How is the Application of Analytical Hierarchy Process in Supplier

Performance Assessment?

Iren Sukmawati R.

1

, Umi Rochayati

1

and Muhammad Imron Romadhon

1

1

Electronic and Informatics Engineering Education Study Program, Universitas Negeri Yogyakarta, Yogyakarta, Indonesia

Keywords:

Decision Support System, Analytical Hierarchical Process, Supply Chain Operation Reference, Performance

Assessment, Supplier.

Abstract:

This study aims to measure supplier performance more accurately using the Analytical Hierarchical Process

(AHP) method. The AHP method does the weighing and measurement of each evaluation criterion in the

Performance Assessment of Decision Support System (DSS). This study took twenty suppliers samples con-

sisting of ten local suppliers and ten national sample suppliers at Karsa Utama Lestari Ltd Gorontalo. This

study is quantitative. We use the interview method to collect data. Besides, data analysis techniques use ana-

lytical descriptions. The results showed that the assessment using the AHP method had five main criteria, 16

sub-criteria, and 37 sub-criteria. Five main measures were taken in the process of the Supply Chain Operation

Reference (SCOR) approach, such as reliability, responsiveness, coast, flexibility, and assets. Therefore, this

method produces better performance measurements compared to conventional performance appraisal models

because the results of supplier performance assessment can be observed quickly and precisely interpreted in a

diagram on a computer.

1 INTRODUCTION

Suppliers are a crucial part of the supply chain. Sup-

pliers also affect the activeness of a company. The

accuracy in choosing suppliers can reduce purchasing

costs, increase market competitiveness and increase

product end-user satisfaction (

¨

On

¨

ut et al., 2009).

A Trial is conducted on suppliers related to the

information function between suppliers and compa-

nies (Hald and Ellegaard, 2011). Suppliers must con-

tinue to be monitored to have cooperation with the

company and are always tracked at all times (Sell-

berf and Broman, 2000). According to Cousins et

al. (2008), the method of Analyzing the Hierarchical

Process (AHP) not only in terms of communication

and operations but in terms of price and business can

be used as a supplier or supplier assessment.

Karsa Utama Lestari Ltd has approximately 500

suppliers spread across parts of Indonesia. A large

number of suppliers cause several problems to pri-

oritize demand for certain goods. These problems

are difficulties with significant demand for products,

limited supply of goods from suppliers, and slow re-

sponse from suppliers. This problem has a profound

impact on company stability. Therefore, companies

need a performance measurement system for suppli-

ers. This system uses the Supply Chain Operations

Reference model (SCOR). The SCOR approach is the

main cafeteria at the company Karsa Utama Lestari

Ltd. The SCOR approach aims to determine crite-

ria and sub-criteria that are suitable for the company

when the company selects the criteria for evaluating

performance against suppliers.

The results of the performance measurement ap-

proach are measured based on criteria using the AHP

(Analytical Hierarchy Process method) method. The

function of this method is to determine the weights for

each supplier’s performance criteria and indicators.

We developed a DSS system using the AHP method

to measure the performance of each supplier more ef-

ficiently and to supervise suppliers who collaborate

with the company. Besides, the company can control

the amount of stock of goods if suppliers make delays

in the supply of goods.

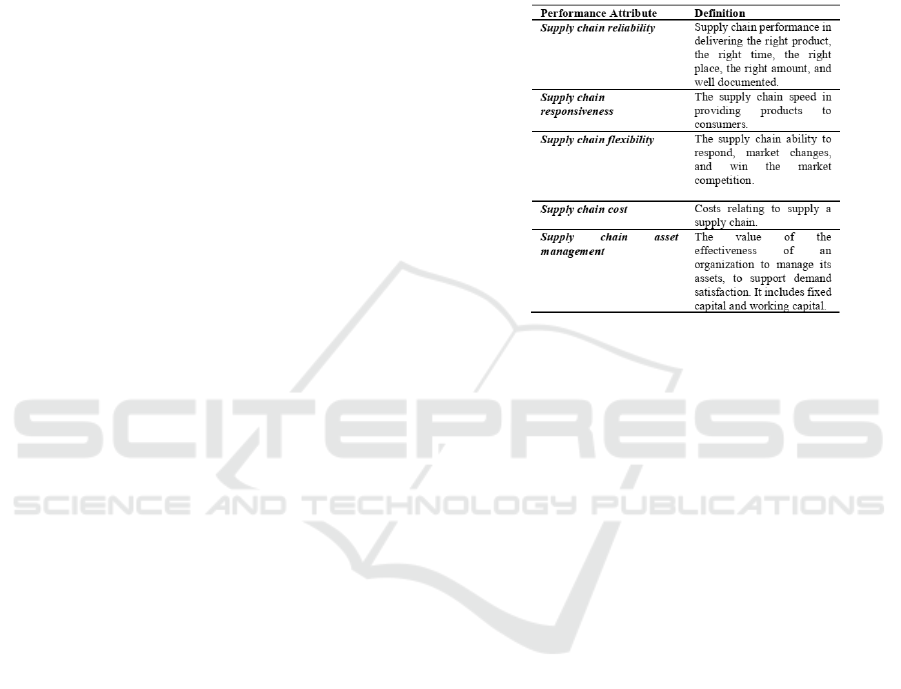

SCOR is effectively applied for evaluating sup-

plier performance because SCOR has performance at-

tributes (Team, 2006). Performance attributes are cell

attributes that are used to assess supply chain pro-

cesses from a variety of different perspectives. The

SCOR method has five attributes to evaluate supply

chain performance. Multiple metrics can be used as

performance measurement metrics in one attribute.

