Analysis of Implementation Contractor Safety Management System

(CSMS) at the Implementation Stage in PT. Multikarya Asia Pasifik

Raya on the Project PT. Pertamina EP Asset 3 Field Jatibarang in

2019

Bustani Anggit Nugroho

1

and Putri Handayani

2

1

Faculty of Health Sciences, Esa Unggul University, Jakarta Barat, Jakarta, Indonesia

2

Study Program of Public Health, Esa Unggul University, Jakarta Barat, Indonesia

Keywords: CSMS, Walktrough Assessment, Temporary Evaluation.

Abstract: CSMS is document the required standards better for contractors in an employer as well as between the side

of a partner of the as the insurer of the on the workforce for individuals the aim is to the venomous system

takes a walk and then the number of work accident can be lowered (PT. Pertamina EP, 2011). According to

a subsidiary to us company evaluations of the restructuration of assumed to proceeds of the assessment of

which had tended to fall January until March 2019 is the lack of the consistency of the multitude the country

working essentially and perfectly morally good from the aspect of HSE and his controversial reform

program the implantation of the HSE. Research objectives analyzed hour by hour the implementation of the

CSMS during the preparatory phase of the implementation of the in reinsurance firm PT. MKAPR.

involving an employee who knows the correct process CSMS and qualitative research was conducted.

Based on the research suggests that needs to be done on the back against personnel who did not understand

the roles and responsibilities in conducting the HSE, no personnel HSE in the area that works is also became

a problem in the supervision.

1 INTRODUCTION

Failure in every process or work activity and at the

time of work accident no matter how small it will

occur due to losses (losses) in general the causes of

workplace accidents, namely displacement (fatigue),

unsafe working conditions and work (unsafe

working conditions), increased worker mastery of

work, suspected cause of change (pre-causes) are the

need for training: the characteristics of the work

itself (Sucipto, 2014).

According The International Association of Oil

and Gas Producers (OGP) when viewed from fatality

accident data consisting of 62 companies spread

across various countries, it is clear that the number

of work accidents occurring at the contractor is

greater than the companies themselves, from the

data published by IOGP from 2007 to 2016 the

fatality rate of companies and contractors for 100

million working hours, the first successful work

contractor for fatal accident cases (OGP, 2017).

According to SKK Migas in 2016, the number of

working hours of Cooperation Contract Employee

(KKKS) employees and working partners in

upstream oil and gas business activities amounted to

358 million hours originating from 48 Production

KKKS, 33 Exploration KKKS and 7 KKKS at the

EPC / Project stage who actively conveyed periodic

reports to the SKK Migas Operations Support

Division. Based on the main category, the highest

number of fatal mining accident victims in 2016

occurred in exploitation activities, with the number

of victims as many as 3 people (75%), while in

exploration activities as much as 1 person (25%). It

can also be reported that in 2012-2015 all accidents

occurred in exploitation activities. SKK Migas also

recorded the number of fatal mine accident victims

in upstream oil and gas business activities by 4 more

victims compared to 2015, which was 6 victims or a

decrease of 33%. When compared with the previous

period (2011-2015) the number of fatal mine

accident victims in 2016 was the smallest where all

370

Nugroho, B. and Handayani, P.

Analysis of Implementation Contractor Safety Management System (CSMS) at the Implementation Stage in PT. Multikarya Asia Pasifik Raya on the Project PT. Pertamina EP Asset 3 Field

Jatibarang in 2019.

DOI: 10.5220/0009778603700379

In Proceedings of the 1st International Conference on Health (ICOH 2019), pages 370-379

ISBN: 978-989-758-454-1

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

the victims who died were from work partners (SKK

Migas, 2018).

PT. Multikarya Asia Pasifik Raya (PT. MKAPR)

is a service company in Indonesia which is engaged

in sales and rental services for mud pumps and water

pumps for drilling (drilling services) and material

suppliers of various types of pumps for exploration

and production activities in the oil and gas sector

earth. PT. MKAPR has onshore and offshore work

activities that have significant potential hazards and

risks. The company also uses many advanced

technologies such as machine tools and other

chemicals. PT. MKAPR employs approximately

50% of employees to be sent to the client's site or

location, while the performance of employees who

work in the client area greatly affects the

performance and impacts on occupational safety and

health, productivity, and the image of PT. MKAPR

(PT Multikarya, 2019).

Based on preliminary surveys conducted by

researchers at PT. MKAPR in 2019 employed 414

workers spread across several oil company projects

in several regions of Indonesia. One of the projects

being undertaken is the Production of Water Pump

Injection Services project of 15,000 BWPD in the

WTIP SPUB work area of PT. Pertamina EP Asset 3

Field Jatibarang, with the high-risk category.

Dangers that are generally high potential in the

implementation of work in the area of PT. MKAPR

includes work accidents (pinched, slipped, tripped,

dropped, shocked, etc.), occupational diseases

(diseases caused by noise, vibration, extreme

weather (heat stress), and other hazards such as

explosions, fires, and pollution environment.

