Quality Characteristics and Antibacterial Activity of Transparent

Solid Soap with Addition of Cananga Oil (Cananga odorata)

Rulita Maulidya

1

, Yuliani Aisyah

1,2

and Dewi Yunita

1

1

Agricultural Industry Technology Department, Agriculture Faculty, Universitas Syiah Kuala,

Banda Aceh, Indonesia 23111

2

Atsiri Research Center, Universitas Syiah Kuala, Banda Aceh, Indonesia, 23111

Keywords: Transparent solid soap, cananga, virgin coconut oil, palm oil, alkali.

Abstract: Cananga oil (Cananga odorata) is a natural source of fragrances that can be used as an antibacterial agent, so

cananga oil can be added to the formulation for making antibacterial soap. Therefore, the aim of this study is

to determine the formulation of cananga soap using different types of oil and to characterize the quality of

transparent solid soap. This study uses a completely randomized design (CRD) with a factorial pattern

consisting of two factors and three replications. Oil type (VCO and palm oil) and cananga oil concentration

(0% (control), 0.5%, 1%, and 1.5%; w / v) were factors in this study. Moisture content, free alkali content,

pH, hardness, foam stability and antibacterial activity were analyzed. Staphylococcus aureus and Escherichia

coli were used to test antibacterial activity. The results showed that soap made from VCO oil and 1.5%

cananga oil was the best formulation. The characteristics of transparent solid soap are water content 1.81-

4.39%, free alkali content 0.63-0.96%, pH 11.33-11.81, hardness 0.042 - 0.065 mm / g / s, and foam stability

69.70-85.45%. However, soaps made from VCO were only able to inhibit the growth of Staphylococcus

aureus with inhibitory diameters of 8.1-11.0 mm. Further research is needed to reduce the levels of free alkali

in soap and to increase the concentration of cananga oil so that it can inhibit the growth of Escherichia coli.

1 INTRODUCTION

Soap is a product of fatty acids and strong alkali salts

(sodium or potassium) hydrolysis. There are two

forms of soaps which are bar and liquid. Bar soap is

divided into 3 types, namely opaque, translucent and

transparent solid soaps. Transparent solid soap has

the highest level of clarity where this soap can be

penetrated by light (Prihandana et al., 2007).

Transparent solid soap has more excellence compared

to opaque soap specifically in its clear appearance and

its softer foam because diethanolamine cocoamide,

alcohol and sugar solution were added during

production. Also, high concentration of glycerine was

added giving the transparent solid soap moister.

The types of fatty acid of the raw materials used

in production of transparent solid soap influence the

characteristics of the soap produced (Momuat et al.,

2017). Fatty acids are the major component which is

made up from fat so selection of the fat in the soap

production is very important. The types of fatty acids

used in making transparent soap can come from VCO

oil and palm oil (Widyasanti, 2016), coconut oil

(Rozi, 2013), used cooking oil (Priani, 2010), VCO

and olive oil (Febriyenti, 2014).

Nowadays, transparent solid soap produced with

addition of natural ingredients is in great demand by

consumers especially because of beneficial effects on

skin health. Many synthetic antibacterial ingredients

such as triclosan and chloroxylenol are used to

produce antibacterial soaps (Wijana et al., 2019).

Unfortunately, the use of chemical soap continuously

can cause antibiotic resistance (Roslan et al., 2009).

Natural antibacterial alternatives are needed in soap

production.

In this research, cananga oil was added as

essential oil because cananga is a local flowering

plant in Aceh Province, Indonesia. In Indonesia, in

addition to being used as flowers for the ceremonial

cananga become the identity flora of the Province of

Nanggroe Aceh Darussalam and North Sumatra

Province (Sotyati, 2016). It has a distinctive and

fragrant flower aroma. The chemical composition of

cananga oil is -humulene (7.1%), germacrene D

(8.1%), -farnesene (12.6%), farnesol (5.6%) and

benzyl benzoate (3.8%). The main components that

112

Maulidya, R., Aisyah, Y. and Yunita, D.

Quality Characteristics and Antibacterial Activity of Transparent Solid Soap with Addition of Cananga Oil (Cananga odorata).

DOI: 10.5220/0009957701120118

In Proceedings of the 2nd International Conference of Essential Oils (ICEO 2019), pages 112-118

ISBN: 978-989-758-456-5

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

contribute to the aroma of cananga oil are linalool

(8.7%), dan -caryophyllene (26.8%) (Giang and

Son, 2016). Cananga has also been used for

antibacterial, anti-inflammatory and local anesthetic

activity (Erindyah, 2002).