Sukmawati R., I., Rochayati, U. and Romadhon, M.

How is the Application of Analytical Hierarchy Process in Supplier Performance Assessment?.

DOI: 10.5220/0009908202190226

In Proceedings of the International Conferences on Information System and Technology (CONRIST 2019), pages 219-226

ISBN: 978-989-758-453-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

219

Based on (Karjalainen, 2012), performance im-

provement from suppliers requires a framework. AHP

is used as an international supplier selection as a

domain strategy model. Assessment criteria on the

supplier’s performance can be obtained based on the

problems in the company. Supplier performance eval-

uation is very important for the sustainability of a

company (Domier, 1998), and the concept of supply

chain management (SCM) can overcome global com-

petition between companies (Ahmad and Yuliawati,

2013). A standardized company is a company that can

meet all market needs, meet the needs of each of its

customers, incur low enough costs to stock products,

manage industries more flexible.

The AHP model has several criteria, including

quality, endurance test (Zahir, 2014). Other mea-

sures are a delivery process, price, response, busi-

ness and stability, information about process devel-

opment, technical capability, and excellent and stable

background. In short, there are three criteria for the

best suppliers to produce decisions in the selection of

suppliers who can cooperate with the company. Ac-

cording to (Baily et al., 2005), an excellent supplier

must deliver goods on time, remains consistent with

the quality of an item, provides a much lower price

or the best price, and has a stable background. Be-

sides, the supplier must give after-sales service good,

provide services to good inventory, conduct what will

be done, and provide information on developments to

consumers or companies.

This study uses the SCOR approach to decide the

category and sub-category appropriating for the com-

pany. Besides, this study also uses the DSS method.

DSS is an AHP method to measure the performance

of suppliers results from the way to be used. Then the

results can be seen to measure supplier performance.

In this study, the main criteria used are those that are

in the SCOR approach. The SCOR approach crite-

ria are reliability, responsiveness, flexibility, coast, as-

sets. Sub criteria are taken from the SCOR approach

based on the main criteria located at PT. Karsa Utama

Lestari. Besides, this study only reached the comple-

tion of level 1- Top-level (a type of process), because

in this study only defines one of the five core manage-

ment processes of the SCOR model, which is called

source.

2 THEORY STUDY

2.1 Supplier

(Chopra and Meindl, 2007) suggested that the supply

chain is a general description of how to manage an

organization in terms of distributors, manufacturers,

and consumers. The goal of the supply chain is to

meet the needs and generate consumer profits. A per-

formance attribute is a cell attribute to evaluate supply

chain processes from a variety of different perspec-

tives. Five attributes to assess supply chain perfor-

mance are the use of performance attributes from the

Supply Chain Operation Reference (SCOR).

Figure 1: Performance attributes.

2.2 Decision Support System

DSS was known in the early 1970s by Michael S.

Scott, as the Management Decision System. DSS was

a computer-based system to helps decision making by

utilizing data and models to solve unstructured prob-

lems (Turban et al., 2005).

2.3 Analytical Hierarchy Process (AHP)

This method is used to decided effective decisions on

complex problems. It began to simplify and speed up

the decision making process by solving the problem

into its parts, arranging variables in a hierarchical ar-

rangement, giving a numerical value. To subjective

considerations of the importance of each variable and

synthesize is to consider and determine which vari-

able has the highest priority and act to influence the

outcome of the situation.

The AHP process can solve the problem in an or-

ganized frame of mind so that it can be expressed to

make effective decisions on the problem. (Marimin,

2004). AHP method has ten advantages proposed by

(Marimin, 2004), namely: (1). The AHP method has

the advantage of dealing with a significant and un-

structured problem into a model that is more flexible

and easier to understand. (2) AHP is very complex,

and this method overcomes very complex problems

by using a system approach and integration by deduc-

tion. (3) influence each other, and this method is able

CONRIST 2019 - International Conferences on Information System and Technology

220

to be used on elements. It consists of free and do

not require linear relationships. (4) hierarchical ar-

rangement, in this method, is a representative of nat-

ural thinking, tending to group more system elements

at different levels from each level that has the con-

tents of similar elements. (5) having measurements,

this method has an alternative measurement scale and

methods for getting priority. (6) Consistent, the AHP

method firmly maintains what is called logical consis-

tency in carrying out assessments used to determine

priorities. (7) Synthesis, AHP leads to overall think-

ing about what some of the alternatives want. (8) Bar-

gaining, the purpose of bargaining in this method is

that AHP takes priority seriously so that other people

can choose the best alternative to achieve what they

have designed. (9) Assessment and Consensus, this

method does not require the presence of a counselor,

but in this method, how to combine the results of dif-

ferent assessments. (10) Repetition of the process,

the intention can make people able to filter the under-

standing of one problem and develop an assessment

and understanding through the process of repetition.

