Design Business Process Management Model for Pharmaceutical with

Good Manufacture Practice and Good Distribution Practice in Indonesia

Erick Fernando

1

, Meyliana

1

and Surjandy

1

1

Information Systems Department, School of Information Systems, Bina Nusantara University, Jakarta, Indonesia 11480

Keywords:

Design model, Business Process Management, Pharmaceutical, Good Manufacture Practice, Good Distribu-

tion Practice

Abstract:

This study aims to present the business processes management of the pharmaceutical industry combined with

supply chain management processes Good Drug Distribution (GDP) and Good Manufacturing Practice (GMP).

Thereby can complete business process management (BPM) by government regulations, giving a good picture

of business processes within the company or pharmaceutical industry by GDP and GMP. This research was

conducted with a qualitative approach, which was carried out by reviewing the literature of several literary

articles related to the subject of this research and conducted a discussion forum with the pharmaceutical in-

dustry in Indonesia. Business process management model with a combination of GMP and GDP approaches

to improve efficiency and effectiveness by creating automation, speed, and process accuracy in change man-

agement. With this BPM model, the BPM can improve business processes and supply chain management

processes in the pharmaceutical industry, and the BPM can provide efficiency and effectiveness in the in-

dustrial drug distribution process. New BPM can reduce the problems in the pharmaceutical industry in the

circulation of medicines and the availability of medicines in the market.

1 INTRODUCTION

The development of information technology in the

current era provides a change in competitiveness that

is so terrible. The effect of this change has an im-

pact on companies today, so companies try to always

improve their competitiveness by changing all orien-

tations from functional to process (Buttigieg et al.,

2016) (Smolnik et al., 2011) (Ramos-Merino et al.,

2019)(Rentes et al., 2019) (Venkatraman and Venka-

traman, 2019). This change leads to the concept

of business process management (BPM) by direct-

ing company changes in the systematic identification,

modelling, and process improvement of company per-

formance. In improving this process, a process of

planning and implementation must lead to improve-

ment and is carried out by combining knowledge in

analyzing the strengths and weaknesses of the com-

pany and its resources to suit the company (Couckuyt

and Van Looy, 2019) (Fernando et al., 2018) (Kitsios

and Kamariotou, 2019) (Tsakalidis et al., 2019).

BPM has a scope and objectives related to changes

and improvements that stem from the analysis of

problems that occur in companies that hurt the ef-

fectiveness and efficiency of the process that is be-

ing implemented (Bitkowska et al., 2018) (Malinova

and Mendling, 2018) (Niehaves et al., 2014) . The

main process in supporting the company’s develop-

ment process that is increasing in the process, build-

ing a knowledge base that leads to all aspects of BPM

implementation (Brocke, 2018) (John, 2008). BPM

has been widely used in various companies with var-

ious fields, specifically in the pharmaceutical indus-

try. The pharmaceutical industry is an industry that

provides drugs on the market. From the focus group

discussion process, there are some problems in the in-

dustry that are most crucial in the manufacturing stage

is not being able to do good planning in fulfilling the

supply of drugs from the ingredients of making the

drug formula to packing material (Hamilton, 2013)

(Marcketti, 2005) (Puri and Ranjan, 2012). This pro-

cess is triggered by the uncertain supply of drug ingre-

dients and the unavailability of drugs at distributors

or influenced by ignorance of the number of drugs on

the market (Puri and Ranjan, 2012). Also, problems

arise in the distribution process that has problems with

many distributions that do not comply with the provi-

sions that lead to the circulation of illegal drugs in the

market. With this problem, the pharmaceutical indus-

try needs BPM for managing business processes that

178

Fernando, E., Meyliana, . and Surjandy, .

Design Business Process Management Model for Pharmaceutical with Good Manufacture Practice and Good Distribution Practice in Indonesia.

DOI: 10.5220/0009907501780183

In Proceedings of the International Conferences on Information System and Technology (CONRIST 2019), pages 178-183

ISBN: 978-989-758-453-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

are carried out following its supply chain (material

providers, manufacturing industries, distributors, re-

tailers, consumers) so that they can be more effective

and efficient in the process. BPM can be combined

with GMP and GDP by government regulations.