Cananga oil has the ability to inhibit the growth of

Staphylococcus aureus bacteria. Activity against

bacteria continued to increase in accordance with the

amount of antibacterial compounds in the oil

(Maulidya, 2016; Anggia et al., 2014). The

components of O-methylmoschatoline, liriodenine

(24%), 3,4-dihydroxybenzoic acid, germacrene D

(11%), and ߚ-caryophyllene (12%) have been

investigated to contribute in antimicrobial activity

(Tan et al., 2015). The use of cananga oil serves not

only as a substitute for synthetic antibacterial

substances, but also as a fragrance in transparent solid

soap.

Therefore, the purpose of this study was to

determine the cananga soap formulation as well as to

characterise the quality of the transparent solid soap.

The raw materials used were palm oil and virgin

coconut oil (VCO). Also, cananga oil was used in

various concentration (0.5%, 1%, 1.5%).

2 MATERIALS AND METHODS

2.1 Material

The materials used in this study were cananga oil,

virgin coconut oil (VCO), palm oil, stearic acid,

NaOH, glycerin, ethanol, sugar solution, NaCl,

diethanolamine cocoamide, aquadest, nutrient agar

(Merck®), commercial antibacterial soap,

Staphylococcus aureus and Escherichia coli.

2.2 Research Design

This study used a completely randomized design

(CRD) with a factorial pattern consisting of two

factors. The first factor was types of oils (M)

consisting of two levels (VCO (M1) and palm oil

(M2)). The second factor was cananga oil

concentration (K; w/v) consisting of four levels (0%

(K1; control), 0.5% (K2), 1% (K3) and 1.5% (K4).

2.3 Transparent Soap Production

The oils (coconut oil and palm oil) were heated at

70°C. Stearate acid and NaOH 30% were added and

mixed until homogeneous to produce soap stocks.

Ethanol, glycerin, sugar solutions, sodium chloride,

and diethanolamine cocoamide were added to the

soap stock and stirred constantly for 10 minutes until

the mixture became homogeneous and clear solution

was formed. Cananga oil (0.5%, 1%, 1.5%) was

added to the soap mixture at 40°C and was stirred

until homogeneous. The soap mixture was molded in

a transparent solid soap mold. Furthermore, the

curing process took for 3 weeks.

2.4 Analysis of Transparent Soap

The chemical (water content, free alkali level, pH)

and physical (hardness and foam stability) properties

were examined following Indonesia National

Standard (SNI 06-4085-1996). The soap was

examined for antibacterial testing on Escherichia coli

and Staphylococcus aureus (Widyasanti, 2016). The

antibacterial ability was observed by measuring the

inhibitory area around the media which had been

placed on disc paper, which was marked by the

presence of a clear zone. The clear zone formed is

measured using a callipers.

2.5 Statistical Analysis

Data from water content, free alkali content, pH test,

hardness and foam stability were analysed with

analyse of variance (ANNOVA). The level used in

this analysis was 5%. If there is a significant effect

between treatments, Least Significance Different

(LSD) was used as the post hoc test to find out the

differences between treatments.