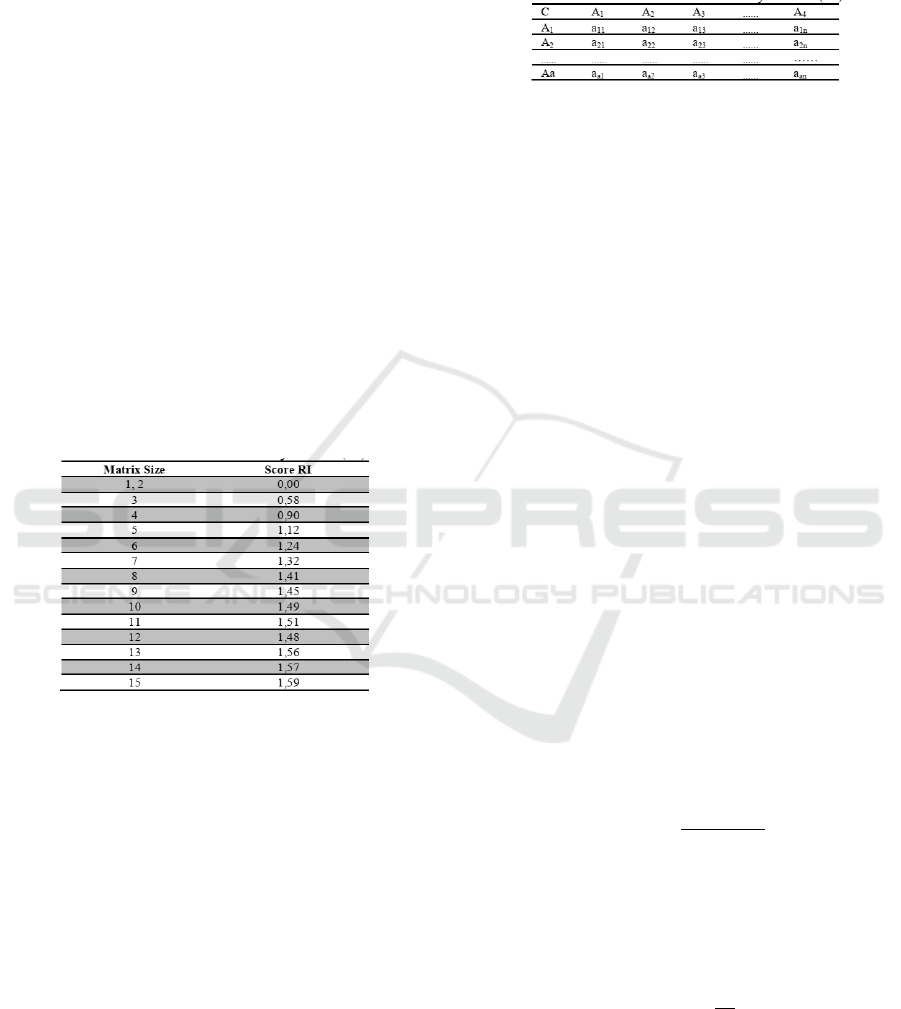

List of random consistency index (IR) can be seen

in the following table:

Figure 2: Performance attributes.

2.4 Steps of the AHP Method

The steps in the AHP method include (Kusrini, 2007)

as follows:

1. Define the problem and determine the desired so-

lution, then arrange the hierarchy of the prob-

lem at hand. The hierarchy arranges to set goals,

which are the overall system goals at a limited

level.

2. Determine the priority of the element

(a) The first step is to make a paired comparison,

i.e., comparing the elements in pairs according

to the given criteria.

(b) Paired comparison matrices are filled using

numbers to represent the relative importance of

one element to the other elements.

The comparison matrix can be seen in Figure 3,

where this matrix explains the relative contribu-

tion or something that influences each element of

the objectives or criteria.

Figure 3: List of Random Consistency Indices (IR) Source:

(Saaty, 1980).

3. Synthesis

Considerations of pairwise comparisons are syn-

thesized to obtain overall priority. The things

done in this step are:

(a) Add up the values of each column in the matrix

(b) Divide each value from the column by the total

column in question to obtain matrix normaliza-

tion.

(c) Add up the values of each row and divide by the

number of elements to get the average value.

4. Measure consistency

In making decisions, it is essential to know how

the right consistency is because we do not want

decisions based on considerations with low con-

sistency. Things are done in this step:

(a) Multiply each value in the first column by the

relative priority of the second element, and so

on.