This study aims to present or describe the manage-

ment of business processes of the pharmaceutical in-

dustry combined with supply chain management pro-

cesses, GMP, and GDP methods. Thereby can com-

plete business process management by government

regulations, giving a good picture of business pro-

cesses within the company or pharmaceutical indus-

try by good drug distribution and good manufactur-

ing practice. The development of BPM in this arti-

cle was developed an update to reach the final stage

starting from the supply of raw materials, the manu-

facturing process to the good distribution process for

consumers. This gets certainty from the outstanding

and quality drugs.

2 THEORY FOUNDATION

2.1 Supply Chain Management in the

Pharmaceutical Industry

The supply chain management (SCM) process in

the pharmaceutical industry is an activity carried out

from the process of raw materials being managed

into drugs to the distribution process to users and

guaranteeing or ensuring that drugs can be well re-

ceived, quality and in accordance with needs(Shao

and Ji, 2006) (Law, 2016) (Rovers and Mages, 2017).

In this SCM, the pharmaceutical supply chain com-

plexity results from the involvement of many large,

highly diverse independent organizations (Dachyar

and Novita, 2016) (Van der Aalst, 2013). The main

stakeholders in this supply chain include government

agencies, hospitals, clinics, drug manufacturers, drug

distributors, pharmaceutical chains, retailers (Indone-

sia, 2009). The same supply chain is responsible for

the distribution of existing drugs such as prescrip-

tion drugs, over-thecounter drugs, generic drugs, hard

drugs and drugs with narcotics that have different op-

erational objectives (Gr

¨

une et al., 2014) (Nwabueze,

2012).

space

Figure 1: Supply Chain Management (Tipton, 2015)

2.2 Business Process Management

Business process management is a model approach to

improve efficiency and effectiveness by building an

automation process, speed, and precision in the man-

agement of a change. This business process manage-

ment analyses existing performance processes then

makes changes by designing new processes by opti-

mizing existing or available processes using various

facilities and methodologies (John, 2008) (Ramos-

Merino et al., 2019). BPM is a dynamic system,

so you can always change what is needed continu-

ously according to the situation and conditions (John,

2008). BPM examines each increase in the company’s

performance to achieve business processes that are

managed with a maximum or optimum. The most im-

portant part of BPM is the process because of how it

can understand, manage and develop an organization

to provide products or services of greater or greater

value to partners or customers (Brocke, 2018)(Mali-

nova and Mendling, 2018). BPM can be supported by

technology to accelerate the processes carried out in

it. Also, many parties discuss GMP from a technolog-

ical or multi-person point of view (John, 2008).

In many companies today, many are implement-

ing BPM with the main reason for the company to

become more competitive in today’s fierce commer-

cial competition and its future (Niehaves et al., 2014)

(Van der Aalst, 2013). This competitive is because

the company has the challenge of being able to sur-

vive or be superior in business competition. Improve-

ments can be made by providing added value, increas-

ing productivity, reducing costs, and improving the

company’s business processes. These are some of the

benefits of BPM that will help a company navigate

business competition, namely: Improve business ca-

pacity, reduce costs and increase profits, increase effi-

ciency, improve visibilit(John, 2008) (Koster, 2009).

BPM main components Each Business Process

Management (BPM) solution has four main compo-

nents (Smolnik et al., 2011) (Van der Aalst, 2013):

2.2.1 Modelling

Users can define and design the structure of each busi-

ness process graphically.

Design Business Process Management Model for Pharmaceutical with Good Manufacture Practice and Good Distribution Practice in

Indonesia

179

2.3 Integration

In BPM, each element can be related in carrying out

the process so that collaboration or exchange of infor-

mation occurs to complete the goal.

2.3.1 Supervision

Users can monitor and control the performance of the

ongoing business processes and the performance of

each staff involved in the business process.

2.3.2 Optimization

Users can analyze and monitor a business process and

also take measures to improve their efficiency.

An excellent way to do this is to describe the pro-

cess view of the organization and the list of processes

from beginning to end, giving a more detailed view of

the process and the list of processes from beginning

to end of the organization.

In the design process, can group the processes that

occur, the grouping can be done on three levels:

1. Strategic processes: this level represents a strate-

gic process, which must ensure that the underly-

ing process meets and continues to meet the spec-

ified objectives.