3 RESULTS AND DISCUSSION

3.1 Chemical Properties of

Transparent Solid Soap

3.1.1 Water Content

Based on SNI 06-3532-1994, the maximum moisture

content in soap is 15%. The amount of water

contained in soap can affect the characteristics of the

soap during the storage period. Soap with a high

water content or > 15% will experience a decrease in

weight and dimensions (Fachmi, 2008). Based on the

analysis of variance, it is known that the type of oils

has a very significant influence on the water content

of the transparent solid soap produced. The

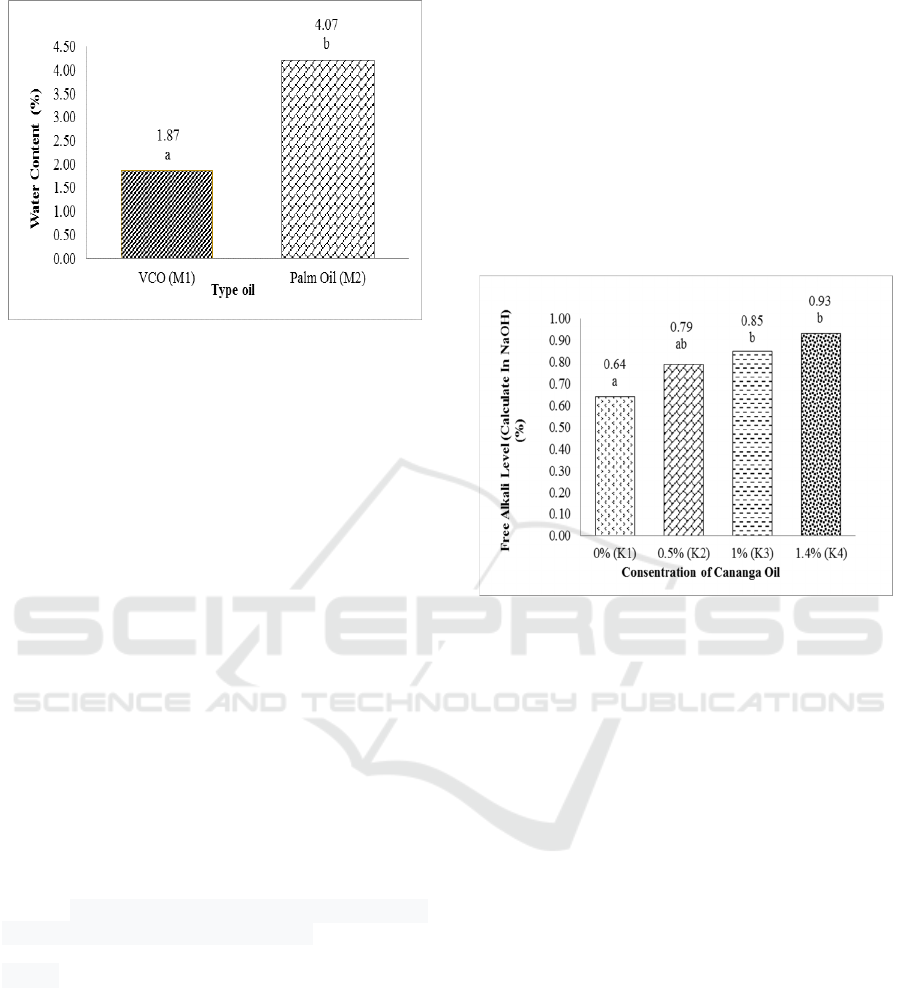

percentage of water content can be seen in Figure 1.

This result showed that the moisture content of

transparent solid soap made from VCO and palm oil

met the SNI.

Quality Characteristics and Antibacterial Activity of Transparent Solid Soap with Addition of Cananga Oil (Cananga odorata)

113

Figure 1: Percentage of water content of transparent solid

soap at different type of oils. The notation followed by the

same letter shows no difference (LSD

0.05

= 0.41 and

coefficient of variation = 15.60%).

Water content is an important quality parameter

on transparent soaps. High water content causes an

increase in rancidity in transparent soap products. The

type of oil in each treatment is sensitive to water

content. The amount of water and volatile substances

in soap will affect the solubility of soap in water when

used (Karo, 2011). The transparent soap produced has

a water content of 1.47% (VCO) and 4.07% (palm

oil).

The results of the diversity analysis (α = 0.05)

showed that the treatment of oil type had a very

significant effect on the water content of transparent

soap. Duncan's further test results show that the water

content of soap in this type of coconut oil is different

from soap made from VCO oil. Fatty acids that react

with NaOH will form soap and water. In addition, the

increase in water content can be caused by the end

result of oxidation of fatty acids contained in soap

which produces volatile aldehyde and ketone

compounds (Karo, 2011). So that soap from VCO oil

has a lower moisture content value than soap from

palm oil.

The highest saturated fatty acid in palm oil is

palmitate acid, and VCO is lauric acid.

3.1.2 Free Alkali Level

Free alkali is alkali in soap which is not needed during

the sapling process (SNI, 1996). Free alkali levels

obtained from this study were 0.64% -0.93%, so as to

increase the pH of the soap. The maximum free alkali

level is 0.1% (SNI, 1996). Soaps that have high free

alkali levels or > 0.1% can cause skin irritation

(Fachmi, 2008). Based on the analysis of variance, it

is known that the concentration of canaga oil has a

very significant influence on the free alkali level of

the transparent solid soap produced. The percentage

of free alkali level can be seen in Figure 2.

Based on Figure 2, the value of alkali levels

increases with increasing cananga oil concentration.

The excess alkali in soap is thought to be caused by

the chemical component of ylang oil containing

alkaloid compounds. The typical chemical

composition of cananga oil generally consists of five

main components, caryophyllene (29.60%),

germacrene-D (19.22%), geraniol acetate (10.79%),

bergamotene (7.97%), α-humulent (7.97%) 7.77%).