(b) Add up each row

(c) The results of the row addition are divided by

the relative priority element in question.

(d) The number of quotient above with the number

of elements available, the result is called max.

5. Calculate consistency index (CI) with the for-

mula:

CI =

λmaks − n

n − 1

(1)

Where:

n = Number of elements

6. Calculate the consistency ratio (CR) with the for-

mula:

CR =

CI

IR

(2)

Where:

CR = Consistency ratio

CI = Consistency index

IR = Index random consistency

How is the Application of Analytical Hierarchy Process in Supplier Performance Assessment?

221

7. Checking is the same as hierarchical consistency.

If the value is more than 10%, then the judgment

data must be improved. However, if the consis-

tency ratio (CI / IR) is less or equal to 0.1, then

the calculation results can be declared correct. A

list of consistency random index (IR) can be seen

in table 2.

3 METHOD

This study uses the Waterfall system development

method (based on the waterfall stage in (Arbani et al.,

2011)). The advantages of the waterfall include the

process is easy to understand and clear and to man-

age the project. Besides, the document is generated

in every phase; a phase is run after the previous pe-

riod is complete; the system structure is transpar-

ent; user needs are well understood; the possibility

of changes in user needs is slight. The sample of the

study is twenty suppliers samples consisting of ten

local suppliers and ten national sample suppliers at

Karsa Utama Lestari Ltd Gorontalo.

3.1 Analysis and Definition

This stage carries out the process of analyzing the val-

uation model previously at Karsa Utama Lestari Ltd.

After we decided on the subsequent analysis stage,

We conducted a literature study and literature study.

We make observations and interviews to obtain infor-

mation and data needed in this study. Data referred to

as the number of suppliers who have partnered with

the company.

Figure 4: The stages in the waterfall

3.2 System Planning

The stages of system design are intended to design

an information system design. The assessment pro-

cess using AHP will be entered into a performance

appraisal information system. Where at this stage, the

application design will be made, and database design.

3.3 Unit Implementation and Testing

This stage will be carried out in the testing process.

The system will be tested using black-box testing; the

coding or program will be written before we translate

the system process design into a language that is rec-

ognized by the computer. The programmer’s tip does

this stage, in which the programmer will explain the

needs desired by a user into the form of a program.

3.4 System Integrity and Testing

This stage is the final stage in the application of the

AHP method in a performance appraisal system. This

stage will also make improvements if problems or de-

ficiencies are found in the performance appraisal sys-

tem.

3.5 Operation and Maintenance

Operation and maintenance is the last stage in the wa-

terfall model because the maintenance process of the

system used, and it has been applied to the decision

support system (DSS) method.

4 RESULTS

The result showed that supplier performance appraisal

is still less than optimal in terms of quality and time.

Karsa Utama Lestari Gorontalo Ltd conducted to as-

sess supplier performance every six months. The as-

sessment result showed that the lack of optimality

and effectively in terms of time because the supplier’s

performance evaluation uses the observation method

without having detailed documentation.