In the Contractor Safety Management System

(CSMS) there is an Ongoing Assessment (PB)

especially in the area of PT. Pertamina EP Asset 3

Jatibarang Field consisting of the HSE Inspection

evaluation and the HSE Plan Implementation

Program evaluation, as well as the Temporary

Evaluation evaluation. The minimum rating for the

Current Assessment (PB) for the high-risk category

is in accordance with the Individual Work

Procedures (TKI) of PT. Pertamina EP is 60% of the

total criteria assessed. PT. MKAPR on the results of

the Current Assessment (PB) checklist for the

January, February and March 2019 periods at PT.

Pertamina EP Asset 3 Jatibarang Field, there are

some declining assessment results both from the

aspects of the HSE Inspection inspection and the

HSE Plan Implementation Program examination. In

January a temporary evaluation score of 79.5 was

obtained, in February a score of 76 was obtained and

in March a temporary evaluation score of 75.5. This

greatly influences the results of the final CSMS

evaluation and if corrective action is not carried out

it will greatly affect the Key Performance Indicator,

in particular, the Lagging Indicator where the

frequency of work accidents can occur in the area of

PT. MKAPR besides that another result is PT.

Pertamina Asset 3 Field Jatibarang can terminate the

contract for the work tender. Therefore, PT.

MKAPR must make improvements to the

prevention, control and follow-up efforts to the

maximum and improvement in the aspects of K3 by

following the OHS Management Work Guidelines in

the area of PT. Pertamina EP Asset 3 Field

Jatibarang, and always consistent in carrying out

supervision and inspection by existing supervisors in

the field of all workers (PT. Multikarya, 2019).

Based on the aforementioned background, the

problem is the inconsistency and lack of monitoring

from field supervisors and the lack of discipline

from workers towards HSE implementation, among

others; inspection aspects of the HSE Inspection and

examination of the HSE Plan Implementation

Program. From the results of the Current

Assessment (PB) checklist for the January, February

and March 2019 periods in Pertamina EP Asset 3,

Jatibarang Field, there are some declining

assessment results both from the aspects of the HSE

Inspection inspection and the HSE Plan

Implementation Program examination. In January a

temporary evaluation score of 79.5 was obtained, in

February a score of 76 was obtained and in March a

temporary evaluation score of 75.5. Impacts that

occur if there is a declining current assessment will

greatly affect the assessment in the final assessment

phase of the Contractor Safety Management System

(CSMS) and if there is no improvement (corrective

action) greatly affects the Key Performance

Indicator, in particular, is the Lagging Indicator

where the frequency of work accidents can occur in

the area of PT. MKAPR besides that another result

is PT. Pertamina Asset 3 Field Jatibarang can

terminate the contract for the work tender.

Therefore, PT. MKAPR must make improvements

to the prevention, control and follow-up efforts to

the maximum and improvement in the aspects of K3

by following the OHS Management Work

Guidelines in the area of PT. Pertamina EP Asset 3

Field Jatibarang, and always consistent in carrying

out supervision and inspection by existing

supervisors in the field of all workers. With these

problems, the authors intend to analyze the

implementation of the Contractor Safety

Management System (CSMS) at the implementation

Analysis of Implementation Contractor Safety Management System (CSMS) at the Implementation Stage in PT. Multikarya Asia Pasifik

Raya on the Project PT. Pertamina EP Asset 3 Field Jatibarang in 2019

371

stage at PT. Multikarya Asia Pasifik Raya on the

PT. Pertamina Asset 3 Jatibarang Field in 2019.

2 METHOD

This type of research used in this study is a

qualitative descriptive approach that aims to analyze

the Contractor Safety Management System (CSMS)

at the implementation stage at PT. Multikarya Asia

Pasifik Raya on the PT. Pertamina EP Asset 3 Field

Jatibarang in 2019 through in-depth interviews with

informants, reviewing documents, and direct field

observations. This study involved 4 key informants,

key informants, and supporting informants. The key

informant is the HSE Officer who monitors the

water injection pump project at PT. Pertamina

Asset 3 Field Jatibarang, the main informant is a

Leader in the water pump injection section who is in

charge of work operations in the area of PT.

Pertamina EP Asset 3 Jatibarang Field and

supporting informants namely HSE Manager and

supervisor unit operating water pump injection.

3 THEORY REVIEW

3.1 Occupational Safety and Health

Management System (SMK3)

Occupational Safety and Health Management

System (SMK3) is part of the overall management

system which includes the organizational structure,

planning, responsibilities, implementation,

procedures, processes, and resources needed for the

development, implementation, achievement, review,

and maintenance of OHS policies, SMK3 activities

are carried out in the context of controlling risks

related to working activities in order to create a safe,

efficient and high productivity workplace

(Hadipoetro, 2014).