Figure 2: Free alkali levels of transparent solid soap at

different cananga oil concentrations. The notation followed

by the same letter shows no difference (LSD

0.05

= 0.16 and

coefficient of variation = 15.81%).

Free alkali levels of soap products produced are

quite high, this is presumably because cananga oil

contains alkaloid compounds. Alkaloids are organic

compounds that are basic or alkaline (Lenny, 2006).

Most alkaloids at room temperature are generally in

the form of colourless crystals and are volatile.

Alkaloids are generally soluble in water, but some are

soluble in organic solvents. Most alkaloids are weak

bases, and some are amphoteric. (Babbar 2015). The

main components that contribute to the aroma of

cananga oil are linalool (8.7%) and β-caryophyllene

(26.8%). This is because linalool is a compound that

gives a distinctive aroma (Oktapiyani, 2004).

3.1.3 pH

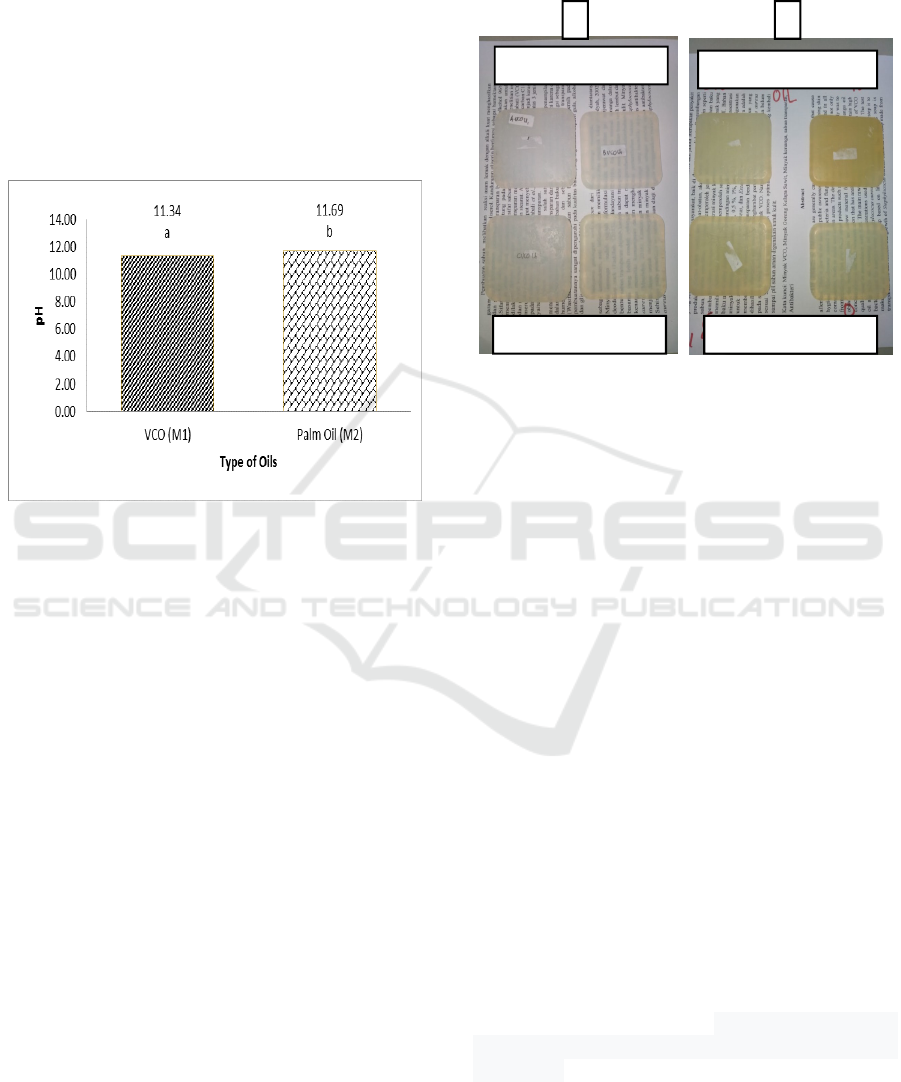

The results of pH measurements can be seen in Figure

3. The type of oil has a very significant effect on the

value of pH. The pH value obtained in VCO oil is

around 11.34 and palm oil is 11.69. The pH values

have met the quality criteria for bath soap ranging

from 9-11 (Hambali, 2005). The final pH value of the

product is strongly influenced by the basic ingredients

ICEO 2019 - 2nd International Conference of Essential Oil Indonesia

114

used (Rahmanto, 2011). In addition, pH

measurements in the range 9-11 are relatively safe for

the skin (Edoga, 2009).