The aimed of assessing the performance of suppli-

ers is to get suppliers that have good quality, respon-

sibility and can meet the needs of the company. The

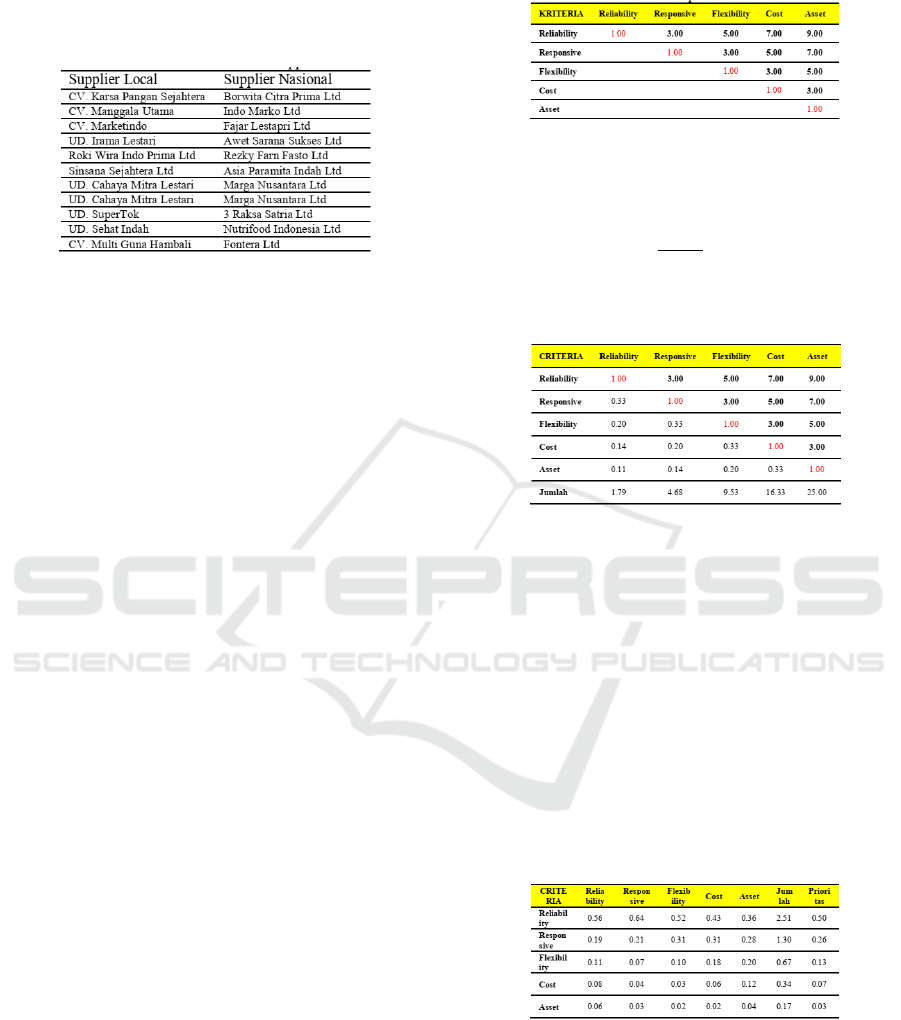

results of the data collection showed that the top 10

local and national suppliers could be seen in Figure 5.

Data inputted on the system implementation is tested

using manual calculations on Excel. The results dis-

played on the system implementation are the same

as manual calculations so that the application created

can view the results of supplier performance measure-

ments using the AHP method appropriately. The as-

sessment process of local suppliers and national sup-

pliers on Karsa Utama Lestari Gorontalo Ltd still uses

the observation evaluation model.

The traditional model does not have detailed doc-

umentation in the performance appraisal process of

each supplier. The DDS method is the Analytical Hi-

erarchy Process (AHP) method, which consists of 5

CONRIST 2019 - International Conferences on Information System and Technology

222

chief criteria, 16 sub-criteria, and 37 sub-criteria. The

results of the assessment used the assessment method

of AHP, which was made into two suppliers, local and

national suppliers:

Figure 5: Local and national suppliers (Source: Interview

with Director of Karsa Utama Lestari Gorontalo, 2015).

4.1 Analysis of the Calculation Process

using the AHP Method

In the analysis of this process, the authors use the

AHP method in completing calculations to measure

supplier performance. All data, subcriteria, and sub-

criteria are used to get the final result of this process.

After obtaining the input data needed, the next step is

to perform calculations using the AHP method. Some

steps that must be done are:

4.1.1 Determine the Types of Criteria

In this study, the authors conducted studyat Karsa

Utama Lestari Gorontalo Ltd in measuring sup-

plier performance in determining supplier ranking,

which will become a partner at Karsa Utama Lestari

Gorontalo Ltd. The criteria that will be used in the

assessment consist of 5 main criteria based on the

SCORE approach. The 5 criteria are:

C1 = Reliability

C2 = Responsive

C3 = Flexibility

C4 = Coast

C5 = Asset

4.1.2 Make a Pairwise Comparison Matrix

A comparison between one criterion and another will

be assessed at this stage. The upper triangle matrix

element is input. A comparison of one criterion and

other criteria will also be evaluated. The results of the

assessment can be seen in Figure 6.

space

Figure 6: Pairwise comparison matrix table.

We use the formula to get the value of the lower

triangular matrix element:

a[ j,i] =

1

a[i, f ]

unuki 6= j (3)

The results add up the values of each column in

the matrix. The results can be seen in Figure 7.

Figure 7: Matrix tables of pairwise comparison values.

In column (C1 row C2) is the result of an interme-

diate calculation ((value in column C1 row C1 = 1)

/ (value in column C2 row C1 = 2)) gets a result of

0.33. While the total value is obtained from the sum

of each column, for example the value of the num-

ber of columns C1 = 1.79 is obtained from the sum of

column values C1 (1 + 0.33 + 0.20 + 0.14 + 0.11).

After getting the paired comparison matrix value,

the next step is to divide the value of each element by

the number of each column in table 6, namely (row

value column = = value in table 6 column C1 row C1

= 1) / (sum of each column = 1.79) Then for the other

values obtained from the same calculation, for more

clearly the results can be seen in Figure 8 below.

Figure 8: Table of the criteria value matrix.

The results of the sum column in Figure 8 are ob-

tained from the sum of each row, for example: value

= 2.51 is obtained from the sum (0.56 + 0.64 + 0.52

+ 0.43 + 0.36), for the next row is obtained from the

same calculation results.

As for the value in the priority column obtained

from (the value of the number of columns) / (number

How is the Application of Analytical Hierarchy Process in Supplier Performance Assessment?

223

of criteria), which is five criteria. For example, for the

priority value of line C1 = 0.50 obtained from (value

of the number of rows C1 = 2.51) / (number of criteria

= 5), the same steps are carried out in the previous

rows.