3.2 Definition of Contractor

A contractor is a provider of goods/services in the

form of a business entity or individual carrying out

the procurement of goods/services for the benefit of

the company in accordance with their line of

business, who has a valid business license issued by

the authorized government agency. Contractors

consist of suppliers of goods, service providers,

contractors, other service providers and providers of

consulting services (PT. Pertamina EP, 2018).

3.3 Contractor Safety Management

System (CSMS)

Contractor Safety Management System (CSMS) is

slightly different from SMK3 in general, because in

contract work there is a time limit, so there needs to

be a process or stages from the selection of the

contractor to the closing of the contract. Contractor

Safety Management System (CSMS) has a meaning

that is a management system to manage contractors

and sub-contractors who work within the company

environment to pay attention to aspects of K3LL and

maintain the implementation of the K3LL in the

work process in order to avoid potential accidents

and risks that can harm the company (PT. Pertamina

EP, 2011).

3.4 Basic Implementation of the

Contractor Safety Management

System (CSMS)

The following is explained the legal basis of

Government Regulation No. 50 of 2012 which

contains guidelines for the application of SMK3 in

Indonesia. In Article 11 the legal basis has explained

the importance of paying attention to aspects of the

safety and health of contractors in a company,

among others as follows:

1. Entrepreneurs in implementing OHS plans

must carry out activities in meeting OHS

requirements

2. The activities referred to in paragraph (1) at

least include:

- Control measures include control of

activities, products, and services that can

pose a risk of accidents and occupational

diseases at least including control of

materials, equipment, work environment,

work methods, nature of work, and work

processes

- Design and engineering include the

development, verification of reviews,

validation, and adjustments based on the

identification of sources of danger,

assessment, and control of the risk of

accidents and occupational diseases.

- Compilation of procedures and work

instructions that take into account

occupational safety and health requirements

and are reviewed in the event of an

accident, changes in processes and / or

changes in raw materials and are regularly

reviewed. - In the contract for the partial

ICOH 2019 - 1st International Conference on Health

372

surrender of work implementation, it

contains a guarantee of the ability of the

recipient's company to meet the

occupational safety and health

requirements.

- In purchasing / procuring goods and

services it is necessary to pay attention to

technical specifications and aspects of

occupational safety and health as well as

the completeness of the material safety data

sheet. - The final product is equipped with

operating instructions, technical

specifications, material safety data sheets,

labels and / or occupational safety and

health information.

- Efforts to deal with industrial accidents and

disaster emergencies; and

- Emergency planning and recovery.

3. The activities referred to in paragraph (2)

letters a through f, are carried out based on

hazard identification, assessment and risk

control.

4. The activities referred to in paragraph (2)

letter g and letter h are carried out based on

the potential for danger, investigation, and

accident analysis.

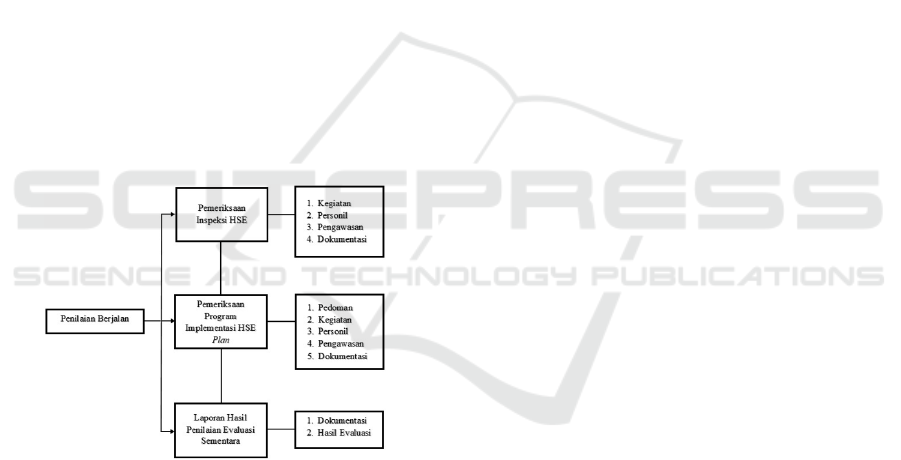

Figure 1: Conceptual Framework.

Source: PT. SMK3 Guidelines for Contractors PT.

Pertamina (2016).

4 RESULT

4.1 Description of HSE Inspection

Check at PT. Multikarya Asia

Pasifik Raya on the PT. Pertamina

EP Asset 3 Field Jatibarang

HSE Inspection Inspection is one of the routines and

scheduled routine activities carried out by the work

supervisor to find potential hazards in the work area

to prevent loss or accident at work in the application

of HSE.

In the HSE inspection activity, there are several

assessment indicators, namely the guideline for HSE

inspection, personnel who carry out the HSE

inspection, supervision of work area activities,

documentation of programs agreed upon in the HSE

plan, and obstacles during HSE inspection activities.