This pH instability can most likely be caused by a

heating factor, due to the hydrolysis of the active

ingredient of sodium ester with fatty acids so that it

can cause free alkali which can increase the pH of

soap (Nurhadi, 2012). The pH of alkaline soap can

help the skin in opening pores and dirt that sticks to

the skin, bound by foam contained in the soap

(Setyoningrum, 2010).

Figure 3: pH value of transparent solid soap at different type

of oils. The notation followed by the same letter shows no

difference (LSD

0.05

= 0.26 and coefficient of variation =

2.65%).

The pH on VCO is lower than that of palm oil. It

is thought that the difference in the fatty acid carbon

chain can affect the low VCO pH value. Addition of

weak fatty acids, such as citric acid, can reduce the

pH of soap (Wasitaatmadja, 1997). Fatty acids in

VCO (lauric acid) have shorter chains when

compared to fatty acids in palm oil (palmitic acid).

This pH instability is most likely caused by a heating

factor, due to the hydrolysis of the active ingredient

of sodium ester with fatty acids so that it can cause

free alkali which can increase the pH of soap

(Nurhadi, 2012).

3.2 Physical Properties of Transparent

Solid Soap

The production of transparent soap made with various

concentration of cananga oil were made on the basis

of 300 g. During the production, the soap loses 100g.

This was expected due to the amount of foam

produced before the printing process so that a lot of

foam was removed when the foam was separated with

the soap mixture. The resulting soap can be said

transparent if when the soap is placed on paper with

12 font size, the letters can be read clearly. The

transparent soap produced in each treatment can be

seen in Figure 4.

Figure 4: Transparent soaps made from: 1) virgin coconut

oil and 2) palm oil at various concentration of cananga oil.

Based on Figure 4 the VCO soap is more

transparent compared to the palm oil soap.

Transparent soap can be produced in several different

ways. One of the oldest methods is by dissolving the

soap in alcohol with gentle heating to make a clear

solution which is then given a fragrance and coloring.

The color of the bar soap depends on the choice of

starting material and if good quality soap is not used,

it is likely that the final product will be very yellow

in color (Williams, 2002). The basic ingredients of

VCO soap have a clear color while palm oil has a

yellowish color. This is thought to be the cause of the

transparent soap from VCO becoming more clear

when compared to palm oil.

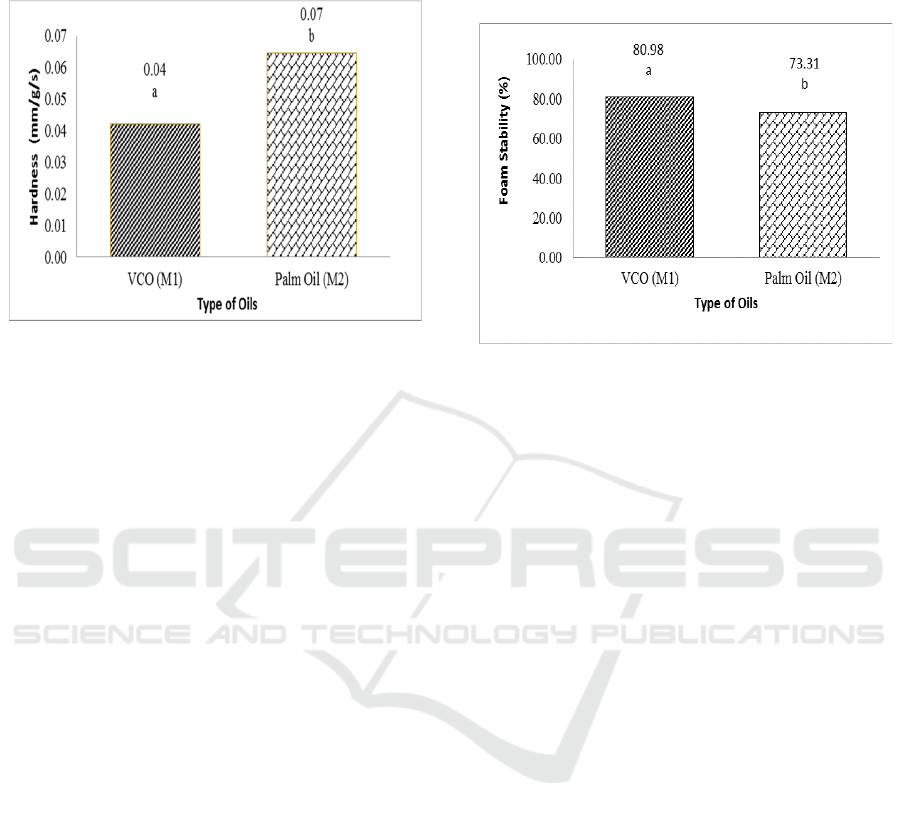

3.2.1 Hardness

The hardness of transparent solid soap can be

influenced by saturated fatty acids which are used as

raw materials in making transparent solid soap. The

results of variance indicate that the type of oil affects

the hardness in soap. Hardness of transparent solid

soap can be seen in Figure 5.