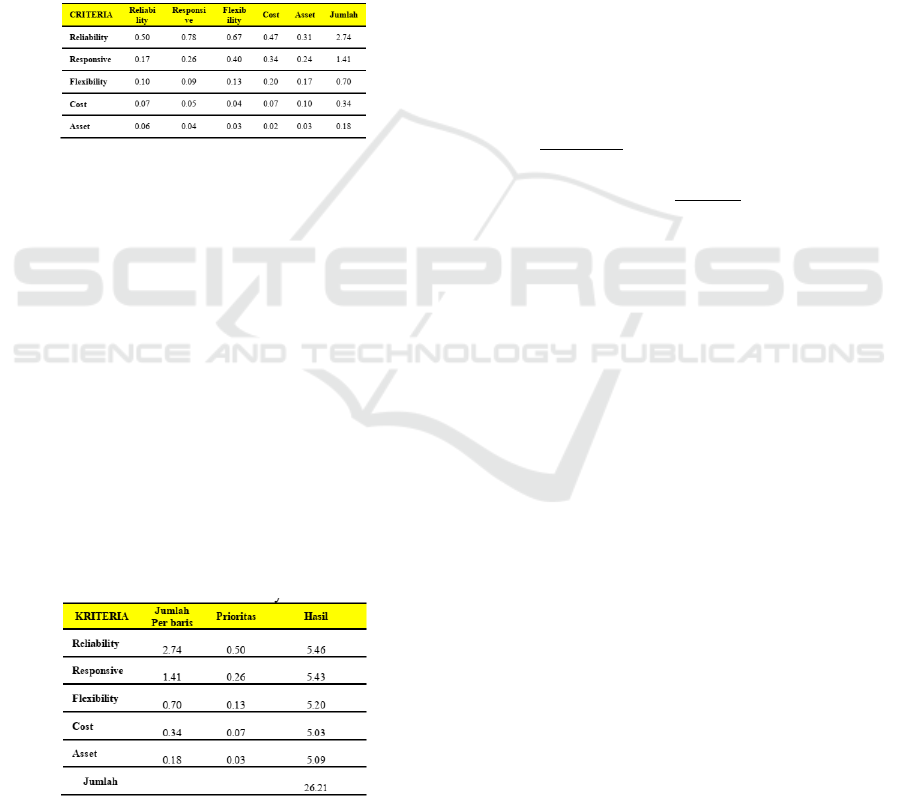

4.1.3 Make an Addition Matrix for Each Line

To make the addition matrix for each row in this way,

(value of priority in table 7) * (pairwise comparison

matrix in table 6). For example, (C1 priority value in

table 7 = 0.50) * (C1 row C1 in table 6 = 1) = 0.50.

The other values are obtained in the same way; the

results can be seen in Figure 9 viz.

Figure 9: Table of the criteria value matrix.

After multiplying each element by the priority

value, then add each row from the obtained matrix.

For example for line elements C1 = 2.74 is the sum

of (0.50 + 0.78 + 0.67 + 0.47 + 0.31), then the other

rows are carried out with the same calculation process

up to C5.

4.1.4 Calculate Consistency Ratio

The value calculation of the consistency ratio aims

to see the value of the consistency ratio (CR). If the

value of CR <= 0.1 then the calculation can be ac-

cepted or valuable. Whereas if the CR value is more

significant than 0.1, then the pairwise comparison ma-

trix must be corrected so that it is declared to be in-

appropriate. To calculate the value of the consistency

ratio can be seen in Figure 10 below.

Figure 10: Consistency ratio table.

The value in the sum column of each row is ob-

tained from the value of the sum column in table 8,

while the priority column value is obtained from the

priority column value in Figure 8. For the result, col-

umn values are obtained from the sum of the sum val-

ues for each row with priority. For example the value

of 5.46 results from (column number in row C1 =

2.74) / (priority column in row C1 = 0.50) = 5.46 and

so on until row C5. After obtaining the value of the

results of each row, then the next is to add all the val-

ues in the results column so that the results obtained

are 26.2.

After obtaining the total value of 26.21, the next

step is to calculate the value of λmax. The value of

λ max is obtained from the value of number = 26.21

/ number of criteria = 5. In this study, the number of

criteria is five criteria, so the λmax value is 5.26.

4.1.5 Calculate the Consistency Index

Calculating the consistency index (CI) using the fol-

lowing formula:

CI =

λmaks − n

n − 1

CI =

5.26 − 5

5 − 1

CI = 0.26/4

CI = 0.06 (4)

4.1.6 Calculate Consistency Ratio

The value of the consistency ratio (CR) is obtained

using the formula below:

CR = CI/IR

CR = 0.06/1.12

CR = 0.05 (5)

Where the value of 0.05 is obtained from the

calculation of the consistency index in the previous

stage, while the value of IR (Random Index) is taken

from the rules of the random index predetermined ac-

cording to the matrix size of the elements, where the

IR value rules have been displayed in table 2 so that

the results of CR are = 0.05, therefore CR ¡= 0.1,

the consistency ratio from the calculation can be ac-

cepted.