Based on the results of the study after

triangulation of data in terms of interviews,

document review and field observations the

inspection picture of the HSE Contractor Safety

Management System (CSMS) at the implementation

stage that the HSE Inspection activities have

followed Inspection form inspection procedures and

personnel carrying out the HSE inspection are the

team listed on the HSE Plan project organizational

structure. On supervision, HSE Plans are made

before work activities begin and to monitor the

findings of the supervision, but training needs to be

done, re-socialization of personnel who do not

understand their roles and responsibilities, the

assertiveness of supervisors and HSE supervisors is

still lacking, there is no HSE Officer personnel. in

the area of work also becomes a problem in the

process of supervising workers and documenting

programs that have been agreed upon in the HSE

documentation plan at the HSE inspection but there

are obstacles in fulfilling the documentation because

there is no special personnel who focus on the

documentation implementation.

4.2 Overview of Examination of HSE

Plan Implementation Program at

PT. Multikarya Asia Pasifik Raya

on the PT. Pertamina EP Asset 3

Field Jatibarang

Inspection of HSE Plan implementation program is

one of the routines and scheduled activities that are

suddenly carried out in conjunction with HSE

inspection checks conducted by the work supervisor

to find potential hazards in the work area to prevent

loss or accidents at work in the application of K3LL,

inspection the HSE plan implementation program

was agreed at the beginning before work began and

the contractor was obliged to ensure that the HSE

plan program was able to run in accordance with the

plan for the Water Injection Pump project at

Pertamina EP Asset 3 Field Jatibarang.

In the HSE plan implementation program

inspection activities there are several assessment

indicators, namely the HSE Plan guideline that has

Analysis of Implementation Contractor Safety Management System (CSMS) at the Implementation Stage in PT. Multikarya Asia Pasifik

Raya on the Project PT. Pertamina EP Asset 3 Field Jatibarang in 2019

373

been bridged with the user of the HSE inspection

activity, the personnel conducting the HSE Plan

implementation inspection program, supervision of

work area activities and documentation of programs

agreed upon in the HSE Plan.

Based on the results of the research after

triangulation of data in terms of interviews,

document review and field observations of the HSE

Plan Contractor Safety Management System

(CSMS) implementation program at the implementa-

tion stage that the description of the HSE plan

implementation program inspection activities has

followed the procedure, there are teams listed on the

HSE Project organizational structure plan, PT.

Multikarya Asia Pacific Raya already has internal

procedures related to personnel competence.

However, field personnel still do not know about the

HSE plan guidelines, in the field observations, there

is a management commitment set forth in the HSE

plan. Management visits must be carried out

periodically to monitor workers at the location that

are not consistent to do, documentation according to

informants has many obstacles in fulfilling

documentation.

4.3 Overview of the Temporary

Evaluation Assessment at PT.

Multikarya Asia Pasifik Raya on

the PT. Pertamina EP Asset 3 Field

Jatibarang

Provisional evaluation assessment report is the final

process in the current assessment phase as an

assessment to determine the value based on the

reference from the HSE inspection and HSE plan

implementation inspection program, the user creates

an interim evaluation report based on the results of

the HSE inspection and evaluation that has been

carried out by filling in the temporary evaluation

report form. No. F-003 / C-020 / A3 / EP8000 /

2014-S0.

In the interim evaluation, there are several

assessment indicators, namely the documentation of

programs agreed upon in the HSE plan, namely the

documentation of the elements of the HSE

inspection and the documentation of the elements of

the HSE plan implementation inspection and the

results of the evaluation in which there are findings

of both unsafe inspection results condition and

unsafe action, follow-up, and recommendations from

users related to the findings at PT. Pertamina EP

Asset 3 Field Jatibarang.

In the HSE plan implementation program

inspection activities there are several assessment

indicators, namely the HSE Plan guideline that has

been bridged with the user of the HSE inspection

activity, the personnel conducting the HSE Plan

implementation inspection program, supervision of

work area activities and documentation of programs

agreed upon in the HSE Plan

5 DISCUSSION

5.1 HSE Contractor Safety

Management System (CSMS)

Inspection Overview at the

Implementation Stage at PT.

Multikarya Asia Pasifik Raya on

the PT. Pertamina Asset 3

Jatibarang Field in 2019

Based on the research results of the inspection

description of the HSE Contractor Safety

Management System (CSMS) at the implementation

stage that the HSE Inspection inspection activities

have followed the HSE inspection form inspection

procedures and personnel carrying out the HSE

inspection checks have a team listed on the HSE

Plan of the project organization structure. In the

supervision activities in accordance with the HSE

Plan that was made before the work activities began

and to monitor the findings of the supervision, but

the firmness of the supervisor and HSE is still

lacking, the absence of HSE Officer personnel in the

work area is also a problem in the process of

supervising workers and program documentation-

programs agreed on the HSE plan documentation on

the HSE inspection there are obstacles in fulfilling

the documentation. This happens because the HSE

Officer in the contract does not exist in the field only

there is a supervisor who prioritizes production

operations and awareness of the field personnel in

making the implementation documentation that is

still less consistent. The results of the study are in

line with studies conducted by Duri & Berlian

(2018) that the constraints that are considered as the

main constraints are the limited time in running a

project. Usually, a project focuses on progress.

