed

reflux time but the varying number of mole of acetic

anhydride which is: 0.03 mole, 0.06 mole, and 0.09

mole.

From Table 4 and Table 5 we could see that The

optimum mole ratio between rhodinol and acetic

anhydride to produce the highest %yield citronellyl

acetate and geranyl acetate yield is 1:1.

There are water molecules in rhodinol so that the

reaction of acetic anhydride to acetic acid is possible

(Figure 3), after that hydrolysis of ester by acetic acid

is possible (Figure 2).

Table 4: Effect of Reflux time on Citronellyl Acetate (CA)

and Geranyl Acetate (GA) percentage.

Acetic

Anhy-

-dride

(mole

)

Before

Synthesis

(%)

After

Synthesis

(%)

synthesis

results (%)

CA GA CA CA CA GA

0,03

11,

1

2,2

6

48,3

3

26,0

4

37,2

3

23,7

8

0,06

11,

1

2,2

6

49,9

9

20,1

8

38,8

9

17,9

2

0,09

11,

1

2,2

6

45,0

9

21,2

5

33,9

9

18,9

9

Table 5: Effect of Reflux time on Citronellyl Acetate (CA)

and Geranyl Acetate (GA) %yield.

Quantity

Of

Rhodino

l

Quantity

Of Acetic

Anhydrid

e

Reflux

Time

(Hour

)

%Yield

CA GA

10 mL

(0,03

mol)

2,92 mL

(0,03 mol)

1

74,06

%

95,92

%

10 mL

(0,03

mol)

5,84 mL

(0,06 mol)

1

79,60

%

74,49

%

10 mL

(0,03

mol)

8,76 mL

(0,09 mol)

1

71,29

%

80,61

%

Figure 3: reaction mechanism of hydrolysis ester (geranyl

acetate)

Esterification of Rhodinol Fraction with Acetic Anhydride using Zeolite Catalyst

125

4 CONCLUSIONS

Based on research by the author, it can be concluded

that:

1. The optimum ratio of rhodinol to acetic anhydride

is 1: 1, with the yield of citronellyl acetate

obtained is 74.06% while the % of geranyl acetate

yield is 95.92%. Based on the results of the GC-

MS analysis obtained 37.23% citronellyl acetate

and 23.78% geranyl acetate.

2. The optimal reflux reaction time for esterification

of rhodinol with acetic anhydride is 1 hour.

REFERENCES

Aldrich, S. (2019) Catalogue Product.

Claon, P. and Akoh, C. 1993. Enzymatic synthesis of

geranyl acetate in n-hexane with Candida antarctica

lipase. Biotechnology Letters, 15(12), 1211–1216.

Eden, W. T. et al. 2018. Fractionation of Java Citronella Oil

and Citronellal Purification by Batch Vacuum

Fractional Distillation. The 12th Joint Conference on

Chemistry. Semarang: IOP Publishing, p. 349.

Fessenden, R. J. and Fessenden, J. s. 1999. Kimia Organik

Jilid 2. 3rd edn. Jakarta: Erlangga.

Fracotte, E. and Lohmann, D. 1989. Helv. Chim. Acta, 114,

647.

Gunawan, W. 2009. Kualitas dan Nilai Minyak Atsiri,

Implikasi pada Pengembangan Turunannya. Booklet

Seminar Nasional Kimia Bervisi SETS. Semarang:

Himpunan Kimia Indonesia Jawa Tengah, 18–29.

Kaul, P. N. et al. 1997. Chemical Composition of the

Essential Oil Of Java Citronella (Cymbopogon

Winterianus Jowitt) Grown in Andhra Pradesh, Pafai

Journal, 19, 29–33.

Ma, Y. et al. 1996. Zeolite-Catalyzed Esterification I.

Synthesis of Acetates, Benzoates, and Phthalates,

Applied Catalyst A: General, 139, 51–57.

ICEO 2019 - 2nd International Conference of Essential Oil Indonesia

126