From Figure 5, the type of oil in this study affects

the value of soap hardness. Factors affecting the

hardness of saturated fatty acids and water content

values (Widyasanti, 2016). The highest saturated

fatty acid in palm oil is palmitate acid, and VCO is

lauric acid. Saturated fatty acids are fatty acids that

do not have double bonds, saturated fatty acids are

usually solid at room temperature, so it will produce

a harder soap (Gusviputri et al., 2013). The longer the

A 0% and B 0.5%

A 0% and B 0.5%

C 1% and D 1.5% C 1% and D 1.5%

1 2

Quality Characteristics and Antibacterial Activity of Transparent Solid Soap with Addition of Cananga Oil (Cananga odorata)

115

carbon chain of fatty acids, the fatty acids tend to be

solid.

Figure 5: Hardness of transparent solid soap at different

type of oils. The notation followed by the same letter shows

no difference (LSD

0.05

= 0.02 and coefficient of variation =

37.94%).

The value of water content from the research

results is higher palm oil (4.07%) and lower VCO

(1.87%). The higher the amount of water content

contained in soap, the higher the level of hardness

shown by the penetrometer scale. If the penetrometer

scale shows a high number, the soap will be soft

(Widyasanti, 2016). If the soap is too soft, it will

cause the soap to dissolve easily and become easily

damaged (Steve, 2008).

3.2.2 Foam Stability

Foam is one of the important parameters in

determining the quality of bath soap. In its use, foam

plays a role in the cleansing process on the skin. The

results of various analyses show that the

concentration of cananga oil added to transparent

solid soap does not show a significant difference in

the stability value of the foam. While the type of oil

used in this study showed a significant effect on the

5% test level on the stability of the soap foam. Foam

stability can be seen in Figure 6.

Palm oil contains palmitic acid which is good in

maintaining foam stability. The saturated fatty acids

found in palm oil are palmitic acid which can function

for foam stability (Widyasanti, 2010). Saturated fatty

acids contained in soap make foam more stable when

compared to unsaturated fatty acids (Gromophone

1983).

However, the water content of products made

from palm oil tends to be high, making the foam on

the product unstable. So that the foam is more stable

in VCO-based soap products. Foam characteristics

are also influenced by the presence of soap active

ingredients or surfactants, foam stabilizers and soap

making materials (Amin, 2006).

Figure 6: Foam stability of transparent solid soap at

different type of oils. The notation followed by the same

letter shows no difference (LSD

0.05

= 4.47 and coefficient

of variation = 6.69%).

3.3 Antibacterial Activity of

Transparent Cananga Oil

Gram positive bacteria Staphylococcus aureus and

Gram negative bacteria Escherichia coli were used to

test the antibacterial effect of transparent solid soap

containing cananga oil. These bacteria were selected

because these pathogenic bacteria are often found on

the hands and skin. The results showed that addition

of cananga oil until 1.5% in transparent solid soap

production made from VCO and palm oil could not

inhibit E. coli. The inhibitory effect of S. aureus was

shown on the soap made from VCO only (Figure 7).

From Figure 7, there is a very significant

influence on inhibitory diameter of S. aureus because

of the interaction between type of oil and cananga oil

concentration ranging from 8.07 - 11.00 mm. The

inhibition occurred in the VCO oil because this oil

contains lauric acid which also has antibacterial effect

(Febriyenti, 2014). Antibacterial compounds in soap

provide activity in inhibiting bacteria caused because

the soap is hydrophilic-lipophilic. Nonpolar groups

on soap are -R and -COONa groups which are

polar in nature. The hydrophilic nature of soap causes

antimicrobial compounds to be able to diffuse in polar

agar media, while the lipophilic nature of soap will

help the penetration of antibacterial compounds into

lipophilic bacterial cell membranes (Pelczar, 1998).

ICEO 2019 - 2nd International Conference of Essential Oil Indonesia

116

Figure 7: Inhibitory diameter of Staphylococcus aureus on

transparent solid soap. The notation followed by the same

letter shows no difference (LSD

0.05

= 0.69 and coefficient

of variation = 8.37%).