Given that the contract for a project has a different

time, the contractor does not hire workers on a

permanent basis. While the contractor must give

time to conduct training or training for workers

before doing work.

The results of the study are in line with the

theory of Ramli (2013) contractor staff are

temporary with limited work periods according to

ICOH 2019 - 1st International Conference on Health

374

their needs and duties. This condition often results in

the contractor being pressured to complete tasks on

time, being chased by targets or deadlines to

complete their tasks and projects. Therefore, often

the contractor employs workers who are also

temporary or limited.

The results of the study are in line with studies

conducted by Pratiwi (2017) based on data on the

fulfillment of monthly reports owned by the K3

department, as many as 76% of contractors have not

routinely submitted monthly reports on their work.

Irregularities in making monthly reports made by

contractors not in accordance with existing

procedures can be caused due to various things. One

of them is the lack of information given to the

contractor at the beginning of the work before the

kick-off meeting. Another cause that can trigger the

delay in reporting is the lack of awareness of the

contractor in fulfilling the report. The results of the

study are in line with OHSAS 18001 in Ramli

(2009) that many aspects of OHS need to be

documented such as the processes and procedures

carried out in developing SMK3. A document

regarding an accident or inspection of equipment

will be needed when conducting an accident investi-

gation or modification of equipment and systems.

Tarwaka (2014) states that the implementation of

inspections is more effective by referring to the

factory map, looking for things according to the

points in the checklist, taking temporary corrective

actions, clearly describing and placing each thing,

hazard classification, and determining the main

factors causing the actions and unsafe condition.

PT. Multikarya Asia Pasifik Raya has conducted

socialization at the beginning of recruitment about

safety induction in general to all personnel from a

supervisor level to the operator and in accordance

with the procedures of PT. Multikarya Asia Pacific

Raya all personnel will be given training in the use

of inspection procedures and checklists. If there is a

change, all personnel will be informed or given

training, the inspection schedule will be prepared by

the K3LL committee every year, and the company

has imposed an obligation to inspect and document

in writing all activities related to the program agreed

with the user so that if there are the findings in the

field can be recorded and control efforts are taken.

However, in the field conditions, the documentation

process is still less consistent because supervisors

prioritize production operational activities, there are

also personnel who still do not know their roles and

responsibilities because socialization is only given at

the beginning of work related to roles and

responsibilities for HSE inspection, lack of firmness

and supervision from supervisors to safety culture in

work areas as well as some personnel who are still

lacking discipline in the use of PPE because

supervisors when visiting work areas are more

focused on operations than the existing performance

units in the location and there is no HSE Officer

who monitors the work area.

Based on the discussion above, it is necessary to

have a training on refreshing outreach or briefing on

HSE program guidelines, especially in the HSE

inspection checklist of field personnel who do not

understand the roles and responsibilities as well as

socialization about the importance of making

documentation when activities related to the

program, so that it can bring up awareness of

personnel, the need for increased supervision in the

field of workers on a daily basis and the firmness of

supervisors, education of personnel on compliance

with the implementation documentation in the field.

5.2 Overview of Examination of the

HSE Plan Contractor Safety

Management System (CSMS)

Implementation Program at the

Implementation Stage at PT.

Multikarya Asia Pasifik Raya on

the PT. Pertamina Asset 3

Jatibarang Field in 2019

Based on the results of the examination of the HSE

Plan Contractor Safety Management System

(CSMS) implementation program at the

implementation stage that the description of the HSE

plan implementation inspection program has

followed these procedures, there are teams listed on

the HSE Plan project organizational structure, PT.

Multikarya Asia Pacific Raya already has internal

procedures related to personnel competence.

However, in the field observations, there is a

management commitment set forth in the HSE plan.

In a period of time, a management visit must be

carried out to monitor the workers in the location.

This is not consistent, according to the informants,

there are many obstacles in fulfilling written

documentation in the HSE Plan activities that have

been made.

This happens because the management visit must

be carried out by top-level management, which is at

the level of the company's director to find out the

conditions in the work area, but PT. Multikarya Asia

Pasifik Raya has many projects, one of which is a

project at PT. Pertamina EP Asset 3 Field Jatibarang

and written documentation are not done because the

Analysis of Implementation Contractor Safety Management System (CSMS) at the Implementation Stage in PT. Multikarya Asia Pasifik

Raya on the Project PT. Pertamina EP Asset 3 Field Jatibarang in 2019

375

management visit program is not carried out

consistently in accordance with the schedule that has

been made.