2. Core processes: this level represents the principal

or main business activities of the organization

3. Support processes: this level describes noncentral

processes, which support the central operations of

the organization

2.4 BPM IN SCM PHARMACY

The pharmaceutical industry has continued to develop

due to globalization, consolidation, and regulatory

compliance. Manufacturing needs to combine more

efficient and quality-focused processes. The phar-

maceutical supply chain must be scalable and ag-

ile enough to adapt to changing scenarios and part-

ners worldwide. Research and development (R&D)

are under pressure to reduce costs and cycle times

(Koster, 2009) (Nwabueze, 2012) . When managed

care organizations limit medication forms and pro-

mote generic drugs, pharmaceutical companies de-

velop strategies to compete with drugs. Staying com-

petitive in this developing environment has never been

more challenging. Sales and marketing must over-

come regulatory demands by reassessing how they

manage more and more channels and partners (Hein

et al., 2015). Amid this background, efficient man-

agement of business processes is essential for sustain-

ability and growth. The standard BPM solution al-

lows organizations to dynamically manage workflows

and electronic form processing with a steady BPM.

2.5 Good Distribution Practice in

Indonesia

This guide is used as a reference to carry out the pro-

cess of distribution of medicines by interested par-

ties (pharmaceutical industry, pharmaceutical indus-

try, and community services (pharmacies, hospitals,

public health centres) at the hands of consumers. HK

03.1 .34.11.12.7542 of 2012 (BPOM RI, 2012) in-

cludes:

2.5.1 Quality Management

The quality system developed must be fully docu-

mented, and its effectiveness monitored. Within the

system, there must be a change control system that

includes the principles of quality risk management.

2.5.2 The Organization, Management, and

Personnel

The correct implementation and management of a

quality management system and the correct distri-

bution of the medications and/or ingredients of the

medications depend very much on the personnel who

carry them out.

2.5.3 Buildings and Equipment

Buildings and equipment to guarantee the protec-

tion and distribution of drugs and/or drug ingredients.

Buildings must be designed and adapted to ensure that

good storage conditions can be maintained, have ad-

equate security and sufficient capacity to allow safe

storage and handling of drugs, and the storage area is

equipped with adequate lighting to allow that all ac-

tivities are carried out accurately and safely.

2.5.4 Operational

All actions taken by the distribution facilities must en-

sure that the identity of the drugs and/or the ingredi-

ents of the drugs is not lost and that the specifications

listed on the packaging manage their distribution.

2.5.5 Self-inspection

Self-inspection should be carried out to monitor the

implementation and compliance with CDOB compli-

ance and to follow up on the necessary corrective

measures.

CONRIST 2019 - International Conferences on Information System and Technology

180

2.5.6 Complaints of Drugs and/or Drug

Ingredients That Are Returned, Allegedly

False, and Withdrawn

All complaints and other information about poten-

tially damaged medications should be collected, re-

viewed, and investigated by written procedures. The

responsible personnel must approve medications to be

resold by their authority.

2.5.7 Transportation

The transport process must apply appropriate trans-

port methods. The medicine must be transported with

storage conditions according to the information on the

package. Appropriate methods of transport should be

used, including transport by land, sea, air or a combi-

nation of the above.

2.5.8 Facilities based on Contract

All contract activities must be in writing between the

contract grantor and the contract recipient, and each

activity must comply with CDOB requirements.

2.5.9 Documentation

Good documentation is an essential part of the quality

management system. Written documentation must be

clear to avoid errors in verbal communication and to

facilitate follow-up, including batch history, instruc-

tions, and procedures.

Figure 2: Good Distribution Practice

Business processes carried out among them are:

1. Receipt of orders

This activity is to receive goods by carrying out

activities such as a collection of order letters,

write of order letters, correction of customer or-

ders.

2. Procurement of Goods

The process of procurement of goods carried out,

such as recapitulation of demand, determine the

procurement policy, procurement of goods, re-

lease of supplies, order goods to the main external

actors.

3. Manufacture invoice

This process will be carried out by verifying the

order letter, the approval of the transaction, the

printing of the invoice, the calculation of VAT, the

claim process, and the customer discount.

4. Delivery of goods

Some of the processes carried out include the de-

livery orders (DO) for customers, the preparation

of products, the shipment of products.