4 CONCLUSIONS

Palm oil and VCO can be formulated into transparent

solid soap by adding different concentrations of

cananga oil. Physical and chemical analyses showed

that the soaps have meet the SNI. Unfortunately, the

value of free alkali in soap exceeds the maximum SNI

limit and in bacterial inhibition tests, only VCO is

significant in Staphylococcus aureus. Further

research is needed to reduce the levels of free alkali

in soap and increase the concentration of cananga oil

so that it can inhibit the growth of Escherichia coli.

REFERENCES

Anggria, F.T., Yuharmen., Balatif, N. 2014. Perbandingan

Isolasi Minyak Atsiri dari Bunga Kenanga (Cananga

odorata (Lam.) Hook.f dan Thoms) Cara Konvensional

dan Microwave serta Uji Aktivitas Antibakteri dan

Antioksidan. Fakultas Matematika dan Ilmu

Pengetahuan Alam, Universitas Riau, Riau.

Amin, H. 2006. Kajian Penggunaan Kitosan Sebagai

Pengisi dalam Pembuatan SabunTransparan. Skripsi,

Fakultas Perikanan dan Ilmu Kelautan, Institut

Pertanian Bogor, Bogor.

Badan Standarisasi Nasional. 1996. Standar Sabun Mandi

Cair, SNI 06-4085-1996, Dewan Standarisasi Nasional,

Jakarta.

Babbar, N. 2015. An Introduction to Alkaloids and Their

Applications in Pharmaceutical Chemistry. The

Pharma Innovation Journal, 4 (10), 74-75.

Edoga, M, O. 2009. Comparison of various fatty acid

sources for making soft soap (Part 1). Qualitative

analysis. Department of Chemical Engineering, Federal

University of Technology, Minna, Nigeria.

Erindyah, R,W., Maryati. 2002. Aktivitas Antibakteri

Minyak Atsiri Pinus Terhadap S. aureus dan E.coli.

Jurnal Farmasi Indonesia Pharmacon 4 (1) : 20-24.

Fachmi, C. 2008. Pengaruh Penambahan Gliserin dan

Sukrosa Terhadap Mutu Sabun Transparan. Skripsi.

Fakultas Tekhnik Pertanian, Institut Pertanian Bogor,

Bogor.

Febriyenti., Sari, L. I., Nofita, R. 2014. Formulasi Sabun

Transparan Minyak Ylang-Ylang dan Uji Efektivitas

terhadap Bakteri Penyebab Jerawat, Fakultas Farmasi,

Universitas Andalas, Padang.

Giang, P. M., Phan, T. S. 2016. GC and GC-MS Analysis

of The Fresh Flower Essential Oil of Cananga odorata

(Lam.) Hook. f. et Th. var. fruticosa (Craib) J. Sincl.

American Journal of Essential Oils and Natural

Products, 4 (4) : 09-11.

Gromophone, M, A. 1983. Lather Stability of Soap

Solutions. JAOCS. 60 (5) : 1022-1024.

Gusviputri, A., Meliana, N. P. S., Aylianawati., Indraswati,

N. 2013. Pembuatan Sabun dengan Lidah Buaya (Aloe

vera) Sebagai Antiseptik Alami. Fakultas Teknik.

Universitas Katolik Widya Mandala. Surabaya.

Hambali, E., Bunasor, T. K., Suryani, A., Kusumah, G. A.

2005. Aplikasi Dietanolamida dari Asam Laurat

Minyak Inti Sawit pada Pembuatan Sabun Transparan.

Fakultas Teknologi Industri Pertanian, Bogor.

Karo, A. Y. 2011. Pengaruh Penggunaan Kombinasi Jenis

Minyak terhadap Mutu Sabun Transparan. Skripsi.

Institut Pertanian Bogor. Bogor.

Lenny, S. 2006. Senyawa Flavonoida, Fenilpropanoida

dan Alkaloida. Karya Ilmiah. Universitas Sumatera

Utara, Medan.

Maulidya, R., Aisyah, Y., Haryani, S. 2016. Pengaruh Jenis

Bunga dan Waktu Pemetikan Terhadap Sifat

Fisikokimia dan Aktivitas Antibakteri Minyak Atsiri

Bunga Kenanga (Cananga odorata). Jurnal Teknologi

dan Industri Pertanian Indonesia, 8(2), 53-60.

Momuat, L, I., Wuntu, A, D. 2017. Produksi Sabun Mandi

Transparan Berbahan Baku Vco Mengandung

Karotenoid Tomat.