The results of the research are in line with

studies conducted by Duri & Berlian (2018), the

difficulty that sometimes arises in the

implementation of CSMS to contractors is the

management committee of the contractor, sometimes

the contractor company is less responsible in

carrying out existing procedures. In the

implementation of Work in Progress, there is a Field

Management Visit. Where this activity is carried out

to provide opportunities for user management and

management of the contractor to show their

respective commitments in terms of OSH to assess

the level of OSH awareness and practice in the field

and to communicate to discuss OSH issues. PT.

Petronesia Benimel appointed K3 Manager and

Project Manager to conduct a Field Management

Visit of at least two visits a month.

The results of the study are in line with Nasution

(2005) the most important elements of an

occupational safety and health program are

statements and policies of the company,

organization, and personnel, maintaining working

conditions to meet safety requirements, making

reports and analysis of the causes of accidents and

providing first aid facilities in accident.

PT. Multikarya Asia Pasifik Raya has authorized

management representatives to conduct a field visit

or management visit, in this case, is the level of a

general manager or the level of operation manager

but in its implementation, the visit is also still

inconsistent due to some busyness of operational

activities at the company.

Based on the discussion above, it is necessary to

notify when a management meeting is related to the

importance of management visits in the work area to

find out the existing issues both from personnel and

units in the location, the need for training and

refresh the socialization or briefing about the agreed

HSE Plan implementation program. between the

user and the contractor before the work begins and

briefings are given back to the field personnel when

the work is running so that personnel are always

aware of the programs that must be run, because so

far only the supervisor level knows better, the

supervisor must be more consistent with his

responsibilities and supervision of field personnel in

carrying out the HSE plan the program does not only

focus on production operations, and reminds

personnel related to making documentation to be

done consistently when there are observations or

findings both unsafe conditions and unsafe actions,

supervisors must be more consistent with their

responsibilities and oversight of field personnel in

carrying out the HSE plan program.

5.3 Overview of Reports on the Results

of the Temporary Evaluation of the

Contractor Safety Management

System (CSMS) at the

Implementation Stage at PT.

Multikarya Asia Pasifik Raya on

the PT. Pertamina Asset 3

Jatibarang Field in 2019

Based on the results of the study description of the

results of the evaluation while the Contractor Safety

Management System (CSMS) at the implementation

stage that the documentation that must be met by

PT. Multikarya Asia Pasifik Raya followed the

guidelines of PT. Pertamina EP Asset 3 Jatibarang

Field, namely the recapitulation of the HSE

inspection list and the recapitulation of the HSE plan

implementation audit program, which must be

attached with some program evidence that has been

carried out during the project and the documentation

that must be fulfilled. occurred because at the K3

inspection each person has not been properly

supervised and documented. Whereas in the

implementation program there is no management

commitment with no management visit and

consistent documentation has not been done because

of PT. Multikarya Asia Pasifik Raya has many

projects, one of which is a project at PT. Pertamina

EP Asset 3 Field Jatibarang and written documenta-

tion are not done because the management visit

program is not carried out consistently in accordance

with the schedule that has been made.

The results of the study are in line with the Duri

& Berlian study (2018) An audit conducted in the

CSMS or CHESM process by Chevron, PT.

Petronesia Benimel conducted an Internal Audit to

see how the company's achievements in the

implementation of the Health, Environment and

Safety program that they implemented during work

activities. Every result of the field inspection is

recorded in every form that is available and reported

whenever there is a discrepancy found and

mitigation actions are taken immediately.

PT. Multikarya Asia Pasifik Raya suspected that

there was a decrease in the temporary evaluation due

to the supervision from supervisors to personnel who

were inconsistent so that there were many violations

from personnel such as lack of discipline in using

PPE, housekeeping was not done in the work area,

ICOH 2019 - 1st International Conference on Health

376

inconsistent daily safety meetings and written

documentation that is not made when there are

inspections or findings. In the inspection of the HSE

program implementation, it was found that the

management visit was supposed to be carried out by

the top-level but did not run according to the

schedule agreed in the HSE plan commitment with

the user.

Based on the above discussion, it is necessary to

have more routine supervision and must be carried

out consistently by supervisors to the personnel to

ensure the HSE program runs well because

previously supervision conducted by supervisors in

the work area is more focused on the technical

operations of the unit, the HSE booklet provided by

company as a guideline for the implementation of

written documentation so that when there are

findings both unsafe conditions and unsafe actions

can be monitored properly and get appropriate

recommendations, as well as commitments from top-

level management in conducting field visits or

management visits that have been agreed upon at

HSE plan and when an assessment is carried out the

contractor safety management system (CSMS)

results of the interim evaluation can meet the

requirements in accordance with the level of hazard

risk set by the user or PT. Pertamina EP Asset 3

Field Jatibarang, if there is a decrease in score in the

current assessment HSE inspection and inspection of

the HSE Plan implementation program will greatly

affect the final assessment and the user will provide

sanctions even termination of the contract.