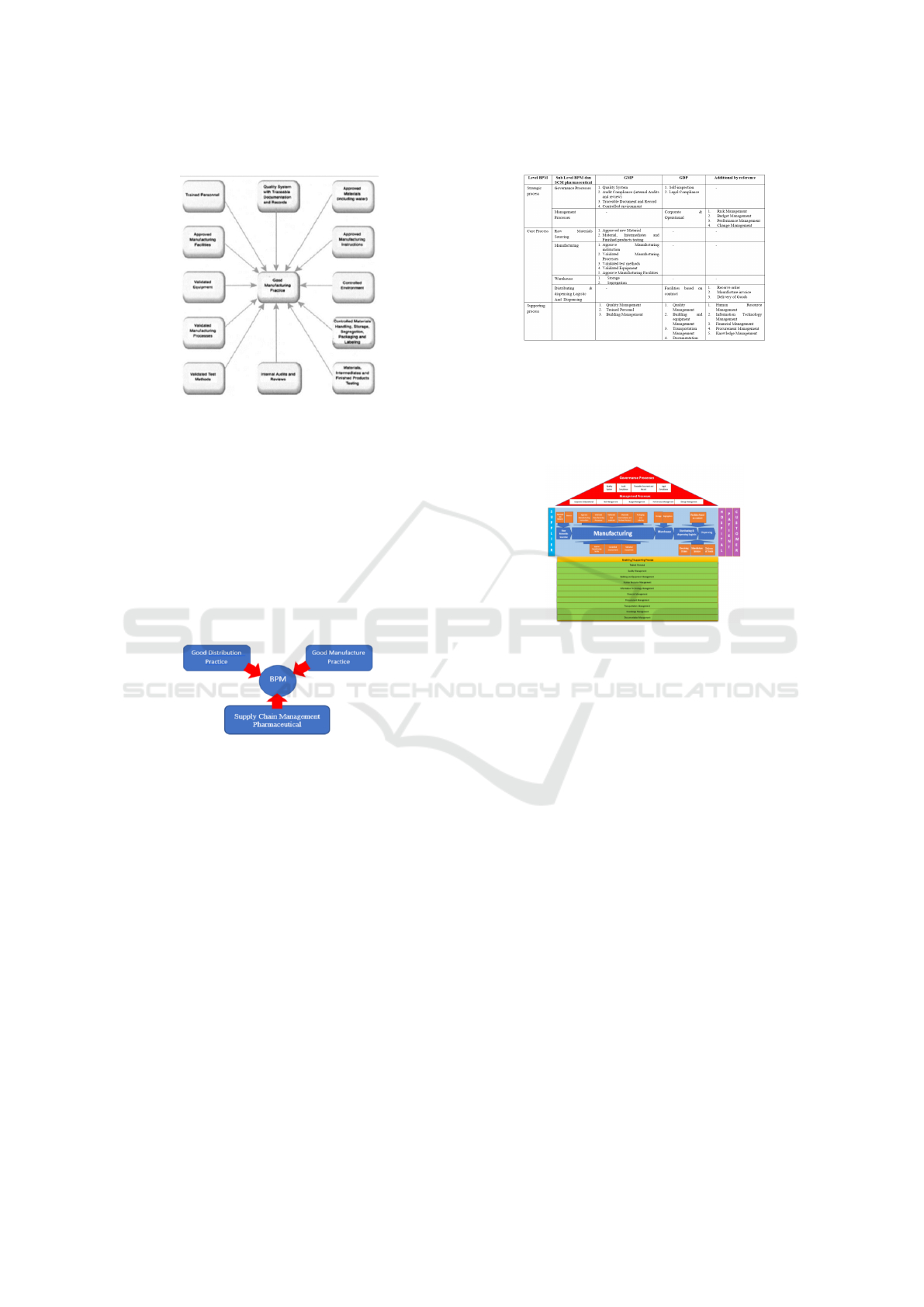

2.6 Good Manufacturing Practice

Good Manufacturing Practices in Figure 3 are : a

model used in the pharmaceutical industry at each

stage of processing from raw material control, for-

mula manufacturing validation, equipment validation,

manufacturing process validation, test method vali-

dation , audit and review functions, material testing,

testing of finished products, material control, han-

dling of raw materials, storage, packaging processes,

environmental monitoring, approval of manufacturing

instructions, approval of the use of materials, includ-

ing the use of water, exhaustive documentation to cre-

ate system quality (Van der Aalst, 2013). Good Man-

ufacturing practice consists of:

1. Trained Personal

2. Quality System with Traceable Documentation

and Records

3. Approved Materials (including Water)

4. Approved Manufacturing instructions

5. Controlled Materials Handling, Storage, Segrega-

tion, Packaging’s, and Labelling

6. Materials, intermediates and finished products

testing

7. Internal Audits and reviews

8. Validated test methods

9. Validated manufacturing processes

10. Validated Equipment’s

11. Approved Manufacturing Facilities

Design Business Process Management Model for Pharmaceutical with Good Manufacture Practice and Good Distribution Practice in

Indonesia

181

space

Figure 3: Good Manufacturing Practice (Van der Aalst,

2013)

3 METHOD

This research was conducted with a qualitative ap-

proach, which was carried out by reviewing the litera-

ture of several literary articles related to the subject of

this research and conducted a discussion forum with

the pharmaceutical industry in Indonesia. The follow-

ing research models can be seen in figure 4.

Figure 4: Research Model

The process carried out in Figure 4 is maps out

the processes that exist in GMP and GDP against the

levels that exist in the business process management

(BPM).

4 RESULTS AND DISCUSSION

This study analyzes the design of the BPM model

needed by companies or the pharmaceutical industry,

especially in Indonesia. According to John Jeston and

Johan Nelis(John, 2008) in the design of BPM, it is

necessary to consider the process architecture, which

is how to provide a process level description of the

business process that is occurring. In the process of

analyzing the BPM model by mapping out existing

processes according to the three BPM process levels,

the BPM process can be seen in Figure 5.

space

Figure 5: BPM Process Mapping GMP and GDP in Supply

Chain Management Pharmaceutical.

From the mapping process that is then carried out

by modelling the BPM design of the pharmaceutical

industry with combined GMP and GDP so that it can

be seen in Figure 6.

Figure 6: Business Process Management in the pharmaceu-

tical industry with Combination GMP and GDP

5 CONCLUSION AND FUTURE

RESEARCH

This study designed a business process management

model with a combination of GMP and GDP ap-

proaches to improve efficiency and effectiveness by

creating automation, speed, and process accuracy in

change management. This business process manage-

ment analyses existing performance processes then

makes changes when designing new processes by op-

timizing existing or available processes using vari-

ous facilities and methodologies. With this BPM

model, can improve business processes and supply

chain management processes in the pharmaceutical

industry, and can provide efficiency and effectiveness

in the industrial drug distribution process. With this, it

can reduce the problems in the pharmaceutical indus-

try in the circulation of medicines and the availability

of medicines in the market.

In the next stage, it is expected that it can validate

BPM for several existing industries, as well as be able

to measure the level of all the components of the BPM

model for the pharmaceutical industry.

CONRIST 2019 - International Conferences on Information System and Technology

182

ACKNOWLEDGEMENTS

Research supported by the Directorate General of

Strengthening for Research and Development, Min-

istry of Research, Technology, and Higher Edu-

cation, Republic of Indonesia is one part of the

results of Penelitian Dasar Unggulan Perguruan

Tinggi Research Grant to Binus University en-

titled “Pemanfaatan Technology Blockchain pada

management, pasok industry farmasi untuk men-

dukung Good Manufacturing Practice” or “Uti-

lization of Blockchain technology in pharmaceu-

tical industry supply chain management to sup-

port Integration of Good Manufacturing Practices”

with contract number: 225/SP2H/LT/DRPM/2019;

12/AKM/PNT/2019; 039/VR.RTT/IV/2019 and con-

tract date: 27 March 2019.

REFERENCES

Bitkowska, A. et al. (2018). Business process management

centre of excellence as a source of knowledge. Busi-

ness, Management and Education, 16(1):121–132.

Brocke, J., . M. J. (2018). Business process management

cases.

Buttigieg, S. C., Prasanta, D., and Gauci, D. (2016). Busi-

ness process management in health care: current chal-

lenges and future prospects.

Couckuyt, D. and Van Looy, A. (2019). Green bpm as

a business-oriented discipline: A systematic map-

ping study and research agenda. Sustainability,

11(15):4200.

