Preliminary Comparison of Pre-gelatinization vs Ultrasound

Modified Sweet Potato Starch for Tablet Formulation

Grace Maria Ulfa

1

, Regita Prihatiningtyas

1

, Irma Nopriyani

1

, Widya Dwi Rukmi Putri

1,2

, Kiki

Fibrianto

1,2

, Simon Bambang Widjanarko

1

1

Departement of Agricultural Product Technology, Universitas Brawijaya, Malang, Indonesia

2

Food Sensory Research Group, Departement of Agricultural Product Technology, Universitas Brawijaya, Malang

Keywords: Modification, pre-gelatinization, starch, sweet potato, ultrasound

Abstract: Starch is a common material for tablet formulation as disintegrant, binder, or filler, however, it needs to be

modify to improve its native properties. Physical modification by heat is one of the easiest way to modify the

starch in tablet formulation. Sweet potato starch were pre-gelatinized and ultrasound to improve some

physical properties of starch. The aim of this study was to compare the properties of starch produce using two

different treatment. The swelling power (SP), solubility (S), and water binding capacity (WBC) of starches

are the properties which important in the usage of starch in tablet formulation. The increase of all parameters

measured could be important for controlled drug delivery. The granule of starches were also analysed using

scanning electron microscopy to determine the effect of different treatments toward starch granules.

1 INTRODUCTION

Indonesia is one of the main producer of sweet potato,

however their use is still short compare to other tuber

such as cassava or potato. According to FAOSTAT

(2017) the trend of sweet potato production increases

from 101,813,946 tonnes in 2012 up to 105,190,501

tonnes in 2016 with the total yield and production in

2015 are 160,533 hg/ha and 2,297,634 ton in

Indonesia. Sweet potato’s leaves and tubers are used

as a source of nutrient for humans and livestock,

whereas its usage can be expanded to increase the

value.

Many industrial and pharmaceutical industry can

use sweet potato starch as their ingredient, however it

still have many shortages in the native form. Native

starch has shortages in application due to its limited

properties towards heat, easily break by shear forces,

and the viscosity is low (Chi et al., 2008; Das et al.,

2010), usually modification is used to overcome those

shortages (Das et al., 2010; Frank and Adebowale,

2010; Krishnakumar and Sajeev, 2018). Pre-

gelatinization is physical modification known to

produce easily soluble starch which improves its flow

ability due to its loss in crystallinity (Visavarungroj

and Remon, 1991; Freitas et al., 2004).

Some research about pre-gelatinized starch for

tablet formulation were done (Visavarungroj and

Remon, 1991; Alebiowu and Itiola, 2002; Odeku,

Schmid and Picker-freyer, 2008; Adedokun and

Itiola, 2010; Jubril, Muazu and Mohammed, 2015).

Physical modification is preferred due to less amount

of by products and the possibility of chemical residue,

so that this approach more sustainable (Krishnakumar

and Sajeev, 2018).

Ultrasound is the sound above the threshold of

human ear that can be used in some food processing,

include the following: extraction, emulsification,

homogenization, and separation (Jambrak et al.,

2010). Very limited studied have been reported on the

effect of ultrasound treatment on starches (Jambrak et

al., 2010; Zhu, 2015; Krishnakumar and Sajeev,

2018). Ultrasound will induce the formation of

cavitation filled with gas which can increased the

temperature locally, modifying the physical and

chemical conditions of the system (Jambrak et al.,

2010; Zhu, 2015). The aim of this research was to

compare the properties of starch produce by pre-

gelatinization and ultrasound.

Ulfa, G., Prihatiningtyas, R., Nopriyani, I., Putri, W., Fibrianto, K. and Widjanarko, S.

Preliminary Comparison of Pregelatinization vs Ultrasound Modified Sweet Potato Starch for Tablet Formulation.

DOI: 10.5220/0009587100150018

In Proceedings of the 6th International Conference on Advanced Molecular Bioscience and Biomedical Engineering (ICAMBBE 2019) - Bio-Prospecting Natural Biological Compounds for

Seeds Vaccine and Drug Discovery, pages 15-18

ISBN: 978-989-758-483-1

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

15

2 MATERIALS AND METHODS

2.1 Preparation of Starch

Sweet potato tubers were obtained from local market

in Yogyakarta, Indonesia. The tubers were washed to

remove the dirt, peeled, and grated using machine.

The water was added into grated tuber to obtain the

starch and the suspension filtered. The filtrate was

precipitated and the water were removed. This

process were repeated three times. The sediment of

starch obtained then dried in the dryer and sieved. The

starch was secured with silica gel and kept for further

analysis.