6 CONCLUSIONS AND

SUGGESTIONS

6.1 Conclusions

1. Overview of HSE Contractor Safety

Management System (CSMS) inspection

checks at the implementation stage at PT.

Multikarya Asia Pasifik Raya on the PT.

Pertamina Asset 3 Field Jatibarang Year 2019,

that the HSE Inspection inspection activities

have followed the HSE inspection form

inspection procedures and personnel carrying

out the HSE inspection checks contained a

team listed on the HSE Plan of the project

organization structure. On supervision, HSE

Plans are made before work activities begin

and to monitor the findings of the supervision,

but re-socialization of personnel who do not

yet understand their roles and responsibilities,

assertiveness of supervisors and HSE

supervisors is lacking, there are no HSE

Officer personnel in the area they work is also

a problem in the process of supervising

workers and documenting programs that have

been agreed upon in the HSE plan

documentation on the HSE inspection but

there are obstacles in fulfilling the

documentation.

2. Overview of the inspection of the HSE Plan

Contractor Safety Management System

(CSMS) implementation program at the

implementation stage at PT. Multikarya Asia

Pasifik Raya on the PT. Pertamina Asset 3

Jatibarang Field In 2019, the audit activities of

the HSE plan implementation program have

followed the procedure, there are teams listed

in the HSE Plan project organizational

structure, PT. Multikarya Asia Pacific Raya

already has internal procedures related to

personnel competence. However, field

personnel still do not know about the HSE

plan guidelines, in the field observations, there

is a management commitment set forth in the

HSE plan. Management visits must be carried

out periodically to monitor workers at the

location that are not consistent to do,

documentation according to informants has

many obstacles in fulfilling documentation.

3. A description of the results of a temporary

evaluation Contractor Safety Management

System (CSMS) at the implementation stage

at PT. Multikarya Asia Pasifik Raya on the

PT. Pertamina Asset 3 Field Jatibarang in

2019, following the guidelines of PT.

Pertamina, namely the recapitulation of the

HSE inspection check list and the

recapitulation of the HSE plan implementation

audit program, which must be attached with

some evidence of the program that has been

carried out during the project and the

documentation that must be met, the results of

a temporary evaluation evaluation that has

decreased.

6.2 Suggestion

1. The company is suggested the need for a

socialization refresh or briefing about the

guideline of HSE program elements especially

in the HSE inspection checklist of field

personnel who do not understand their roles

and responsibilities as well as socialization on

Analysis of Implementation Contractor Safety Management System (CSMS) at the Implementation Stage in PT. Multikarya Asia Pasifik

Raya on the Project PT. Pertamina EP Asset 3 Field Jatibarang in 2019

377

the importance of making documentation when

activities related to the program, so as to raise

awareness of personnel, the need to increase

supervision in the field of workers on a daily

basis and the firmness of the supervisor,

education to personnel on the fulfillment of

implementation documentation in the field.

2. The company is advised the need for

notification when the management meeting

related to the importance of management

visits in the work area to find out the issues

that exist in the location of both personnel and

units, the need for training and refresh the

socialization or briefing about the HSE Plan

implementation program that has been agreed

between the user and the contractor before the

work begins and briefing is given back to the

field personnel when the work is running so

that personnel are always aware of the

programs that must be run because so far only

the supervisor level knows better, the

supervisor must be more consistent with his

responsibilities and supervision of field

personnel in carrying out the program The

HSE plan does not only focus on production

operations but also reminds personnel related

to making documentation to be done

consistently when there are observations or

findings, whether unsafe conditions or unsafe

actions, supervising or must be more

consistent with their responsibilities and

supervision of field personnel in carrying out

the HSE plan program.

3. The company is advised to conduct more

consistent supervision by supervisors to the

personnel to ensure the HSE program runs

well, written documentation so that when

there are findings both unsafe conditions and

unsafe actions can be monitored properly and

get appropriate recommendations, and

commitment from the top-level management

in conducting field visits or management visits

that have been agreed upon in the HSE plan

and when an evaluation is carried out the

contractor safety management system (CSMS)

results of the interim evaluation can meet the

requirements according to the level of hazard

risk set by the user or PT. Pertamina EP Asset

3 Field Jatibarang, if there is a decrease in

score in the current assessment HSE

inspection and inspection of the HSE Plan

implementation program will greatly affect the

final assessment and the user will provide

sanctions even termination of the contract.

4. Further researchers are advised to conduct

field observations with sufficient time periods

in order to get a deeper quality of observation

results to monitor the activities and safety

culture of workers in the field.

REFERENCES

Duri, B., & Berlian, M. (2018). Analisis Implementasi

Contractor Safety Management System (CSMS) pada

Tahap Pelaksanan di PT. Petronesia.

Ervianto, W. I. (2005). Manajemen Proyek Konstruksi.