Program Studi Kimia FMIPA,

Universitas Sam Ratulangi, Manado.

Nurhadi, S, C. 2012. Pembuatan Sabun Mandi Gel Alami

dengan Bahan Aktif Mikroalga Chlorrela pyrenoidosa

Beyerinck dan Minyak Atsiri Lavandula lativolia

Chaix. Fakultas sains dan Teknologi, Universitas Ma

Chug, Malang.

Oktapiyani, S. 2004. Respon Penyimpanan Bunga Ylang-

ylang (Cananga odorata forma genuina) terhadap

Rendemen dan Kualitas Minyak Atsiri. Institut

Pertanian Bogor, Bogor.

Pelczar, M, J. 1988. Dasar-Dasar Mikrobiologi. UI Press,

Jakarta.

Priani, S, E., Lukmayani, Y. 2010. Pembuatan Sabun

Transparan Berbahan Dasar Minyak Jelantah Serta

Hasil Uji Iritasinya Pada Kelinci. Jurusan Farmasi,

Universitas Islam Bandung, Bandung.

Prihandana, R., Erliza, H., Siti, M., Roy, H. 2007. Meraup

Untung dengan Jarak Pagar. Agromedia Pustaka,

Jakarta.

Quality Characteristics and Antibacterial Activity of Transparent Solid Soap with Addition of Cananga Oil (Cananga odorata)

117

Rahmanto, A., 2011. Pemanfaatan Minyak Jarak Pagar

(Jatropha curcas, Linn) Sebagai Komponen Sediaan

dalam Formulasi Produk Hand and Body Cream.

Program Studi Teknologi Industri Pertanian

Pascasarjana, Institut Pertanian Bogor, Bogor.

Roslan, A, N., Sunariani, J., Irmawati, A. 2009. Penurunan

Sensitivitas Rasa Manis Akibat Pemakaian Pasta Gigi

yang Mengandung Sodium Lauryl Sulphate 5%. Jurnal

Persatuan Dokter Gigi Indonesia Vol 58 (2) : 10-13.

Rozi, M., Sulaiman, T, N, S., Indrayudha, P. 2013.

Formulasi Sediaan Sabun Mandi Transparan Minyak

Atsiri Jeruk Nipis (Citrus Aurantifolia) Dengan

Cocamid Dea Sebagai Surfaktan. Fakultas Farmasi,

Universitas Muhammadiyah Surakarta.

Setyoningrum., Maharani, E, N. 2010. Optimasi Formula

Sabun Transparan dengan Fase Minyak Virgin

Coconut Oil dan Surfaktan Cocoamidopropil Betaine.

Fakultas Farmasi, Universitas Sanata Dharma,

Yogyakarta.

Sotyati. 2016. Kenanga, Flora Identitas Aceh.

http://www.satuharapan.com/read detail/read/kenanga-

flora-identitas-aceh-kaya-manfaat.16 Desember 2019.

Steve., 2008. Saponification Table Plus The

Characteristics of Oils in Soap. USA. http://www.soap-

making-resource.com/saponification-table.html. 19

Desember 2019.

Tan, L. T. H., Learn, H. L., Wai, F. Y., Chim, K. C.,

Habsah, A. K., Kok, G. C., Bey, H. G. 2015. Traditional

Uses, Phytochemistry, and Bioactivities of Cananga

odprata (Ylang-Ylang). Evidence-Based

Complementary and Alternative Medicine : 1-30.

Wasitaatmadja, S. M. 1997. Penuntun Ilmu Kosmetik

Medik. Universitas Indonesia, Jakarta.

Widyasanti, A., Farddani, C, L., Rohdiana, D. 2016.

Pembuatan Sabun Padat Transparan Menggunakan

Minyak Kelapa Sawit (Palm Oil) dengan Penambahan

Bahan Aktif Ekstrak Teh Putih (Camellia sinensis).

Fakultas Teknologi Industri Pertanian Universitas

Padjadjaran, Bandung.

Wijana, S., Tika, P., Nur, L. R. 2019. Optimization of

Solubilizers Combinations on The Transparent Liquid

Soap with The Addition of Peppermint (Mentha

piperita L.) and Lavender (Lavandula L.) Oil. AIP

Conference Proceedings 2120, 050020 (2019).

Williams, D, F., Schmitt, W, H. 2002. Kimia dan Teknologi

Industri Kosmetika dan Produk-produk Perawatan

Diri. Fakultas Teknologi Pertanian,IPB. Bogor.

ICEO 2019 - 2nd International Conference of Essential Oil Indonesia

118