2.2 Pre-gelatinization Modification

The design described by Adedokun and Itiola (2010)

with modification was done to pre-gelatinized the

starch. A quantity (100 ml) water was added into 100

g starch to make the suspension. The suspension was

heated at 55˚C with constant stirring for 10 minutes.

The paste then dried, pulverized, and sieved. The

starch then kept with silica gel for further analysis.

2.3 Ultrasound Modification

The method of Jambrak et al. (2010) with

modification was done to treat the starch. Prepared

samples of 500 ml volume were place in the

ultrasound bath and treated with ultrasound 24 kHz

frequency. The temperature was set to 55˚C for 10

minutes. The paste then dried, pulverized, and sieved.

The starch then kept with silica gel for further

analysis.

2.4 Physical Characteristics

2.4.1 Swelling Power and Solubility Test

SP and S was measured by using Leach method with

some modification (Kaur et al., 2011; Lee and Yoo,

2011; Grace et al., 2019). A mixture of starch was

prepared in centrifuge tube then heated at 90˚C for 30

minutes and cooled down into room temperature.

After that, the tube were centrifuged and the fraction

obtained was separated. The sediment and liquid part

then dried and counted.

2.4.2 Water Binding Capacity Test

WBC was measured by using Medcalf method with

some modification (Robertson et al., 2000;

Iheagrawa, 2013; Grace et al., 2019). A mixture of

starch was prepared in tube and stirred for 1 hour and

centrifuged. After that, the excess water was

separated and the sediment part obtained was

counted.

2.5 Morphological Characteristics

Native, pre-gelatinized, and ultrasound modified

starches were observed for its morphological

characteristics conducted with Scanning Electron

Microscopy (SEM) (Hitachi TM3000, Japan). The

accelerating potential used was 15 kV and the

samples were coated with palladium.

3 RESULTS

3.1 Physical Characteristics

The SP, S, and WBC of native and treated starches

are shown in Table 1. SP represent the interaction

between amorphous and crystalline area inside the

granule (Takizawa, Oliveira and Konkel, 2004).

During the gelatinisation process, there is an

increase in the SP and a large amount of starch

content leaks from the granule (Mat et al., 1992).

The solubility of starch increased along with the

increasing of process's temperature (Paterson et al.,

1994). The increase of S indicated an increase of

solubilized amylopectin and this increase was

enormous after the granule start to rupture

(Srichuwong et al., 2005).

Table 1: Physical characteristics of native, pre-gelatinized,

and ultrasound modified starches (n=3).

Parameters Native

Pre-

gelatinized

Ultrasound

Swelling

power (g/g)

17.95±0.55 30.31±1.06 36.05±0.11

Solubility

(%)

1.48±0.07 26.55±1.18 2.41±0.09

Water

binding

capacity

(%)

89.32±1.00 232.39±1.83 166.63±1.14

Pre-gelatinization could increase the solubility of

starch in water probably due to the rupture of

granule during process (Adedokun and Itiola, 2010;

Grace et al., 2020). The WBC of starch is observed

higher due to the increasing of water binding sites

inside the granules which represent the availability

of the hydroxyl groups. The disruption of granule

during gelatinization also increase the hydophilicity

ICAMBBE 2019 - 6th ICAMBBE (International Conference on Advance Molecular Bioscience Biomedical Engineering) 2019

16

of the granule enabling the increasing of hydration

of starch (Wootton and Bamunuarachchi, 1978).

The increase of SP and S in ultrasound modified

starch also happen due to the loss of granule integrity

after the swelling process happened. This loss could

be happened due to the amorphous area become more

damaged so that the hydrophylicity of starch

increases (Herceg et al., 2010). The increasing of SP

and S value probably happened due to the weaken

bonding within the crystalline area and the

availability of hydrogen bonds (Luo et al., 2008;

Sujka and Jamroz, 2013). The increasing of starch

WBC might be due to the result of gelatinisation that

happen after the weaken bond inside amorphous area

happened (Wootton and Bamunuarachchi, 1978). The

higher availaibility of water penetration into the

granule due to the disruption by mechanically

damages of ultrasound process could leads to a higher

water retention (Manchun et al., 2012).

The increasing of physical characteristics was

higher in conventional pre-gelatinization than in

ultrasound process, even though the temperature of

process were set at the same temperature. It might be

due to there is an engagement of hydroxyl groups to

form covalent and hydrogen bonds between starches

in ultrasound starch. Apart from that, maybe there

was an excessive amount of energy in ultrasound

treated starch that could trigger the retrogradation

happen higher than in pre-gelatinization.