The same steps are carried out in the calculation of

sub-criteria and calculation of sub-criteria, the same

calculation in the previous stage determines the prior-

ity of sub-criteria and priority of subcriteria using the

AHP method. In order to obtain the values of each

element in the sub-criteria and sub-criteria, as shown

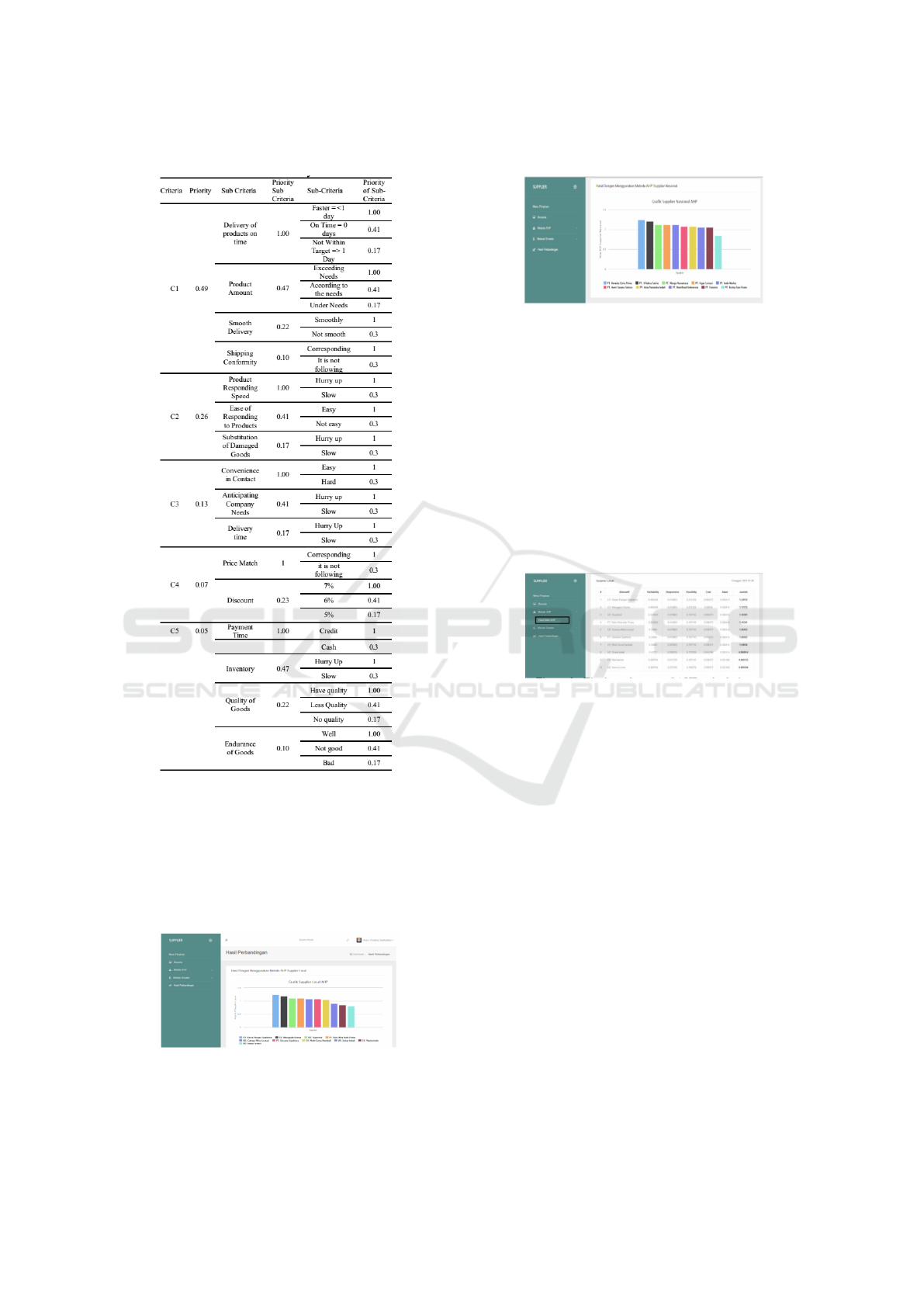

in Figure 11 below.

CONRIST 2019 - International Conferences on Information System and Technology

224

space

Figure 11: Consistency ratio table

4.2 Solving Results using the AHP

Method

This display is a display of the results of local and

national supplier assessments using the AHP method.

Figure 12: Comparison results page of local AHP method

space

Figure 13: Comparison results page of the national AHP

method

In this research, the problem that has been ex-

plained above is resolved by the application made,

namely Measuring Supplier Performance, with the

SCOR approach using the AHP method, which can

be accessed through the website. How is the Applica-

tion of the Analytical Hierarchy Process in Supplier

Performance Assessment? In this study, it can be

seen that the application of the AHP method in perfor-

mance appraisal provides more structured and stored

results in a database. The several displays that show

information about the measurement results using the

AHP method can be chosen in Figure 14.