Yogyakarta: Andi Ofset.

Falenshina, N. (2012). Implementasi Contractor Safety

Management System (CSMS) Terhadap Kontraktor

Project Ta Unit CD III PT. Pertamina RU III

Palembang.

Hadipoetro, S. (2014). Manajemen Komprehensif

Keselamatan Kerja. Jakarta: Yayasan Putra Tarbiyyah

Nusantara.

Handayani, Putri., dan Modjo, R. (2016). Metode Online

Dalam Pelaksanaan Contractor Safety Metode Online

Dalam Pelaksanaan Contractor Safety, (November).

ILO (2001). Guidelines of Occupational Safety and Health

Management System. USA.

ILO. (2018). Meningkatkan Keselamatan dan Kesehatan

Pekerja Muda. In Hari K3 sedunia (Pertama, pp. 2–3).

Jakarta: Internasional, Kantor Perburuhan. http://www.

oit.org/wcmsp5/groups/public/---asia/---ro-bangkok/---

ilo-jakarta/documents/publication/wcms_627174.pdf

Kemenaker. (2012). PP No. 50 Tahun 2012 tentang

Penerapan SMK3, Jakarta.

Kemenkes RI. (2018). Menaker Hanif Canangkan

Peringatan Bulan K3 Nasional 2018. KEMENKES.

Lukiatsinto, Rewi., dan Widajati, N. (2014). Penerapan

CSMS (Contractor Safety Management System)

Sebagai Upaya Pencegahan Kecelakaan Kerja. The

Indonesian Journal of Occupational Safety and

Health, 3, 2.

Migas, S. (2018). Pengelolaan Kesehatan, Keselamatan

Kerja dan Lindung Lingkungan di Kegiatan Usaha

Hulu Minyak dan Gas Bumi. Jakarta.

Pratiwi, H. Y. (2017). Analisis Penerapan Contractor

Safety Management System (CSMS) di PT. X, Bontang

Kalimantan Timur, (March), 187–196. https://doi.org/

10.20473/ijosh.v6i2.2017.187-196.

PT. Multikarya, A. P. R. (2019). Laporan Work in

Progress Contractor Safety Management System.

Jakarta.

PT. Pertamina EP. (2011). HSE plan. Jakarta.

PT. Pertamina EP. (2014). TKI C-019/A3/EP8000/2014-

S0 Evaluasi HSE Plan Untuk Pekerjaan Yang

Dikontrakan. Indonesia.

PT. Pertamina EP. (2016). Pedoman Sistem Manajemen

HSE Kontraktor. Indonesia.

PT. Pertamina EP. (2018). Tata Kerja Individu

Pelaksanaan Penilaian Berjalan dan Penilaian Akhir

ICOH 2019 - 1st International Conference on Health

378

HSE Kontraktor, Pub. L. No. C- 020/A3/EP0300/

2018-S0. Indonesia.

PT. Vico Indonesia. Pedoman Tata Kerja Pengelolaan

Keselamatan, Kesehatan Kerja dan Lindungan

Lingkungan Kontraktor. (2006). Indonesia.

PT. Multikarya, A. P. R. (2019). Company Profile.

Jakarta

Ramli, S. (2009). Sistem Manajemen Keselamatan &

Kesehatan Kerja. (H. Djajaningrat, Ed.). Jakarta: Dian

Rakyat.

Ramli, S. (2010). Sistem Manajemen Keselamatan &

Kesehatan Kerja. Dian Rakyat, Jakarta.

Ramli, S. (2013). Smart Safety Panduan Penerapan SMK3

yang Efektif. Jakarta: Dian Jakarta.

Salami, I. R. S. (2016). Kesehatan dan Keselamatan

Lingkungan Kerja. Yogyakarta: Gadjah Mada

University Press.

Suaery, Abidin, Z., Kurniawan, Bina, & Ekawati. (2016).

Analisis Implementasi Contractor Safety Management

System (CSMS) Pada Tahap Persiapan Kerja di Coca

Cola Amatil Indonesia (CCAI) Semarang. Kesehatan

Masyarakat, Vol 4, 3.

Suardi, R. (2005). Sistem Manajemen Keselamatan dan

Kesehatan Kerja. Jakarta: Penerbit PPM.

Sucipto, C. D. (2014). Keselamatan dan Kesehatan Kerja.

Jakarta: Gosyen Publishing.

Tarwaka. (2014). Manajemen Keselamatan dan Kesehatan

Kerja di Tempat Kerja. Surakarta: Harapan Press.

The International Association of Oil & Gas Producers.

(2017). Safety Performace Indicators. Maret 07, 2019.

http://www.ogp.org.uk/pubs/2017s.pdfb

Analysis of Implementation Contractor Safety Management System (CSMS) at the Implementation Stage in PT. Multikarya Asia Pasifik

Raya on the Project PT. Pertamina EP Asset 3 Field Jatibarang in 2019

379