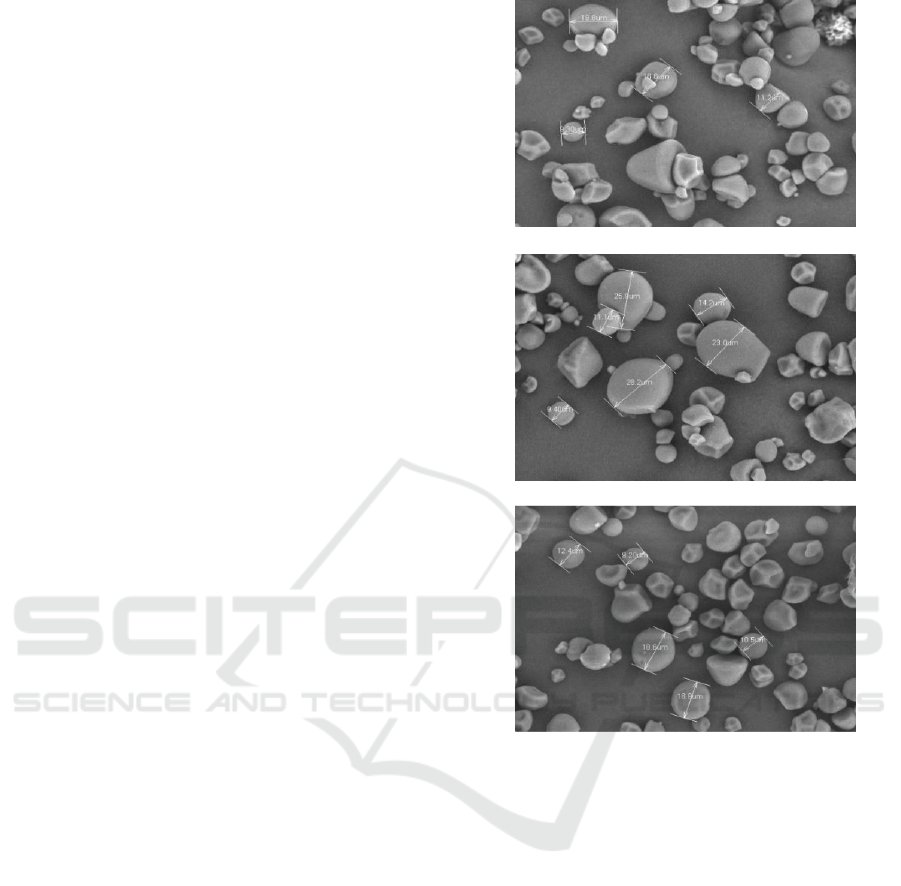

3.2 Morphological Characteristics

The SEM of native, pre-gelatinized, and ultrasound

modified starches are shown in Figure 1. The sweet

potato starch consisted of mixed size granule from

small to large and in various shapes (Das et al., 2010).

Polygonal is the most shape shown in the most of

sweet potato starch granule, however there are also

round and irregular shapes. Modification process can

change the shape of granules (Babu, Parimalavalli

and Jagannadham, 2014).

All the treatments of starch showed the

improvement of starches’ granule size. This

improvement is related to the ability of the starch to

trap the water inside the granule so the SP of starches

was also higher in treated starch. From the pictures,

pre-gelatinized starch has relatively larger granules

than other starches. It indicates the swelling process

happened inside the granule due to the process.

(a)

(b)

(c)

Figure 1: SEM of a) native; b) pre-gelatinized;

c) ultrasound modified starch (1200x)

Ultrasound starch also has larger granules than native

starch due to the process even though not as big as

pre-gelatinized starch. These morphological

characteristics was in accordance to the result of SP,

S, and WBC earlier.

4 CONCLUSIONS

Compared to ultrasound starch, pre-gelatinized

starch has resulted in greater changes in SP, S, WBC,

and the size of granule. However, both modification

results are better than native starch. These results

could be adjusted according to industrial and

pharmaceutical needs. The effect of pre-

gelatinization or ultrasound treatment of sweet potato

starch on the tablet formulation have not been studied

Preliminary Comparison of Pregelatinization vs Ultrasound Modified Sweet Potato Starch for Tablet Formulation

17

enough yet. Some parameters should be optimized to

gain the best results accordance with the needs.

REFERENCES

Adedokun, M. O. & Itiola, O. A. (2010).

Journal.Carbohydrate Polymers. Elsevier Ltd, 79(4),

pp. 818– 824.

Alebiowu, G. & Itiola, O. A. (2002). Research paper. Drug

Development and Industrial Pharmacy. 28(6), pp. 663–

672.