Figure 14: Final result page of AHP calculation

5 CONCLUSIONS

The study explained that how to solve a problem

with a measuring supplier performance that is less ef-

fective in measuring supplier performance to deter-

mine which suppliers can be maintained as partners

in Karsa Utama Lestari Gorontalo Ltd. The supplier

performance appraisal process still uses the conven-

tional appraisal process without supporting data, and

there is no decision support system in measuring sup-

plier performance to determine which suppliers will

be partners with Karsa Utama Lestari Ltd.

The supplier performance evaluation system is a

system to assess the performance of suppliers who are

at Karsa Utama Lestari Gorontalo Ltd. The method

is used DSS, which is called the Analytical Hierar-

chy Process (AHP). The AHP method consists of five

studies at criteria, 16 sub-criteria, and 37 sub-criteria.

We used five main criteria in the supply chain op-

eration reference (SCOR) approach. They are reli-

ability, responsiveness, flexibility, coast, and assets.

How is the Application of Analytical Hierarchy Process in Supplier Performance Assessment?

225

The DSS method used in the supplier performance

evaluation process, the Analytical Hierarchy Process

(AHP) method, is significantly better than the conven-

tional assessment process.

The results showed that the evaluation of the fi-

nal results using the method is the company can see

which suppliers can be used as partners in the com-

pany.

The process of applying the AHP method begins

by making a pairwise comparison matrix, making a

sum matrix for each row, calculating the consistency

ratio, calculating the consistency index, and calculat-

ing the consistency ratio. Furthermore, the values ob-

tained in the priority criteria, priority sub-criteria, and

priority sub -sub-criteria will be used in the process

of evaluating the performance of local suppliers and

national suppliers. In contrast, the previous method

did not have a valuation model because it was still

conventional.

The result of the calculation process carried out by

the AHP method with the calculation of the assess-

ment done manually will undoubtedly produce differ-

ent values.

The applying of the AHP method used priority

values on sub-criteria. The product delivery subcri-

teria on time and sub-criteria are faster, more timely,

and not on target, as well as other subcriteria and sub-

criteria obtained by the AHP method. In contrast,

the company does not use the assessment model as

above. While the assessment process carried out be-

tween AHP methods has different values and results

at local and national suppliers.

The AHP modeling, the weighting process, uses

interests based on guidelines on the decision support

system (DSS). The benefits entered in the triangle

matrix are the results that have been agreed by the

company, where reliability is more important than all

the main criteria. So, the analytical hierarchy pro-

cess method can help to determine company perfor-

mance. The results are shown in the previous dis-

cussion, where the conventional assessment process

is a subjective assessment. With the application of the

AHP method of supplier performance appraisal in the

company to get results following the quality of each

company.

6 SUGGESTIONS

The result of the study is the development of a mea-

suring supplier performance system. However, sup-

pliers cannot see the results of the assessments given

by the company. For this reason, this future study is

expected to be developed to produce an information

system, and suppliers can see the results of the assess-

ment provided by the company. Suppliers can access

the system, for example, getting their logins from the

relevant agencies.

REFERENCES

Ahmad, N. H. and Yuliawati, E. (2013). Analisa penguku-

ran dan perbaikan kinerja supply chain di pt. xyz.

Teknologi, 6.

Arbani, M. et al. (2011). Pengembangan sistem informasi

sekolah berbasis web: studi kasus mi an-nizhomiyah

depok.

Baily, P., Farmer, D., and Jessop, D. (2005). Purchasing

principles and management. Pearson Education.

Chopra, S. and Meindl, P. (2007). Supply chain man-

agement. strategy, planning & operation. In Das

summa summarum des management, pages 265–275.

Springer.

Hald, K. S. and Ellegaard, C. (2011). Supplier evaluation

processes: the shaping and reshaping of supplier per-

formance. International Journal of Operations & Pro-

duction Management.

Karjalainen, M. (2012). Framework for supplier perfor-

mance measurement system.

Kusrini, K. (2007). Aplikasi sistem pendukung keputusan.

Yogyakarta: Andi.

¨

On

¨

ut, S., Kara, S. S., and Is¸ik, E. (2009). Long term supplier

selection using a combined fuzzy mcdm approach: A

case study for a telecommunication company. Expert

systems with applications, 36(2):3887–3895.

Saaty, T. (1980). The analytic process: planning, priority

setting, resources allocation. McGraw, New York.

Saaty, T. L. (2001). Decision making for leaders the analyt-

ical hierarchy process. University of Pittsburgh, USA.

Team, S.-C. C. (2006). Supply chain operation reference

model version 8.0. Supply Chain Council, inc.

Turban, E., Liang, T.-P., and Aronson, J. E. (2005).

Decision Support Systems and Intelligent Sys-

tems:(International Edition). Pearson Prentice Hall.

Zahir, S. M. (2014). Evaluasi pemasok dengan metode an-

alythic hierarchi process.

CONRIST 2019 - International Conferences on Information System and Technology

226