Dachyar, M. and Novita, G. (2016). Business process

reengineering of logistics system in pharmaceutical

company. ARPN Journal of Engineering and Applied

Sciences, 11(7):4539–4546.

Fernando, E., Warnars, H. L. H. S., Kosala, R., Abdurach-

man, E., et al. (2018). Critical success factor of in-

formation technology implementation in supply chain

management: Literature review. In 2018 5th Interna-

tional Conference on Information Technology, Com-

puter, and Electrical Engineering (ICITACEE), pages

315–319. IEEE.

Gr

¨

une, G., Lockemann, S., Kluy, V., and Meinhardt, S.

(2014). Business Process Management Within Chem-

ical and Pharmaceutical Industries. Springer.

Hamilton, B. A. (2013). Implementing a pharmaceutical se-

rialization and traceability system in the united states.

Hein, T., Winkler, M., Gulati, H., and Balakrishnan, A.

(2015). Product lifecycle management for the phar-

maceutical industry. Oracle Life Sciences. Page-1-2.

Indonesia, P. R. (2009). Peraturan pemerintah nomor 51

tahun 2009 tentang pekerjaan kefarmasian. Jakarta:

Pemerintah RI.

John, J., . N. J. (2008). Business process manage-

ment: Practial guidelines to successful implementa-

tions (second edition).

Kitsios, F. and Kamariotou, M. (2019). Business strategy

modelling based on enterprise architecture: a state of

the art review. Business Process Management Journal.

Koster, S. R. (2009). An evaluation method for business

process management products. Master’s thesis, Uni-

versity of Twente.

Law, K. M. (2016). How schedule issues affect drug lo-

gistics operations: an empirical study in hospitals in

china. Industrial Management & Data Systems.

Malinova, M. and Mendling, J. (2018). Identifying do’s

and don’ts using the integrated business process man-

agement framework. Business Process Management

Journal.

Marcketti, S. B. (2005). Consumer concern, knowledge,

and attitude towards counterfeit apparel products: An

application of the theory of reasoned action theory.

Niehaves, B., Poeppelbuss, J., Plattfaut, R., and Becker, J.

(2014). Bpm capability development–a matter of con-

tingencies. Business Process Management Journal.

Nwabueze, U. (2012). Process improvement: the case of

a drugs manufacturing company. Business Process

Management Journal.

Puri, S. and Ranjan, J. (2012). Study of logistics issues

in the indian pharmaceutical industry. International

Journal of Logistics Economics and Globalisation,

4(3):150–161.

Ramos-Merino, M.,

´

Alvarez-Sabucedo, L. M., Santos-

Gago, J. M., and de Arriba-P

´

erez, F. (2019). A pattern

based method for simplifying a bpmn process model.

Applied Sciences, 9(11):2322.

Rentes, V. C., de P

´

adua, S. I. D., Coelho, E. B., Cintra, M.

A. d. C. T., Ilana, G. G. F., and Rozenfeld, H. (2019).

Implementation of a strategic planning process ori-

ented towards promoting business process manage-

ment (bpm) at a clinical research centre (crc). Busi-

ness Process Management Journal.

Rovers, J. P. and Mages, M. D. (2017). A model for a

drug distribution system in remote australia as a so-

cial determinant of health using event structure analy-

sis. BMC health services research, 17(1):677.

Shao, X. and Ji, J. (2006). Reconfiguration of pharmaceu-

tical logistics operations in china: an empirical study.

Transportation Journal, pages 52–66.

Smolnik, S., Urbach, N., Fjermestad, J. L., Cragg, P., and

Mills, A. (2011). It support for business processes in

smes. Business Process Management Journal.

Tipton, R. (2015). Industry overviews - pharmaceutical

management - research guides at rutgers university.

Tsakalidis, G., Vergidis, K., Kougka, G., and Gounaris, A.

(2019). Eligibility of bpmn models for business pro-

cess redesign. Information, 10(7):225.

Van der Aalst, W. M. (2013). Business process manage-

ment: a comprehensive survey. ISRN Software Engi-

neering, 2013.

Venkatraman, S. and Venkatraman, R. (2019). Process

innovation and improvement using business object-

oriented process modelling (boopm) framework. Ap-

plied System Innovation, 2(3):23.

Design Business Process Management Model for Pharmaceutical with Good Manufacture Practice and Good Distribution Practice in

Indonesia

183