Babu, A. S., Parimalavalli, R. & Jagannadham, K. (2014).

Journal of Food Science and Technology.

Chi, H., Xu, K., Wu, X., Chen, Q., Xue, D., Song, C.,

Zhang, W., and Wang, P. (2008). Journal. Food

Chemistry, 106(3), pp. 923–928.

Das, A. B., Singh, G., Singh, S., & Riar, C. S. (2010).

Journal.Carbohydrate Polymers. Elsevier Ltd, 80(3),

pp. 725–732.

Frank, O.& Adebowale, O. (2010). Journal. RJPBCS. 1(3),

pp. 255–270.

Freitas, R. A., Paula, R. C., Feitosa, J. P. A., Rocha, S.&

Sierakowski, M. R. (2004). Carbohydrate Polymers.

55(1), pp. 3–8.

Grace, M. U., Widya, D. R. P., & Simon, B. W. (2019). AIP

Conference Proceedings 2120, 050020

Grace, M. U., Widya, D. R. P., Kiki, F., Regita, P., Simon,

B. W. (2020). IOP Conf. Series: Earth and

Environmental Science. 475, 012036

Herceg, I. L., Jambrak, A. R., Subaric, D., Brncic, M.,

Brncic, S. R., Badanjak, M., Tripalo, B., Jezek, D.,

Novotni, D., & Herceg, Z. (2010). Journal. Czech

Journal of Food Sciences, 28(2), pp. 83–93.

Iheagrawa, M. C. (2013). Journal. Journal of Food

Processing Technology. 4(1)

Jambrak, A. R., Herceg, Z., Subaric, D., Babic, J., Brncic,

M., Brncic, S. R., Bosiljkov, T., Cvek, D., Tripalo, B.

& Gelo, J. (2010). Journal. Carbohydrate Polymers. 79,

pp. 91-100

Jubril, I., Muazu, J. & Mohammed, G. H. (2015). Journal.

Journal of Applied Pharmaceutical Science. pp. 28–33.

Kaur, M., Oberoi, D. P. S., Sogi, D. S., & Gill, B. S. (2011).

Journal. Journal of Food Science and Technology,

48(4), pp.460–465.

Krishnakumar, T. & Sajeev, M. S. (2018). Journal.

International Journal of Current Microbioly and

Applied Science 7(10), pp. 3122–3135.

Lee, H. L. & Yoo, B. (2011). Journal. LWT - Food Science

and Technology. Elsevier Ltd, 44(3), pp. 765– 770.

Luo, Z., Fu, X., He, X., Luo, F., Gao, Q. & Yu, S. (2008).

Journal. Starch/Stärke, 60(11), pp. 646–653.

Manchun, S., Nunthanid, J., Limmatvapirat, S. &

Srimornsak, P. (2012). Journal. Advanced Materials

Research. 506, pp 294-297

Mat, D. B. H., Moorthy, S. N., Hill, S. E., Linfoot, K. J.&

Blanshard, J. M. V. (1992). Journal. Starch/Stärke. pp.

471–475.

Odeku, O. A., Schmid, W. & Picker-freyer, K. M. (2008).

Journal. European Journal of Pharmaceutics and

Biopharmaceutics. 70, pp. 357–371.

Paterson, L. A., Mat, D. B. H., Hil, S. E., Mitchell, J. R.&

Blanshard, J. M. V. (1994). Journal. Starch/Stärke. 46,

pp. 288–291.

Robertson, J. A., Monredon, F. D., Dysseler, P., Guillon, F.,

Amado, R. & Thibault, J-F. 2000. Journal. Academic

Press. 79, pp. 72–79.

Srichuwong, S., Sunarti, T. C., Mishima, T., Isono, N. &

Hisamatsu, M. (2005). Journal. Carbohydrate

Polymers. 62(1), pp. 25–34.

Sujka, M. & Jamroz, J. (2013). Journal. Food

Hydrocolloids. Elsevier Ltd, 31(2), pp. 413–419.

Takizawa, F. F., Oliveira, G. De. & Konkel, F. E. (2004).

Journal. Biology and Technology, 47, pp. 921–931.

Visavarungroj, N. & Remon, J. P. (1991). Journal. Drug

Development and Industrial Pharmacy, 17(10), pp.

1389–1396.

Wootton, M. & Bamunuarachchi, A. (1978). Journal.

Starch Stärke, 30(9), pp. 306–309.

Zhu, F. (2015). Journal. Trends in Food Science &

Technology. Elsevier Ltd.

ICAMBBE 2019 - 6th ICAMBBE (International Conference on Advance Molecular Bioscience Biomedical Engineering) 2019

18